Brick stacking device

A technology of stacking bricks and brick supports, which is applied in the field of ceramic brick production equipment, can solve problems such as scratched surfaces, chipped corners, height differences, etc., and achieves the effects of reducing the breakage rate and solving chipped corners or scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

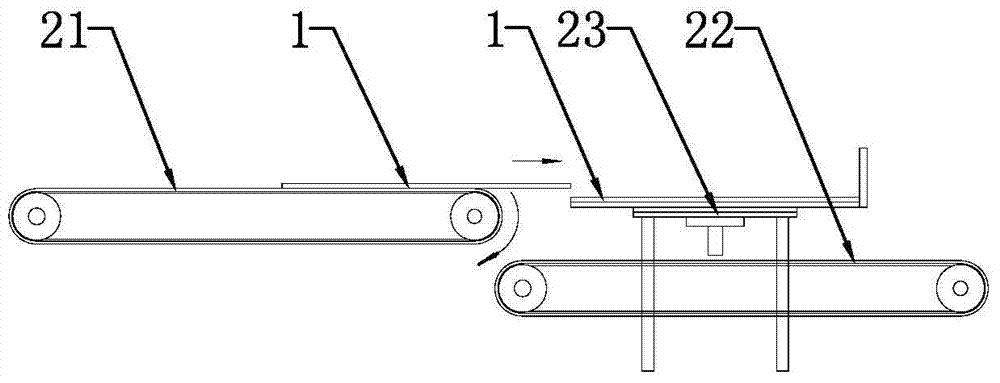

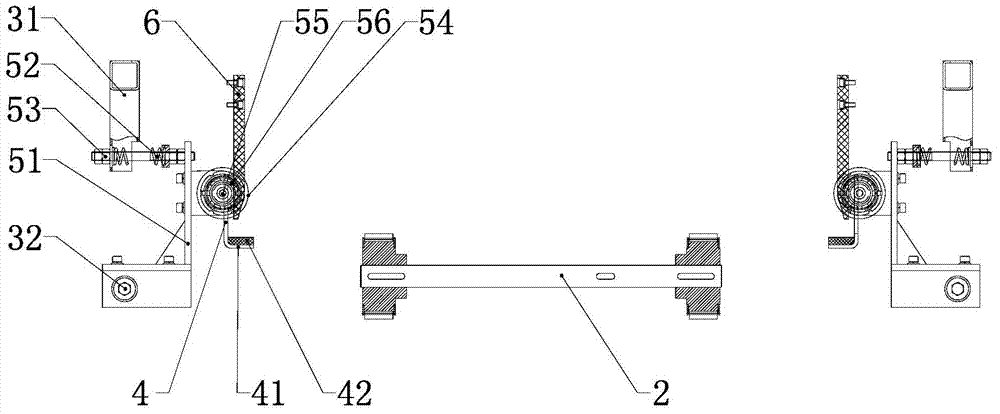

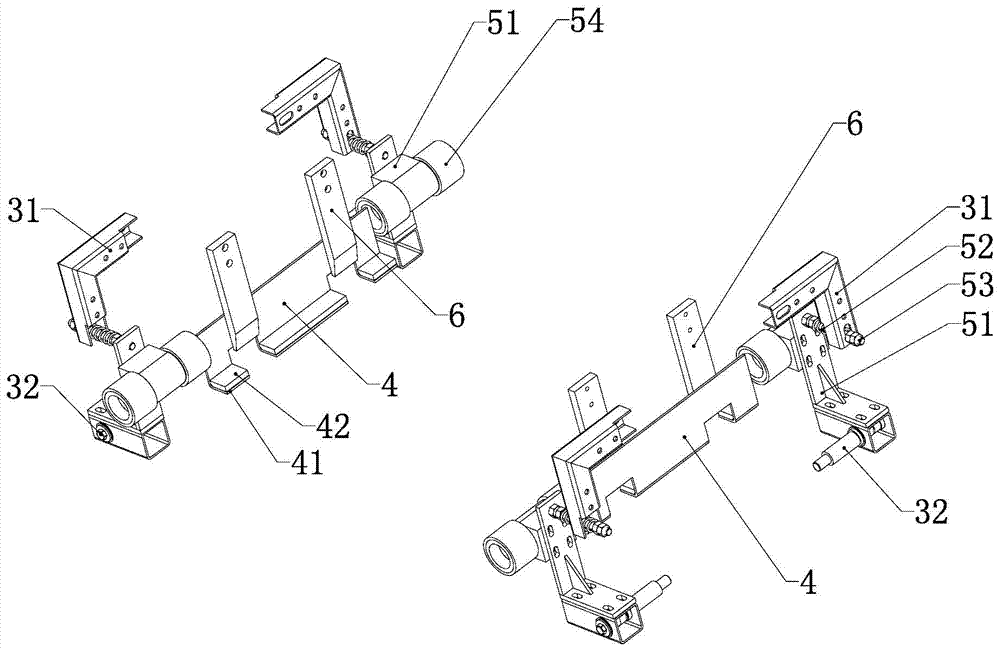

[0020] Such as figure 2 with image 3 As shown, the brick stacking device of the present invention is mainly composed of two stacking components, which are symmetrically arranged on the left and right sides of the conveyor belt 2.

[0021] Each brick stacking assembly is mainly composed of a fixing frame (not shown in the figure), a brick supporting plate 4, two one-way wheels and two guiding side plates. The fixing frame is arranged on one side of the conveyor belt, and two fixing seats 31 and two fixed shafts 32 are provided on it. The brick pallet 4 is arranged on one side of the conveyor belt and connected to a vertical lifting mechanism (not shown in the figure) arranged on the fixed frame. The lower edge of the brick pallet 4 is provided with three brick hooks 41. A rubber pad 42 is provided on the upper end of each brick hook 42. Two one-way wheel assemblies are respectively arranged on both sides of the brick pallet 4. Each one-way wheel assembly is mainly composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com