Ceramic glaze decoration method

A technology for ceramic glaze and color decoration, applied in the field of ceramic color decoration, can solve the problem of not being able to color decoration, and achieve the effects of not easily falling off, solving the problem of high rejection rate and small damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix 1.5g of vanadium-zirconium blue material with a particle size of 400 mesh and 20g of transparent frit powder with a particle size of 400 mesh and a glaze forming temperature of 1110°C, then add 9g of water, and ball mill evenly to prepare a colored glaze slurry, and spray the colored glaze with a spray gun. The slurry is evenly coated on the white ceramic glaze fired at 1250°C, so that the thickness of the glaze slurry is 0.15mm. Glaze slurry for drying ceramic glazes.

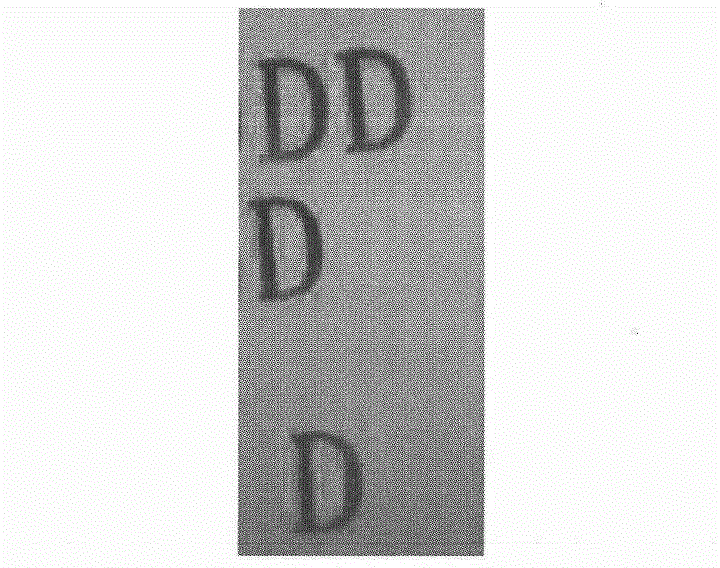

[0027] Using a fiber laser, adjust the power of the laser to 60W, the defocus to 0.2cm, the scanning speed to 100mm / s, the frequency to 40Hz, and the scanning line spacing to 0.01mm. At this time, the laser temperature can reach 1100-1130°C. Enter the letter "D" on the PC, start to heat the dried color glaze slurry with laser scanning, wash off the remaining dry color glaze slurry, and leave a clear, bright blue, smooth "D" pattern on the glaze surface ,Such as figure 1 shown

Embodiment 2

[0029] Mix 1.5g of cobalt-magnesium-tin color material with a particle size of 400 mesh and 20g of transparent frit powder with a particle size of 400 mesh and a glaze forming temperature of 1110°C, then add 9g of water, and ball mill evenly to prepare a colored glaze slurry, and use a spray gun to The color glaze paste is evenly coated on the white ceramic glaze fired at 1250°C, so that the thickness of the glaze paste is 0.15mm. Glaze slurry for drying ceramic glazes.

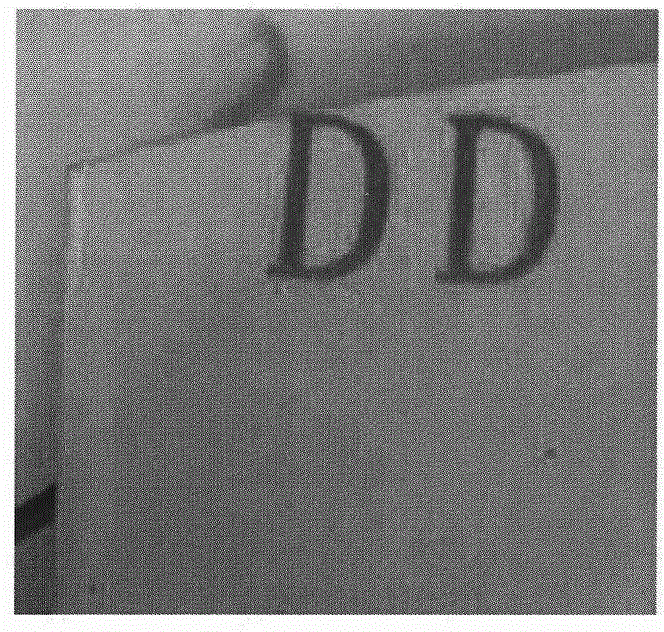

[0030] Using a fiber laser, adjust the power of the laser to 80W, the defocus to 0.2cm, the scanning speed to 100mm / s, the frequency to 40Hz, and the scanning line spacing to 0.01mm. At this time, the laser temperature can reach 1100-1130°C. Enter the letter "D" on the PC, start to heat the dried color glaze slurry with laser scanning, wash off the remaining dry color glaze slurry, and leave a clear, bright blue, smooth "D" pattern on the glaze surface ,Such as figure 2 shown.

Embodiment 3

[0032] Mix 1.5g of cobalt-magnesium-tin color material with a particle size of 400 mesh and 20g of transparent frit powder with a particle size of 400 mesh and a glaze forming temperature of 1110°C, then add 9g of water, and ball mill evenly to prepare a colored glaze slurry, and use a spray gun to The color glaze paste is evenly coated on the white ceramic glaze fired at 1250°C, so that the thickness of the glaze paste is 0.01mm. Glaze slurry for drying ceramic glazes.

[0033] Using a fiber laser, the power of the laser is adjusted to 80W, the defocus is 0.2cm, the scanning speed is 100mm / s, the frequency is 40Hz, and the scanning line spacing is 0.01mm. At this time, the laser temperature reaches 1240-1260°C. Enter the letter "D" on the PC and start scanning with laser. After washing with water, it turns out that because the color glaze paste is too thin and the laser energy is high, not only the painted color glaze paste is not printed, but also the glaze surface to be dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com