Patents

Literature

38results about How to "Fall smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

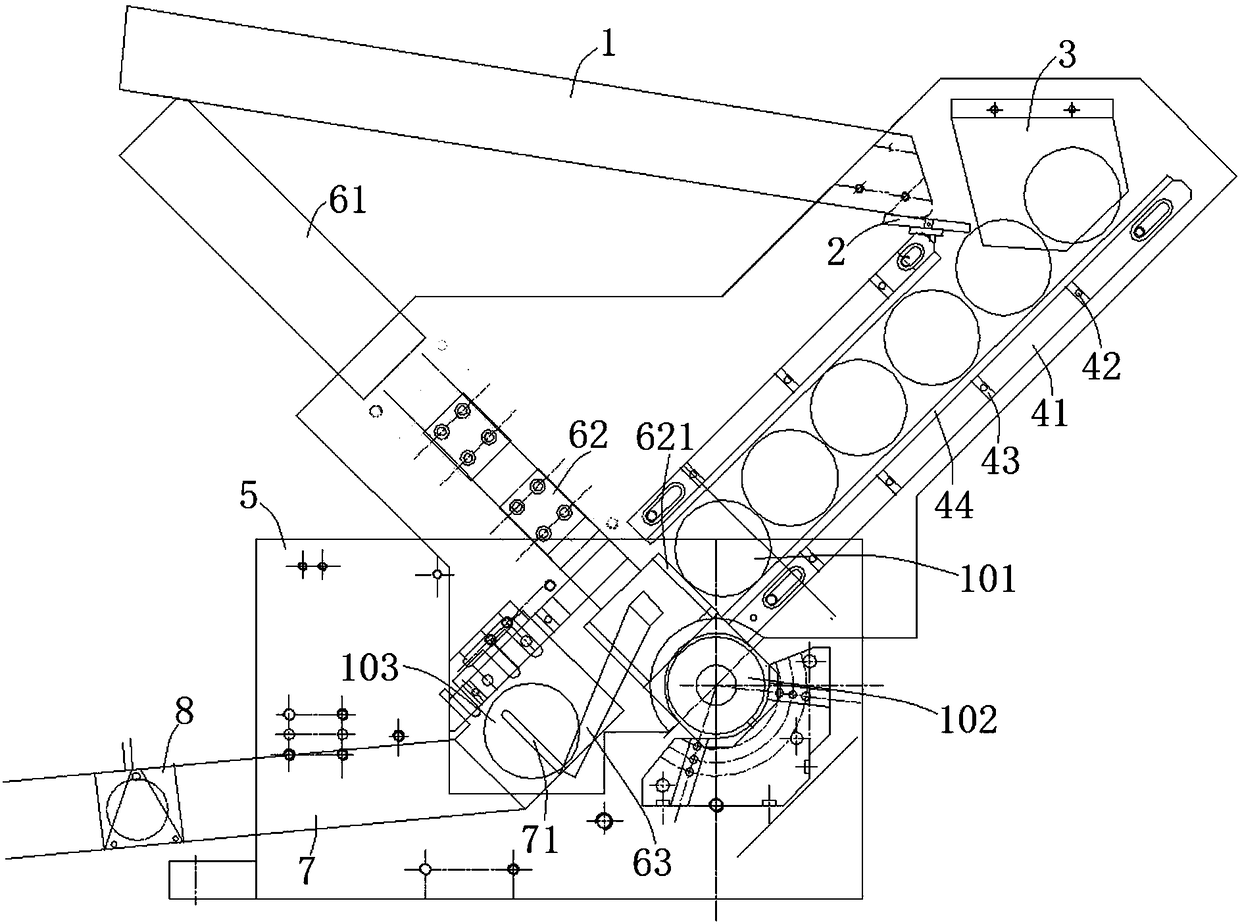

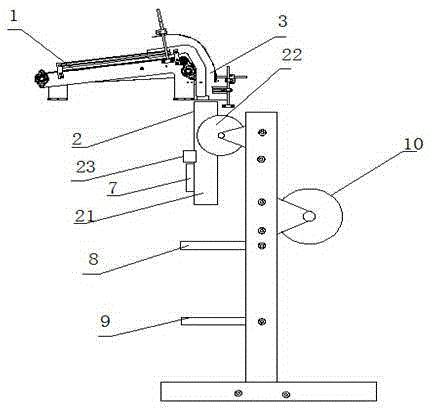

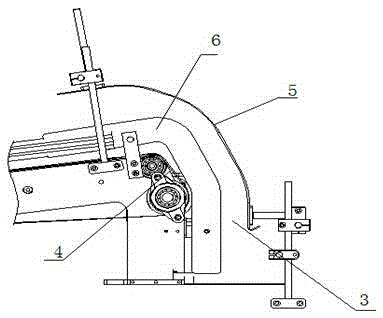

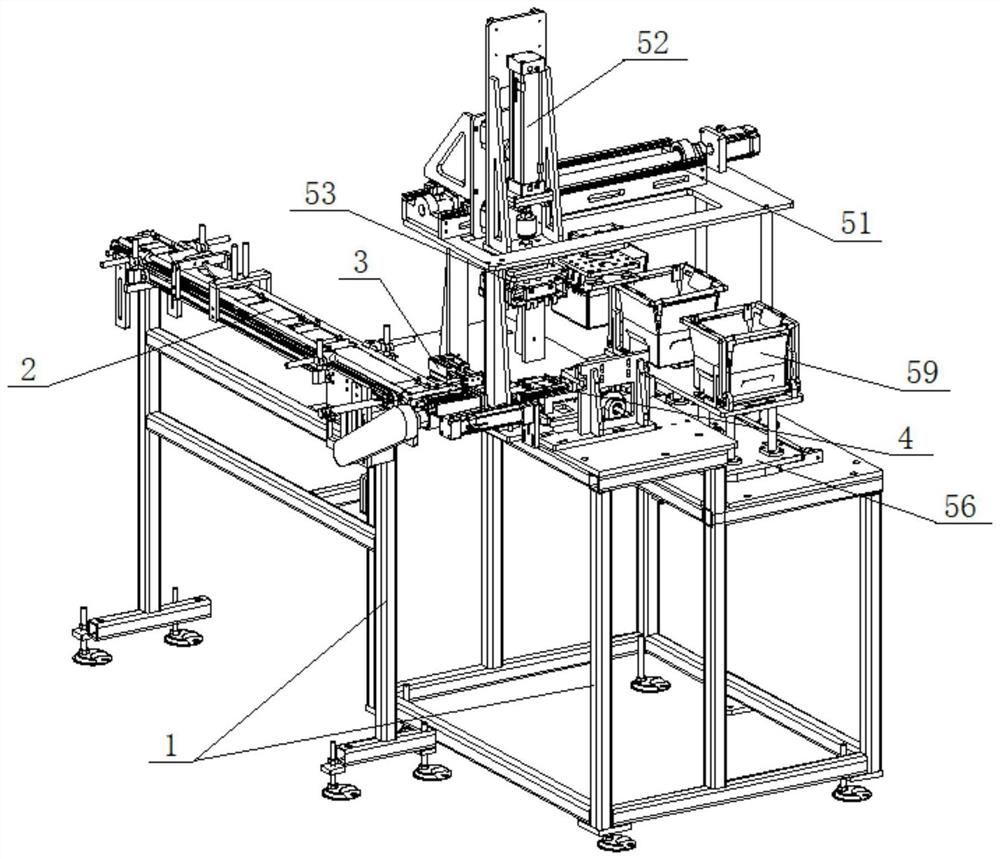

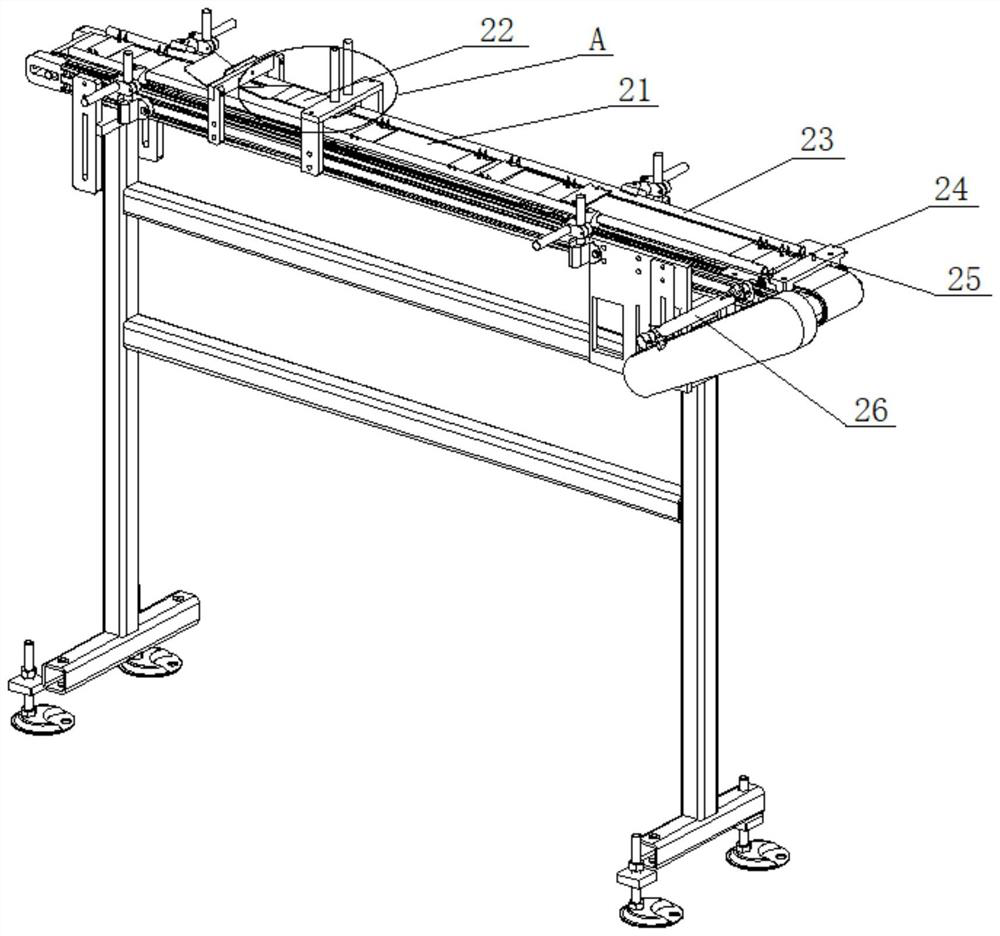

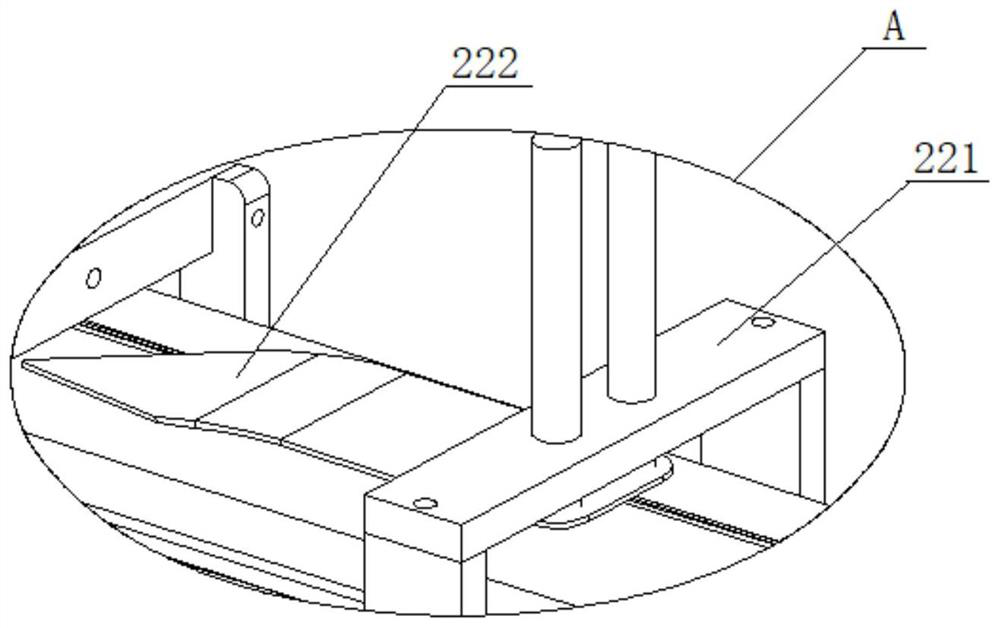

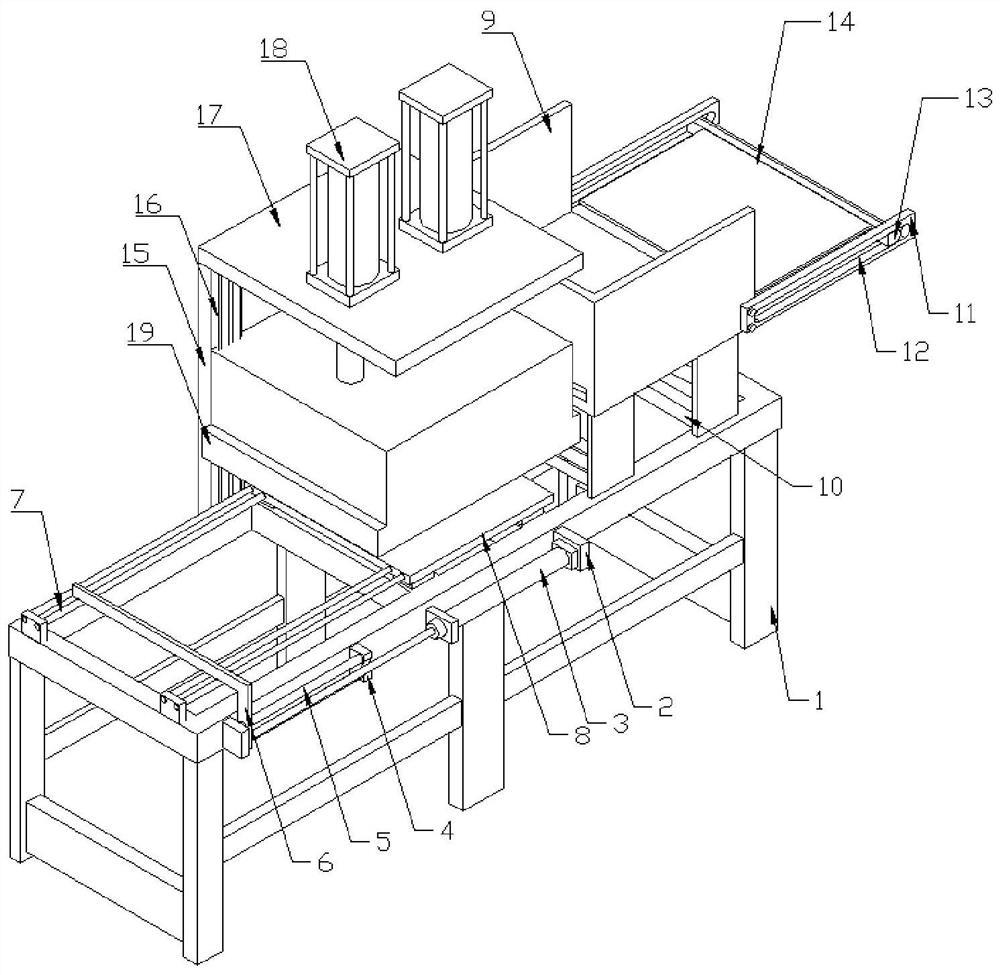

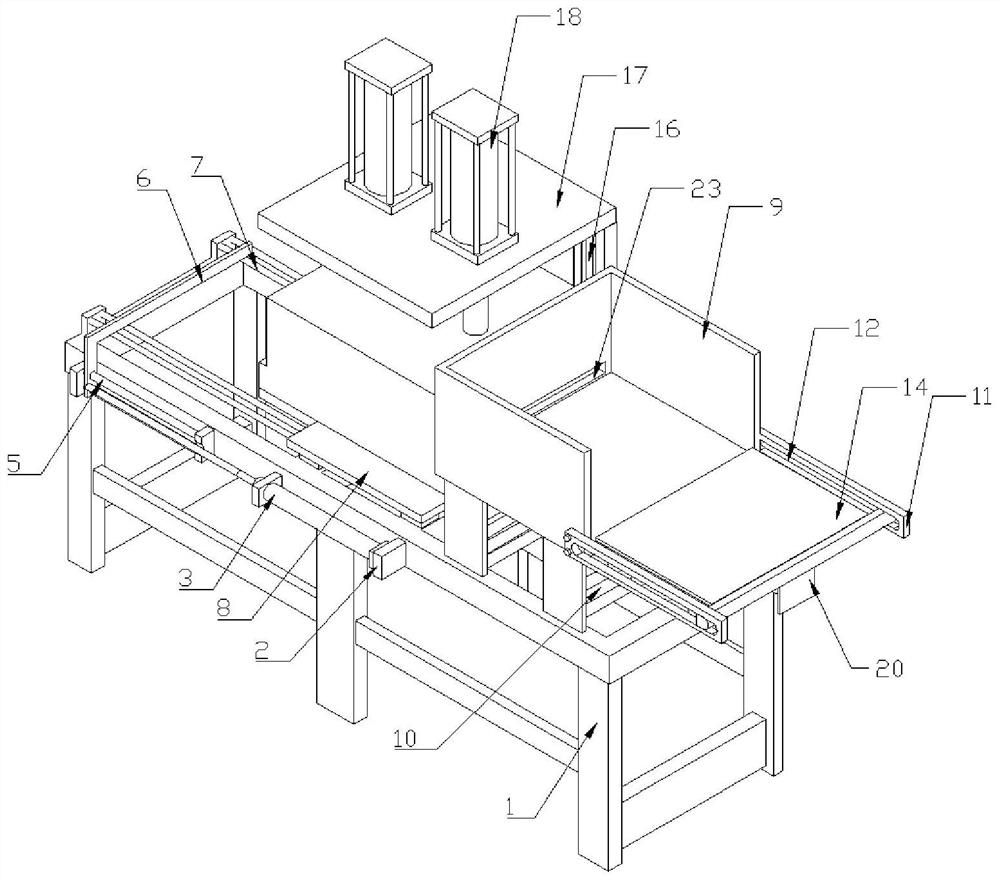

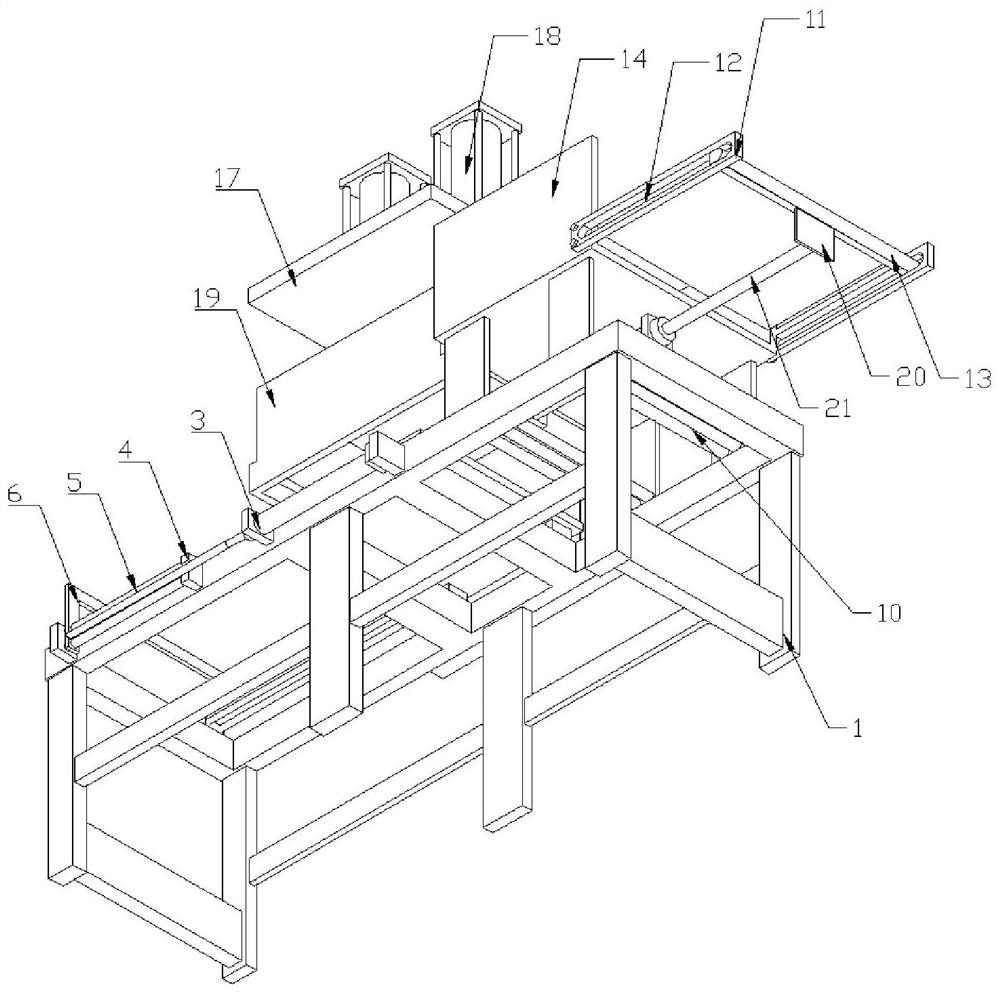

Automatic bottle detection production line

InactiveCN104029982AFully automatedIncrease productivityConveyorsSortingProduction lineBiochemical engineering

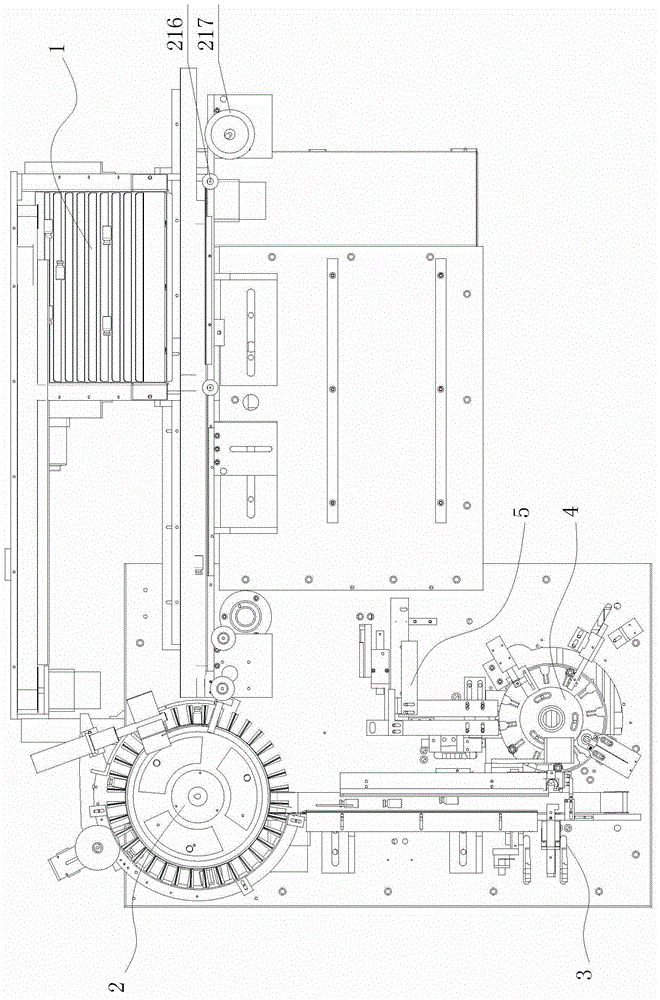

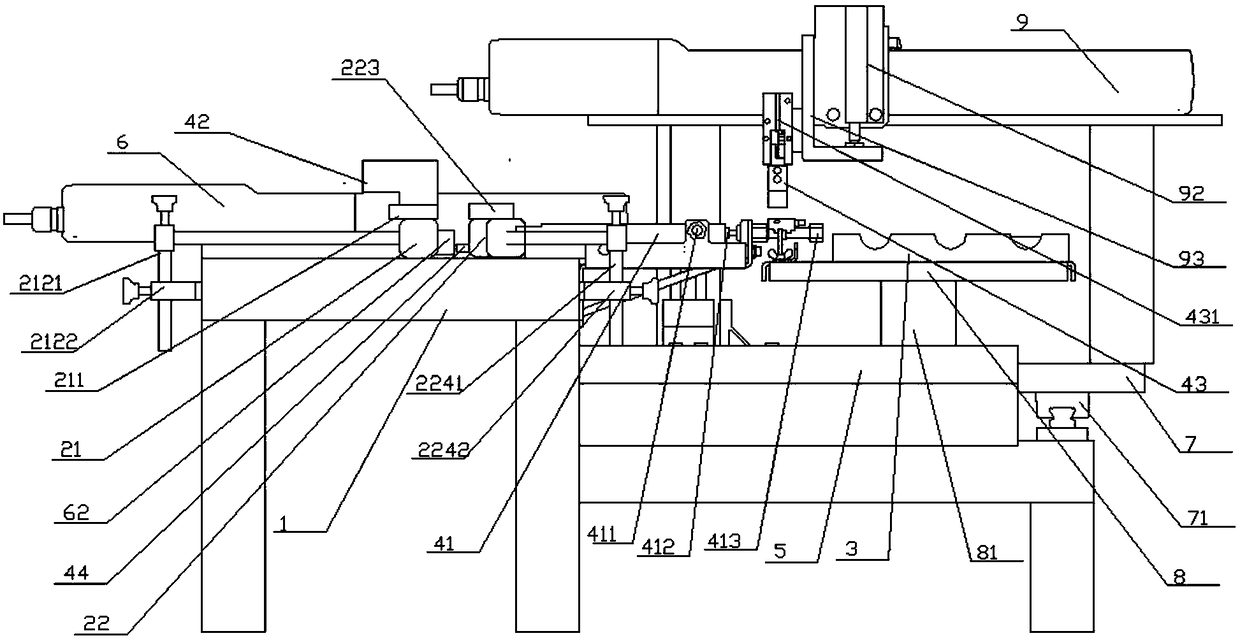

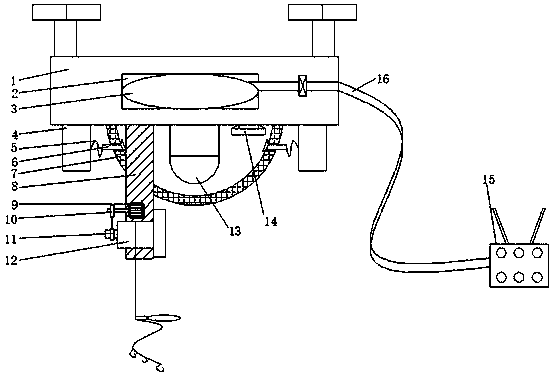

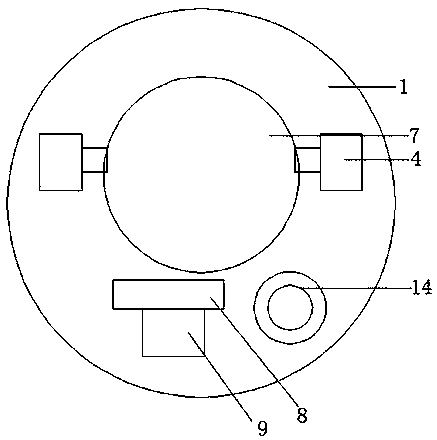

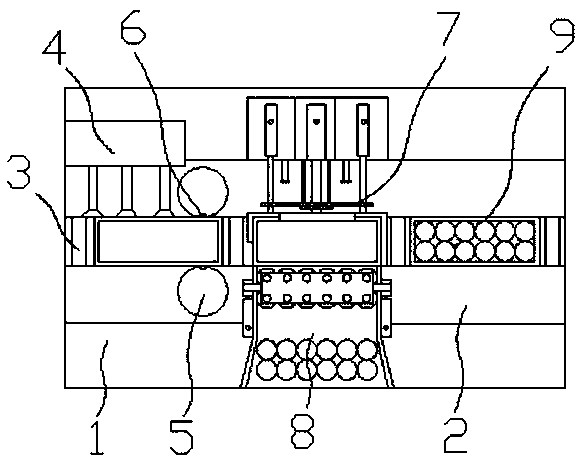

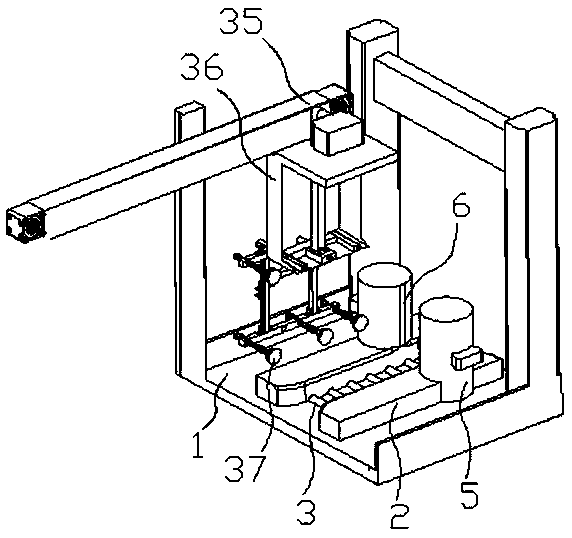

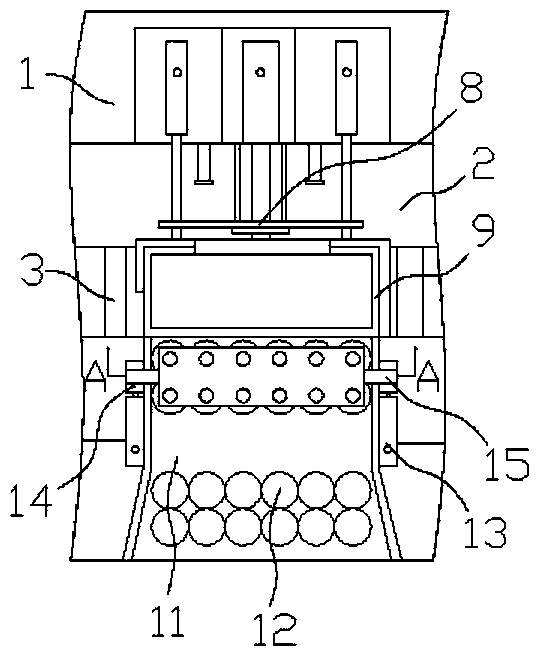

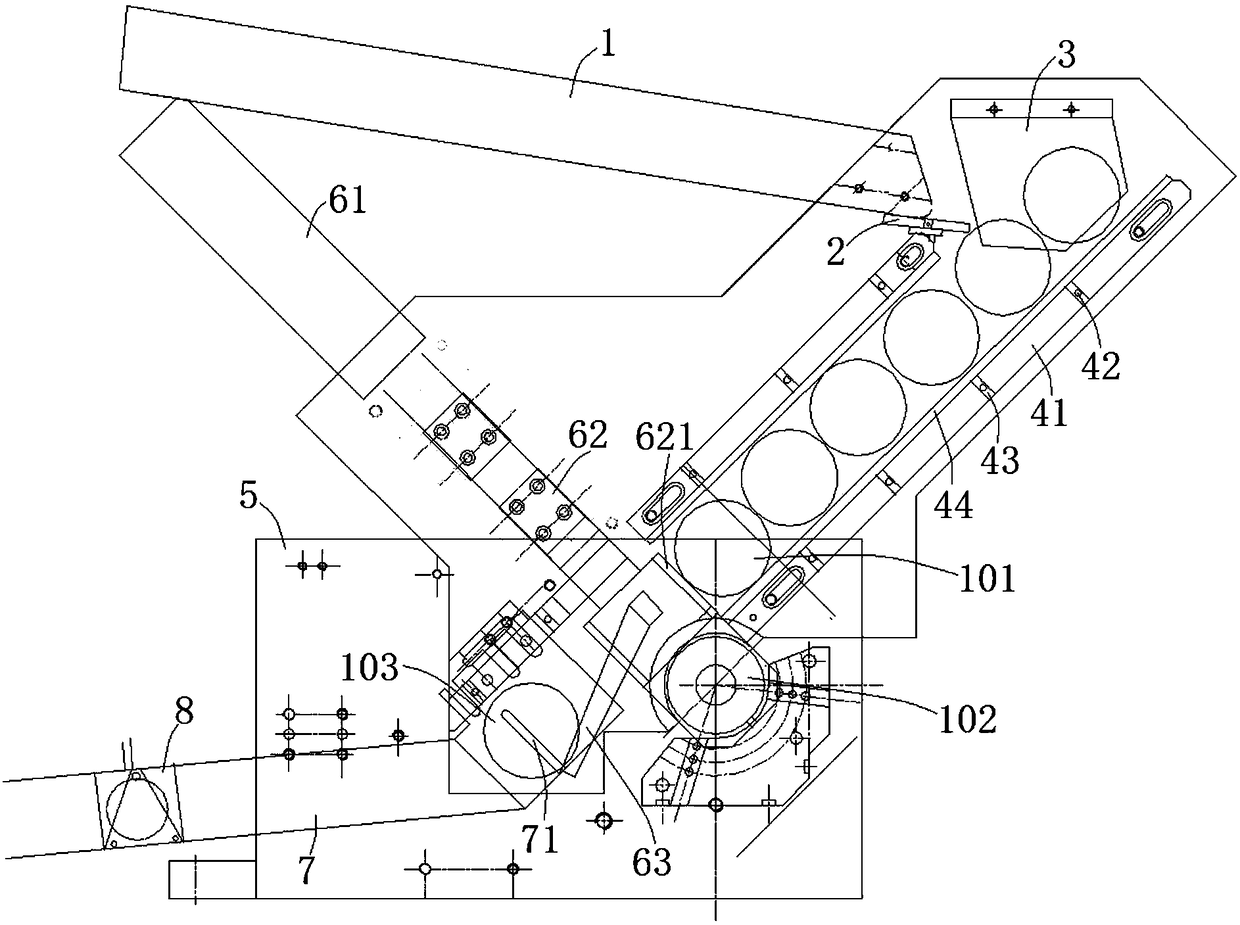

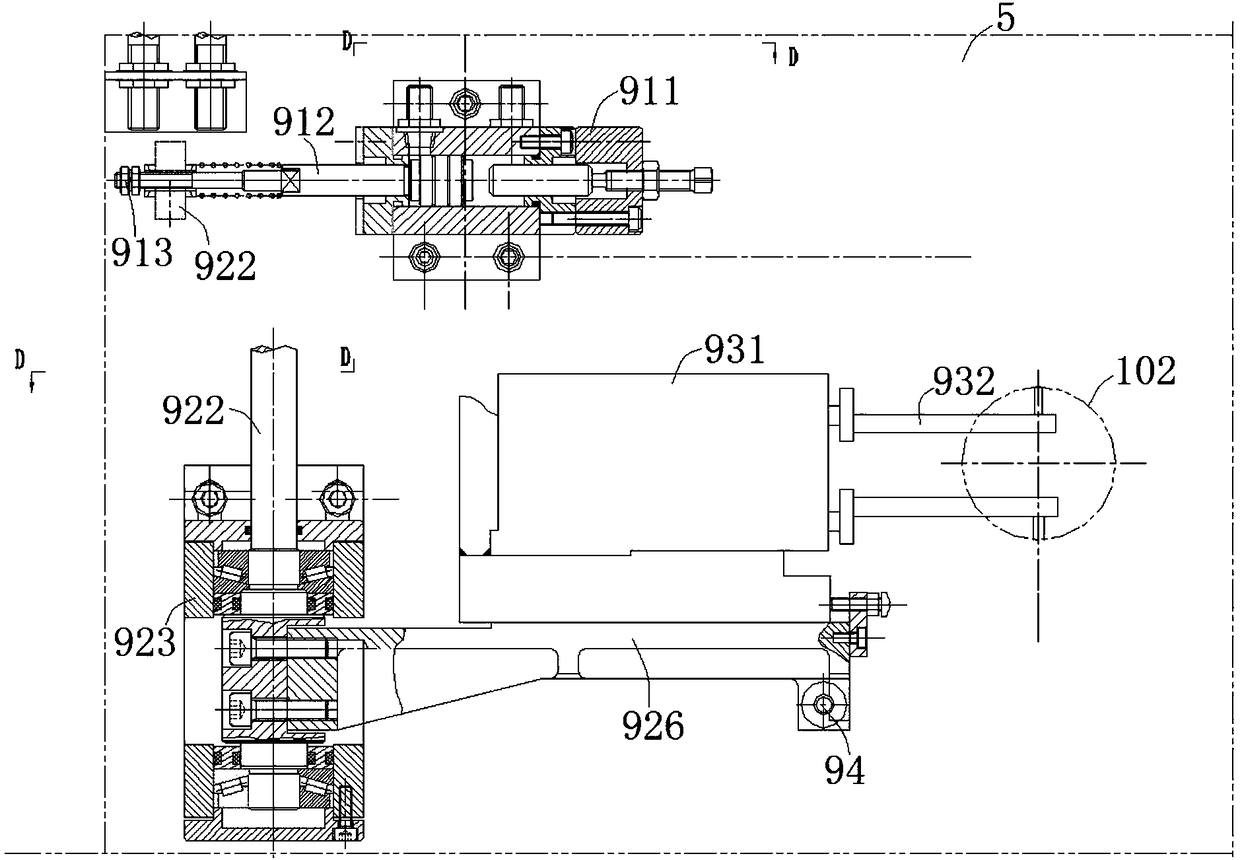

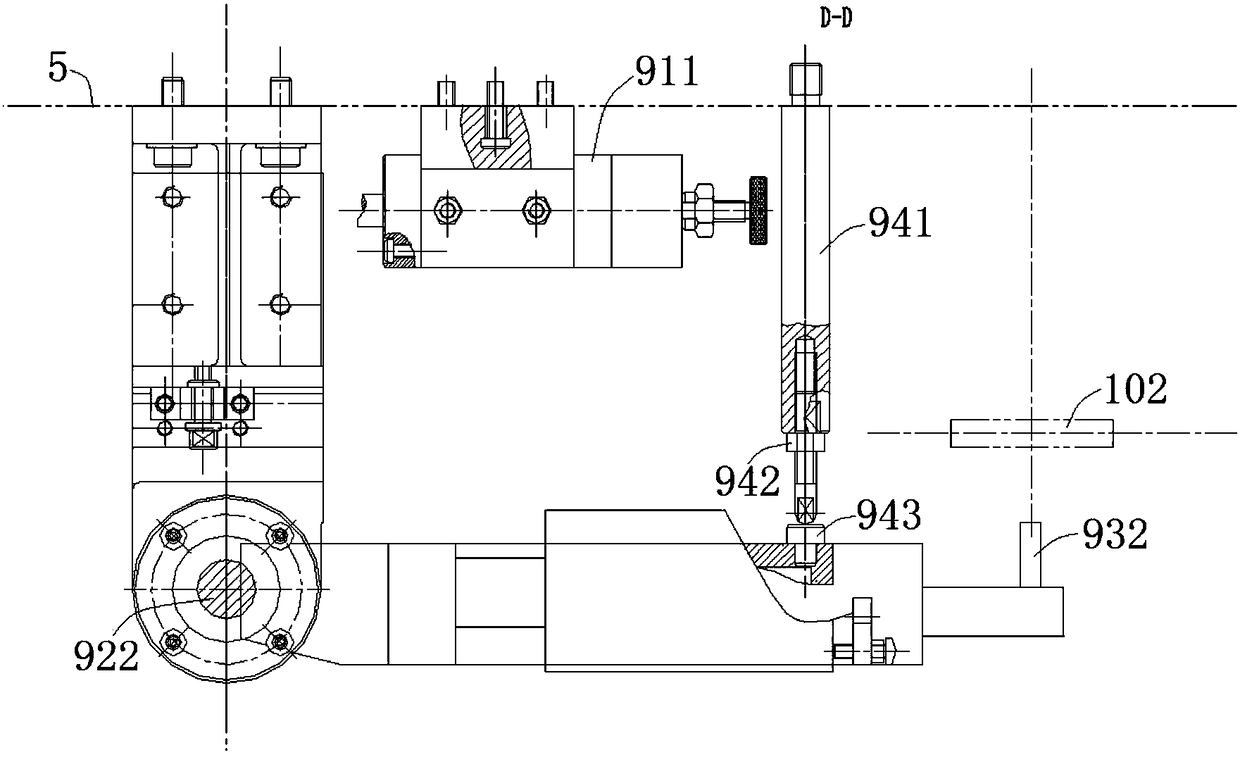

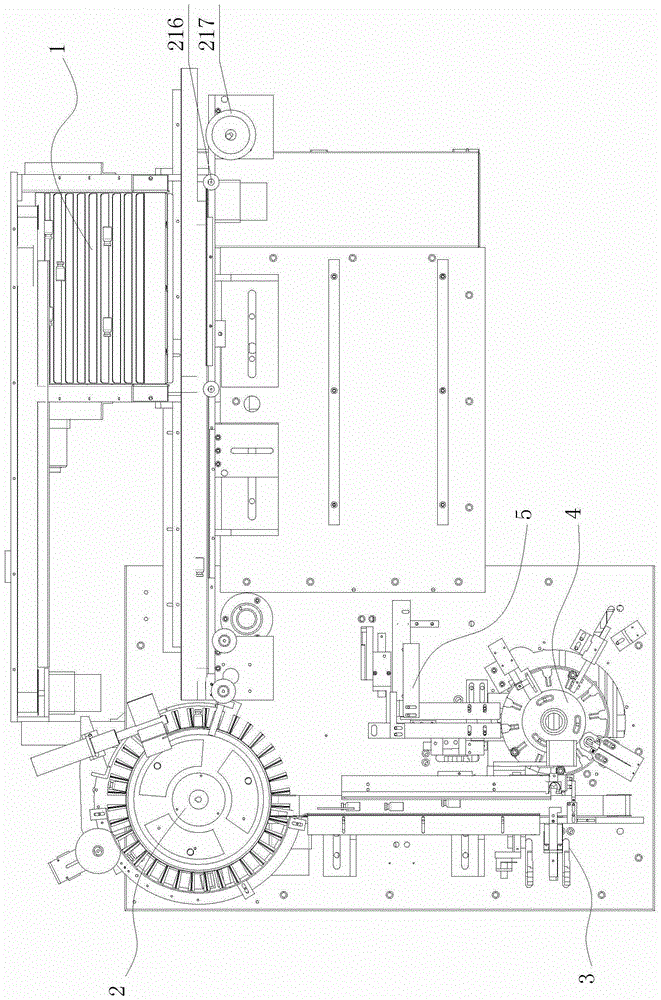

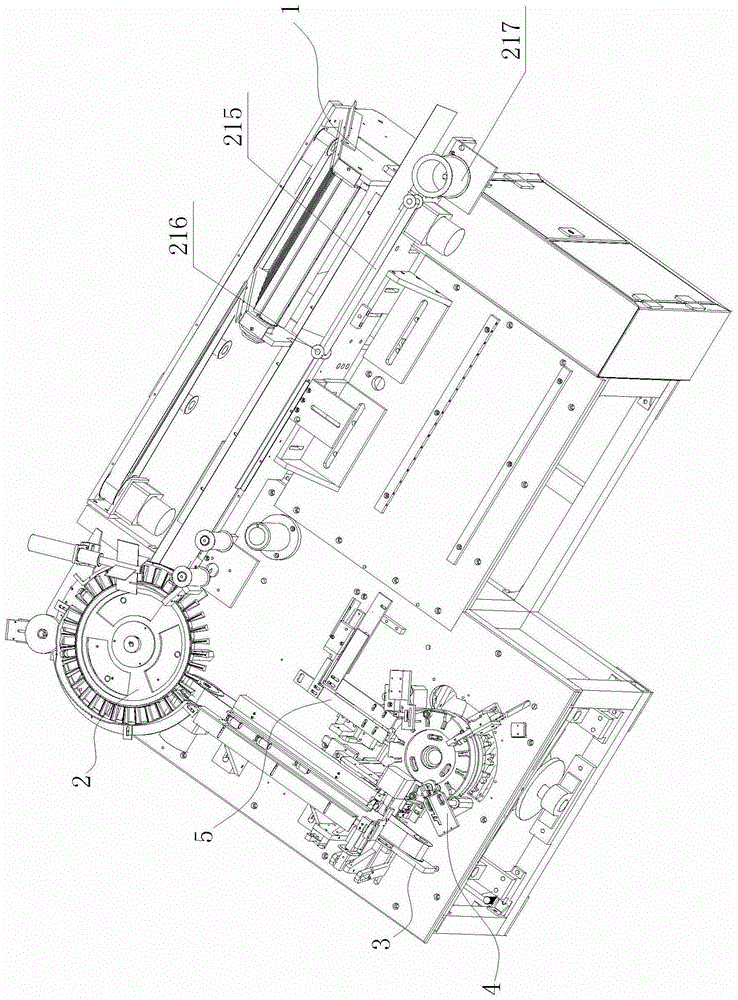

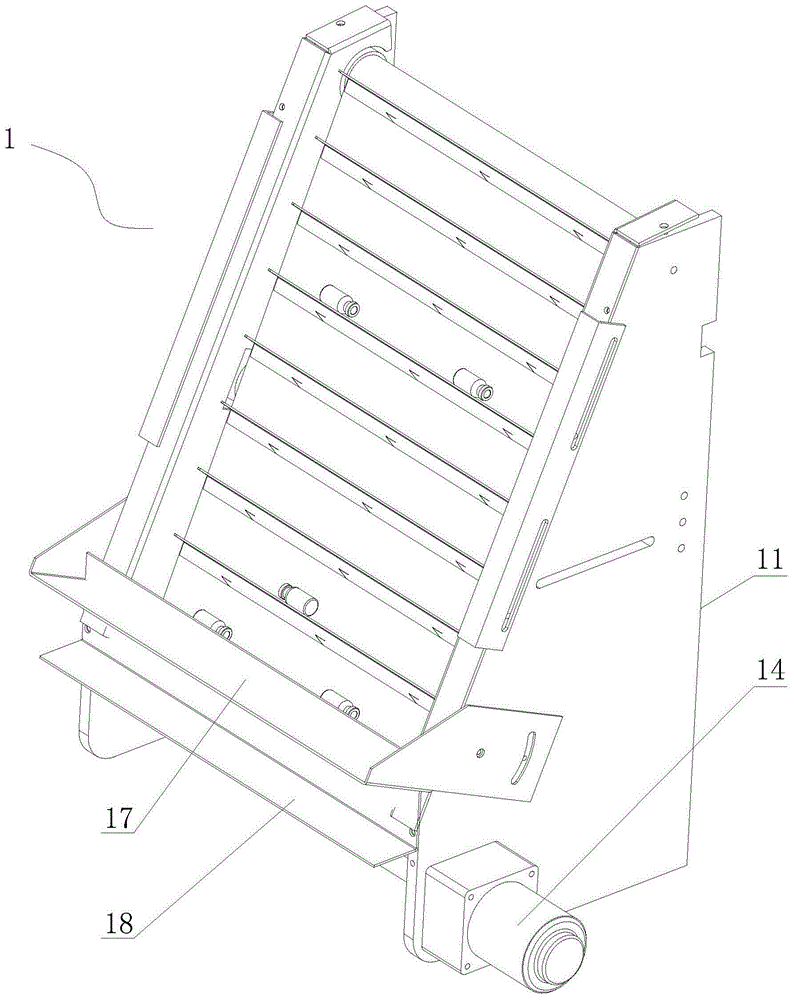

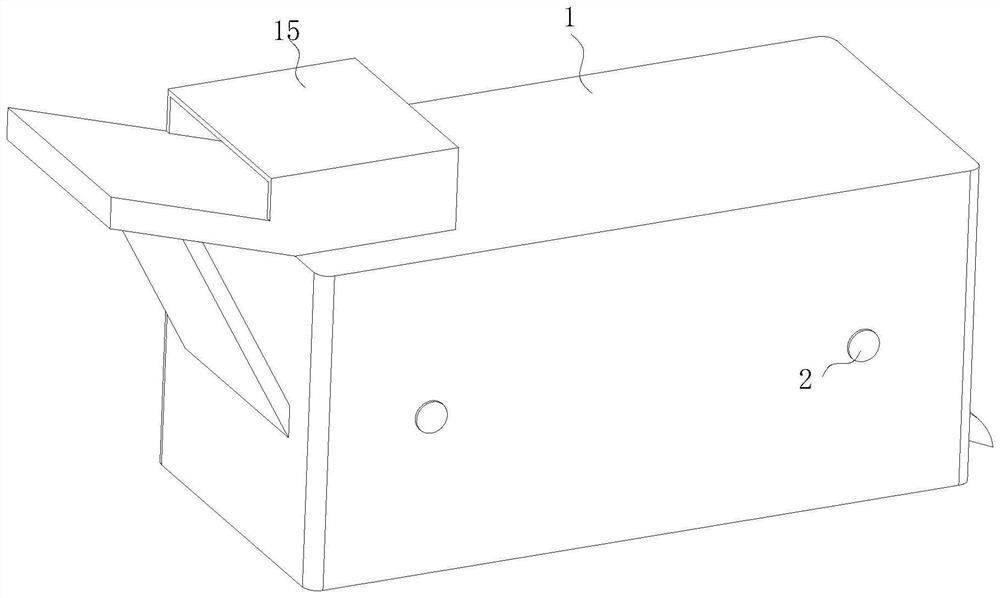

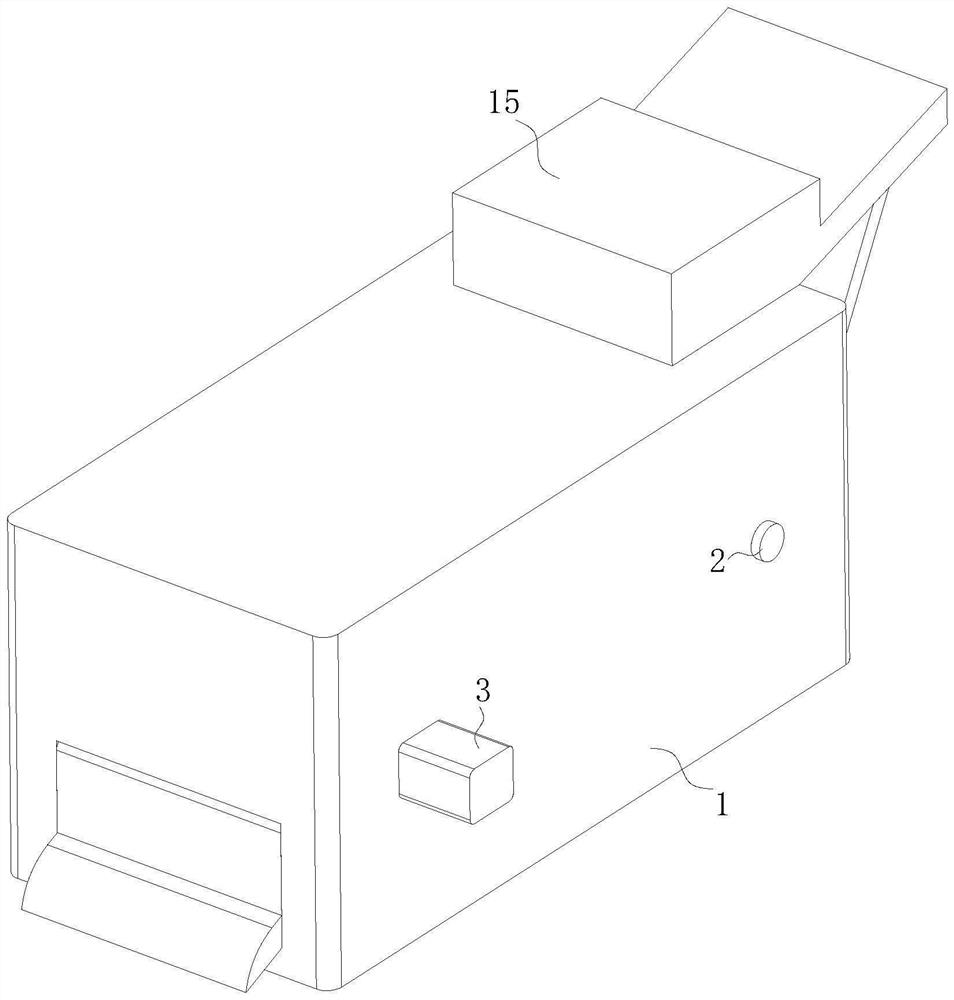

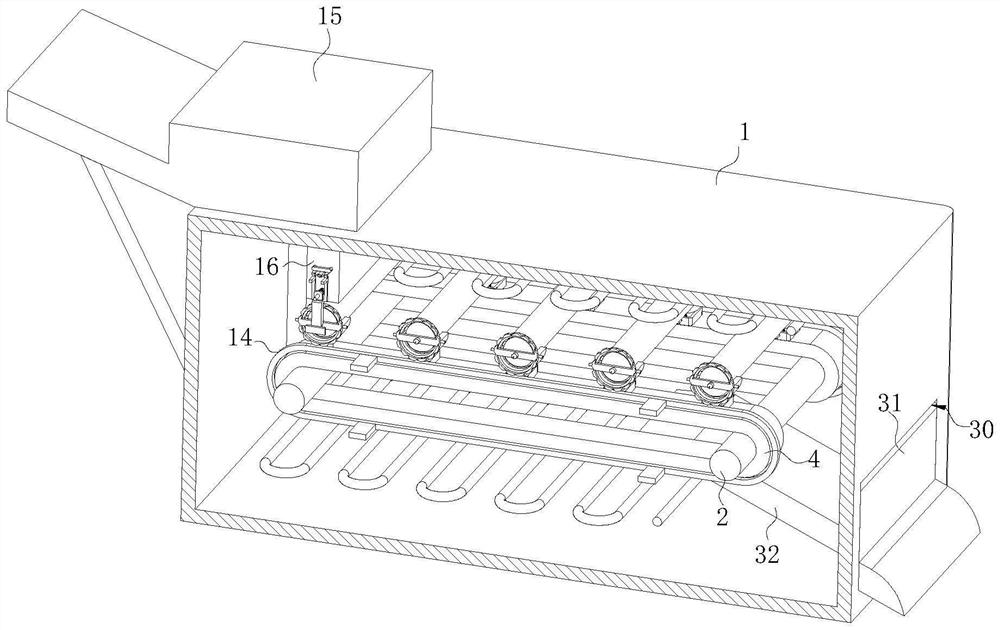

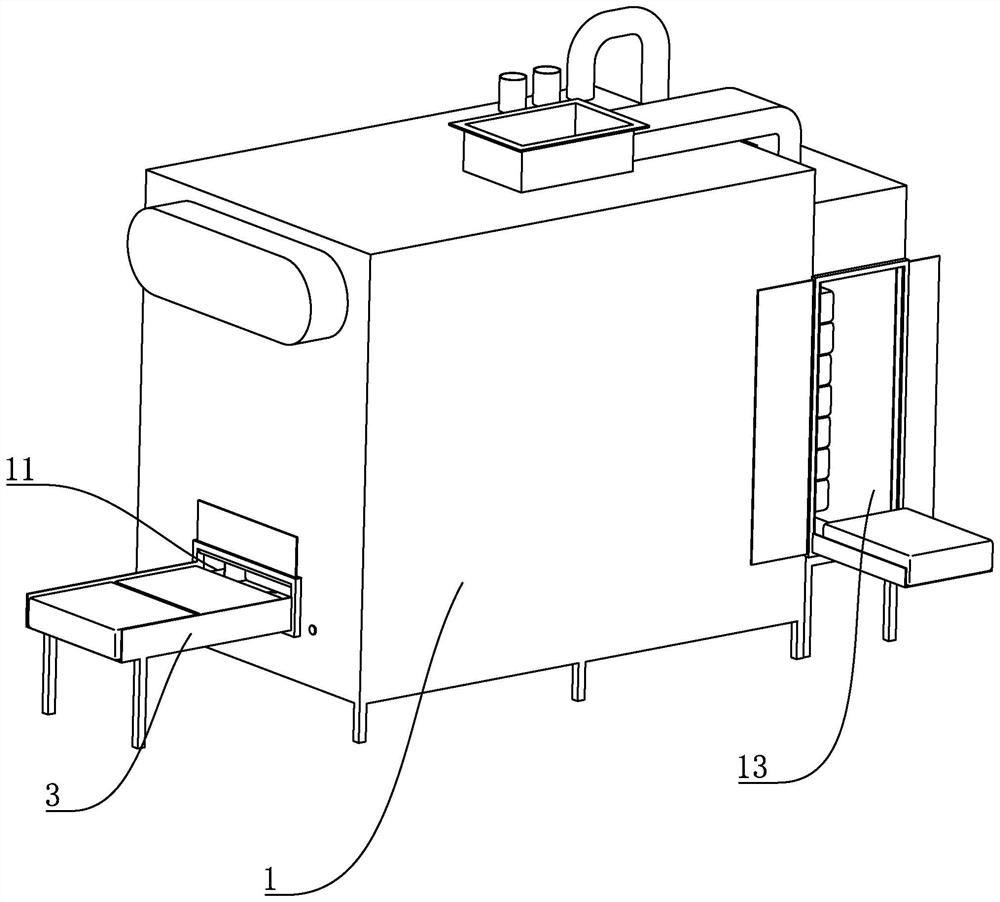

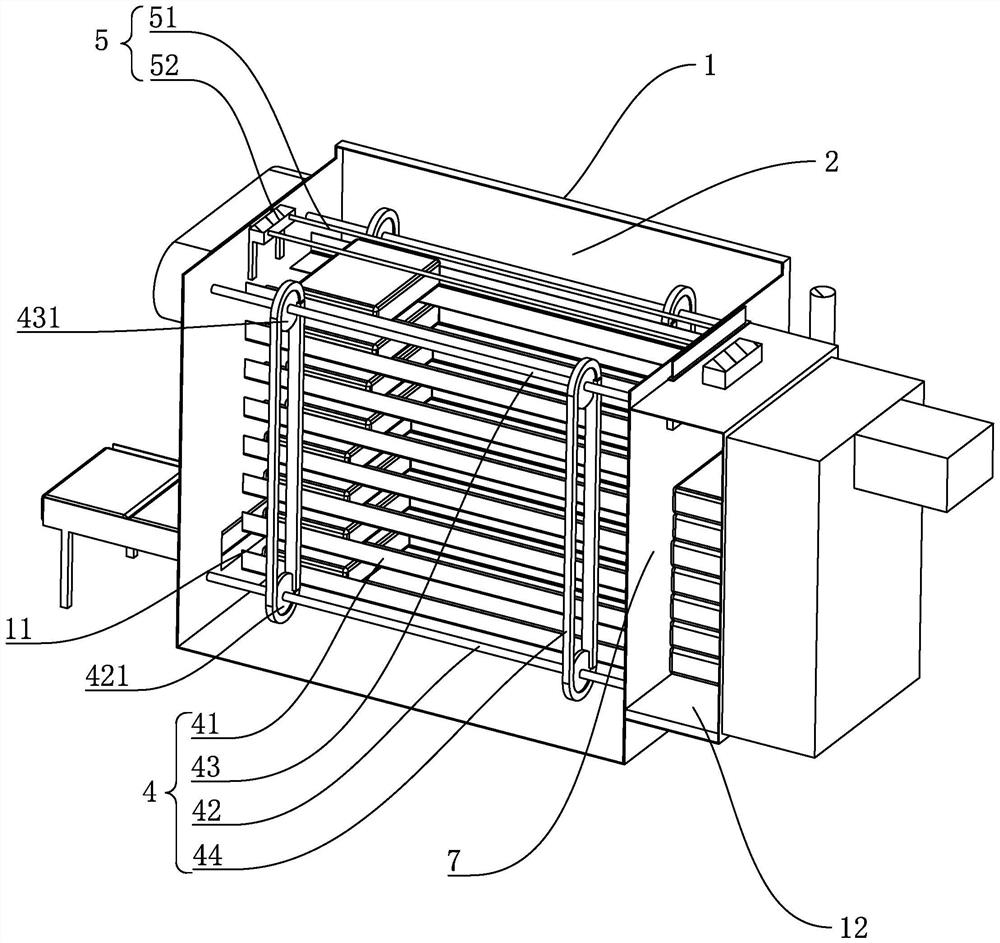

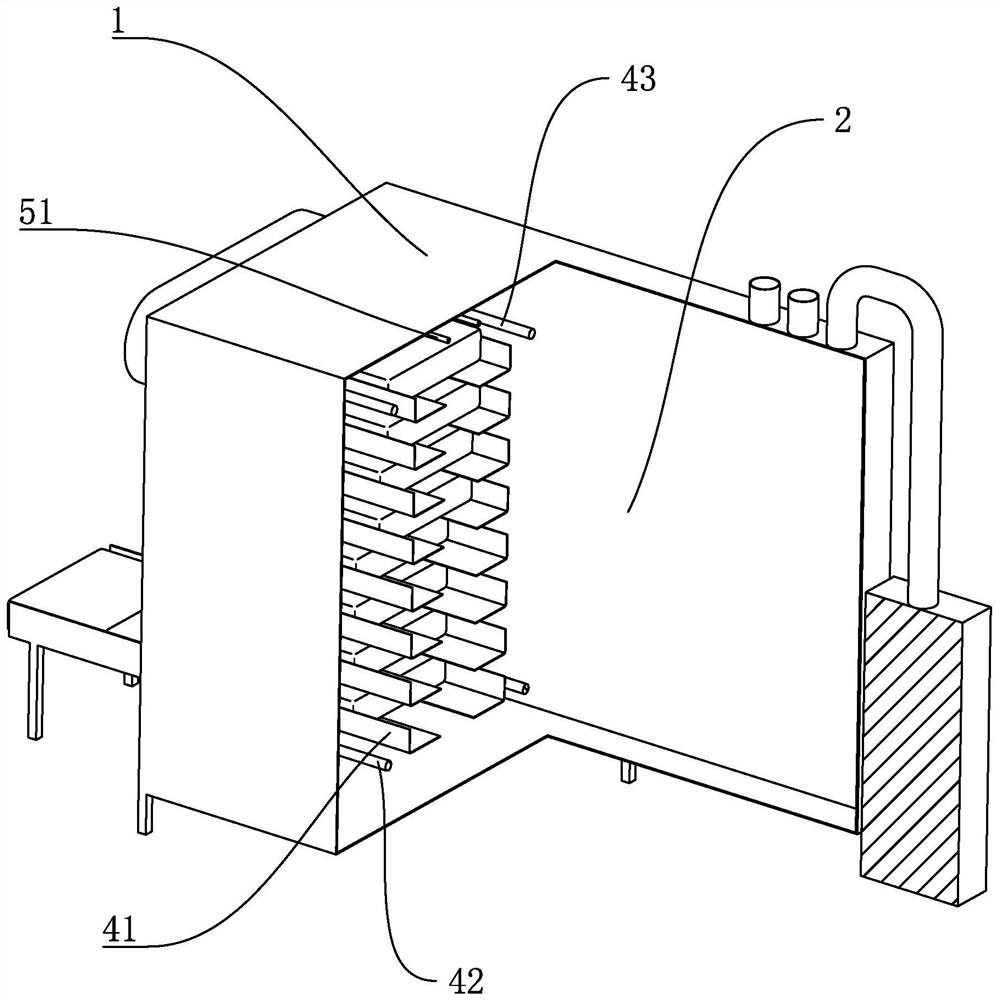

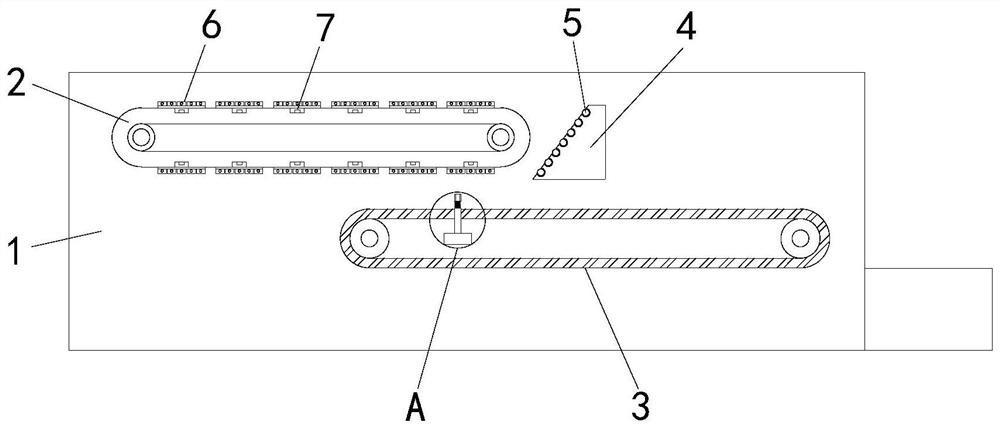

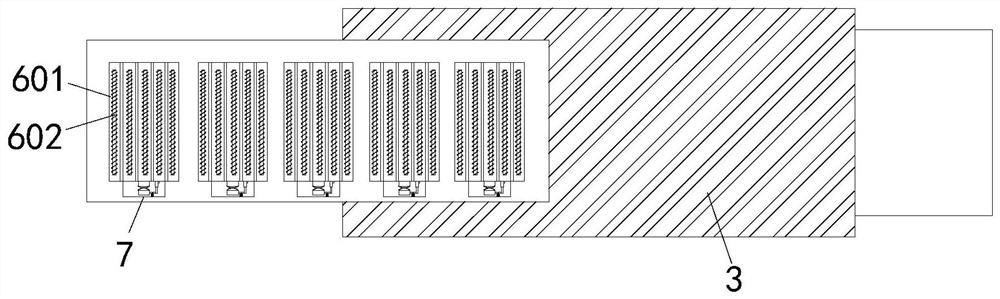

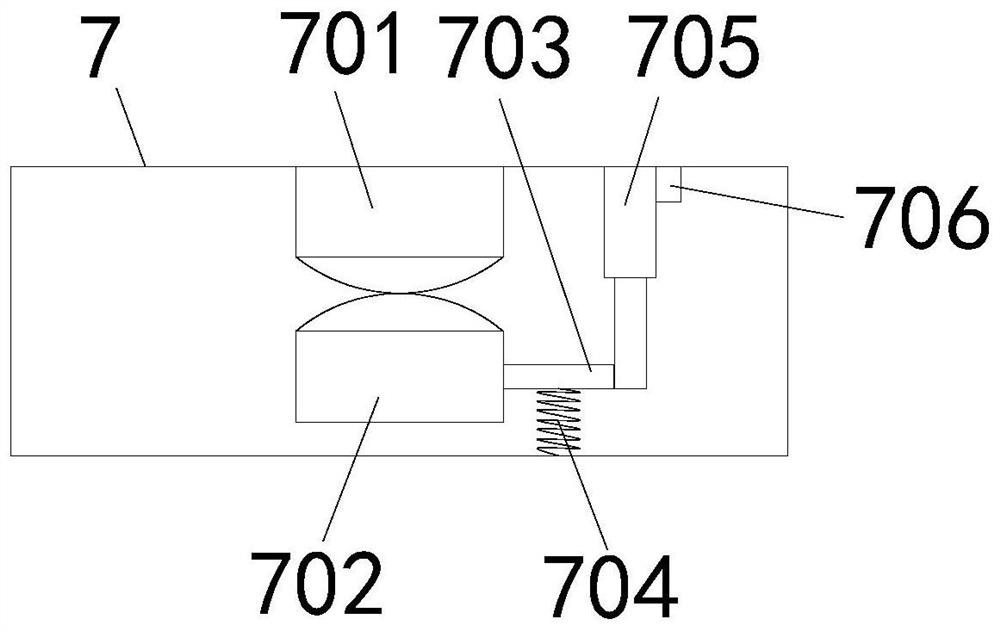

The invention relates to the technical field of automatic detection, in particular to an automatic bottle detection production line. The automatic bottle detection production line is provided with a rack, wherein a conveying device, an automatic sorting device, an automatic bottle arranging and erecting device, a fine detection device and a crack and broken bottle detection device are arranged on the rack in sequence. Bottles can be conveyed through the whole production line, and bottles meeting the requirements are preliminarily sorted and screened and then reach to the automatic bottle arranging and erecting device. When the bottles reach to set positions, an infrared detection assembly detects and judges whether one end of each bottle firstly entered the conveying device is a bottle opening or a bottle bottom or not and transmits a signal to a controller; after that, a pushing rod assembly pushes the bottles to a reversing device, the reversing device receives the signal of the controller and performs anticlockwise or clockwise rotation to enable the bottle openings of the bottles to upward fall into a product conveying channel to be output, and then the fine detection device performs accurate screening and outputting on the bottle heights and the calibers. The whole production line is automatic, the production efficiency is improved, the cost is reduced, production can be rational, and the automatic bottle detection production line is suitable for large-scale production.

Owner:CHANGZHOU JIANGRUN PRECISION MACHINERY

Gas-liquid separator and refrigeration device with the gas-liquid separator

InactiveCN101371085AAchieve homogenizationRegular and stable importCompression machines with non-reversible cycleFluid circulation arrangementVapor–liquid separatorEngineering

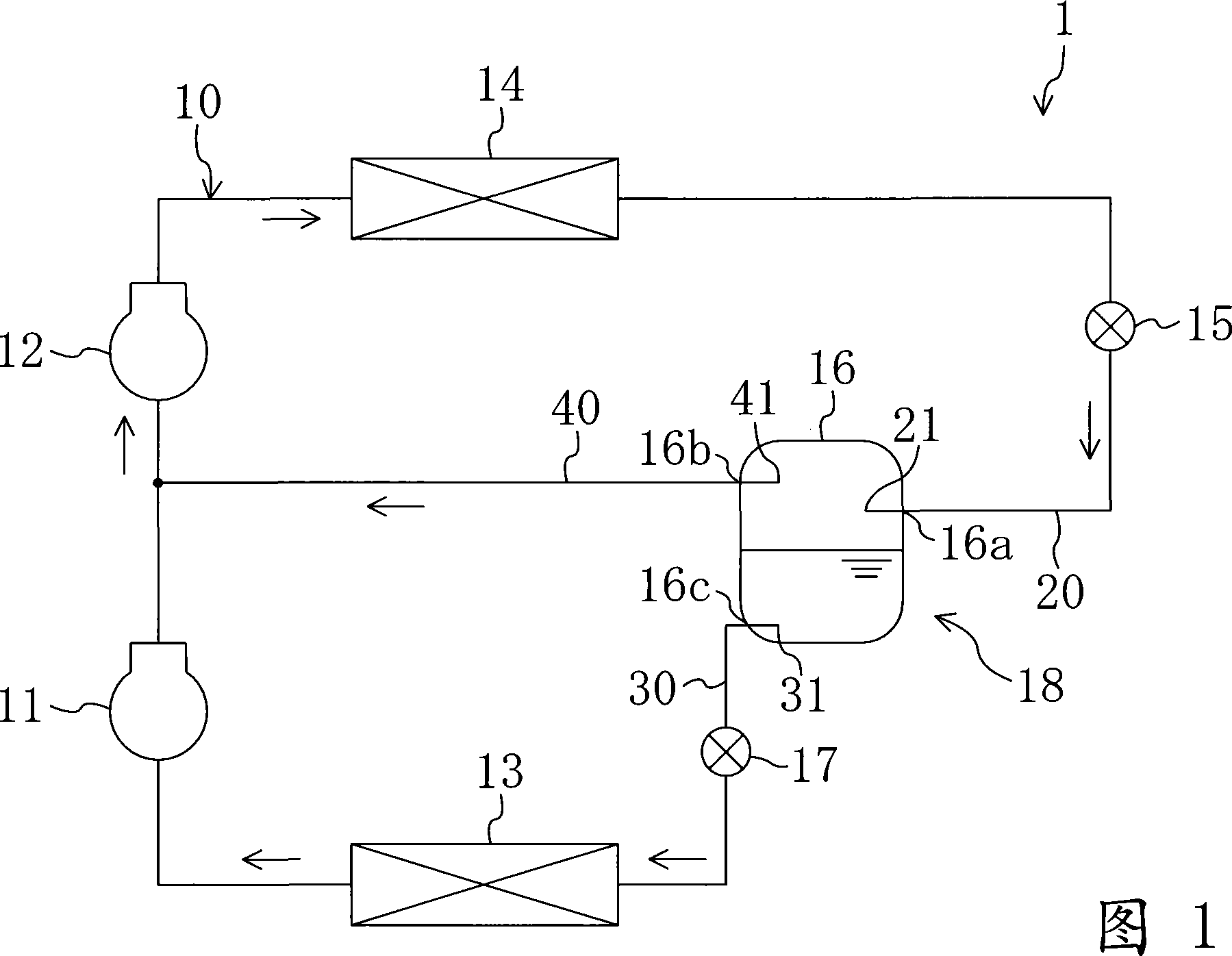

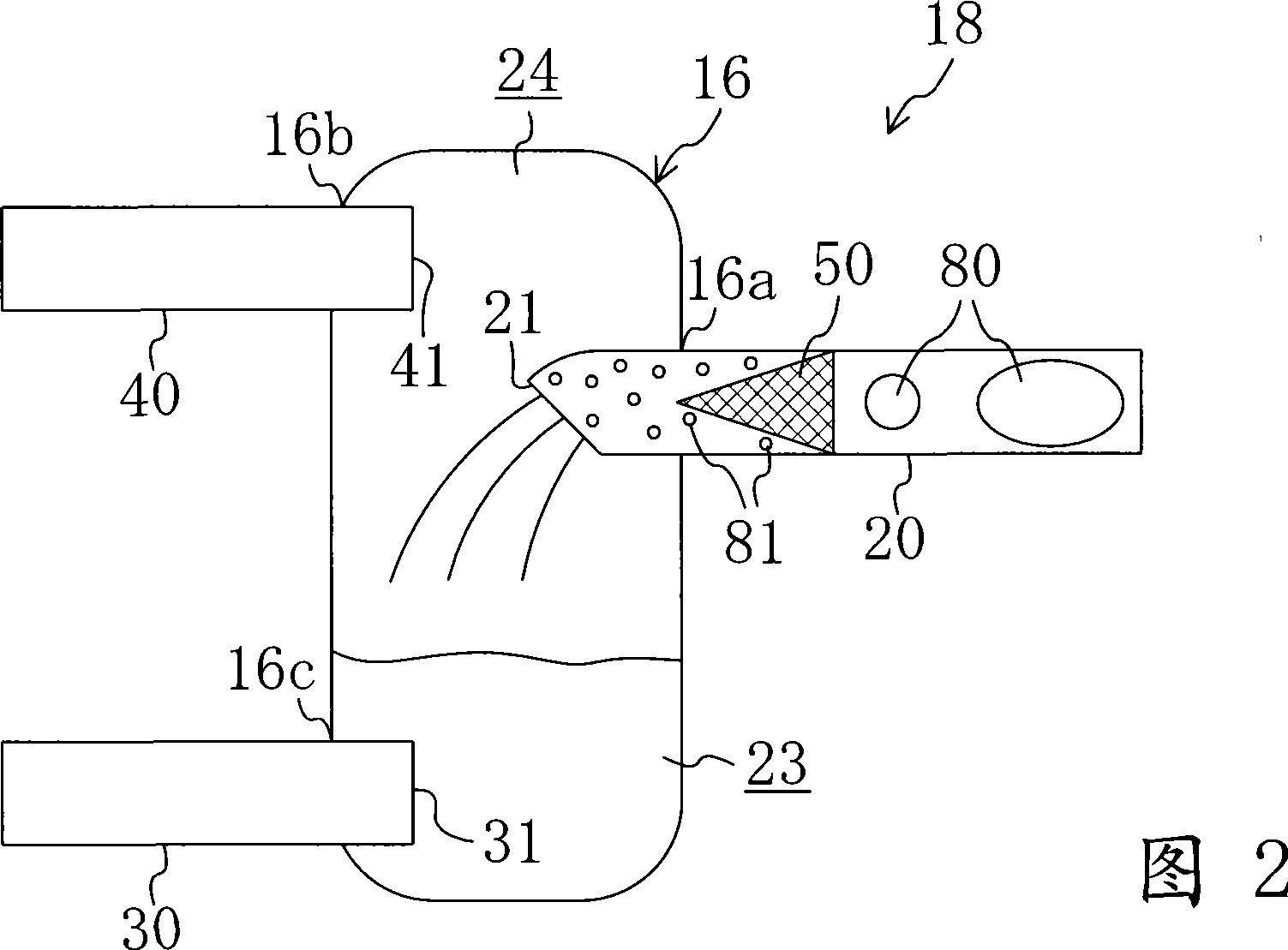

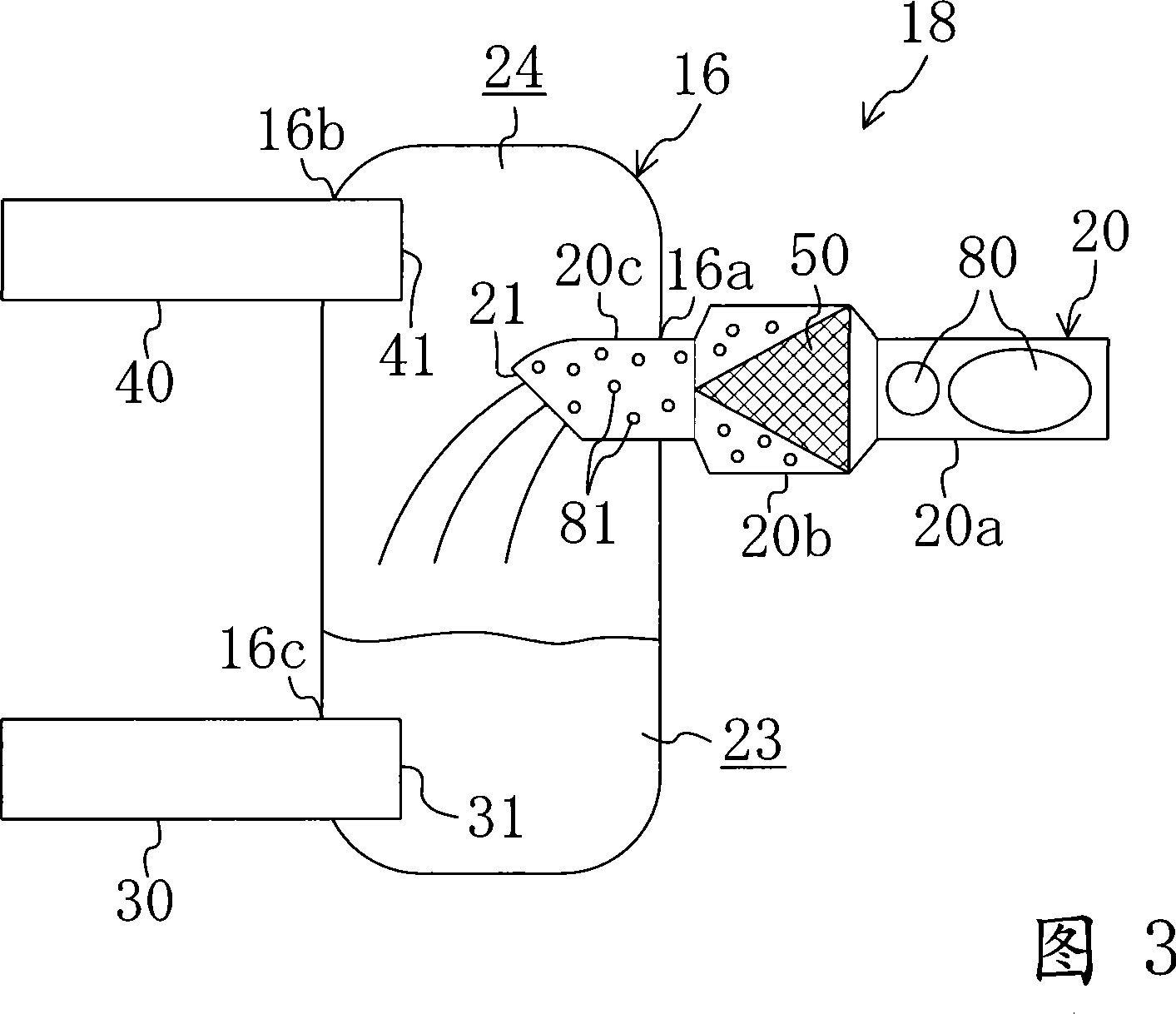

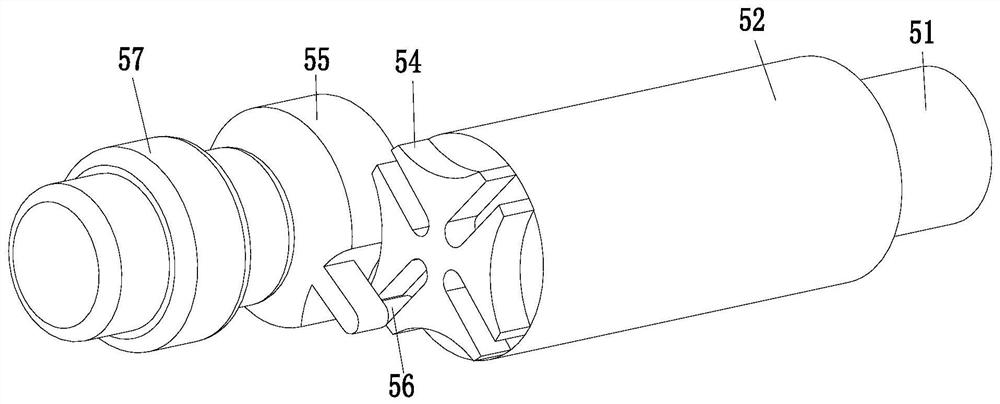

The invention discloses a gas-liquid separator and a refrigeration deivce with the same. A refrigeration device has a gas-liquid separator (18) and a refrigerant circuit for performing a two-stage compression, two- stage expansion refrigeration cycle. In the refrigeration circuit, an intermediate-pressure, gas-liquid two-phase refrigerant passed from an outdoor heat exchanger to an intermediate expansion valve is introduced into a container body (16) via an inlet tube (20) of the gas-liquid separator (18) and separated into liquid refrigerant and gas refrigerant. The liquid refrigerant flows out of a liquid outlet tube (30), flows through a refrigerant heat exchanger via a main expansion valve, and is then drawn into a low-stage-side compressor. The gas refrigerant flows out of a gas outlet tube (40) to be supplied to the suction side of a high-stage-side compressor and is then drawn into the high-stage-side compressor together with refrigerant discharged from the low-stage-side compressor. A mesh member (50) for breaking up bubbles (80) formed of the gas refrigerant in the gas-liquid two-phase refrigerant is provided in the inlet tube (20).

Owner:DAIKIN IND LTD

Automatic permanent magnet product dividing and box packing equipment

PendingCN108583995AGuaranteed accuracySave the area occupied by the stationPackaging automatic controlEngineeringMechanical engineering

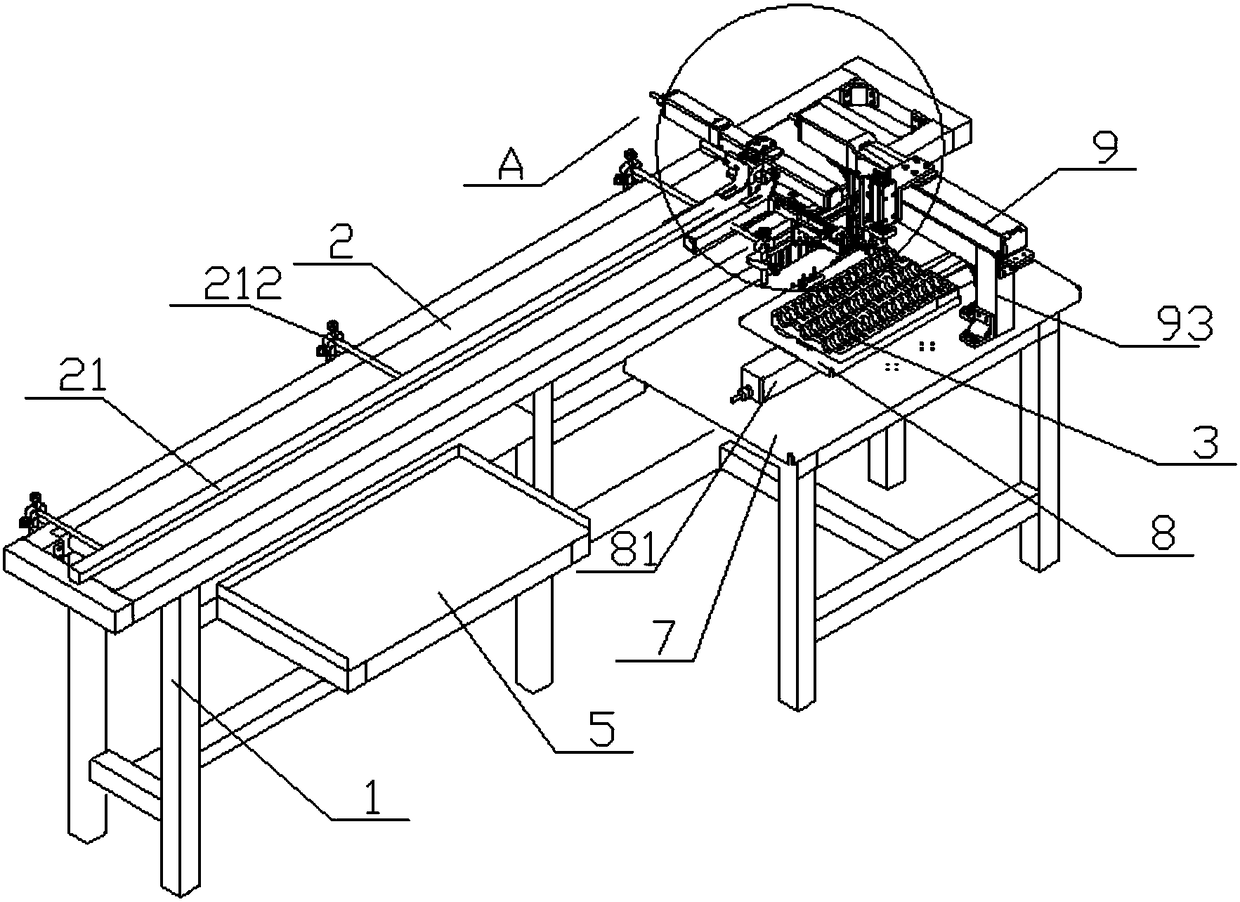

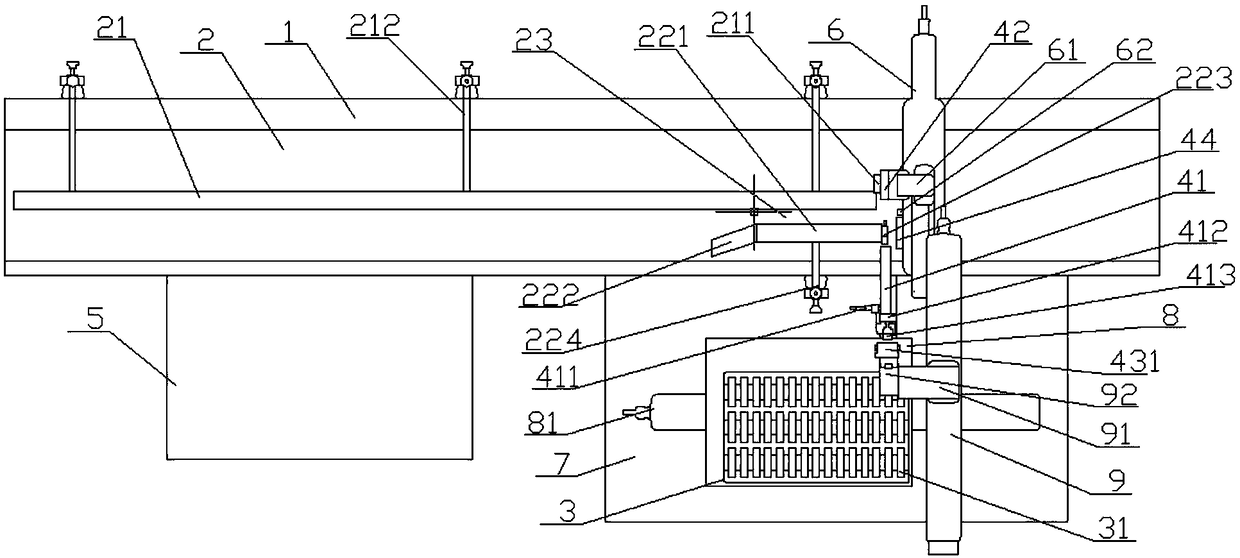

The invention discloses automatic permanent magnet product dividing and box packing equipment which comprises a rack, a conveyor belt, a loading device and a loading box, wherein the loading device comprises a storage groove, a first push block and an air claw; the storage groove and the conveyor belt are perpendicularly and fixedly arranged on the rack; the first push block is positioned on the second side close to the second end of the conveyor belt and is in sliding fit with the rack; the air claw is in sliding fit with the rack, can move up and down and can move horizontally in the lengthdirection of the storage groove; and the air claw is driven by a third air cylinder. The automatic permanent magnet product dividing and box packing equipment is suitable for box packing operation ofpermanent magnet products with multiple specifications, realizes general utilization of the products with multiple specifications, is integrally designed, reduces the equipment station occupied area,can reduce the investment cost compared with the original equipment with the single specification, can automatically adjust the key sizes including box packing position, quantity and the like according to the product specification requirement, greatly improves the working efficiency, ensures the precision of the box packing quantity, and lowers the strength of manual labor.

Owner:京磁材料科技股份有限公司

Landing platform for unmanned aerial vehicle

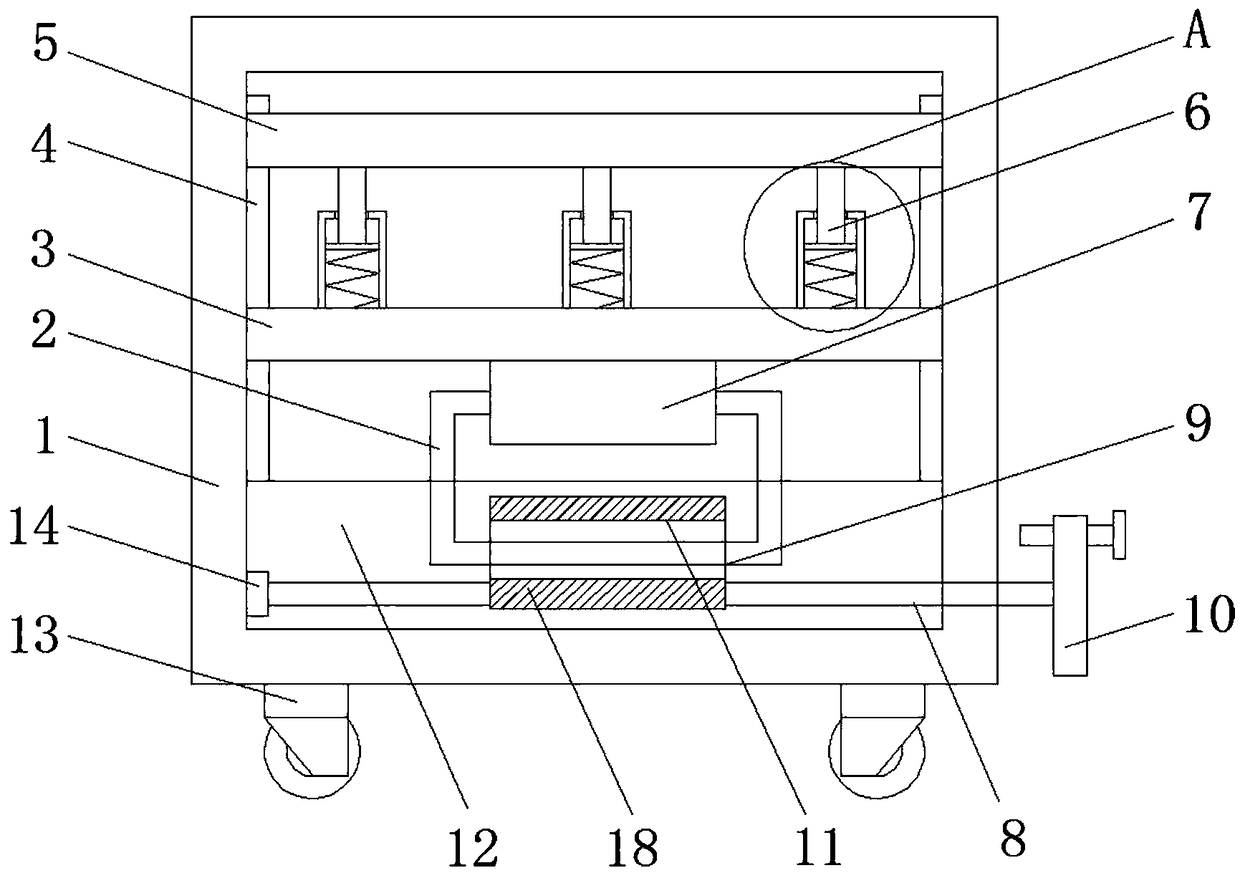

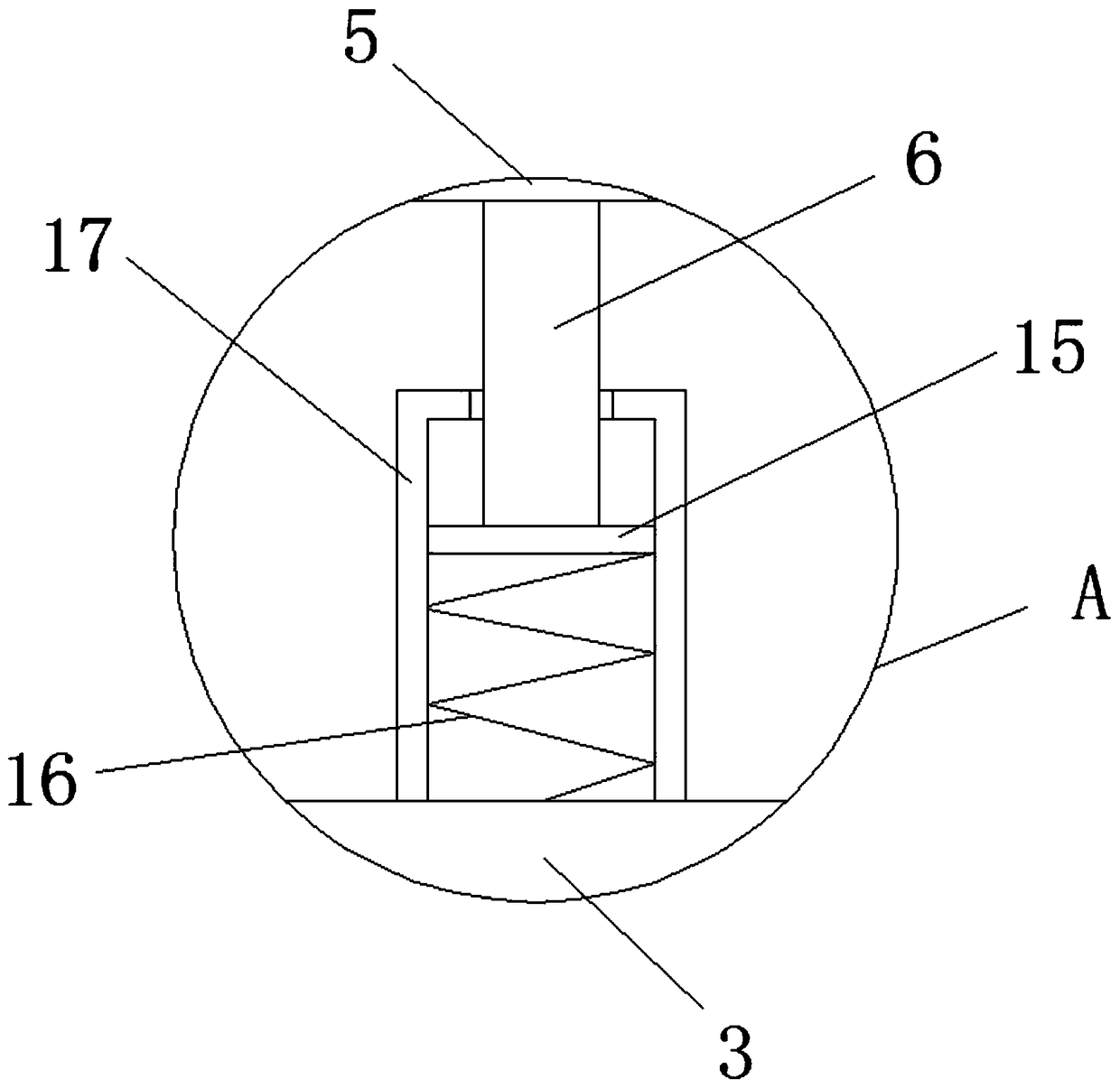

InactiveCN108820239APlay a shock absorbing roleFall smoothlyArresting gearPortable landing padsGear driveGear wheel

The invention discloses a landing platform for an unmanned aerial vehicle (UAV). The landing platform for the UAV comprises the landing platform, wherein a box body is fixedly connected to the bottominner surface of the landing platform; a bearing housing is fixedly connected to the inner wall of one side of the box body; a rotating shaft is rotationally connected to the inner wall of the bearinghousing; the end, away from the bearing housing, of the rotating shaft penetrates through the box body and is fixedly connected with a rotating disk; a first gear is fixedly connected to the outer wall of the rotating shaft; a synchronous toothed belt is connected to the outer wall of the first gear in a gear-drive manner; the synchronous toothed belt is connected with a second gear in a gear-drive manner at the end away from the first gear; a support plate is connected to the inner wall of the synchronous toothed belt in a gear-drive manner; two ends of the support plate penetrate through the box body and are fixedly connected with a mounting base; and a first horizontal plate is fixedly connected to the upper surface of the mounting base. The landing platform for the UAV can play a storage role for the UAV and can also play a protective effect for the UAV so as to prevent damage to the UAV. The landing platform for the UAV is simple in structure and convenient to operate.

Owner:芜湖新尚捷智能信息科技有限公司

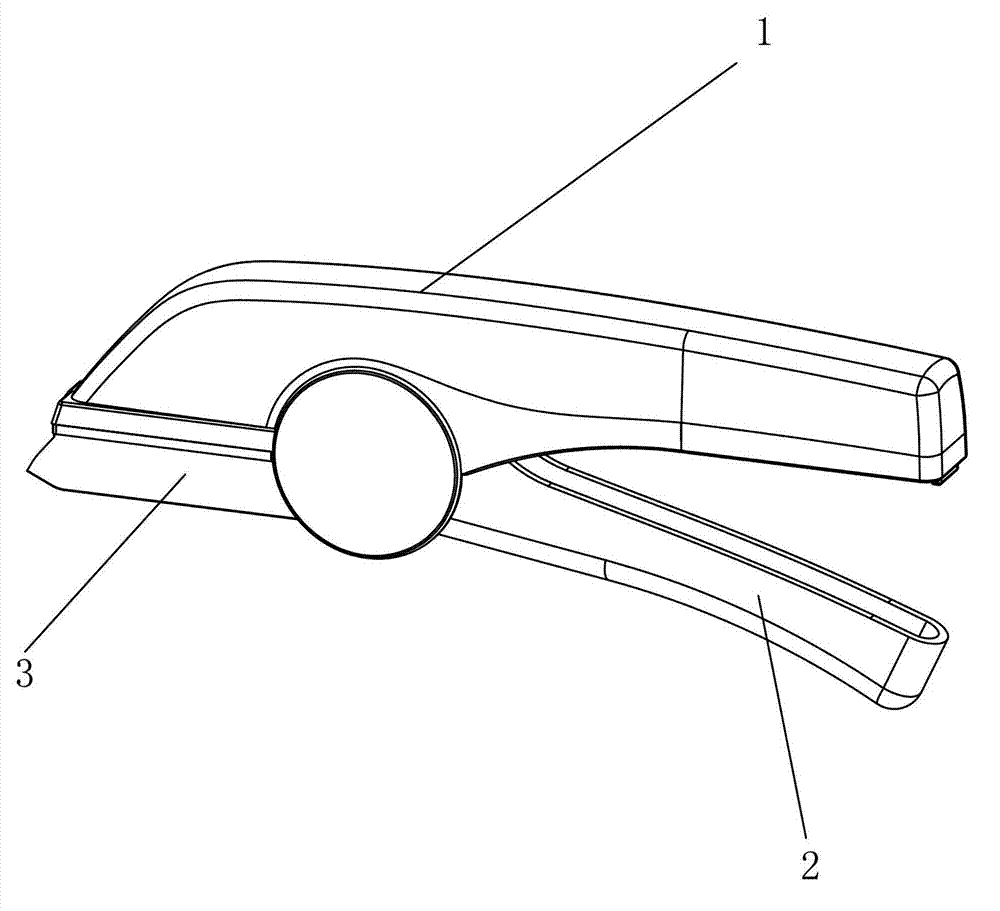

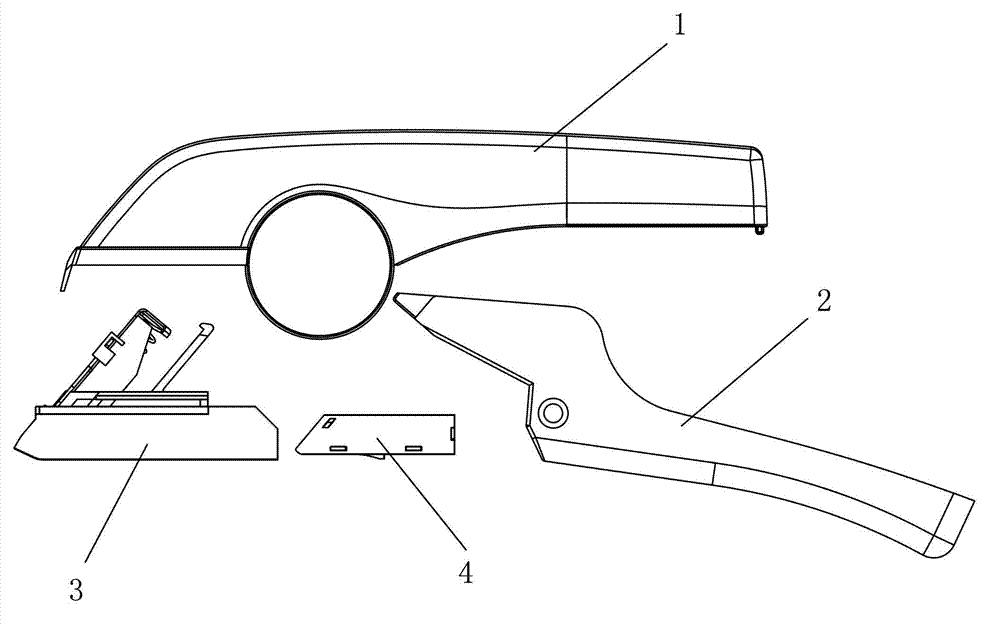

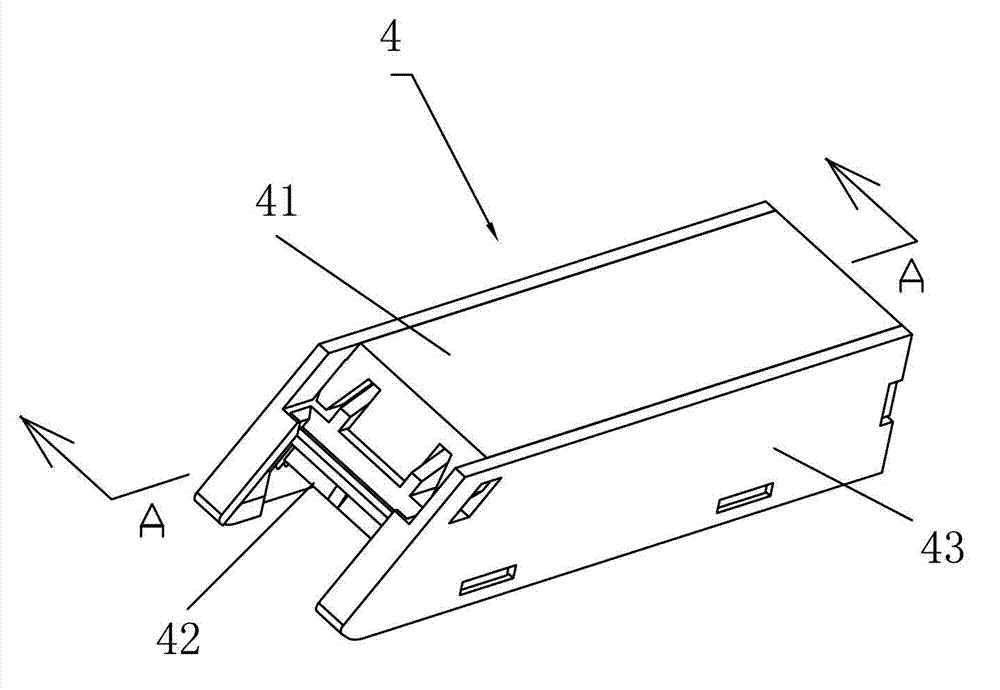

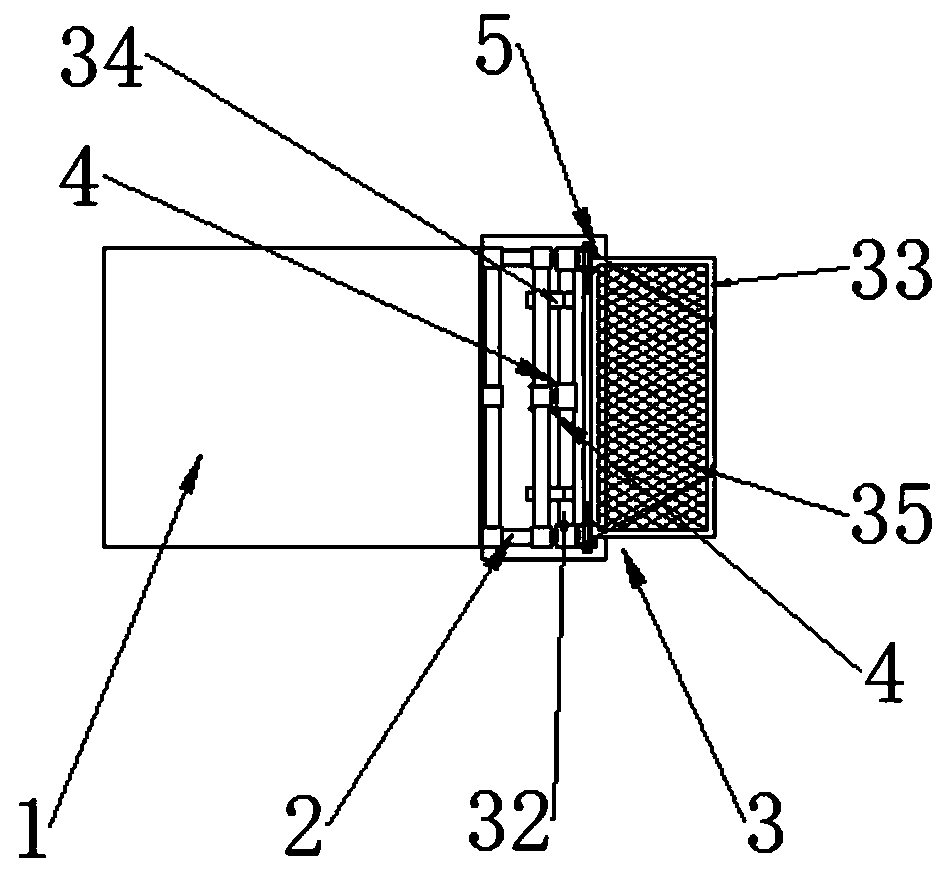

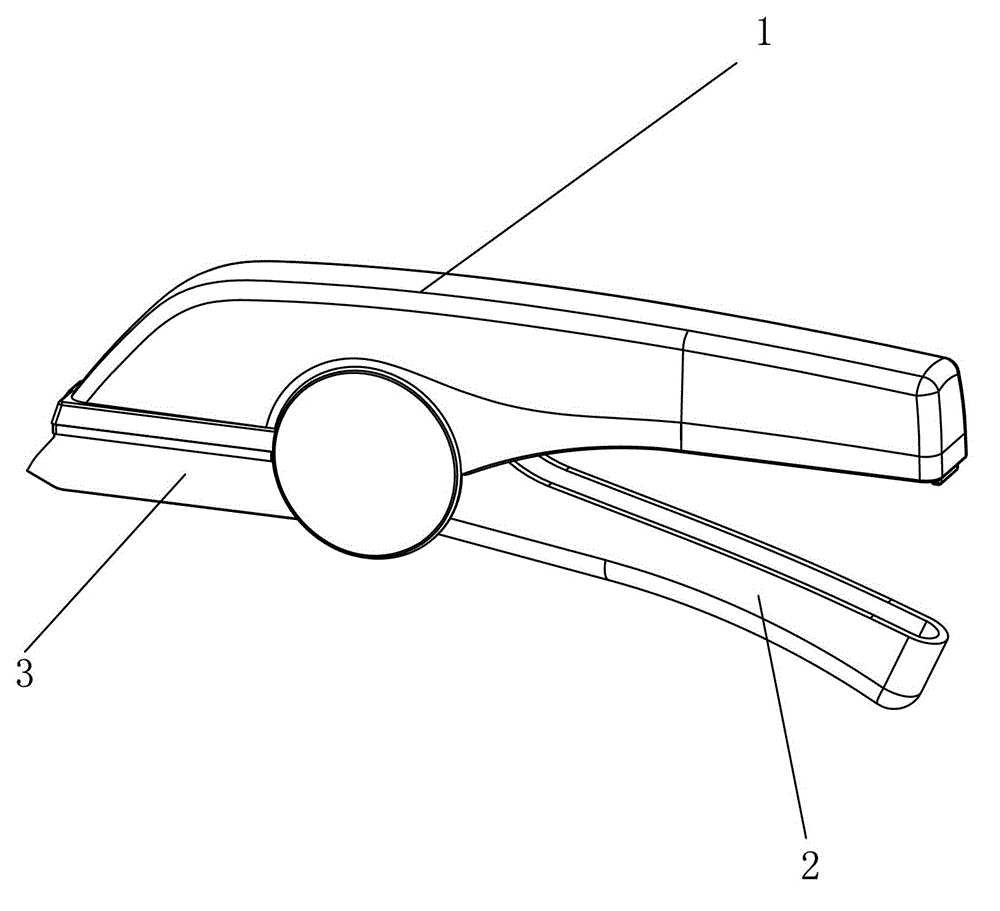

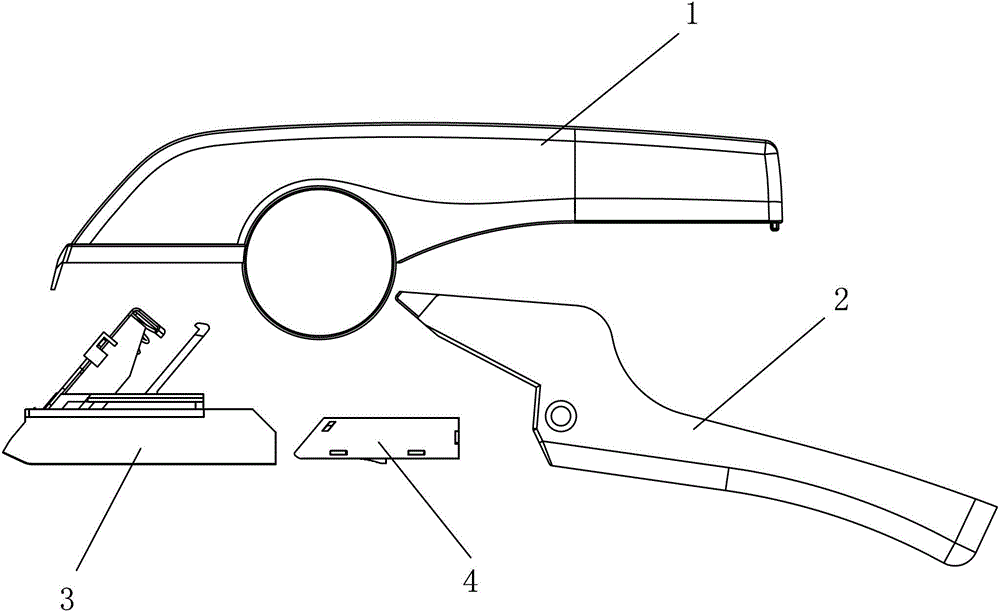

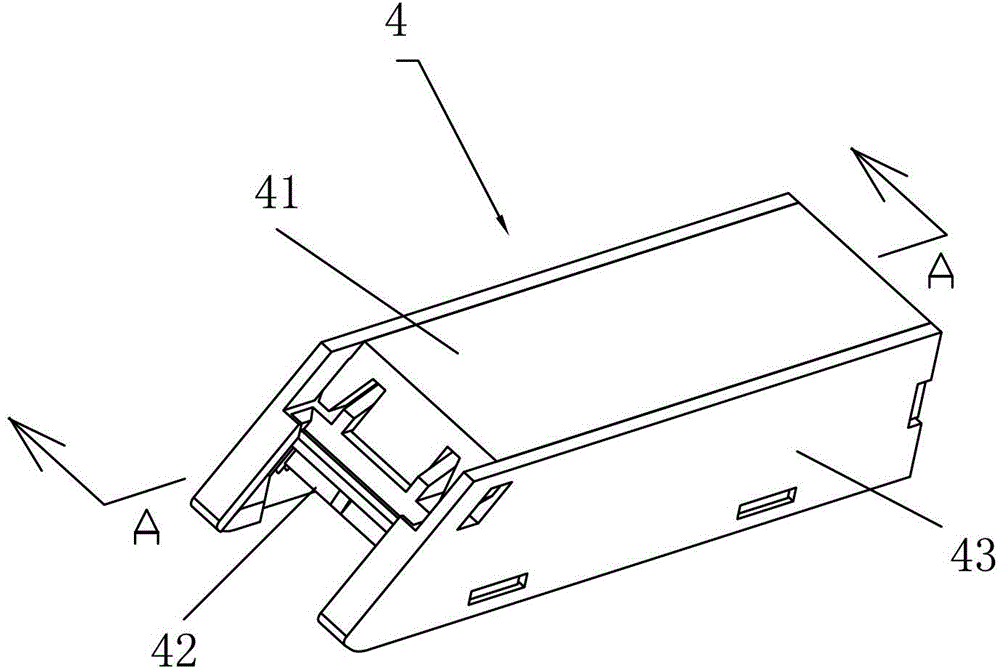

Reusable animal skin stitching instrument

The invention discloses a reusable animal skin stitching instrument. A needle storage box for placing stitching needles used for the skin stitching instrument can be replaced frequently according to requirements, and the needle storage box can be used for placing various specifications of stitching needles. The reusable animal skin stitching instrument comprises a function housing, a fixed handle and a fixed handle; the needle storage box is arranged inside the function housing; and a needle box for placing stitching needles in which the height is 1-1.5 times of that of the stitching needles is formed between the box bottom and a box holder of the needle storage box. The skin stitching instrument adopts a reusable needle storage box structure capable of being replaced quickly, so that the use efficiency of the skin stitching instrument can be greatly improved, the instrument consumption is reduced, and the cost of medical operations is reduced; moreover, the needle storage box adopts a structure containing a first inclined plane, a second inclined plane and a lug boss at a stitching needle outlet end, so that the stitching needle can be fallen in a conveying passage stably and accurately without casing needle blocking, needle blockage and needle disorder, normal use of the skin stitching instrument is ensured, and safety of medical operations is ensured.

Owner:RWD LIFE SCI

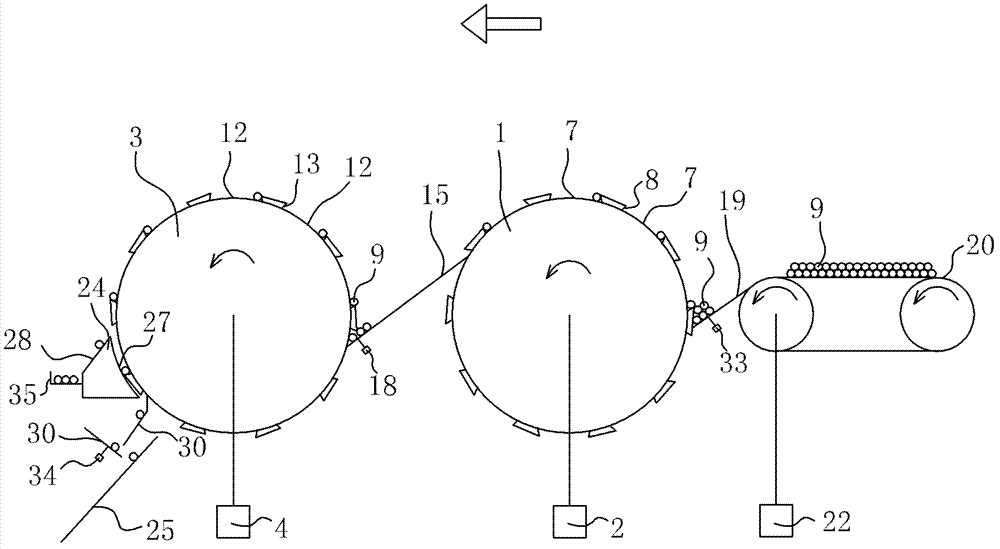

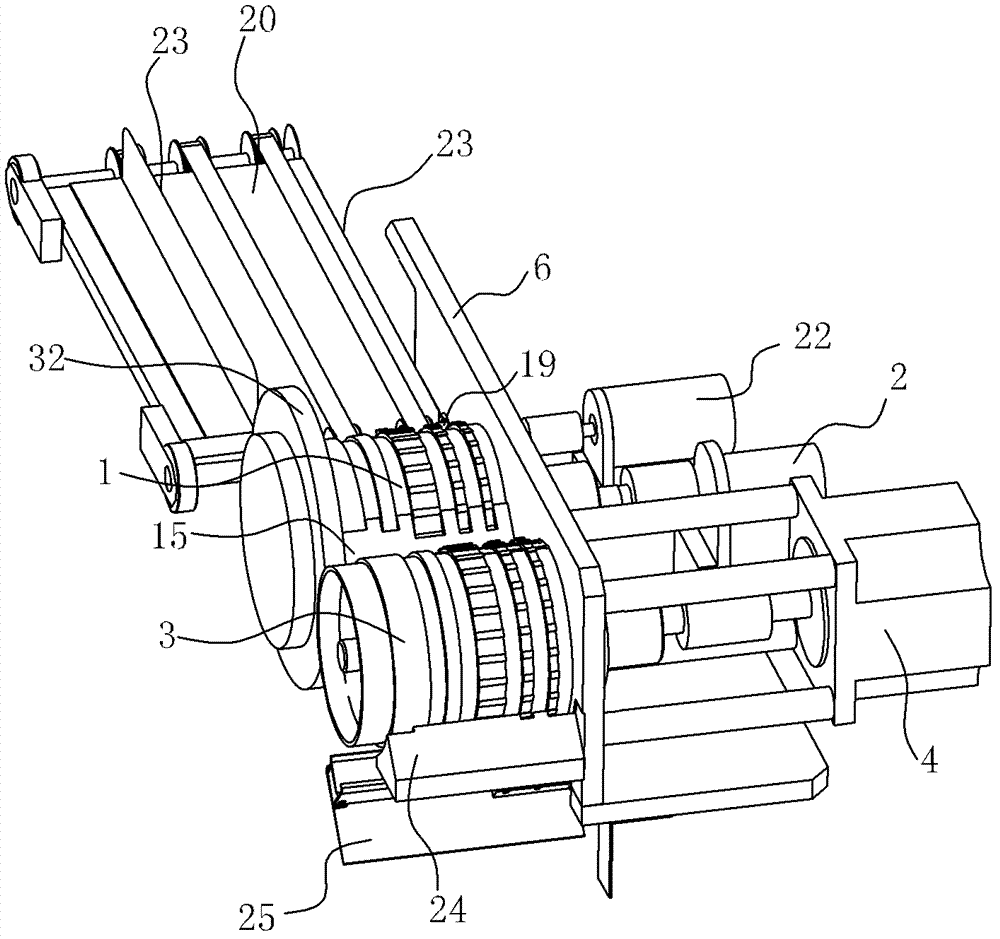

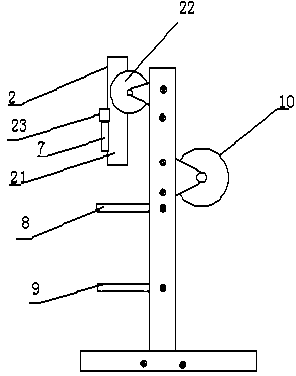

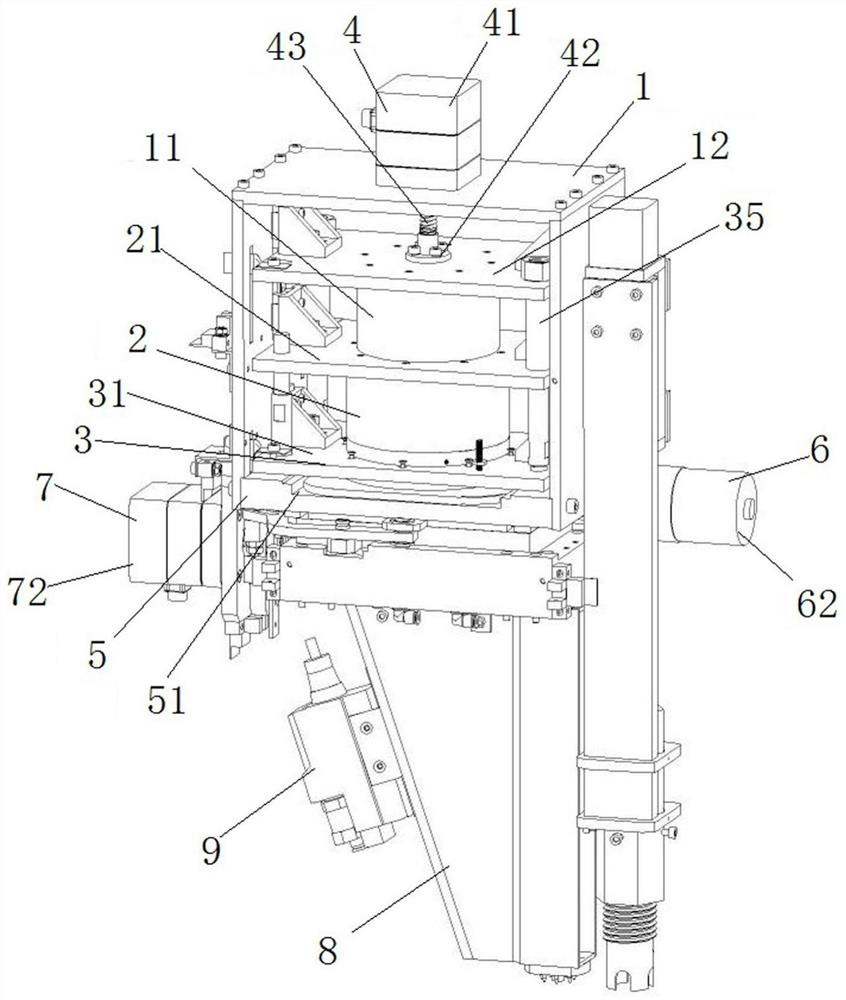

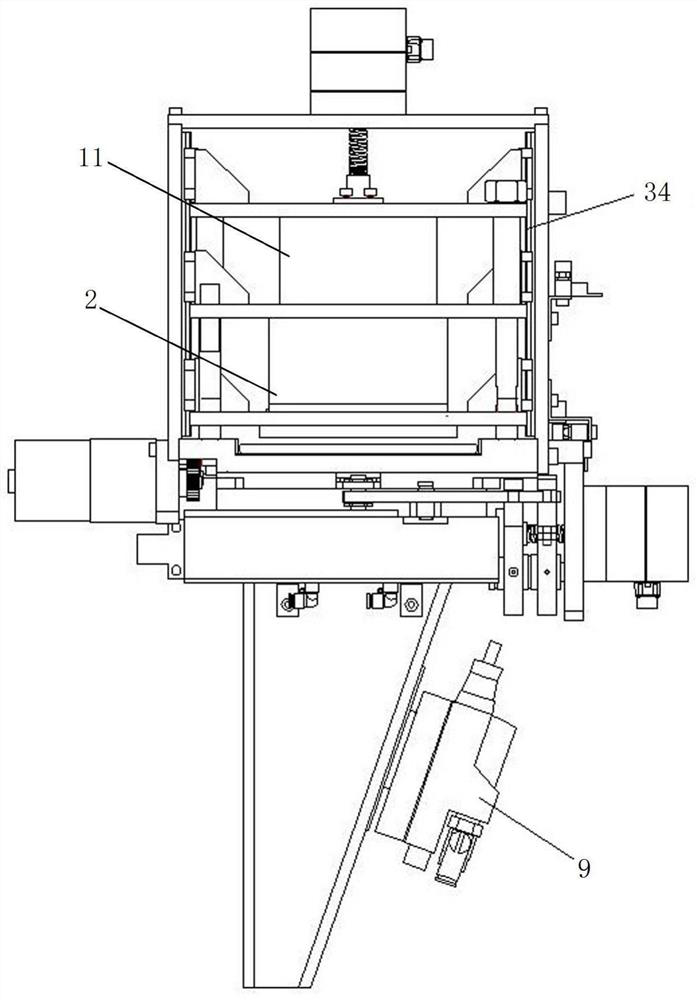

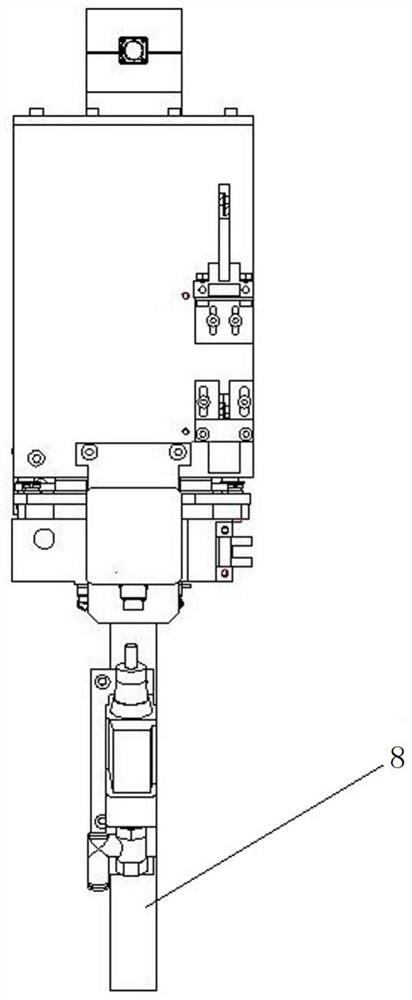

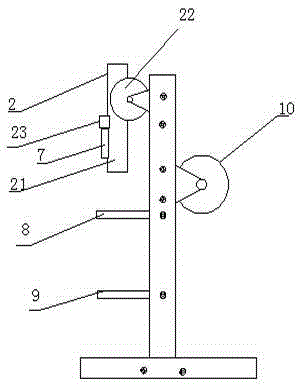

Automatic sorting mechanism for acupuncture needles

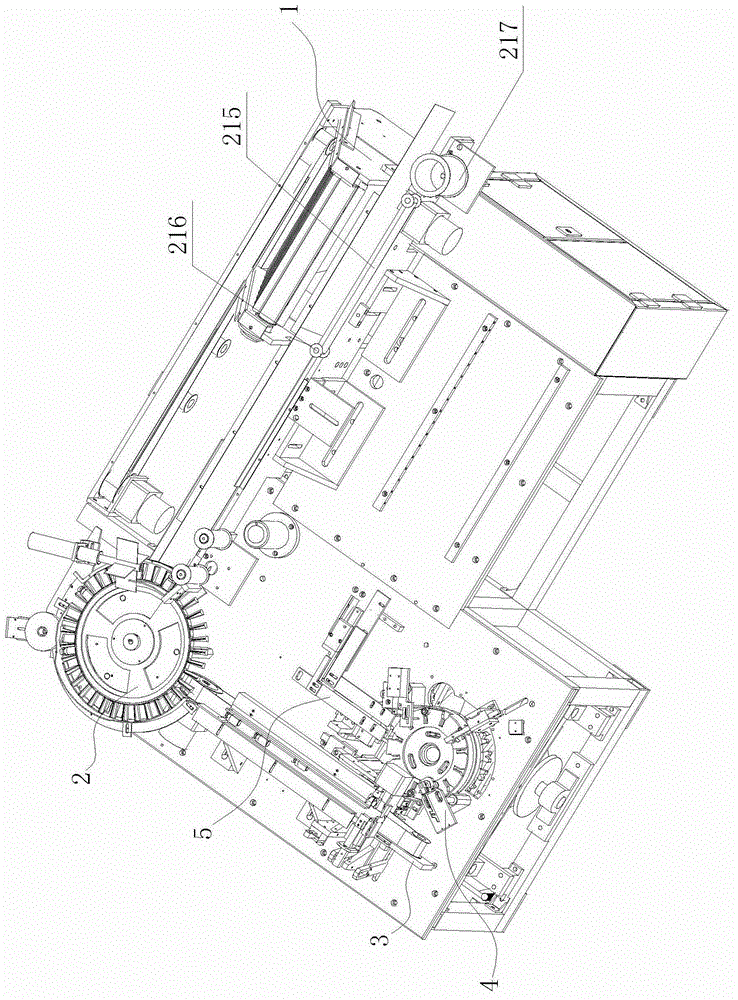

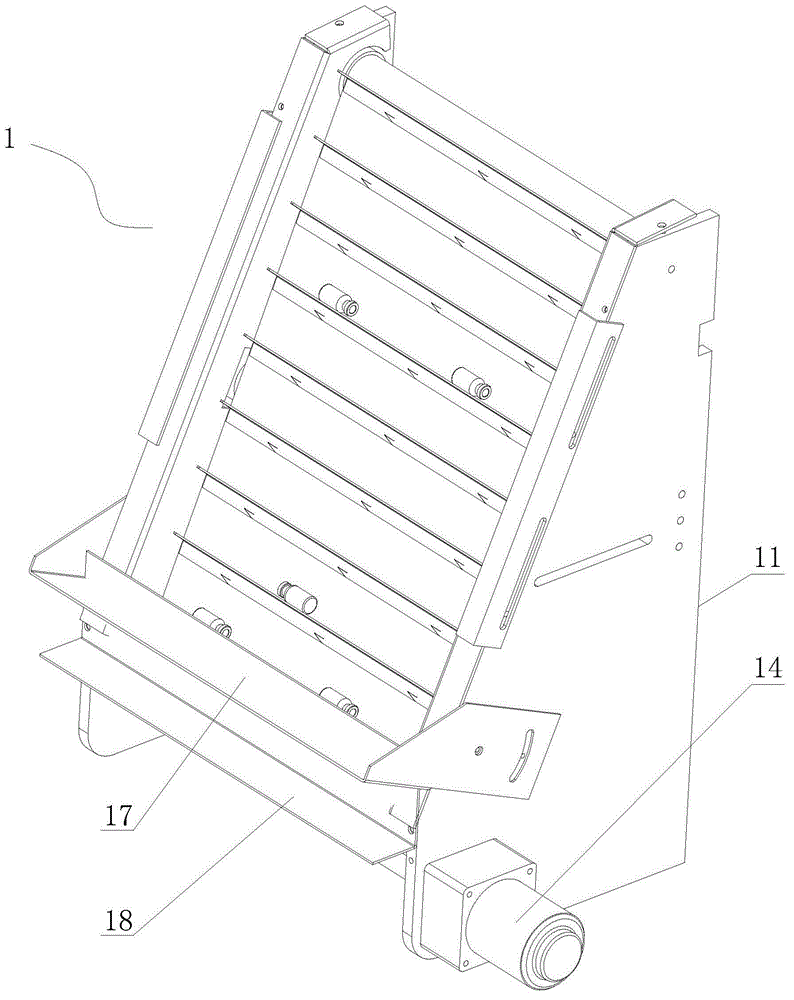

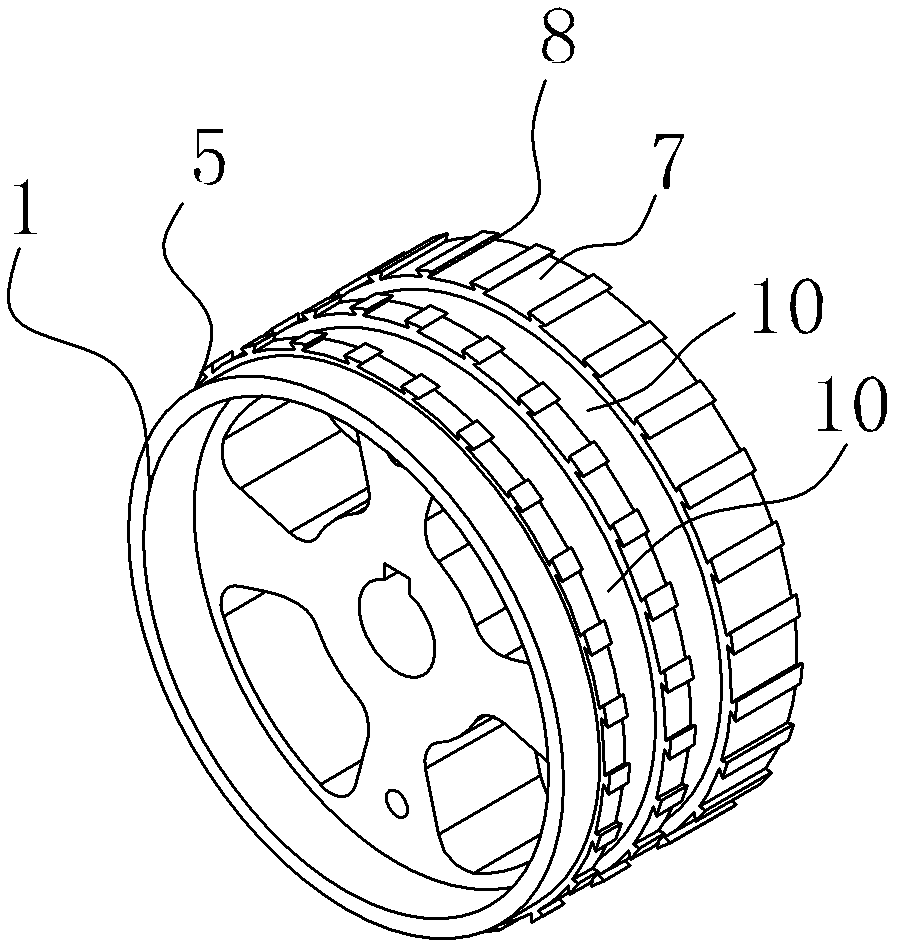

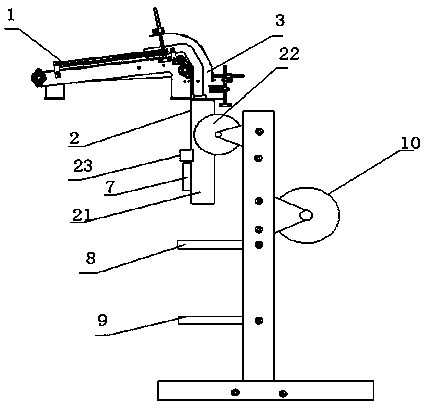

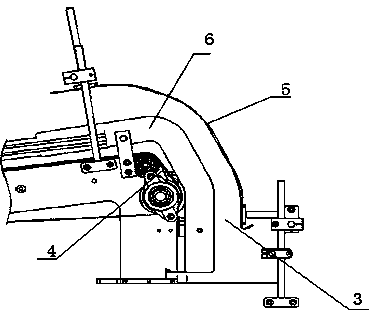

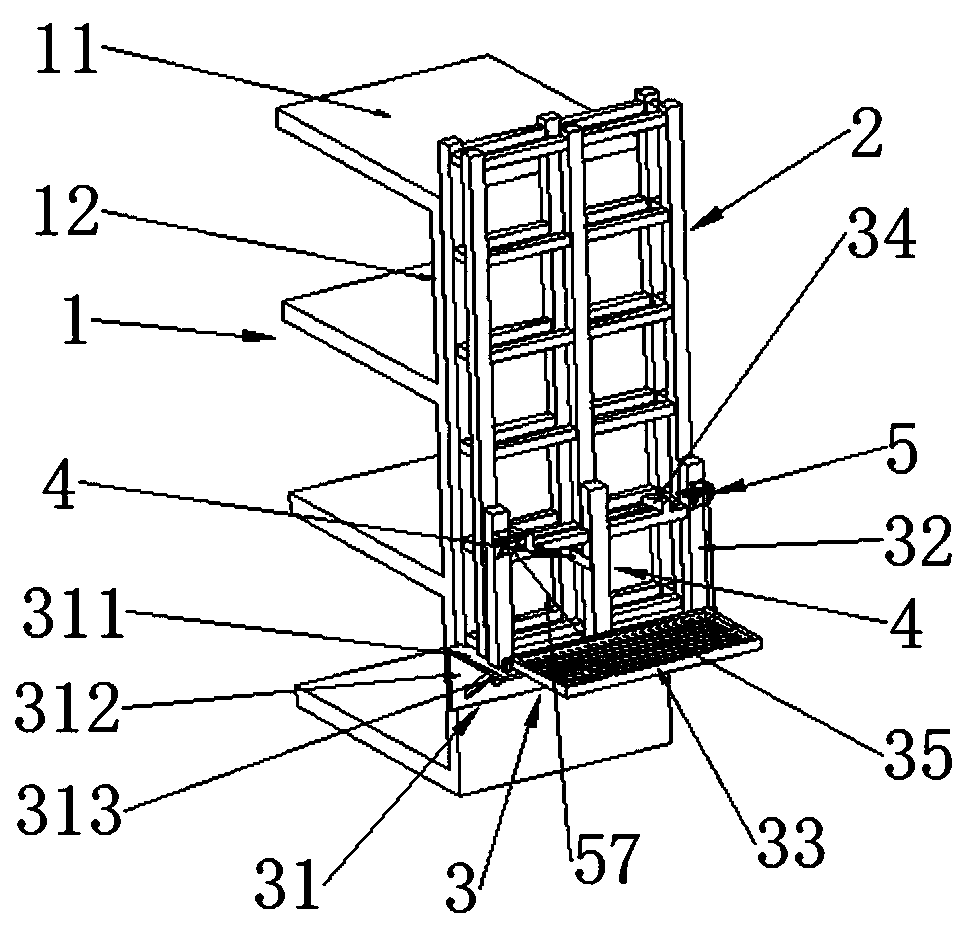

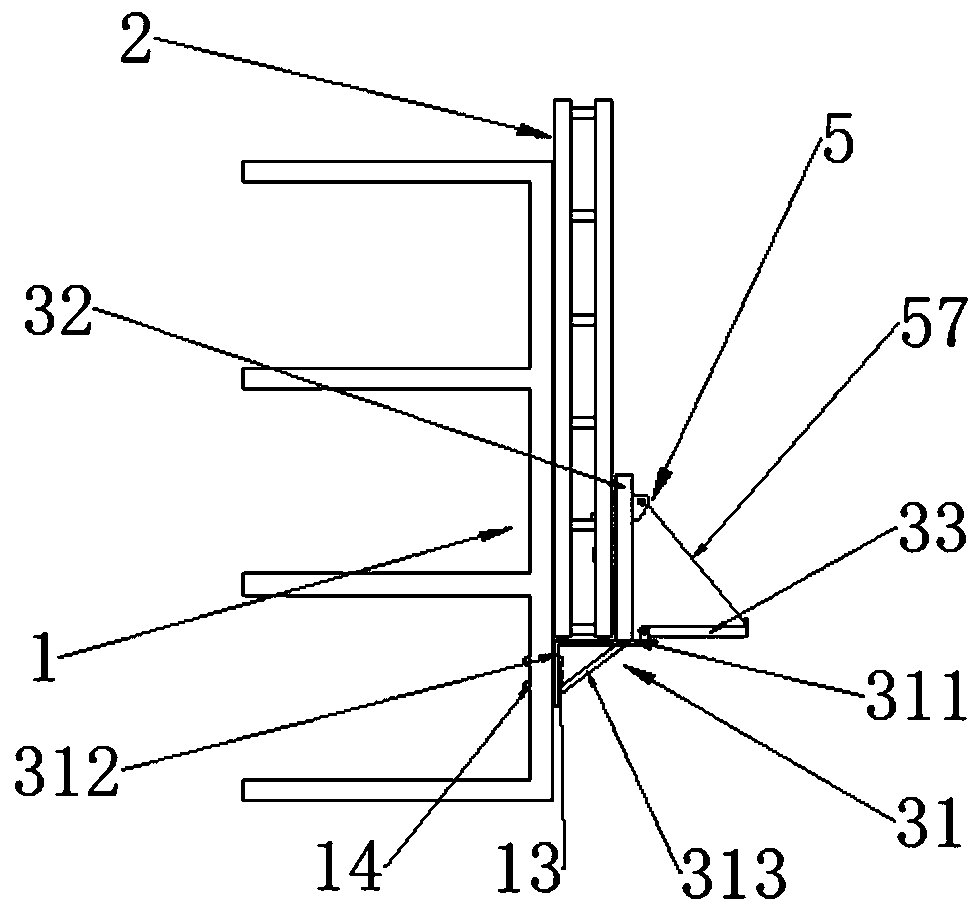

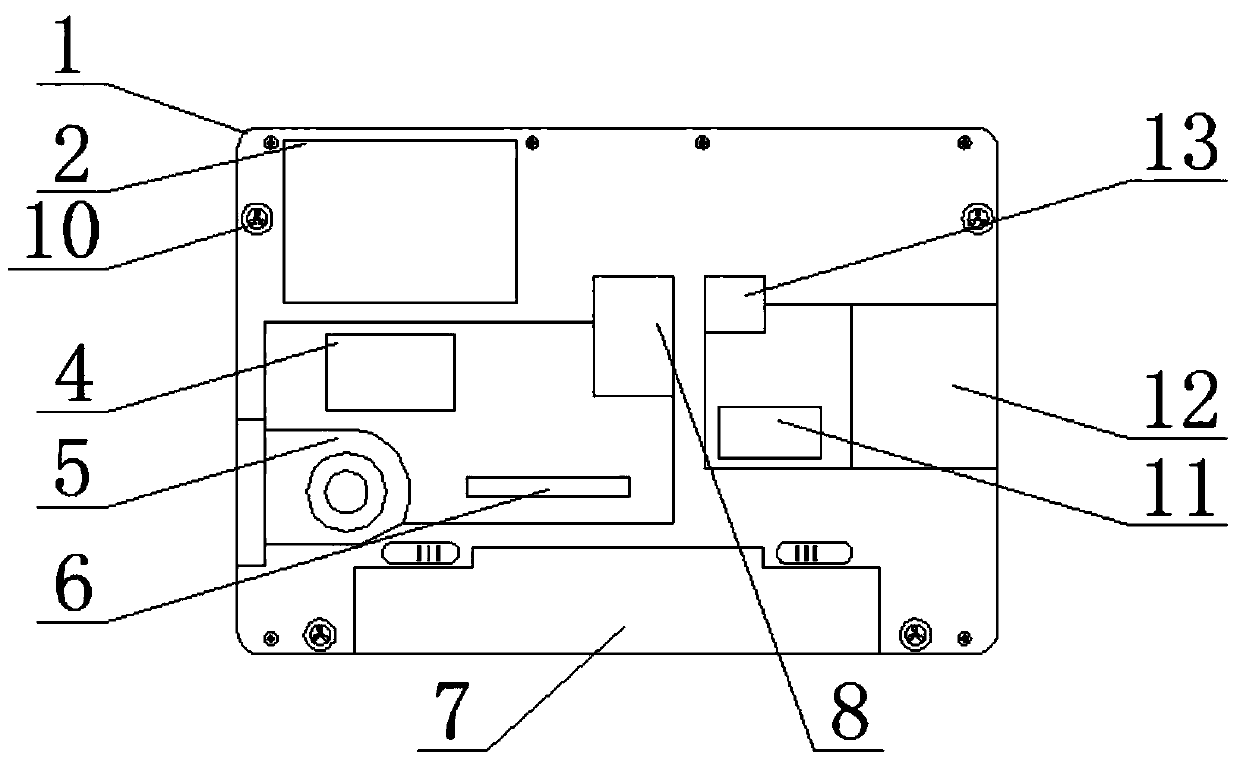

ActiveCN102502001BReduce in quantityFall smoothlyPackaging automatic controlRod-shaped articlesAcupuncture needlesElectric machinery

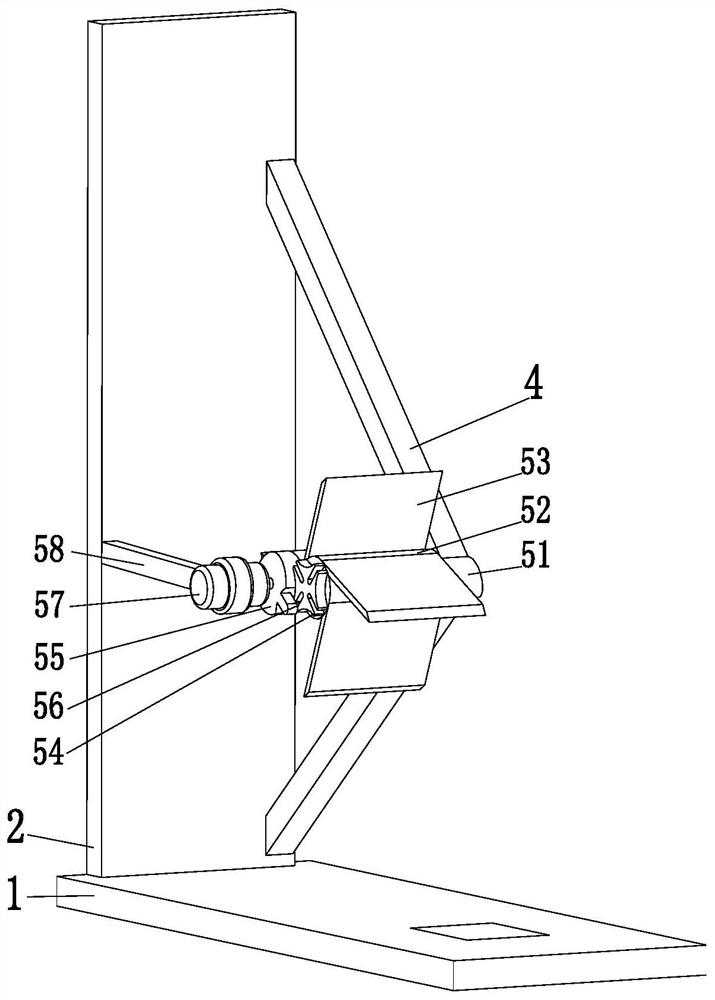

The invention discloses an automatic sorting mechanism for acupuncture needles. The automatic sorting mechanism mainly comprises a first-stage needle sorting wheel structure and a second-stage needle sorting wheel structure which are combined with each other, wherein the first-stage needle sorting wheel structure consists of a first needle sorting wheel and a first motor; the second-stage needle sorting wheel structure consists of a second needle sorting wheel and a second motor; the first needle sorting wheel consists of a cylindrical first barrel; a first needle sorting groove is formed on the outer edge of the first barrel along the axial direction; a first annular groove is formed on the outer edge of the first barrel along the circumferential direction; the cross section of the firstneedle sorting groove has a dovetail groove shape; the structure of the second needle sorting wheel is similar to that of the first needle sorting wheel; the second motor can be a stepping motor or aservo motor; the first needle sorting wheel and the second needle sorting wheel are arranged parallel to each other; a first bearing plate is obliquely arranged in the space between the rear half part of the first needle sorting wheel and the front half part of the second needle sorting wheel; and a first sensor for detecting the acupuncture needles is arranged at one end of the first bearing plate corresponding to the second needle sorting wheel. The automatic sorting mechanism for the acupuncture needles is reliable and stable.

Owner:SUZHOU MEDICAL SUPPLY FACTORY CO LTD

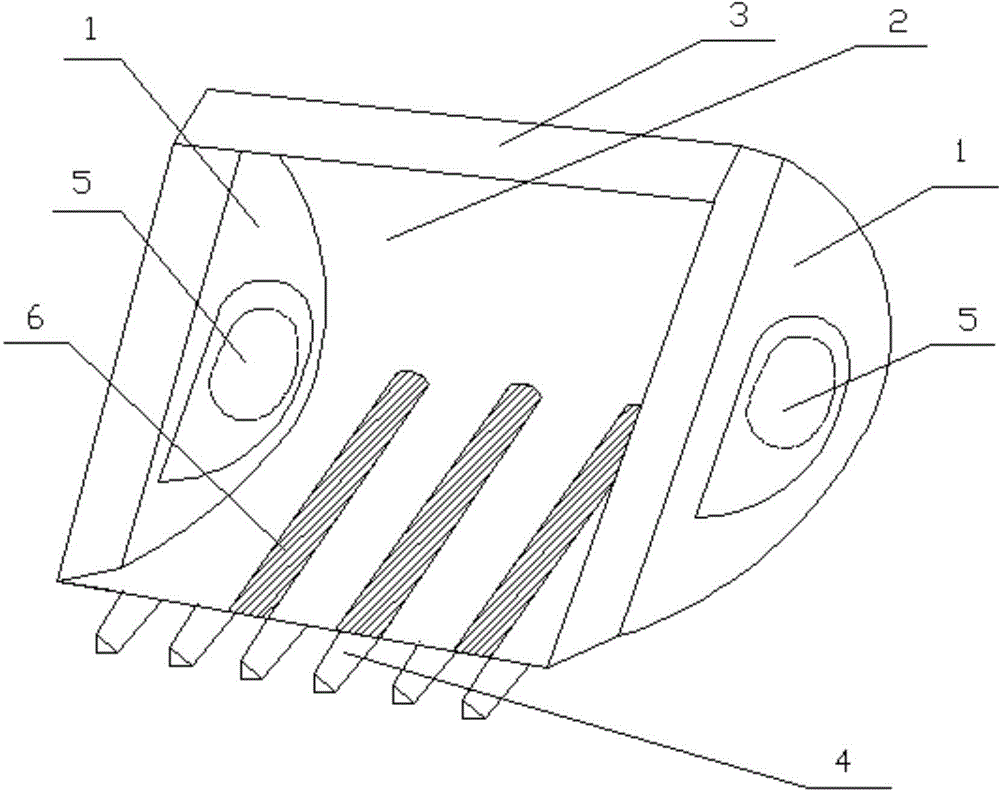

Excavation bucket

The invention discloses an excavation bucket. The excavation bucket comprises two side wall plates, a bucket wall plate, a reinforcing beam and bucket teeth, wherein the bucket wall plate is in an arc shape, the two side wall plates are fixedly arranged on the two sides of the bucket wall plate respectively, the reinforcing beam is fixedly arranged at the upper end of the bucket wall plate, the two sides of the reinforcing beam are fixedly connected with the side wall plates respectively, the bucket teeth are arranged at the lower end of the bucket wall plate, the middle portions of the two side wall plates are each provided with an oval groove protruding from inside to outside, and a smooth slope is formed at the edge of each oval groove and is close to one side of the bucket teeth. The excavation bucket has the advantages that when an excavator conducts excavation, the utilization rate of the bucket is increased, and the working efficiency is improved; through arrangement of the smooth slopes, the bucket can pour off objects more smoothly.

Owner:LIUZHOU JINTE NEW WEAR RESISTANT MATERIAL CO LTD

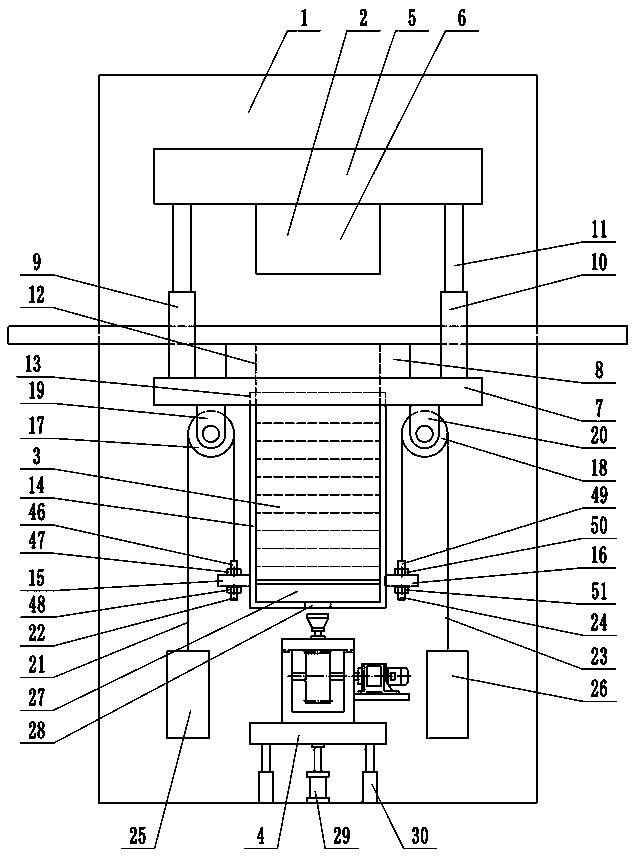

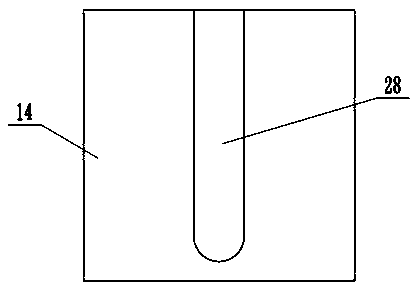

Steel plate punching welding device

InactiveCN108889864AAchieve adsorptionProcess stabilityMetal-working feeding devicesStripping-off devicesSheet steelPunching

The invention provides a steel plate stamping welding device, and belongs to the technical field of mechanical processing. The device comprises a punching mechanism, a material bearing mechanism and ablanking mechanism, a lower punching die of the punching mechanism is installed at the upper end of a lower punching support seat, an upper punching die is installed at the lower end of an upper punching support seat, a blanking slot is formed in the lower end of the front side of a material bearing box of the material bearing mechanism, a U-shaped blanking groove is formed in the lower side of the material bearing box, an opening faces the front side, the upper end of the material bearing box is inserted into a material bearing box slot of the lower punching support seat under the action ofa left gravity block and a right gravity block, a blanking sliding plate of the blanking mechanism can slide back and forth on a sliding groove of a gear box through a sliding block, a blanking gear and a blanking rack are meshed with each other, and a blanking sucking disc is mounted on the upper side of the blanking sliding plate. The device not only utilizes the floating material bearing box toachieve the material bearing of a workpiece after the stamping, and facilitates the smooth falling of the workpiece into the material bearing box, but also uses a gear rack structure to achieve the blanking one by one of the workpiece in the material bearing box.

Owner:赵锋

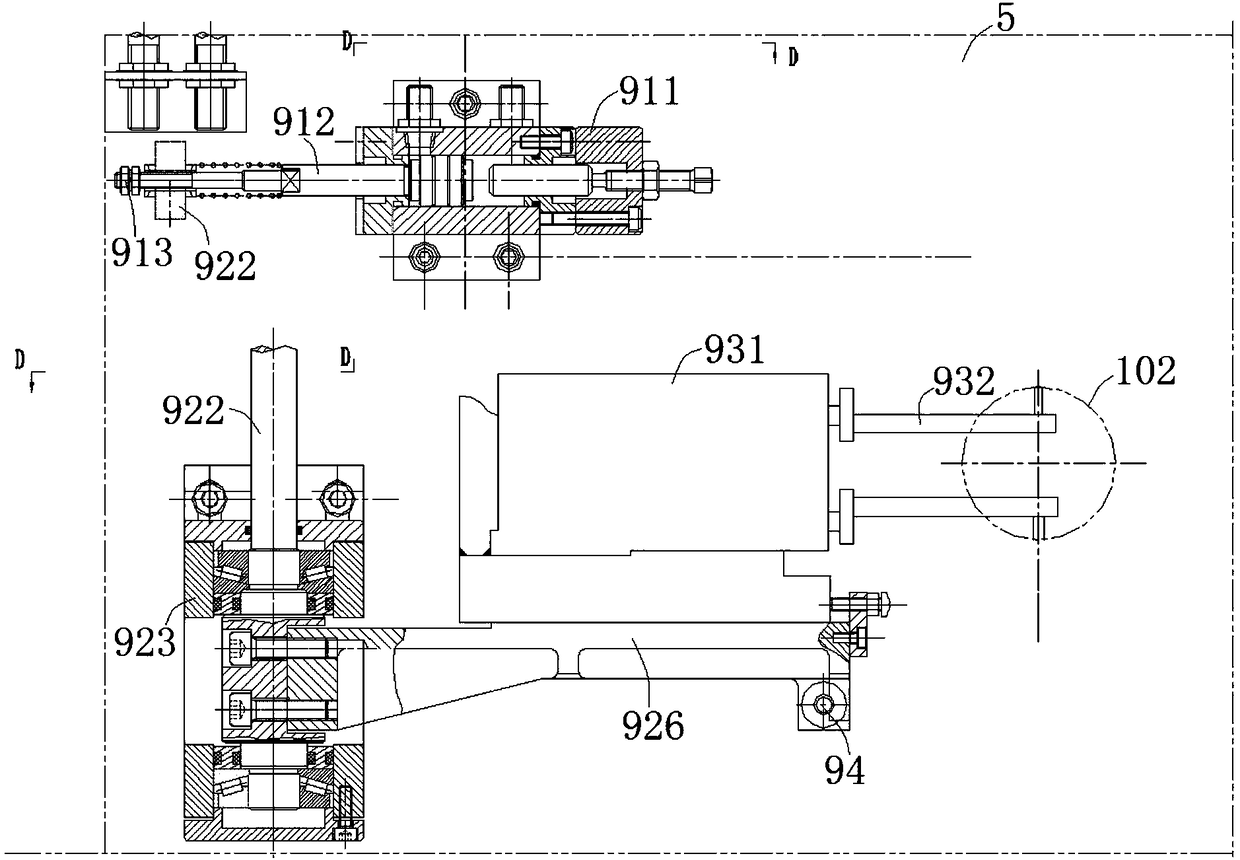

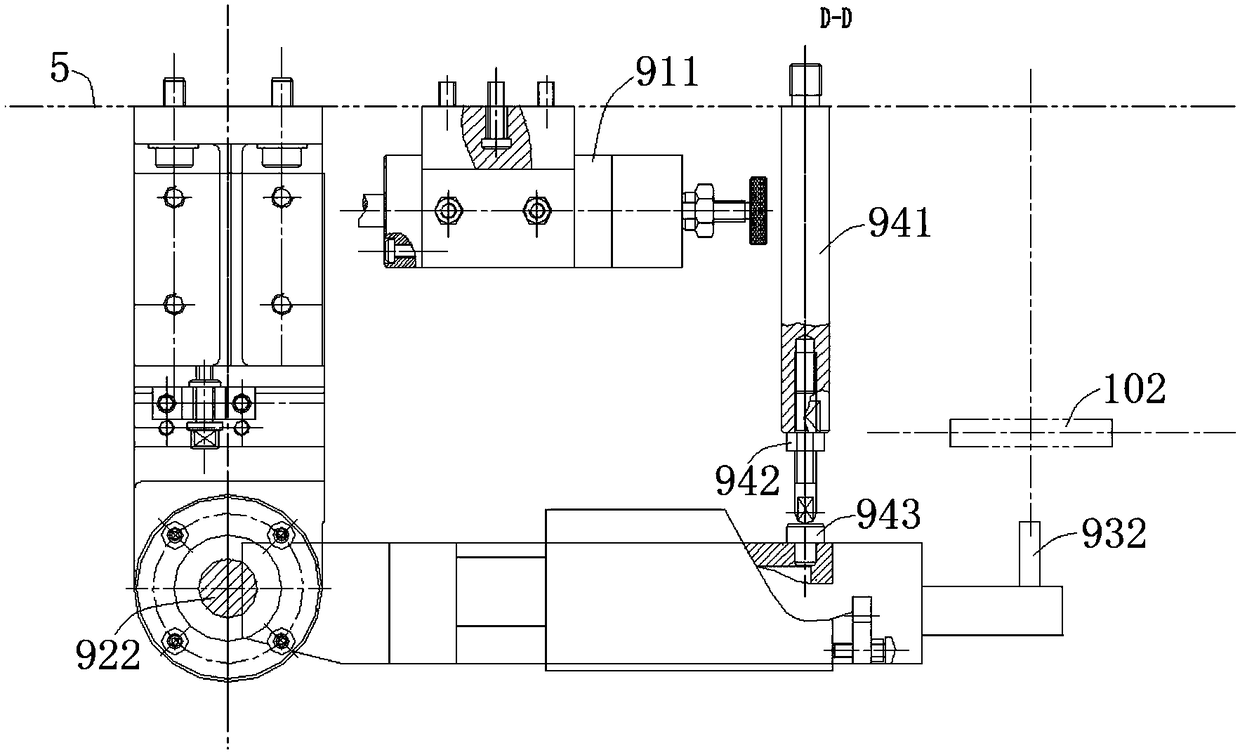

Automatic workpiece inner hole machining method

ActiveCN106041653AImprove processing efficiencyEfficient cooperationRevolution surface grinding machinesEngineeringMachining

The invention discloses an automatic workpiece inner hole machining method and belongs to the technical field of inner hole machining. According to the method, a feeding channel, a workpiece pushing mechanism and a discharging channel are included. A to-be-ground workpiece is conveyed to a gripping station of the workpiece pushing mechanism through the feeding channel. When the workpiece pushing mechanism pushes a ground workpiece to an inner hole machining station, the to-be-ground workpiece is limited; and meanwhile, limitation on the ground workpiece is released, and the ground workpiece is output through the discharging channel. After machining of an inner hole is completed, the workpiece pushing mechanism carries the ground workpiece to return; and the ground workpiece automatically falls out of the gripping station and is limited by the workpiece pushing mechanism. The to-be-ground workpiece in the feeding channel enters the gripping station automatically as supplement. According to the automatic workpiece inner hole machining method, the structure is simple; control is conducted conveniently; automatic circulation of the whole process including feeding, machining and discharging can be achieved; products are stable in quality; and the automation degree of equipment is further improved.

Owner:马鞍山市恒永利机械科技有限公司

Fishing entertainment device of unmanned aerial vehicle

The invention discloses an unmanned aerial vehicle fishing entertainment device, which comprises a multi-rotor unmanned aerial vehicle body and a remote controller with an inner cavity, an air bag is placed in the inner cavity, and a communication port is opened on one side of the inner cavity, and the communication port An air pipe is welded on the inner wall of the multi-rotor UAV body, and a lighting lamp is fixed on the bottom outer wall of the multi-rotor UAV body by bolts, and an insecticidal grid is fixed on the bottom outer wall of the multi-rotor UAV body by bolts, and the lighting lamp is located at the bottom of the multi-rotor UAV body. Inside the insect net, two vibrating devices are provided on the bottom outer wall of the multi-rotor UAV body, and the two vibrating devices are respectively located on both sides of the insect-killing net. The invention can inflate the airbag when the UAV is suspended, drive the UAV to float, reduce the load of the UAV, save electric energy, improve the endurance of the UAV, and can detect the approximate position of the fish school, and can Attract and kill mosquitoes at night, provide fresh bait to fish on the water surface, and improve fishing efficiency.

Owner:深圳市香蕉宿科技有限公司

Packaging machine for massive food

The invention provides a packaging machine for massive food, and relates to the technical field of food packaging machines. A material is packaged in the film sending process, so the packaging efficiency is improved; in the packaging process, the positions of patterns on the packaging film can be well controlled, so that the patterns are packaged in the specific positions of the material, and thus the packaged tissue is more attractive, and the needs of daily life of people are met.

Owner:扬州彼米科技研发有限公司

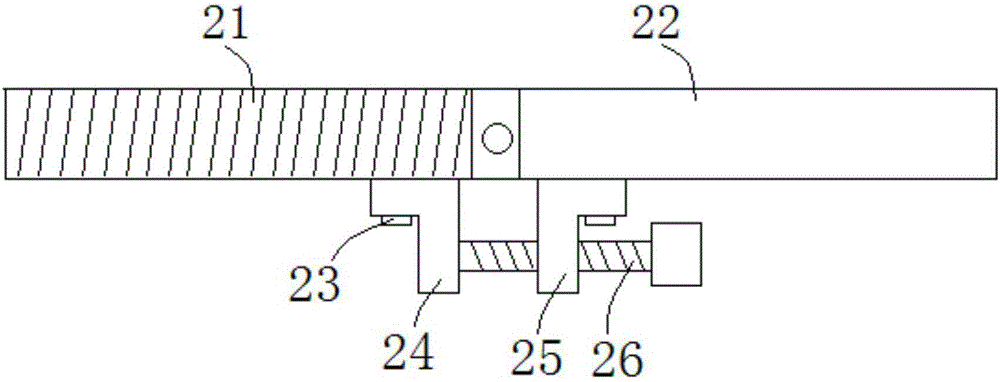

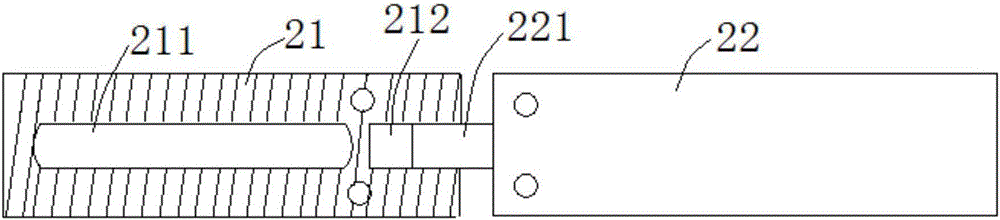

A method of inner hole grinding using fully automatic numerical control internal grinding

ActiveCN106271917BEfficient cooperationImprove processing efficiencyRevolution surface grinding machinesGrinding feed controlNumerical controlDimension measurement

The invention discloses a method for carrying out inner hole grinding by virtue of a fully-automatic numerically-controlled internal grinding machine, and belongs to the technical field of inner hole machining. The internal grinding machine disclosed by the invention comprises a loading channel, a workpiece pushing mechanism, an unloading channel and an inner hole dimension measurement mechanism, wherein a workpiece to be grinded is conveyed to a grabbing station of the workpiece pushing mechanism via the loading channel, and the workpiece pushing mechanism limits the workpiece to be grinded, and releases and outputs the grinded workpiece via the unloading channel while pushing the grinded workpiece to an inner hole machining station; the grinded workpiece automatically falls off from the grabbing station and is limited by the workpiece pushing mechanism after inner hole machining is completed, and another workpiece to be grinded in the loading channel is automatically fed to the grabbing station; and the inner hole dimension measurement mechanism continuously measures the dimensions of inner holes during a machining process. The internal grinding machine disclosed by the invention is simple in structure, and capable of realizing linkage of a measurement procedure and a grinding procedure while realizing automatic circulation of a whole process of loading, machining and unloading, thus ensuring the dimensional accuracy of the inner holes of the workpieces, and further increasing the automation degree of equipment.

Owner:马鞍山市恒永利机械科技有限公司

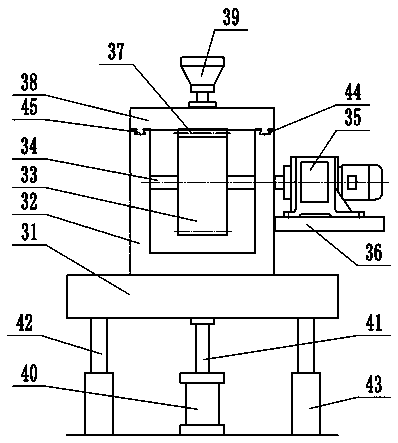

An automatic processing system for rubber manufacturing

ActiveCN111532497BQuick Position CorrectionFast transferPackagingHandling systemIndustrial engineering

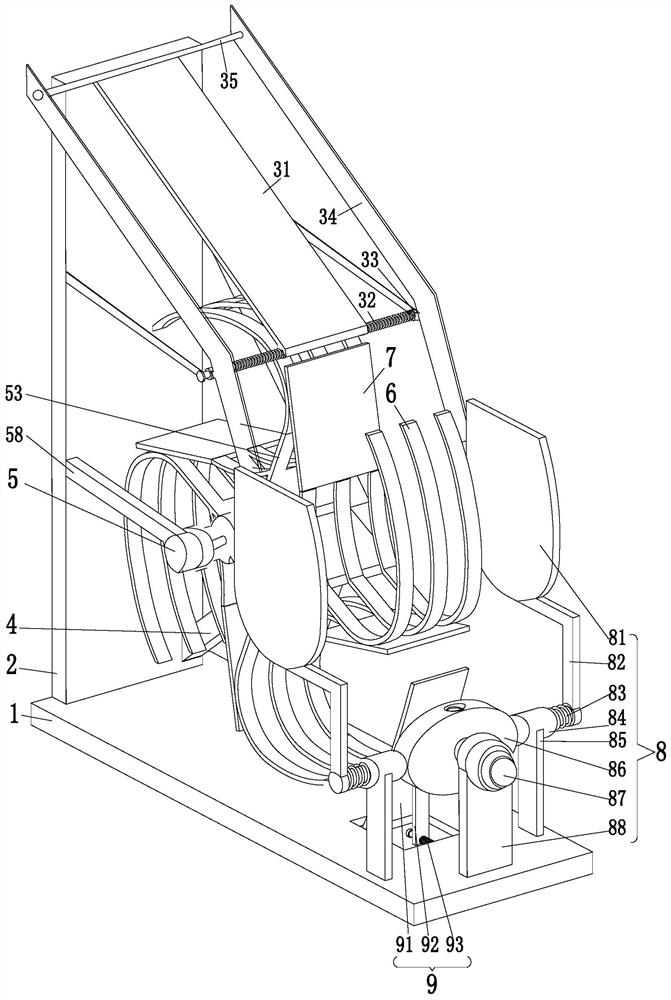

The invention relates to an automatic processing system for rubber manufacturing, which includes a bottom plate, a side vertical plate, a guide mechanism, a V-shaped frame, a driving mechanism, a U-shaped frame, a guide plate, a positive position mechanism and an auxiliary mechanism. The rear end of the bottom plate is equipped with a side vertical plate, the top of the side vertical plate is equipped with a guide mechanism, the rear end of the V-shaped frame is installed on the front surface of the side vertical plate, the front end of the V-shaped frame is installed with a driving mechanism, and the outside of the driving mechanism is evenly installed. Four U-shaped frames, the left end of the U-shaped frame in the counterclockwise direction is equipped with a guide plate, and the front end of the U-shaped frame located at the front end of the driving mechanism is provided with a positive position mechanism. The lower end of the positive position mechanism is installed on the upper surface of the bottom plate, and the auxiliary mechanism is installed on the bottom plate In the rectangular groove; the present invention can solve the problem of the existing rubber rod production: when the rubber rod falls into the storage box, it is easy to damage and pop out of the storage box; the rubber rod is messy after falling into the storage box; Sticks are replaced with empty boxes.

Owner:杭州美联塑胶有限公司

Automatic boxing mechanism for strip-shaped beverages

The invention relates to an automatic boxing mechanism for the strip-shaped beverages. The automatic boxing mechanism includes a rack, and the rack is provided with the conveying check blocks used forconveying a box body and a conveying roller with a driver between the conveying check blocks. The automatic boxing mechanism is characterized in that the rack is equipped with a clamping device matched with the box body on the conveying roller and a discharging device matched with the box body after the clamping device clamps in place, the discharging device comprises a product conveying groove formed on the rack, and a discharging feeding air cylinder is arranged on the side face of the product conveying groove; the discharging feeding air cylinder is connected with a discharging lifting aircylinder, the discharging lifting air cylinder is connected with a discharging lifting block, and the discharging lifting block is connected with a discharging suction installation block; the discharging suction installation block is provided with the electromagnet rods in the vertical direction, and the positions and the number of the electromagnet rods are matched with those of the single tankbodies in a product. According to the automatic boxing mechanism, the continuous and automatic strip-shaped red bull product packaging can be achieved, the packaging efficiency is greatly improved, and the labor consumption is reduced.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Assembled protecting device on building construction site and construction method thereof

PendingCN110185264AEasy to disassembleImprove carrying capacityBuilding material handlingScaffold accessoriesFalseworkArchitectural engineering

The invention relates to an assembled protecting device on a building construction site and a construction method thereof. The building comprises a plurality of horizontal floorslabs and a vertical wall body as well as a scaffold, a protecting rack, two clamping mechanisms and two coilers. The scaffold is fixed to the outer side of the wall body; the protecting rack comprises a supporting platformarranged below the scaffold and fixed to the outer side of the wall body, a fixed rack vertically fixed to the upper end of the supporting platform and a protecting plate hinged to the end, far awayfrom the wall body, of the supporting platform. The clamping mechanisms are separately fixed to the two sides of the middle part of the fixed rack and can clamp and fix the fixed rack and the scaffoldtogether; the coilers are separately fixed to the upper ends of two sides of the fixed rack; the tail ends of steel ropes of the coilers are fixed to the tail end of the protecting plate; the steel ropes of the coilers are coiled to fold the protecting plate; and the steel ropes of the coilers are released to lay down the protecting plate.

Owner:福州建工集团有限公司

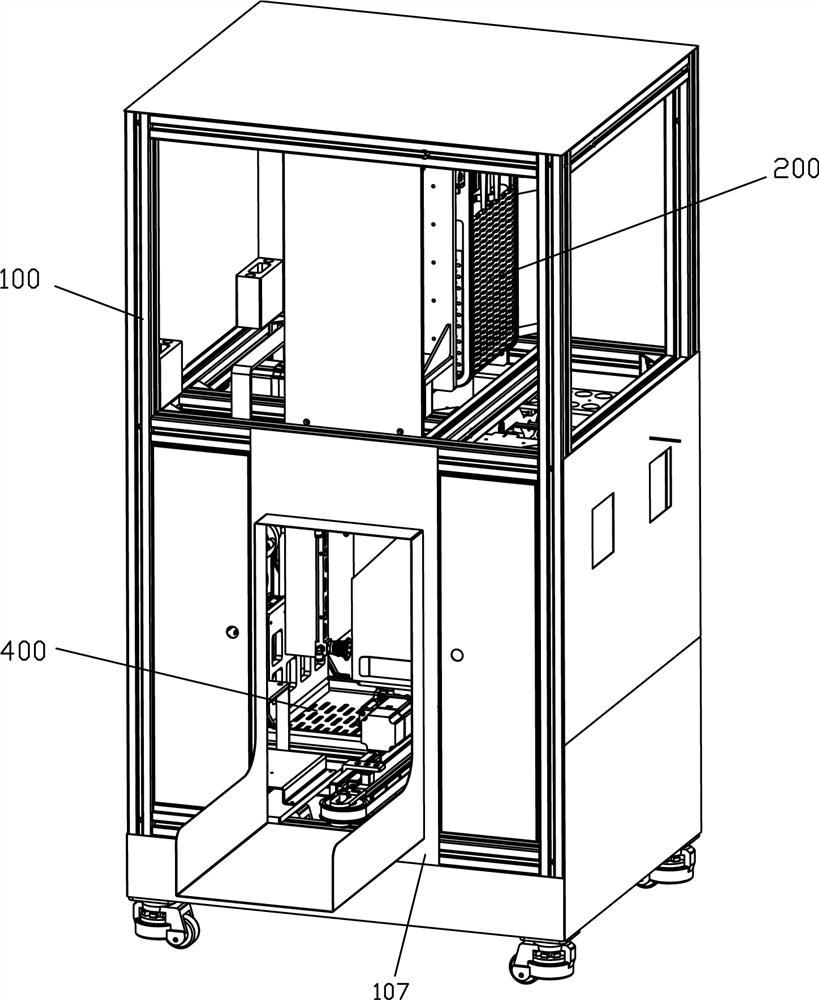

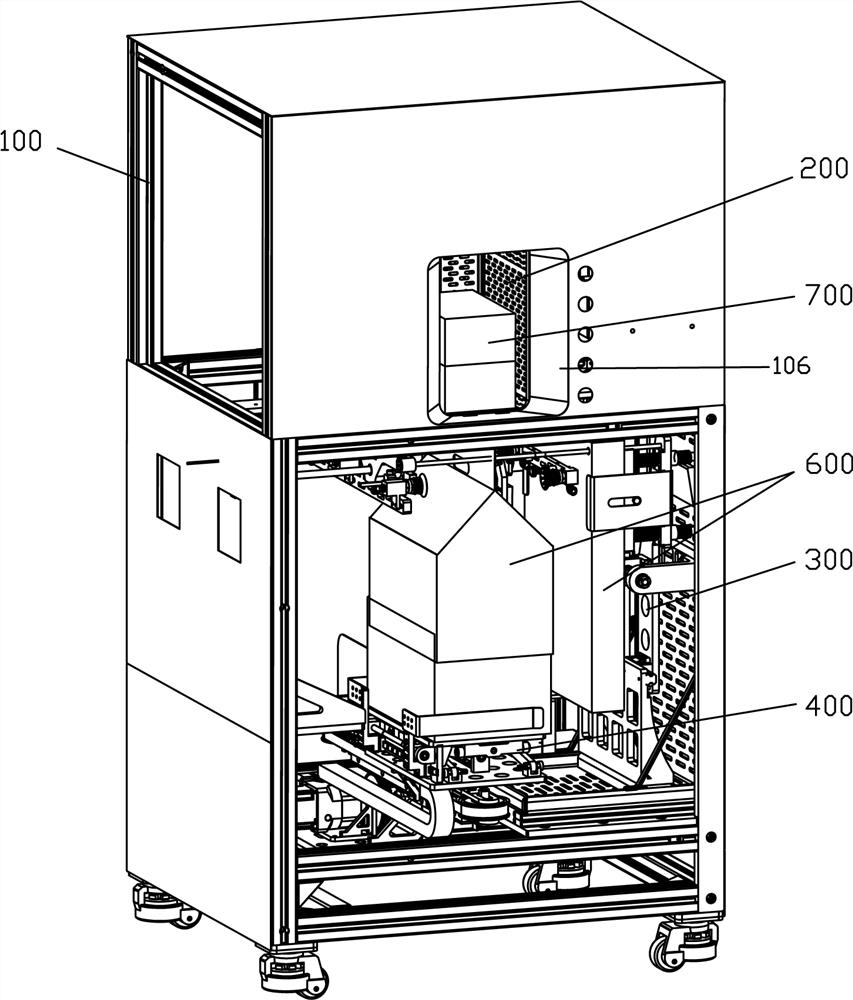

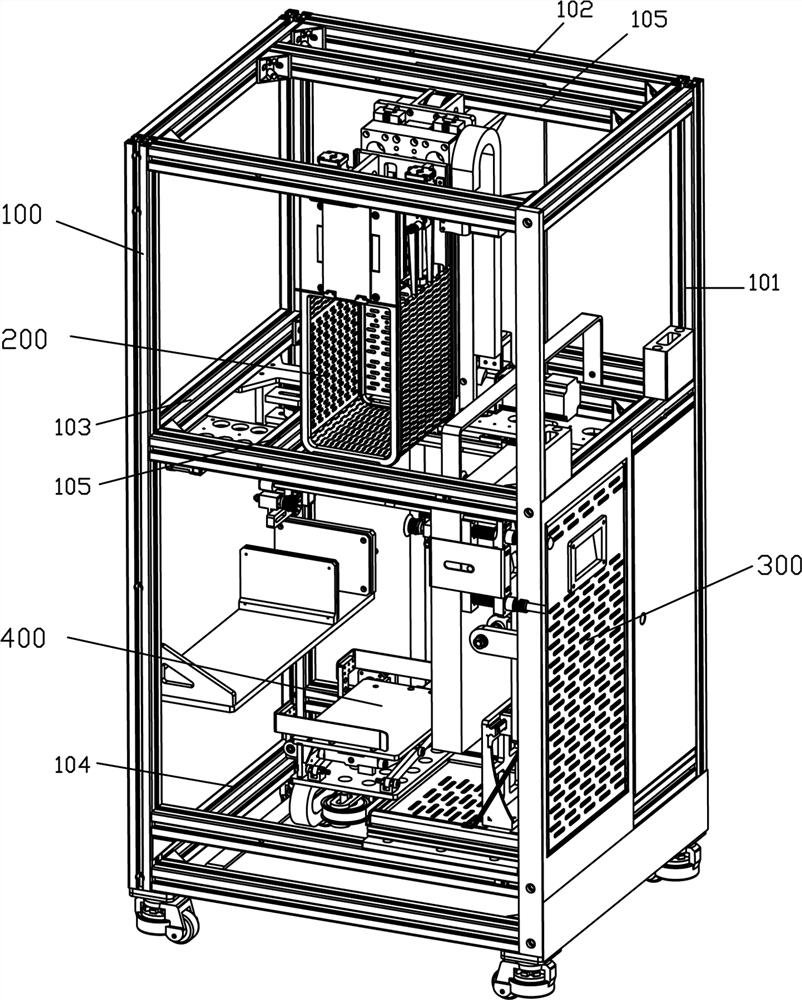

Packing machine suitable for retail take-out industry

PendingCN114802930APrevent riders from stealingImprove securityIndividual articlesManufacturing engineeringMechanical engineering

A packing machine suitable for the retail take-out industry comprises a rack, a feeding device, a discharging device and a bag storage and opening device, wherein the feeding device, the discharging device and the bag storage and opening device are located in the rack. The rack is of a box type frame structure and comprises stand columns, an upper frame, a middle frame, a lower frame, cross beams located in the upper frame and the middle frame and a plurality of corresponding side plates, and the upper frame, the middle frame and the lower frame are arranged on the stand columns. A goods taking window is arranged on the lower portion of the opposite back face of the machine frame. Automatic packaging is completed between an automatic container outlet and a delivery unmanned trolley, and the automatic packaging system is suitable for the civil catering retail take-out industry and can also be suitable for unmanned supermarkets, unmanned pharmacies and the like in the new retail industry.

Owner:上海捷焕智能科技有限公司

A fully automatic CNC internal grinding

ActiveCN106078378BEfficient cooperationImprove processing efficiencyRevolution surface grinding machinesGrinding feed controlNumerical controlEngineering

Owner:马鞍山市恒永利机械科技有限公司

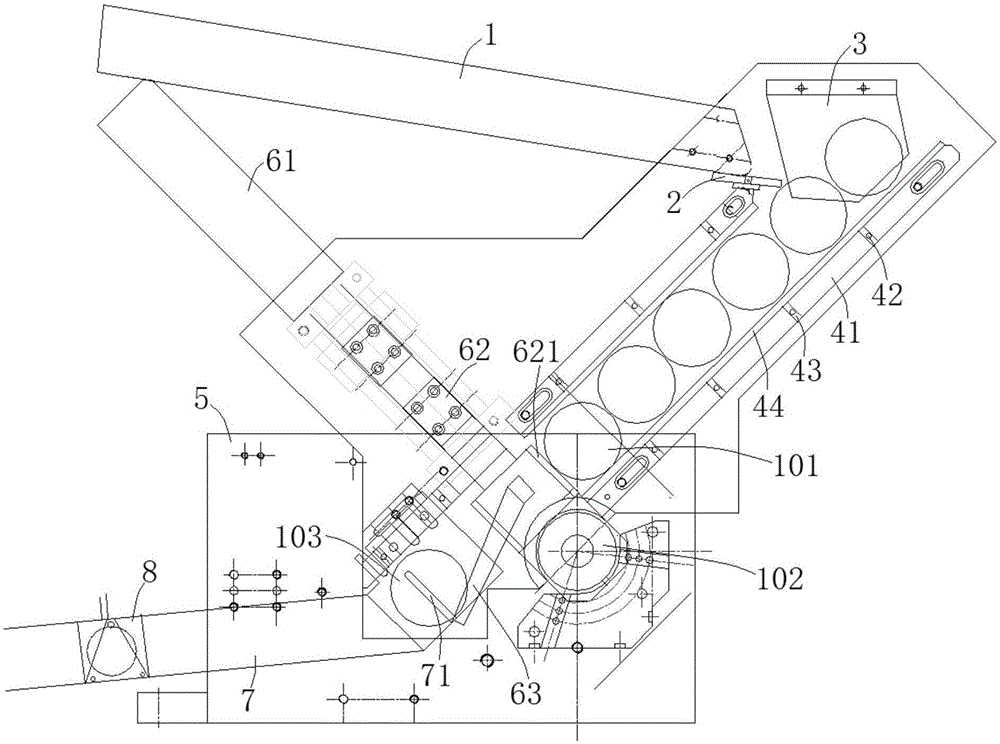

Bottle automatic inspection production line

InactiveCN104029982BFully automatedIncrease productivityConveyorsSortingProduction lineBiochemical engineering

The present invention relates to the technical field of automatic detection, in particular to an automatic detection production line for bottles, which has a frame on which a conveying device, an automatic sorting device, an automatic bottle unscrambling and vertical device, a precision inspection device, and crack and Broken bottle detection device: The bottles can be conveyed through the whole production line, and the bottles that meet the requirements are preliminarily sorted and screened out, and then reach the bottle unscrambling and vertical bottle device. When the bottle reaches the set position, the infrared detection component detects and judges that the bottle enters the conveying first One end of the mechanism is the bottle mouth or the bottom of the bottle, and the signal is transmitted to the controller; then, the push rod assembly pushes the bottle to the reversing device, and the reversing device receives the signal from the controller and rotates counterclockwise or clockwise to make the bottle The mouth of the bottle falls into the product conveying channel and is output, and then the height and diameter of the bottle are accurately screened and output by the fine inspection device. The entire production line is automated, which improves production efficiency, reduces costs, and makes production more organized. Suitable for Mass production.

Owner:CHANGZHOU JIANGRUN PRECISION MACHINERY

A chain plate type aluminum rod heating furnace with intelligent feeding device

ActiveCN114111330BJoin precisionHeating evenlyCharge supportsFurnace typesElectric machineDrive motor

The invention discloses a chain plate type aluminum bar heating furnace with an intelligent feeding device in the technical field of aluminum bar heating furnaces, comprising a heating box, and two first rotating shafts are rotatably connected inside the heating box, and one of the first The outer end of the rotating shaft is fixedly connected with a drive motor; the present invention uses the receiving mechanism to cooperate with the feeding mechanism every time the aluminum rod needs to be heated, and automatically controls the maximum position in the feeding mechanism every time the bearing mechanism moves to the feeding position. The aluminum rod at the bottom is automatically added to the top of the bearing mechanism, and other aluminum rods are kept in place to avoid falling multiple aluminum rods at a time, which is conducive to the accurate addition of aluminum rods each time, and the use of the bearing mechanism to cooperate with the rotating mechanism, in the aluminum In the process of rod conveying, the aluminum rod that falls on the top of the bearing mechanism is continuously rotated, so that the circumferential surface of the aluminum rod can be heated evenly, which makes the heating effect better and faster, and improves the processing efficiency.

Owner:南京裕高机械科技有限公司

Full-automatic bottle bag disinfection transfer machine and disinfection system

PendingCN114852943AImprove disinfection efficiencyImprove efficiencySynchronising machinesConveyor partsProcess engineeringFully automated

The invention provides a full-automatic bottle package disinfection transfer machine and a disinfection system, and aims to overcome the defect that the production cost is increased due to the fact that a mode of arranging a disinfection transfer room is adopted to disinfect bottle packages due to the lack of automatic equipment for transferring and disinfecting the bottle packages in the prior art. The technical problem is solved through the following technical scheme: a disinfection chamber is arranged in a disinfection box body; the feeding device is used for feeding the bottle bags into the disinfection chamber for disinfection; the stacking device is arranged in the disinfection chamber and is used for stacking the bottle bags in the disinfection chamber; and the discharging device is used for conveying the bottle bags in the disinfection chamber out of the disinfection chamber. By arranging the feeding device, the stacking device and the discharging device at the same time, disinfected bottle bags can be automatically sent out of the disinfection box body, automatic feeding, disinfection and discharging are achieved in the whole process, and the efficiency of disinfecting and subpackaging bottles is improved.

Owner:北京中业园净化空调工程有限公司 +2

Reusable animal skin stitching instrument

The invention discloses a reusable animal skin stitching instrument. A needle storage box for placing stitching needles used for the skin stitching instrument can be replaced frequently according to requirements, and the needle storage box can be used for placing various specifications of stitching needles. The reusable animal skin stitching instrument comprises a function housing, a fixed handle and a fixed handle; the needle storage box is arranged inside the function housing; and a needle box for placing stitching needles in which the height is 1-1.5 times of that of the stitching needles is formed between the box bottom and a box holder of the needle storage box. The skin stitching instrument adopts a reusable needle storage box structure capable of being replaced quickly, so that the use efficiency of the skin stitching instrument can be greatly improved, the instrument consumption is reduced, and the cost of medical operations is reduced; moreover, the needle storage box adopts a structure containing a first inclined plane, a second inclined plane and a lug boss at a stitching needle outlet end, so that the stitching needle can be fallen in a conveying passage stably and accurately without casing needle blocking, needle blockage and needle disorder, normal use of the skin stitching instrument is ensured, and safety of medical operations is ensured.

Owner:RWD LIFE SCI

Shearing device for automatic fluoride tester

PendingCN112549181AAchieve continuous shearImprove extraction efficiencyGrain treatmentsMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a shearing device for an automatic fluoride tester. The shearing device for the automatic fluoride tester comprises a machine box and a controller, a membrane containing plateis arranged in the machine box, a compactor, a circle cutter located on the inner side of the compactor and a mold pushing plate located on the inner side of the circle cutter are sequentially arranged right above the membrane containing plate, the top ends of the compactor, the circle cutter and the mold pushing plate are driven to ascend and descend through a driving mechanism, and the controlled end of the driving mechanism is connected to the output end of the controller; a circular leakage hole matched with the circle cutter is formed in the membrane containing plate; and a paper shredding mechanism is arranged below the membrane containing plate, a discharging port is formed in the bottom end of the paper shredding mechanism, and the controlled end of the paper shredding mechanism isconnected to the output end of the controller. According to the shearing device, the continuous shearing of the filter membrane can be realized under the condition of no manual guarding, and the paper shredding mechanism is arranged below the membrane containing plate, so that the filter membrane can be shredded into uniform fragments meeting the standard after being cut into circles.

Owner:河北快特环保科技有限公司

A block food packaging machine

The invention provides a packaging machine for massive food, and relates to the technical field of food packaging machines. A material is packaged in the film sending process, so the packaging efficiency is improved; in the packaging process, the positions of patterns on the packaging film can be well controlled, so that the patterns are packaged in the specific positions of the material, and thus the packaged tissue is more attractive, and the needs of daily life of people are met.

Owner:扬州彼米科技研发有限公司

SP product automatic boxing mechanism and boxing control method thereof

PendingCN114655509AImprove packaging efficiencyLabor savingPackaging automatic controlIndividual articlesProcess engineeringIndustrial engineering

According to the automatic SP product boxing mechanism and the boxing control method thereof, mechanical and electrical automation is adopted for sequencing, sorting, counting, typesetting, boxing and other operations of SP products, the boxing efficiency is greatly improved, labor force is reduced, and the problem that defective products are generated due to the fact that short packaging and excessive packaging are conducted and zinc coatings of the SP products are scratched is solved.

Owner:合肥市奥比特电气有限公司

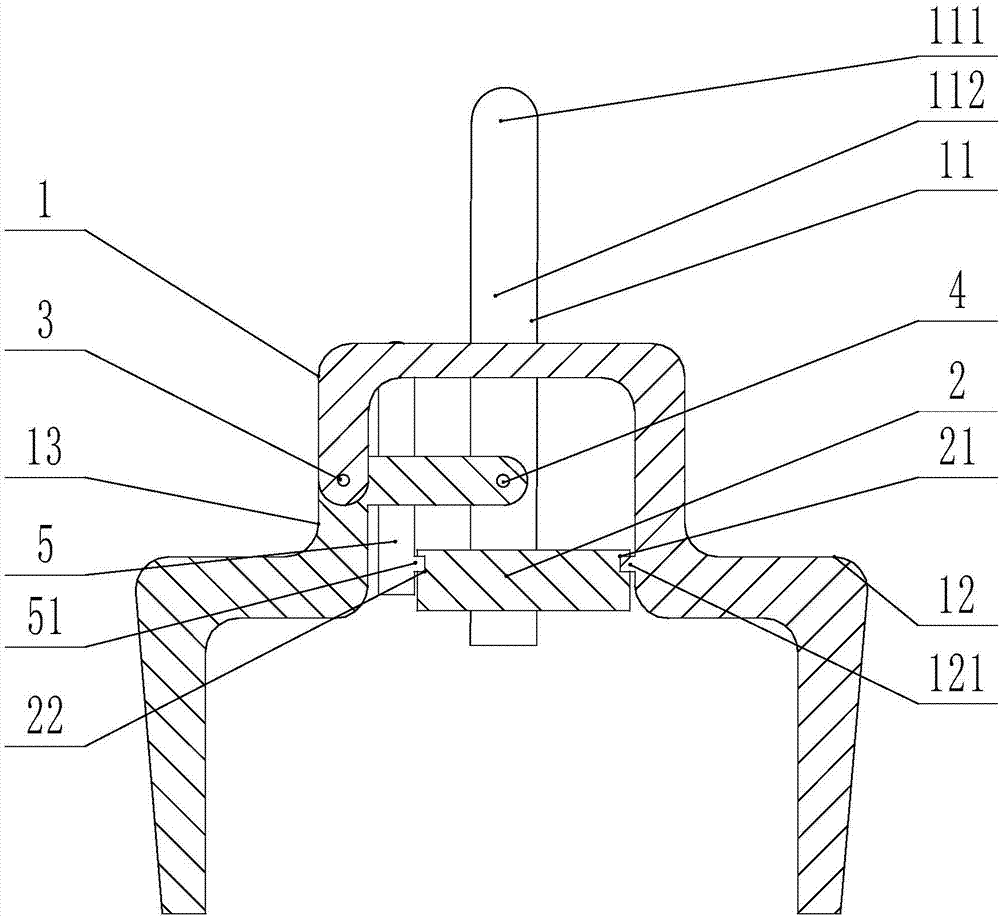

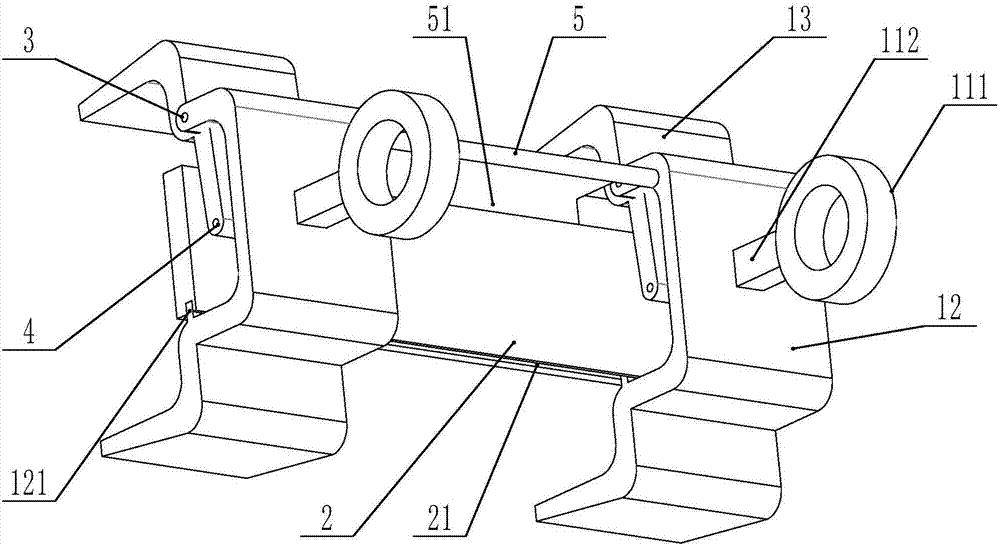

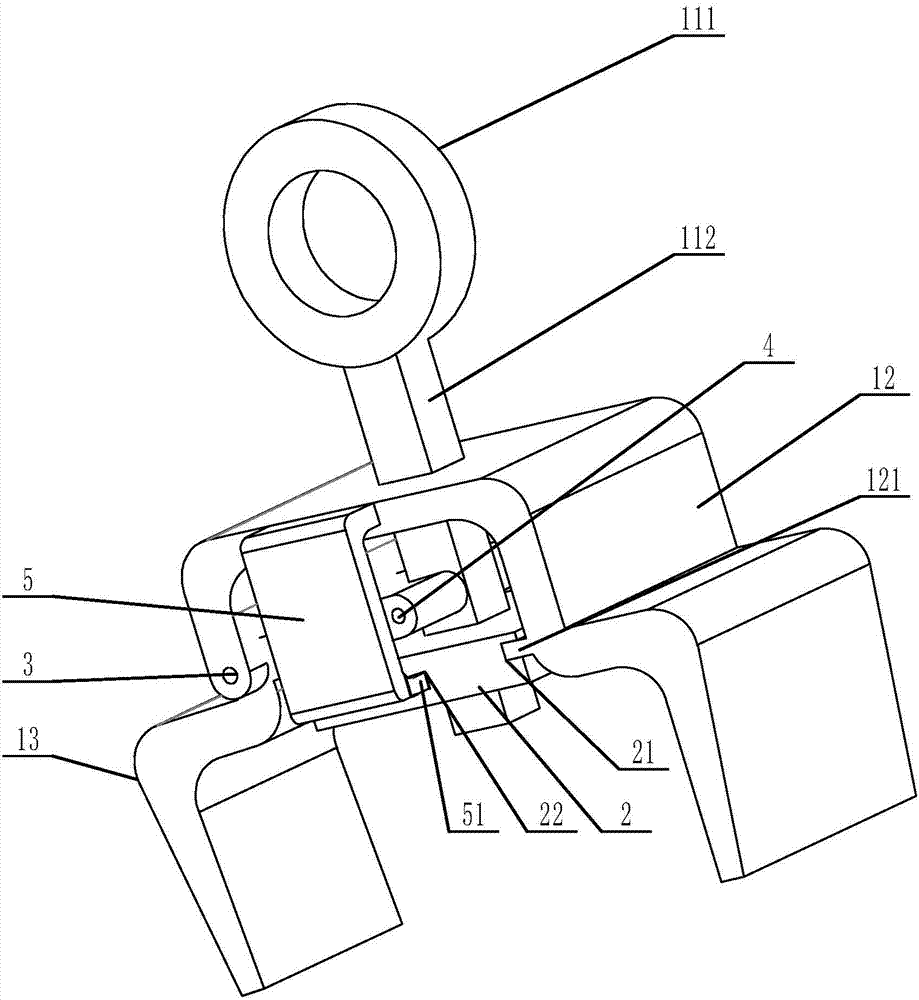

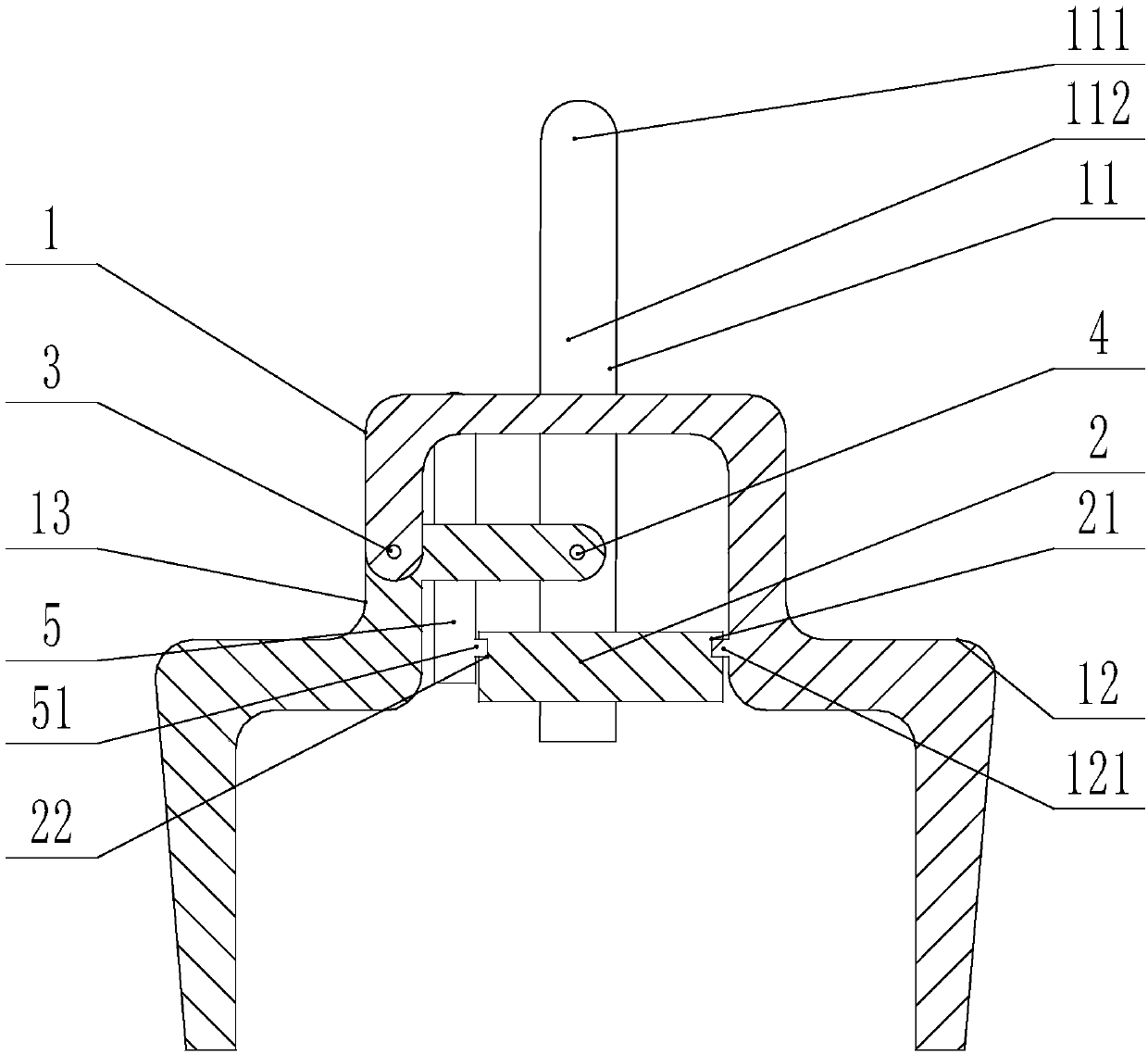

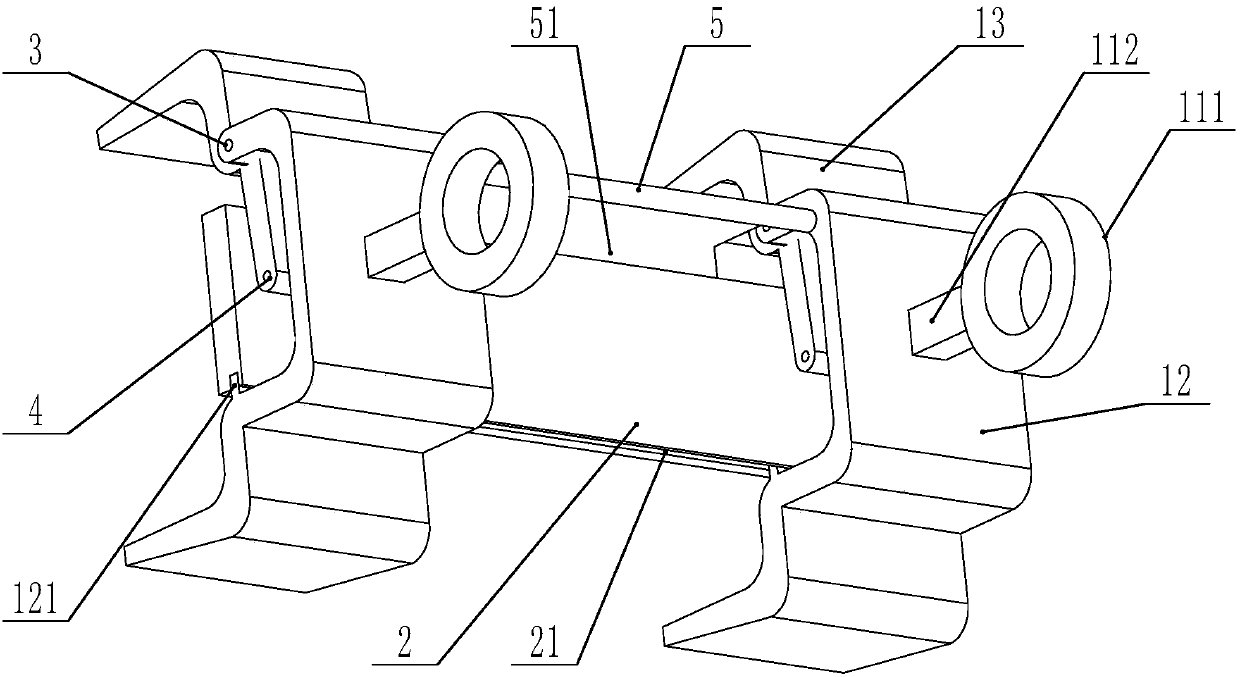

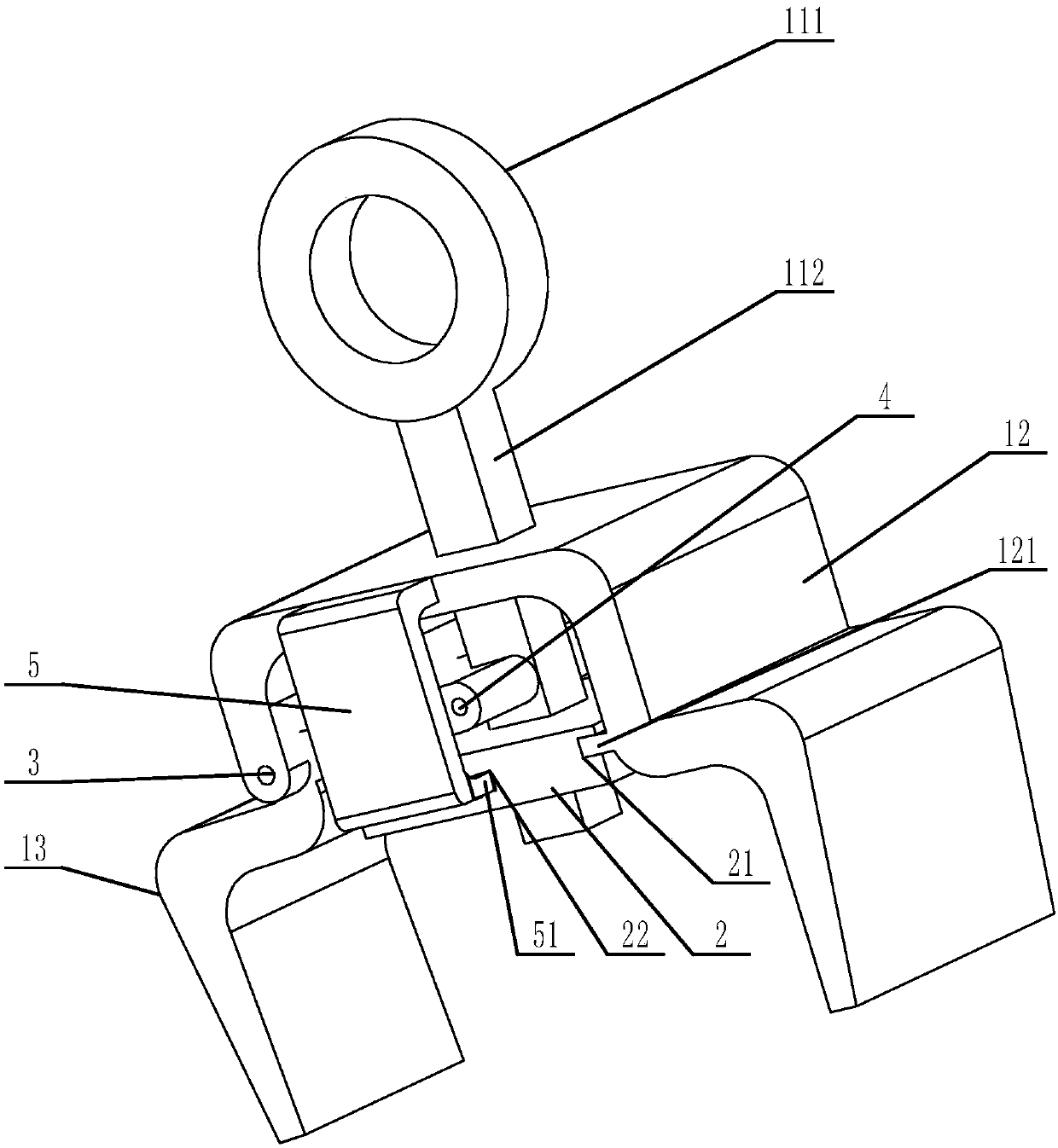

Clamp used for carrying automobile leaf spring

ActiveCN107010533AReduce salesCause unsafe phenomena such as fallingLoad-engaging elementsChinese charactersEngineering

The invention provides a clamp used for carrying an automobile leaf spring. The clamp comprises a clamping structure and a magnet. The clamping structure comprises a hanger rod, a fixed clamping jaw and a movable clamping jaw. The hanger rod further comprises a lifting ring and a connecting rod, the lifting ring is located at the top of the hanger rod and fixedly connected with one end of the connecting rod, and the connecting rod penetrates through the fixed clamping jaw and the magnet through a through hole in the fixed clamping jaw and a through hole in the magnet. The perpendicular distance between the end face of one end, far away from the lifting ring, of the connecting rod and the magnet is 4cm-8cm. The fixed clamping jaw is shaped like a Chinese character 'gong', the magnet is fixed to the fixed clamping jaw, the movable clamping jaw is M-shaped, the fixed clamping jaw is in hinge joint with the movable clamping jaw through a first hinge joint hole, and the movable clamping jaw is in hinge joint with the connecting rod through a second hinge joint hole which is formed between the fixed clamping jaw and the magnet. One end of the magnet is fixedly connected with the fixed clamping jaw, the other end is fixedly connected with a fixed rod arranged on the fixed clamping jaw, and the magnet is provided with a magnetic resistance switch. The clamp is high in clamping efficiency and automation degree and convenient to operate, and is exclusively used for carrying the automobile leaf spring.

Owner:湖北远成鄂弓汽车悬架弹簧有限公司

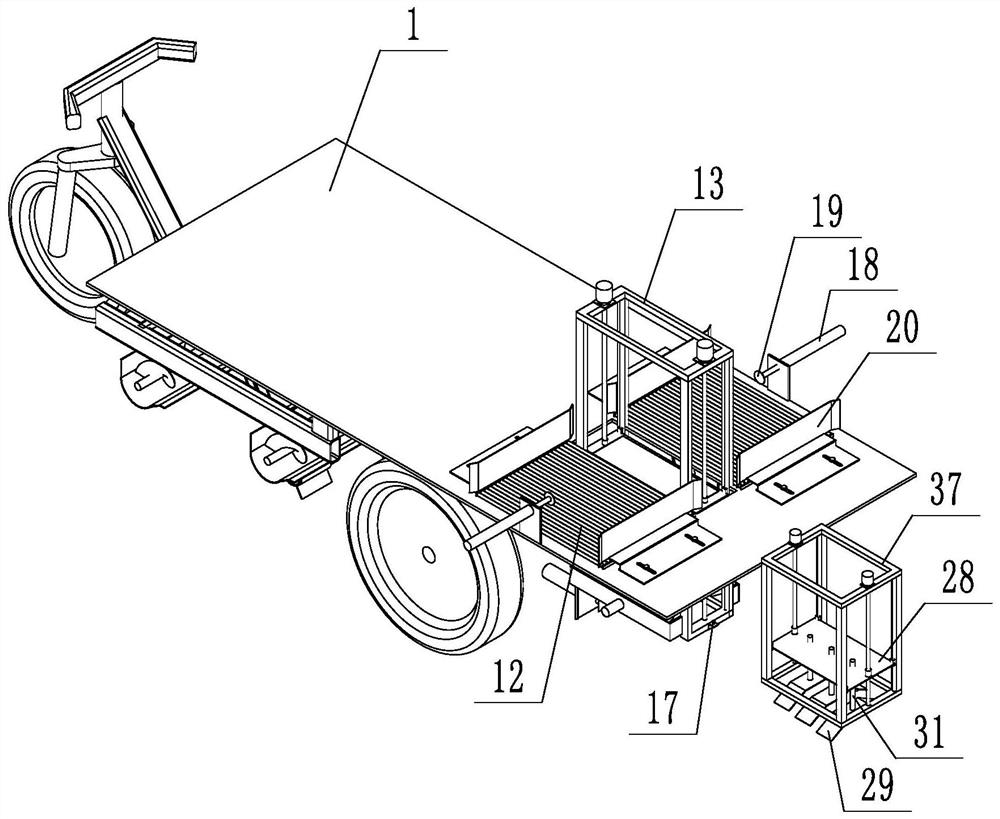

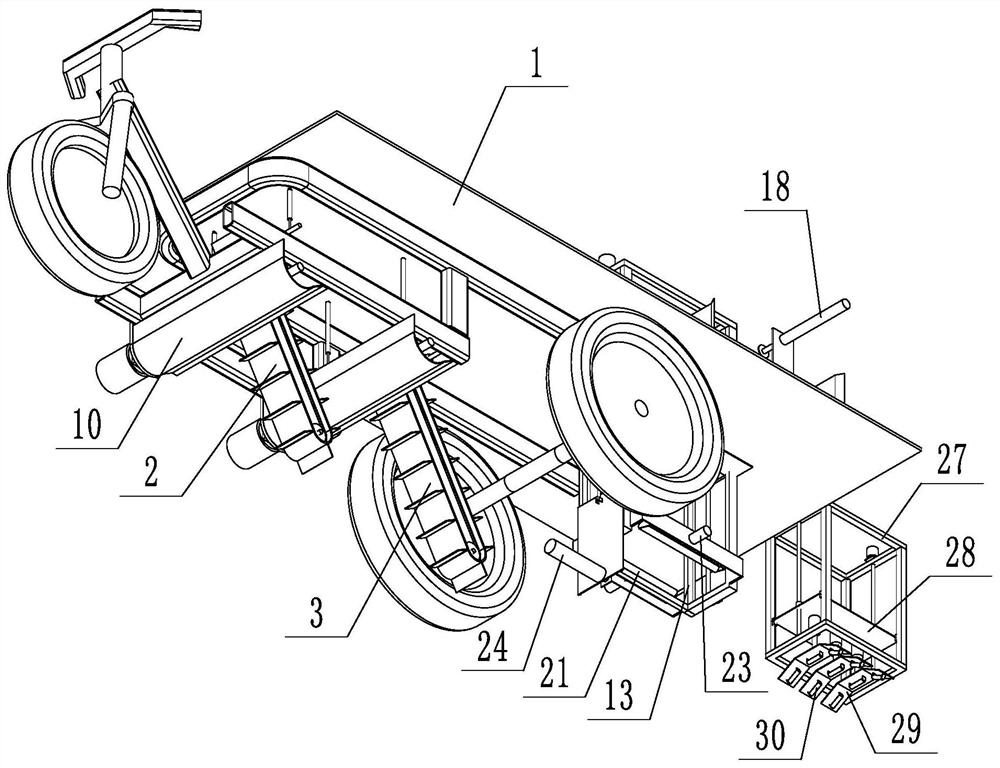

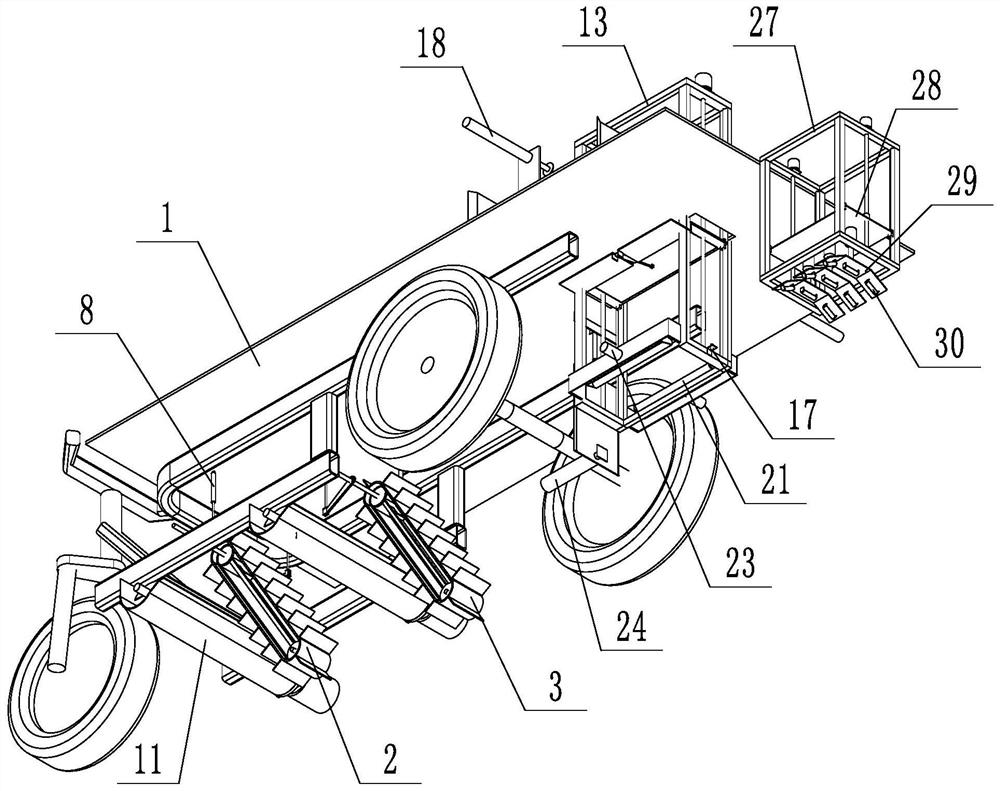

Green belt separation line construction equipment for preventing water loss

ActiveCN113737618AHigh degree of automationReduce labor intensitySoil-shifting machines/dredgersRoads maintainenceArchitectural engineeringMechanical engineering

The invention discloses green belt separation line construction equipment for preventing water loss. The equipment comprises a vehicle body, a grooving mechanism used for digging a curb installation groove, an installation mechanism used for lowering curb and a compaction mechanism used for compacting the curb. The grooving mechanism, the installation mechanism and the compaction mechanism are all installed on the vehicle body. The grooving mechanism, the installation mechanism and the compaction mechanism are sequentially arranged from front to back. In the working process, the vehicle body moves forwards, the grooving mechanism conducts grooving on the ground, the installation mechanism installs a curb in a formed groove, the compaction mechanism compacts the curb, then soil is manually back-filled, installation of the curb is completed, the automation degree is high, the labor intensity is low, and the installation efficiency is improved.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队

A jig for handling automobile leaf springs

ActiveCN107010533BReduce salesCause unsafe phenomena such as fallingLoad-engaging elementsEngineeringPerpendicular distance

The invention provides a clamp used for carrying an automobile leaf spring. The clamp comprises a clamping structure and a magnet. The clamping structure comprises a hanger rod, a fixed clamping jaw and a movable clamping jaw. The hanger rod further comprises a lifting ring and a connecting rod, the lifting ring is located at the top of the hanger rod and fixedly connected with one end of the connecting rod, and the connecting rod penetrates through the fixed clamping jaw and the magnet through a through hole in the fixed clamping jaw and a through hole in the magnet. The perpendicular distance between the end face of one end, far away from the lifting ring, of the connecting rod and the magnet is 4cm-8cm. The fixed clamping jaw is shaped like a Chinese character 'gong', the magnet is fixed to the fixed clamping jaw, the movable clamping jaw is M-shaped, the fixed clamping jaw is in hinge joint with the movable clamping jaw through a first hinge joint hole, and the movable clamping jaw is in hinge joint with the connecting rod through a second hinge joint hole which is formed between the fixed clamping jaw and the magnet. One end of the magnet is fixedly connected with the fixed clamping jaw, the other end is fixedly connected with a fixed rod arranged on the fixed clamping jaw, and the magnet is provided with a magnetic resistance switch. The clamp is high in clamping efficiency and automation degree and convenient to operate, and is exclusively used for carrying the automobile leaf spring.

Owner:湖北远成鄂弓汽车悬架弹簧有限公司

A pressing device for plywood

ActiveCN112792936BRealize automatic deliveryRealize feedingPlywood pressesVeneer pressesStructural engineeringMechanical engineering

The invention discloses a pressing device for plywood, which comprises a frame body. Two cylinder seats for the fixed installation of the feeding cylinder are fixedly installed on one side of the frame body; the push rod of the feeding cylinder It is connected with a feeding lever; in the present invention, the bottom plate of the plywood is placed on the sliding shaft, and the push rod of the feeding cylinder shrinks, driving the feeding lever to move along the slide bar to the side of the press-fitting platform. While the material lever is moving, the bottom plate of the plywood is conveyed from the sliding shaft to the pressing stand, realizing the automatic delivery of the bottom plate of the plywood; the top plate of the plywood is placed in the plywood storage box, when the automatic feeding and pressing mechanism When the side feed port is flush with the discharge port, the pushing cylinder drives the cross brace to move along the chute to the automatic feeding and pressing mechanism through the connecting plate, and the top plate of the plywood is pushed from the discharge port by the push plate. Enter the automatic feeding and pressing mechanism, thus realizing the feeding of the plywood top plate.

Owner:贵港市润达木业有限公司

Device facilitating flanging of bearing ring in tempering furnace

ActiveCN113355506AImprove adsorption capacitySmooth transmissionFurnace typesHeat treatment furnacesTemperingTransmission belt

The invention discloses a device facilitating flanging of a bearing ring in a tempering furnace. The device comprises the tempering furnace, a first conveying device and a second conveying device; the first conveying device and the second conveying device are arranged on the side wall of the tempering furnace, the first conveying device is located above the second conveying device, and trapezoidal limiting blocks are arranged at the two sides of the first conveying device and are distributed close to the outer wall of the first conveying device; a plurality of groups of adsorption parts are uniformly distributed on a conveying belt of the first conveying device, and a control center is arranged at one side of each adsorption part; and each adsorption part comprises a plurality of groups of separation adsorption strips which are connected in sequence, and magnets are arranged in the separation adsorption strips. The device overcomes the defects in the prior art, is reasonable in design, can achieve effective flanging of the bearing ring, effectively improves the temperature uniformity of the bearing ring during tempering, removes product stress, improves the product percent of pass, and has higher social use value and application prospects.

Owner:安徽汇晟源工业炉科技有限公司

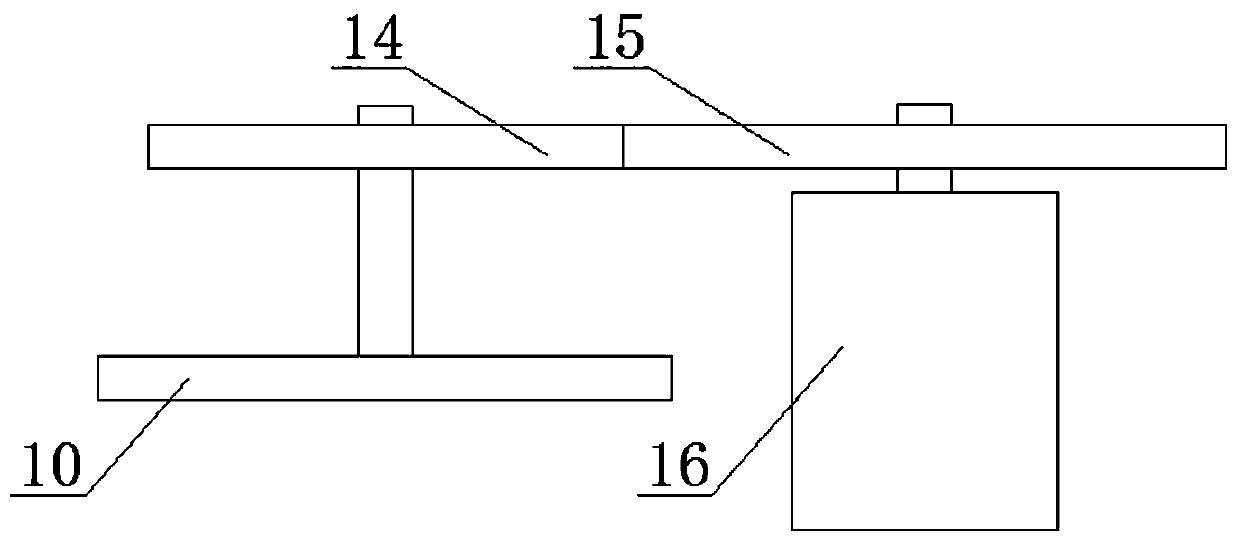

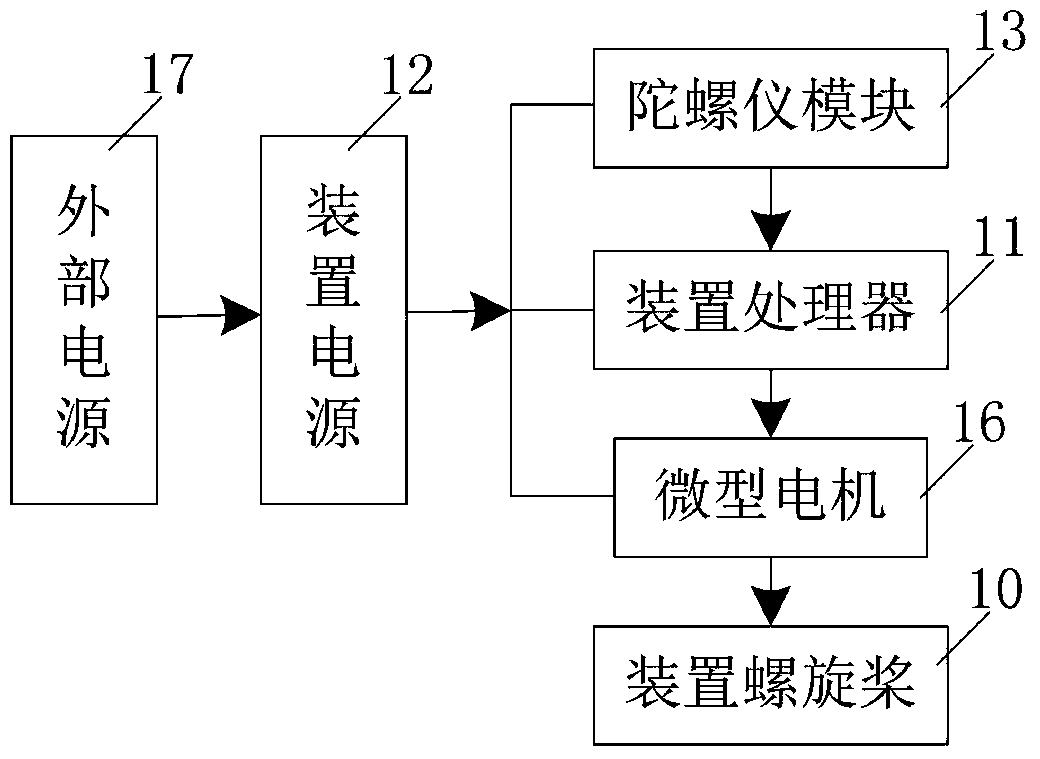

A Gyroscope-Based Propeller Laptop Drop Protection Device

The invention discloses a propeller type notebook computer falling protection device based on a gyro. The device comprises a notebook computer, device propellers, a device processor, a device power supply, a gyro module, propeller gears, motor gears and micromotors, wherein the notebook computer comprises a computer shell, a hard disc, a computer processor, a cooling fan, a memory bank, a computer power supply and a wireless module, and the device processor, the device power supply and the gyro module are installed on the right portion of the interior of the computer shell; the device propellers and the micromotors are installed on the four corners of the computer shell, and the motor gears on the micromotors and the propeller gears on the device propellers are meshed; the device power supply is electrically connected with the device processor, the gyro module and the micromotors, and the device processor is electrically connected with the gyro module and the micromotors. The device can protect the notebook computer by means of the gyro and the propellers when the notebook computer falls off.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com