A pressing device for plywood

A pressing device and plywood technology, which is applied in the direction of plywood presses, veneer presses, manufacturing tools, etc., can solve the problems of high labor intensity, unevenness of two boards, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

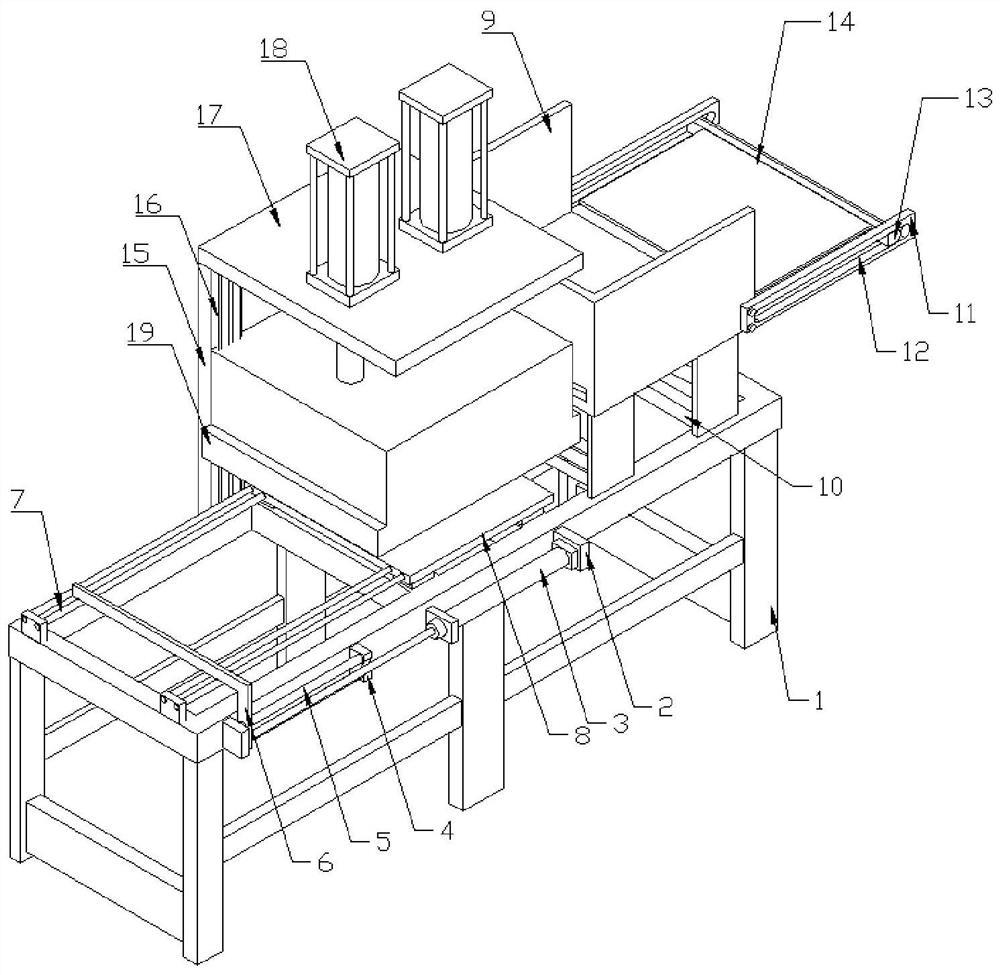

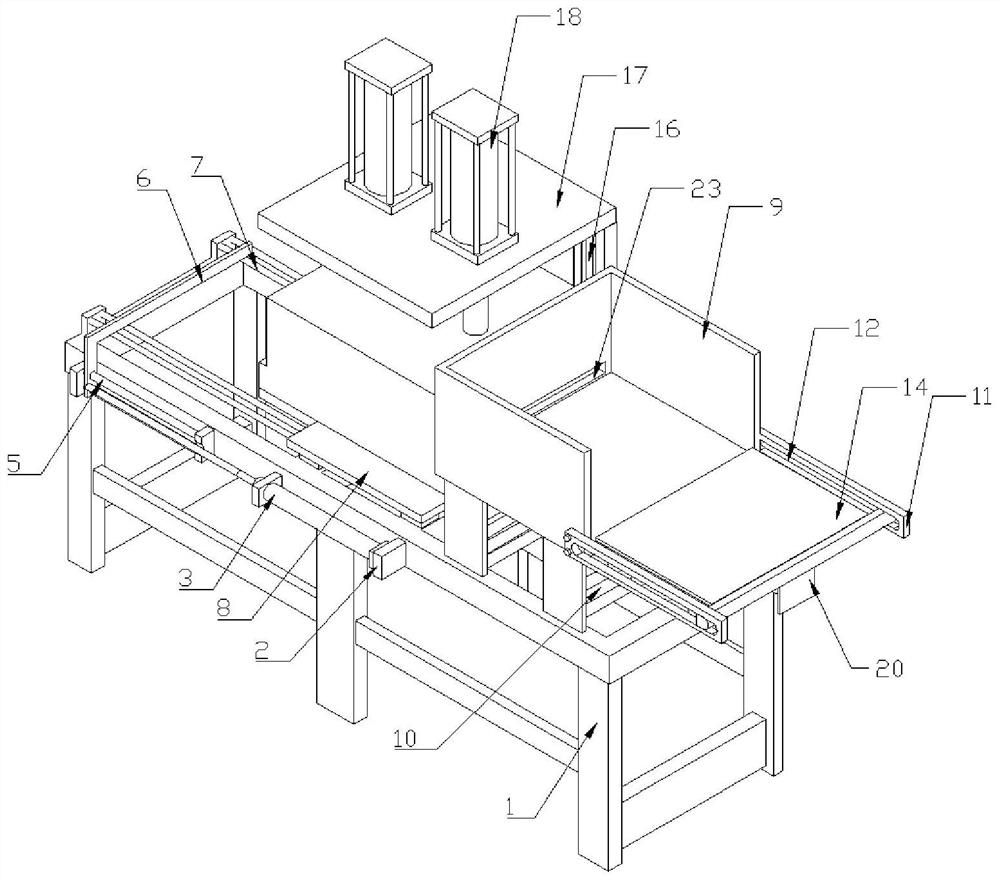

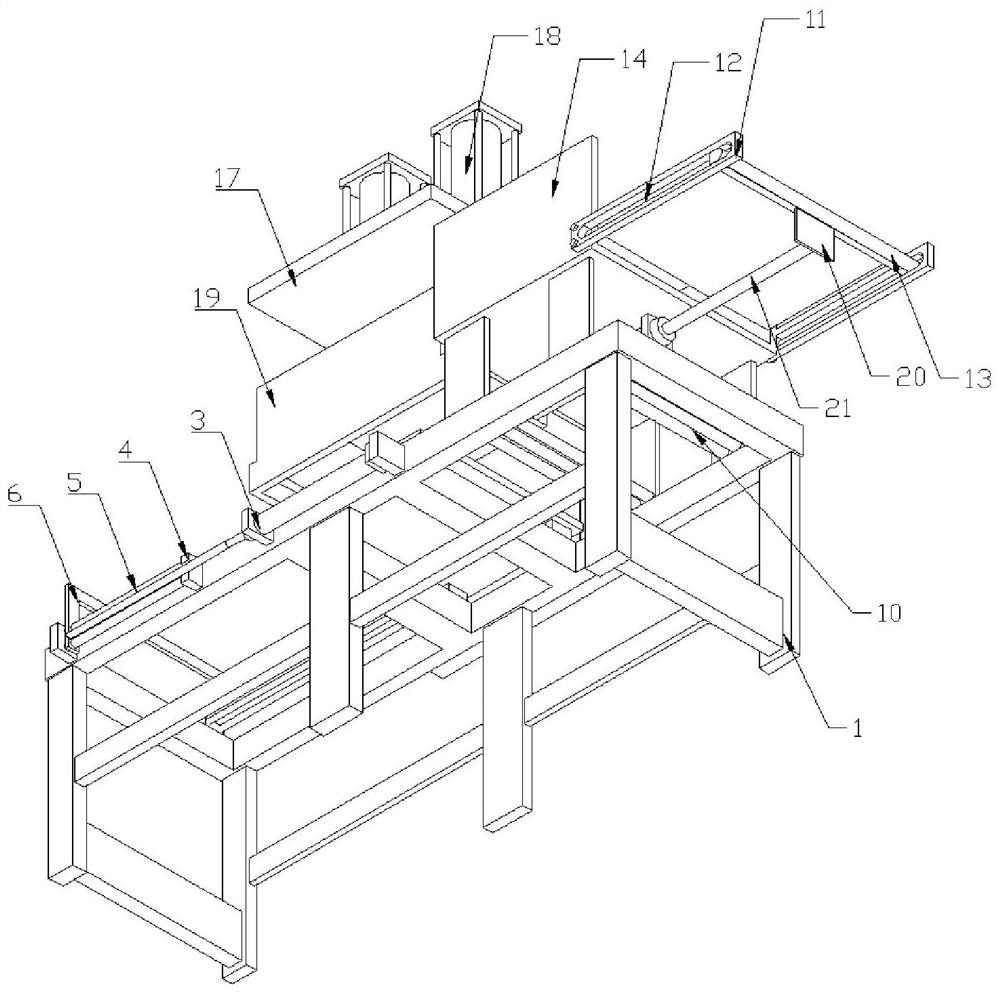

[0035] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, a pressing device for plywood, including the following structure.

[0036] Frame body 1, one side of the frame body 1 is fixedly installed with two cylinder seats 2 for the fixed installation of the feeding cylinder 3; the push rod of the feeding cylinder 3 is connected with a feeding lever 6 ; The feeding lever 6 is set in an L shape, and the feeding lever 6 is provided with two through holes that match the slide bar 5, and the loading lever 6 can slide axially along the slide bar 5; The two slide bars 5 are arranged parallel to each other, and the two ends of the slide bar 5 are connected to the fixed seat 4; the other end of the loading lever 6 is located above the slide shaft 7; the slide shaft 7 Two are used and arranged parallel to each other. One end of the sliding shaft 7 is fixedly connected to the pressing frame 8, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com