MPCVD carrier and method for depositing diamond coating on surface of cutter

A diamond coating and surface deposition technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problem of ineffective deposition adhesion, etc., to improve tool life and cutting efficiency, strong adhesion , the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

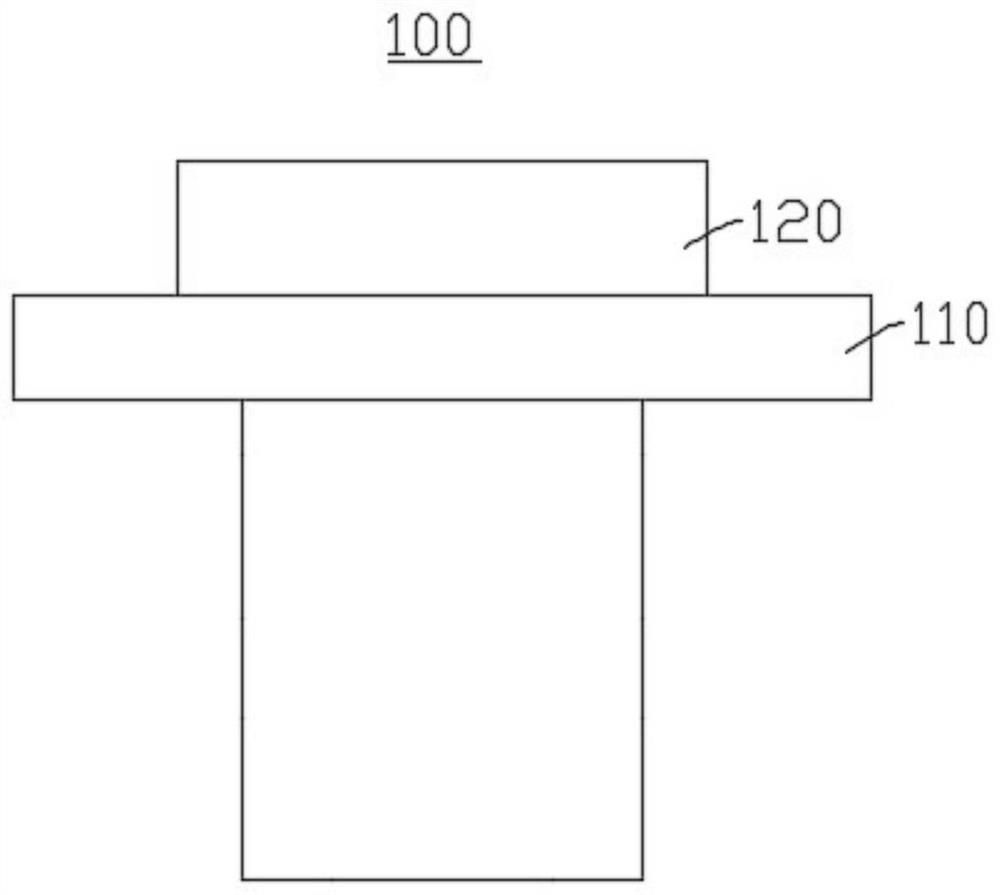

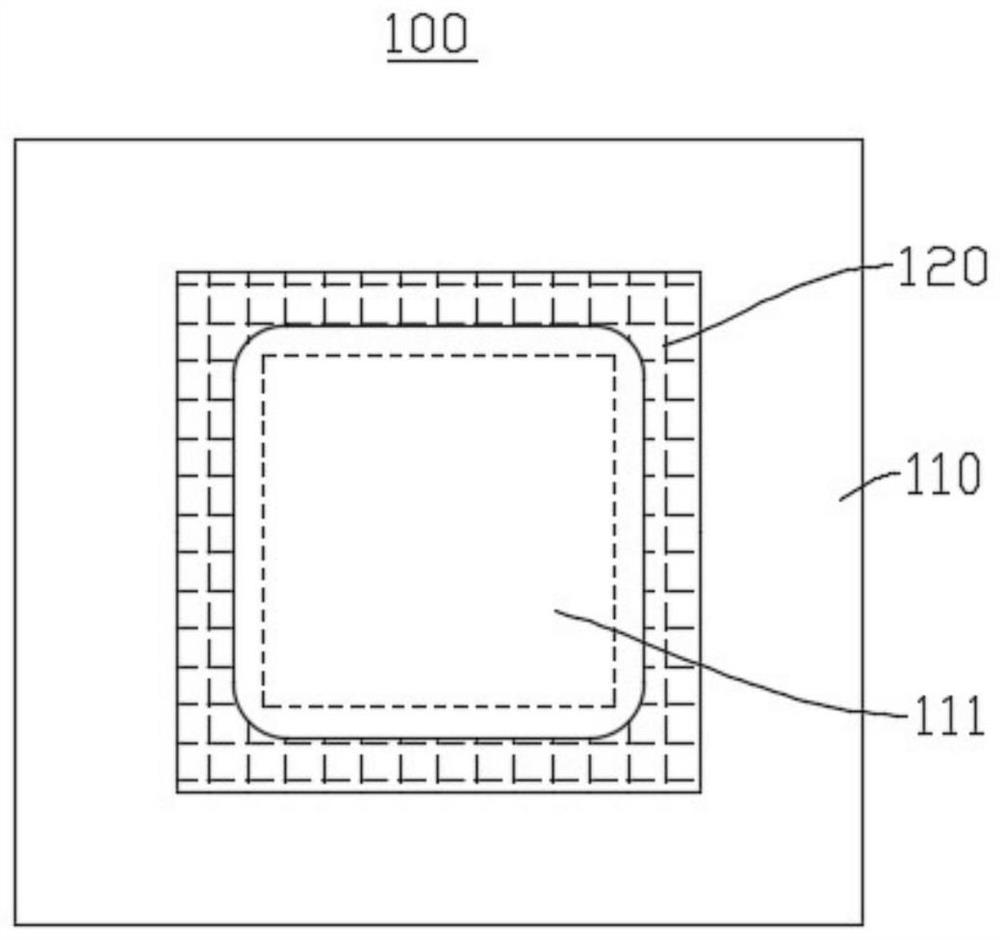

[0053] This embodiment provides an MPCVD carrier and a method for depositing a diamond coating on the surface of a tool, wherein the dimensions of the tool are: length 12.7mm, width 12.7mm, and height 5mm.

[0054] The MPCVD carrier includes a submount with a placement area and a metal enclosure. The size of the placement area is 12.7*12.7mm, and the metal fences are placed end to end around the placement area. The metal enclosure is made of molybdenum. The metal enclosure is square, with a height of 5.6mm and a thickness of 2.0mm. The gap between the metal enclosure and the tool is 0.5mm; the four right angles of the inner wall of the metal enclosure have a chamfered structure with a radius of 1.2mm.

[0055] A method of depositing a diamond coating on a tool surface includes the following steps:

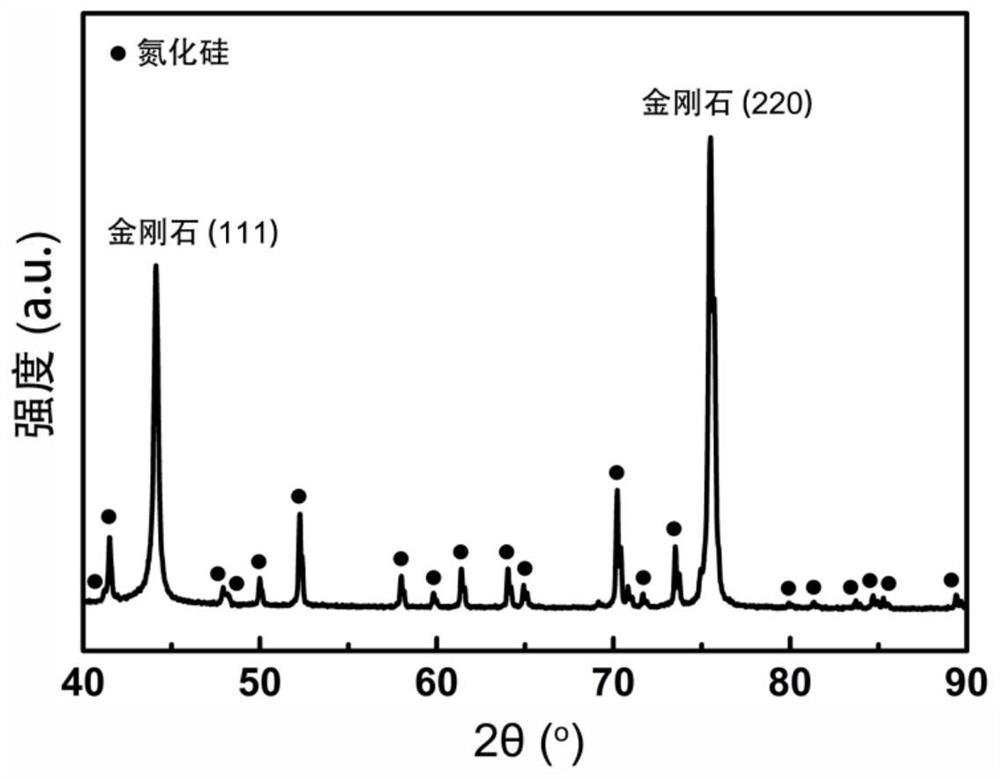

[0056] (1) The silicon nitride tool was sonicated in acetone solution for 10 minutes, and then dried at 50 °C for 20 minutes; then the tool was dry-polished in diamond powder wit...

Embodiment 2

[0061] The difference between Example 2 and Example 1 is that the height of the metal enclosure is 5 mm.

Embodiment 3

[0063] The difference between Example 3 and Example 1 is that the volume ratio of methane and hydrogen in step (3) is 8:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com