Novel packaging machine for massive food

A new type of packaging and food technology, applied in packaging, transportation packaging, multiple packages, etc., can solve the problems of low packaging efficiency, pattern or pattern deviation, difficult positioning of packaging film, etc., to achieve beautiful packaging products and improve packaging. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

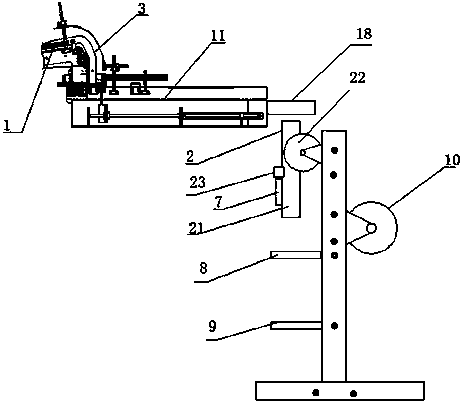

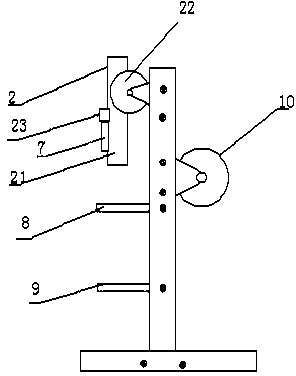

[0046] As a preferred embodiment of the present invention, with reference to the attached figure 1 , the invention includes

[0047] The material conveying mechanism 1, the tail end of the material conveying mechanism 1 is provided with a turning channel 3; the upper end of the bag turning channel 3 is arranged at the tail end of the material conveying mechanism 1, and the lower end of the bag turning channel 3 extends downward; the conveying device 11 is arranged on one side of the material conveying mechanism 1, and one end of the conveying device 11 is arranged below the bag turning channel 3; the other end of the conveying device 11 is provided with a receiving platform 18; The blanking bag forming device 2; the bag turning channel 3 includes a side baffle 6, a guide plate 4 and a guide baffle 5, the guide plate 4 is located at the tail end of the material conveying mechanism 1 and is inclined downward; the guide baffle The plate 5 is arranged above the guide plate 4, one...

Embodiment 2

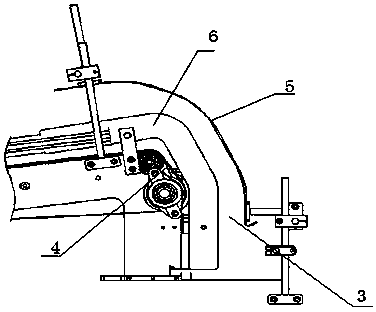

[0051] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , the invention includes

[0052] The material conveying mechanism 1, the tail end of the material conveying mechanism 1 is provided with a turning channel 3; the upper end of the bag turning channel 3 is arranged at the tail end of the material conveying mechanism 1, and the lower end of the bag turning channel 3 extends downward; the conveying device 11 is arranged on one side of the material conveying mechanism 1, and one end of the conveying device 11 is arranged below the bag turning channel 3; the other end of the conveying device 11 is provided with a receiving platform 18; The blanking bag forming device 2; the bag turning channel 3 includes a side baffle 6, a guide plate 4 and a guide baffle 5, the guide plate 4 is located at the tail end of the material conveying mechanism 1 and is inclined downward; the guide baffle The plate 5 is arranged above the guide...

Embodiment 3

[0058] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , the invention includes

[0059] The material conveying mechanism 1, the tail end of the material conveying mechanism 1 is provided with a turning channel 3; the upper end of the bag turning channel 3 is arranged at the tail end of the material conveying mechanism 1, and the lower end of the bag turning channel 3 extends downward; the conveying device 11 is arranged on one side of the material conveying mechanism 1, and one end of the conveying device 11 is arranged below the bag turning channel 3; the other end of the conveying device 11 is provided with a receiving platform 18; The blanking bag forming device 2; the bag turning channel 3 includes a side baffle 6, a guide plate 4 and a guide baffle 5, the guide plate 4 is located at the tail end of the material conveying mechanism 1 and is inclined downward; the guide baffle The plate 5 is arranged above the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com