Assembled protecting device on building construction site and construction method thereof

A technology for on-site assembly and protective devices, which is applied in construction, building construction, and building material processing, can solve problems such as low load-bearing and impact-resistant capacity, safety accidents, personal and property losses, etc., and achieve load-bearing and impact-resistant capacity Strong, easy to disassemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

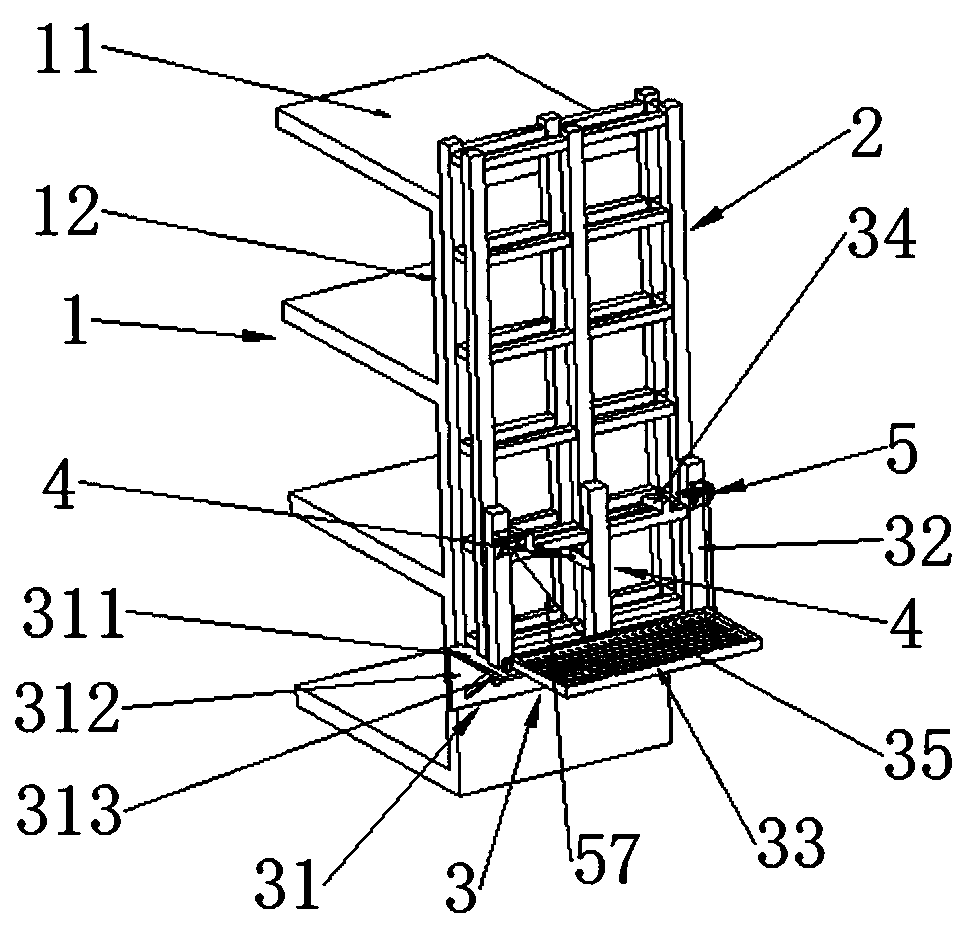

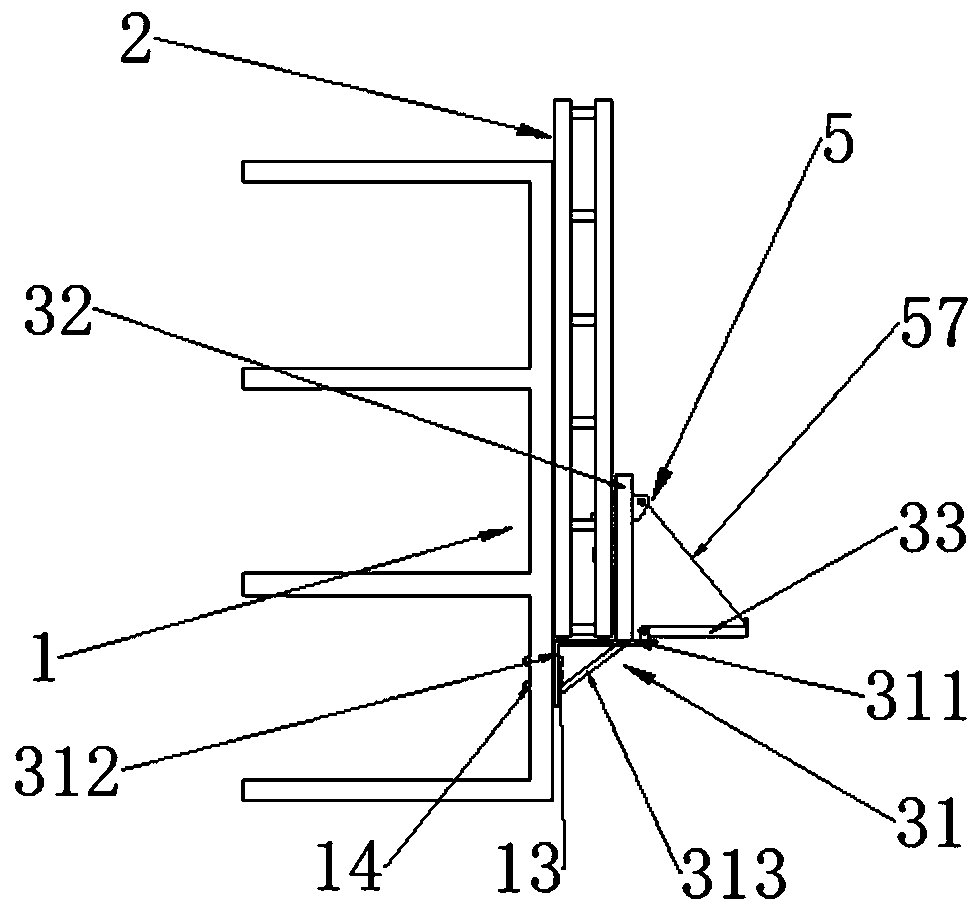

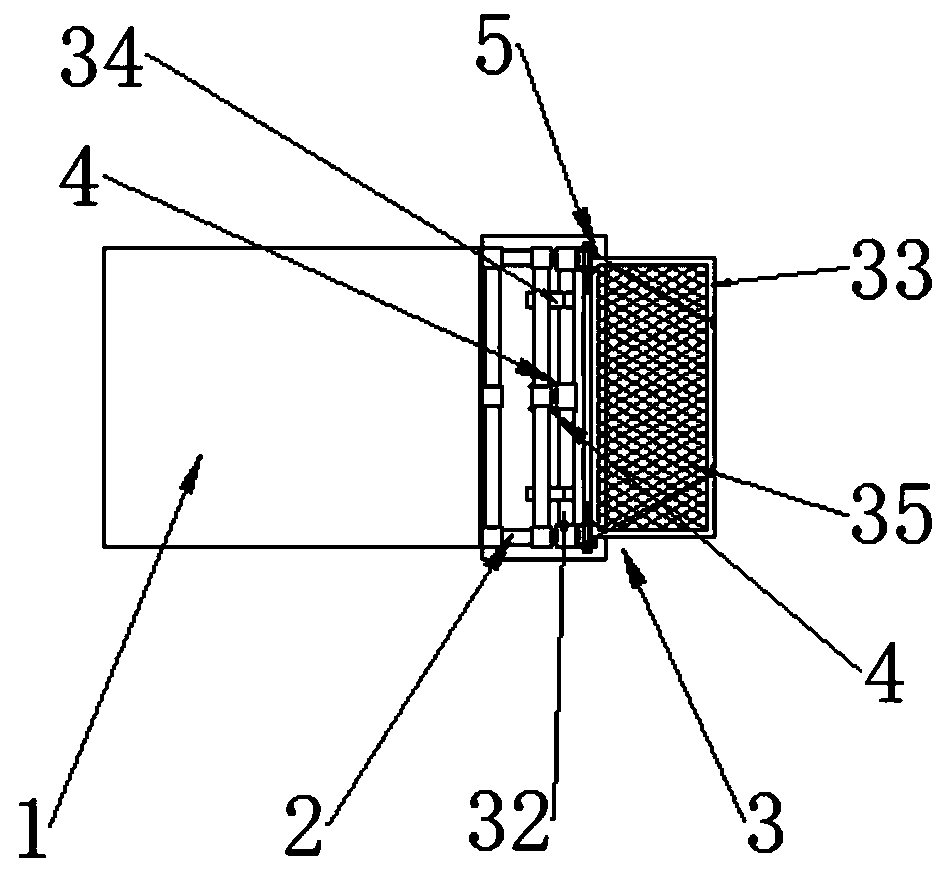

[0028] see Figure 1-5 , an assembly-type protective device at a building construction site, the building 1 includes several horizontal floors 11 and vertical walls 12, including a scaffolding 2, a protective frame 3, a locking mechanism 4 and a retractor 5; the scaffolding 2 fixed on the outside of the wall 12; the protective frame 3 includes a supporting platform 31 arranged below the scaffold 2 and fixed on the outside of the wall 12, and a fixing frame vertically fixed on the upper end of the supporting platform 31 32 and the protective plate 33 hinged at the end of the support platform 31 away from the wall 12; the two engaging mechanisms 4 are respectively fixed on both sides of the middle part of the fixing frame 32; the engaging mechanism 4 can hold the The fixed frame 32 is engaged and fixed with the scaffold 2; the two retractors 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com