Intelligent method for optical fiber preform deposition process based on big data model prediction control framework

An optical fiber preform and preform technology are applied in the field of realizing the intelligentization of the deposition process of the optical fiber preform, and can solve the problem of high rejection rate of the preform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] DETAILED DESCRIPTION further embodiment of the present invention in conjunction with the accompanying drawings below.

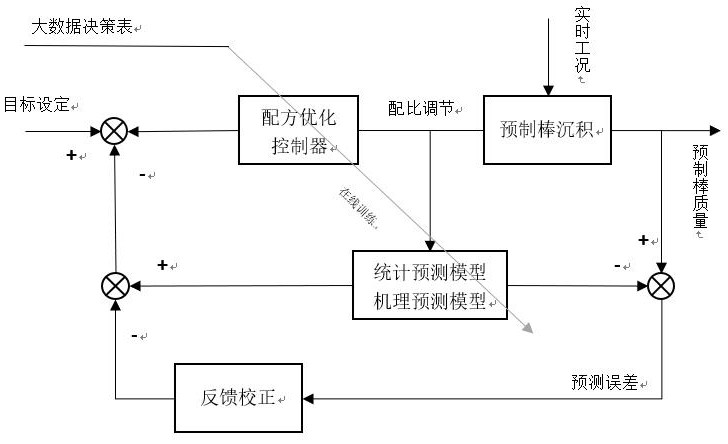

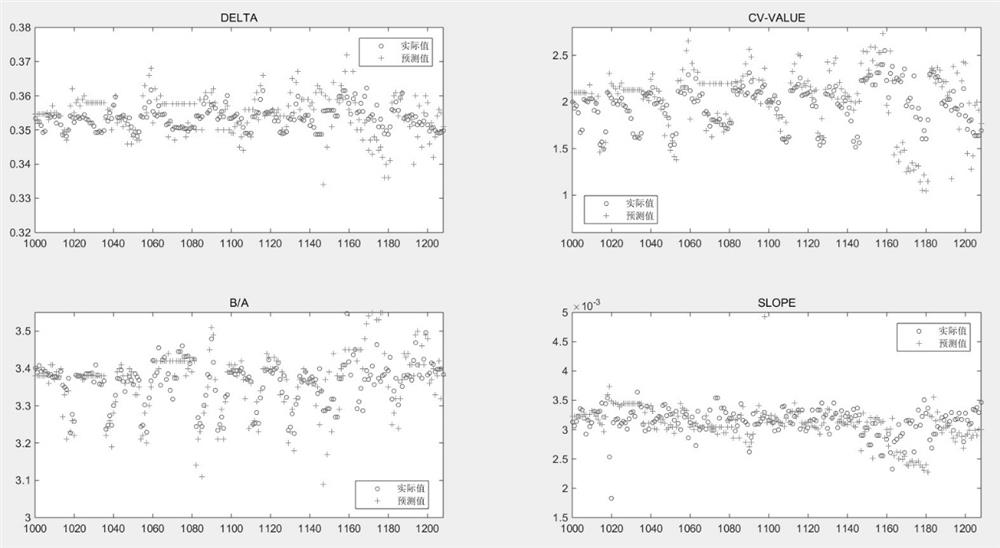

[0026] figure 1 FIG framework of the present embodiment of the invention, the present invention mainly comprises the following: (1) an optical fiber preform deposition step depth analysis process, (2) when depositing the PK test results splicing production data, (3) after the splicing preprocessing data mining critical factors affecting the formulation and conditions of the quality of the preform, (4) a neural network prediction model line quality, (5) based on the prediction result of adjusting the proportion of the formulation to achieve optimization rolling, (6) test results feedback PK formulation ratio correction deposition process. Detailed process is as follows:

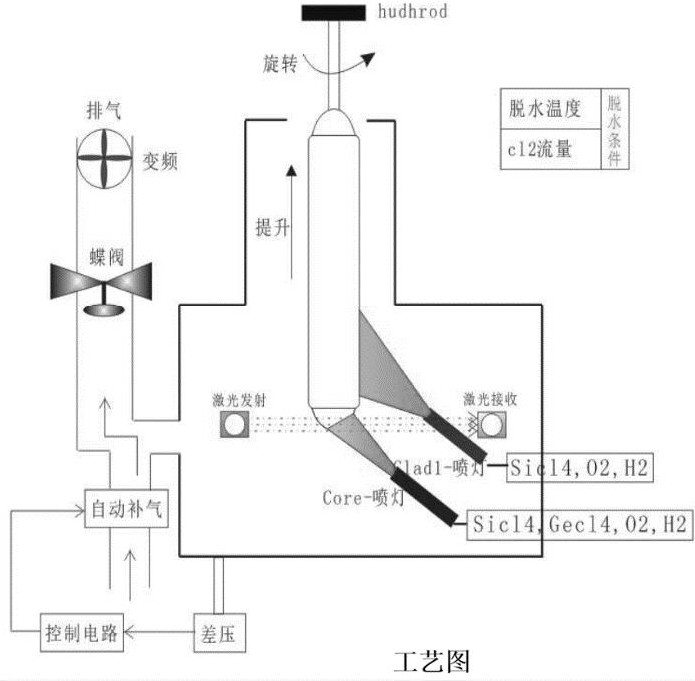

[0027] figure 2 FIG step deposition process of the present invention, mainly by the burner (including a core layer and light lamp), a gas composition of formulation and production equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com