Grinding device and method for producing semitransparent BGO scintillation crystal material

A technology of grinding device and scintillation crystal, applied in grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of chipping, edge chipping, yin-yang surface chipping, scrapping, etc., and achieve the effect of solving chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

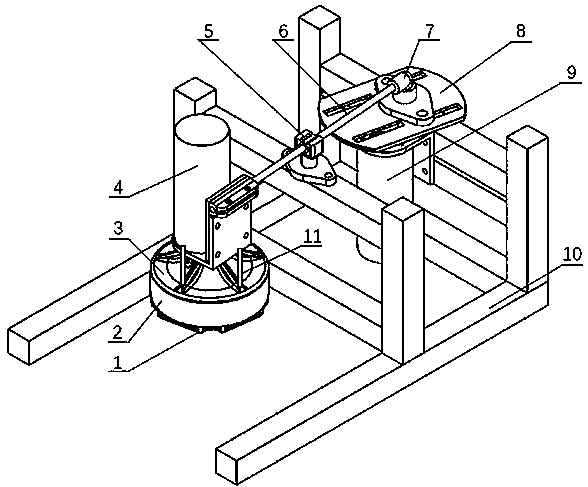

[0038] Hereinafter, the present invention will be further described in conjunction with the embodiments and drawings, which are only for explanation and not intended to limit the protection scope of the present invention.

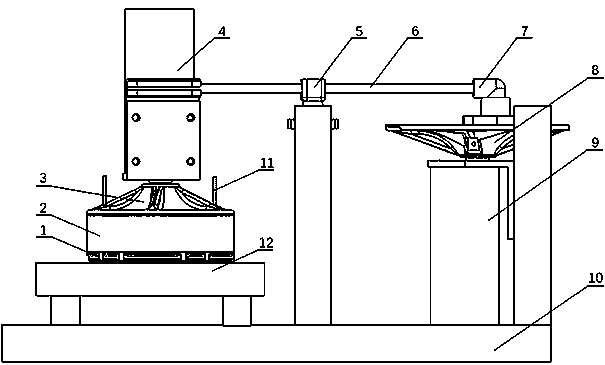

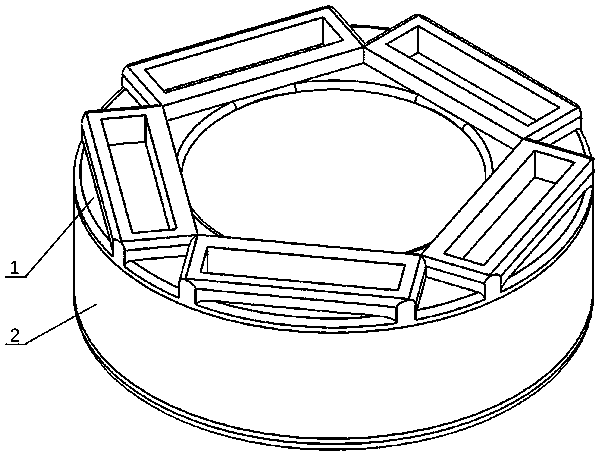

[0039] Such as figure 1 with figure 2 As shown, the grinding device for producing translucent BGO scintillation crystals in this embodiment includes:

[0040] Grinding plate having a grinding surface for grinding,

[0041] Grinding head, the grinding head includes a coupling support plate connected to the output shaft of the first motor on the upper part, a quick mounting head in the middle and a plurality of clamping grooves in the lower part, and the coupling support plate, quick mounting head and clamping grooves are magnetically attracted The magnetic attraction is realized in the following way. Embedding such as magnets or magnetic components in the above components to achieve mutual magnetic installation for quick disassembly and assembly. In actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com