Hot stamping foil with low-temperature printing and high-temperature sterilizing properties and preparation method thereof

A technology for high-temperature sterilization and hot stamping foil, applied in the field of hot stamping materials, can solve the problems of high printing temperature, high rejection rate and high energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

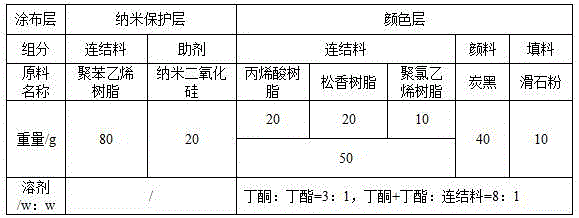

Embodiment 1

[0020]

[0021] The method for preparing the above-mentioned hot stamping foil with low-temperature printing and high-temperature sterilization performance includes the following steps:

[0022] a. Heat and melt the connecting material of the nano protective layer at 140~150°C, add additives in proportion, mix evenly to form a protective layer ink, coat it on the surface of the other side of the tape base, and heat it at a temperature of 30°C Dry to form a nano-protective layer, which requires a thickness of 1 µm, and enter the next process;

[0023] b. First, mix methyl ethyl ketone and butyl ester in a weight ratio to obtain a mixed solvent, use the mixed solvent of methyl ethyl ketone and butyl ester to dissolve the link material of the color layer (temperature 60°C), then add fillers and pigments in proportion, and grind to make For color layer inks, the pigments are required to be dispersed evenly and the fineness is less than 5 μm, coated on the surface of the nano-pr...

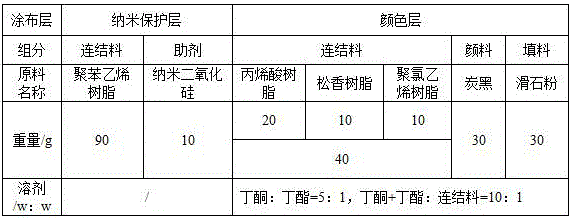

Embodiment 2

[0025]

[0026] Preparation process: in step a, the drying temperature is 31°C, the thickness of the nano protective layer is 2µm; in step b, the melting temperature is 59°C, the drying temperature is 78°C, and the thickness of the color layer is 2µm; the others are the same as in Example 1, and the obtained product has low temperature The total thickness of the hot stamping foil for printing and autoclavability is 16 µm.

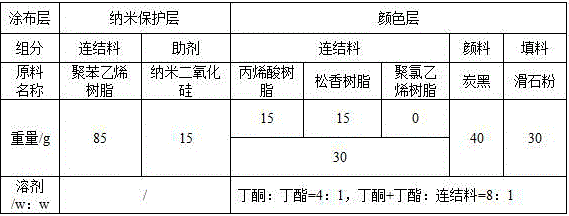

Embodiment 3

[0028]

[0029] Preparation process: in step a, the drying temperature is 30°C, the thickness of the nano protective layer is 1.5µm; in step b, the dissolution temperature is 60°C, the drying temperature is 80°C, and the thickness of the color layer is 1.5µm; the others are the same as in Example 1, and the obtained The total thickness of hot stamping foils with low temperature printing and high temperature sterilization properties is 15µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com