Packaging sponge cutting device

A cutting device and sponge technology, applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of high scrap rate and high labor intensity, and achieve the effects of simple structure, high labor intensity and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

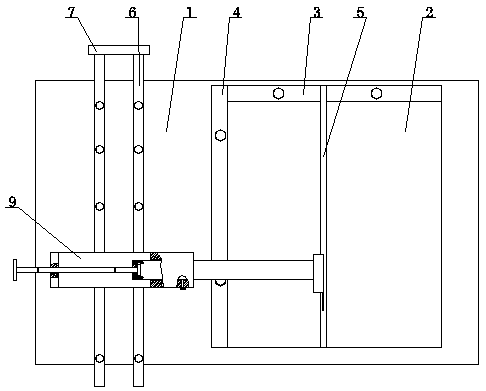

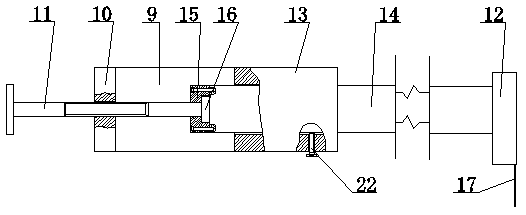

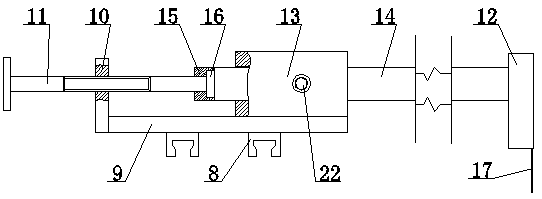

[0017] The packaging sponge cutting device is composed of a machine platform 1, a cutting plate 2, a transverse positioning bar 3, a longitudinal positioning bar 4 and a cutter.

[0018] The cutting board 2 is fixed on the machine table 2, and the horizontal positioning strip 3 and the vertical positioning strip 4 are fixed on the cutting board 2 in a staggered shape; when working, the two sides of the sponge to be processed can be connected with the horizontal positioning strip 3 and the vertical positioning strip 4 close to fit, so that the sponges to be processed can be positioned by the horizontal positioning bar 3 and the vertical positioning bar 4, so that the placement position of each sponge to be processed is consistent.

[0019] The assembly positions of the transverse positioning bar 3 and the vertical positioning bar 4 can be changed, so that the sponge cutting device can be adapted to various sizes of cutting.

[0020] Cutting plate 2 is provided with cutting groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com