Automatic sorting mechanism for acupuncture needles

A technology of automatic sorting and acupuncture needles, which is applied in the direction of automatic packaging control, tubular objects, packaging, etc., and can solve problems that affect the packaging operation of tubes, unstable minute needles, empty needles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

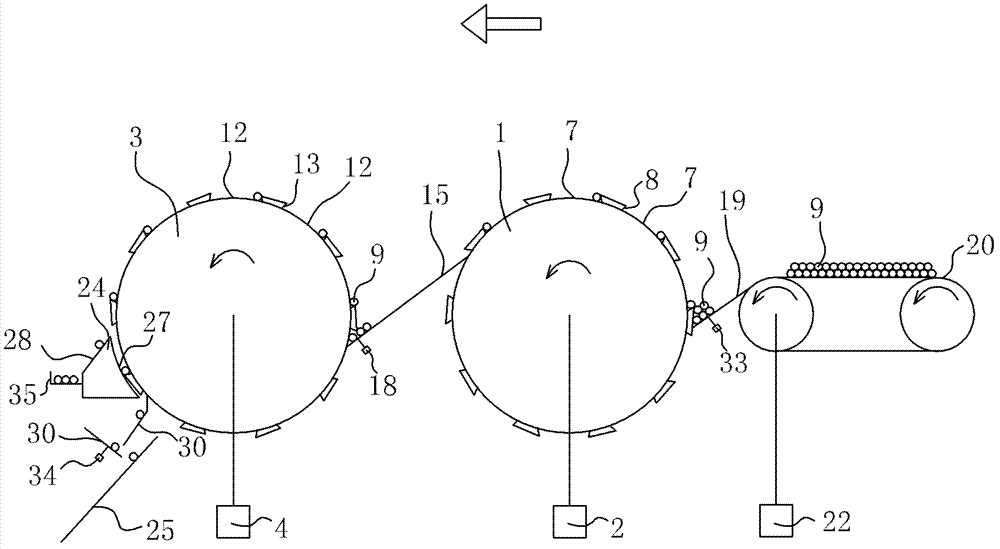

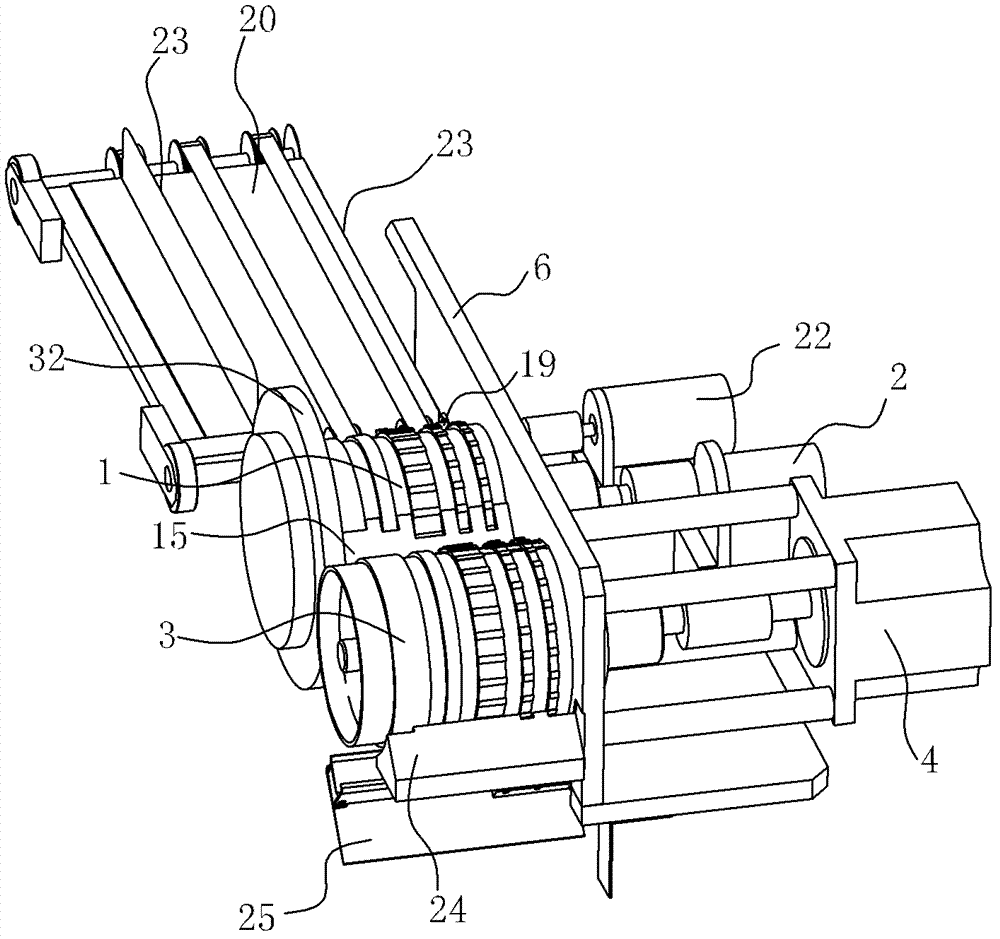

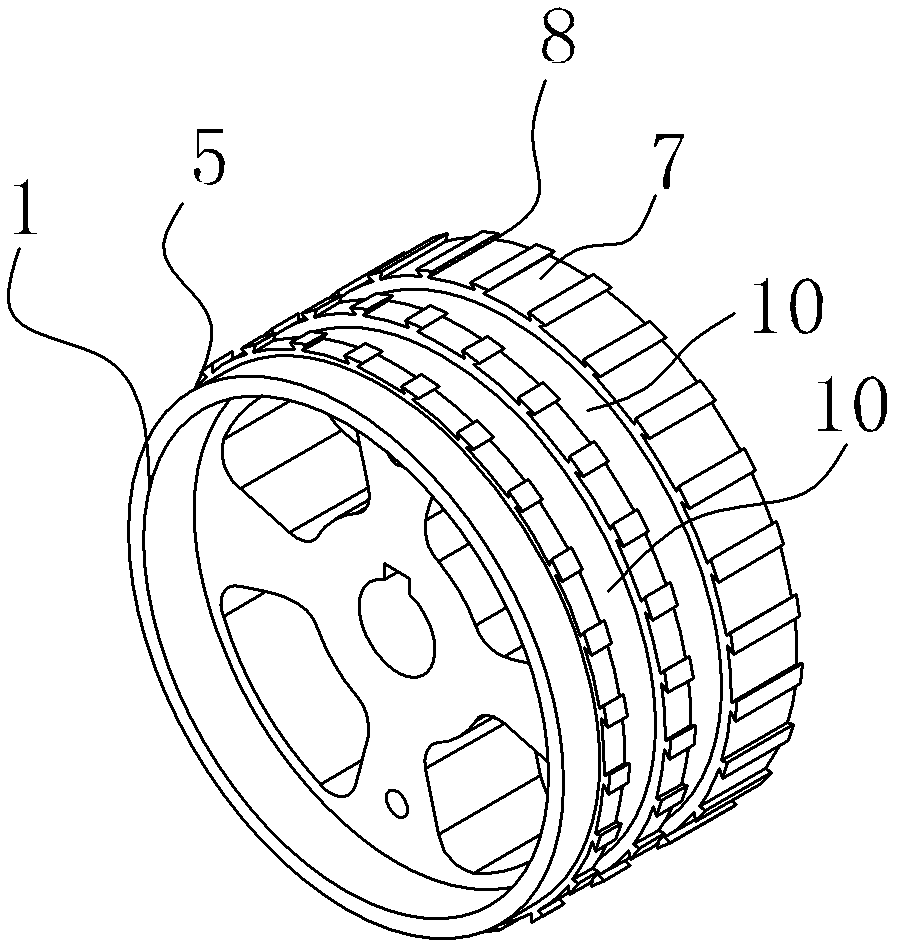

[0030] Example: see attached Figure 1-10As shown, an acupuncture needle automatic sorting mechanism is mainly composed of two-stage minute wheel structures. The first minute wheel structure is composed of the first minute wheel 1 and the first motor 2, and the second minute wheel structure is composed of the second The minute wheel 3 and the second motor 4 are composed; the first minute wheel 1 is composed of a cylindrical first cylinder body 5, the axis of the first cylinder body 5 is arranged horizontally, and the first cylinder body 5 is rotatably supported relative to the supporting body 6. The rotating shaft of a motor 2 is connected in transmission with respect to the first cylindrical body 5; the outer edge of the first cylindrical body 5 is provided with a first minute hand groove 7 along the axial direction, and the first minute hand groove 7 is arranged circumferentially on the outer edge of the first cylindrical body 5 , the cross-section of the first minute hand g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com