Preparation method of aluminum-based boron carbide neutron absorption composite material

A technology of absorbing composite materials and aluminum-based boron carbide, which is applied in the field of non-ferrous metal reinforcement and powder metallurgy, can solve the problems of poor toughness, difficulty, and high brittleness of boron carbide, and achieve reasonable proportioning, detailed and accurate data, and stable physical and chemical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

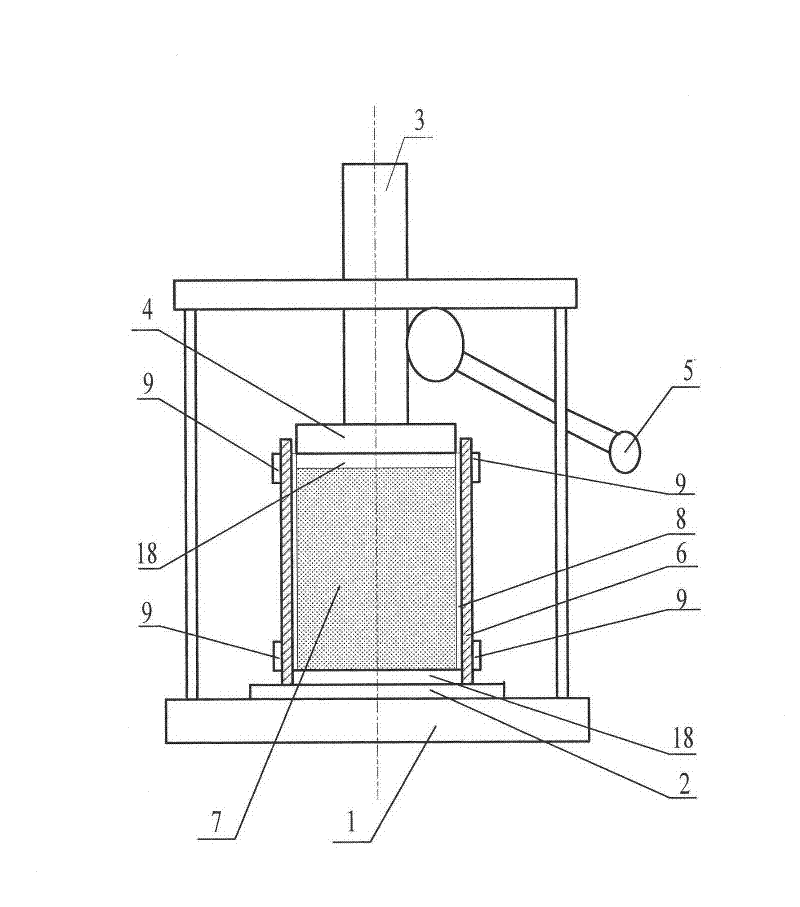

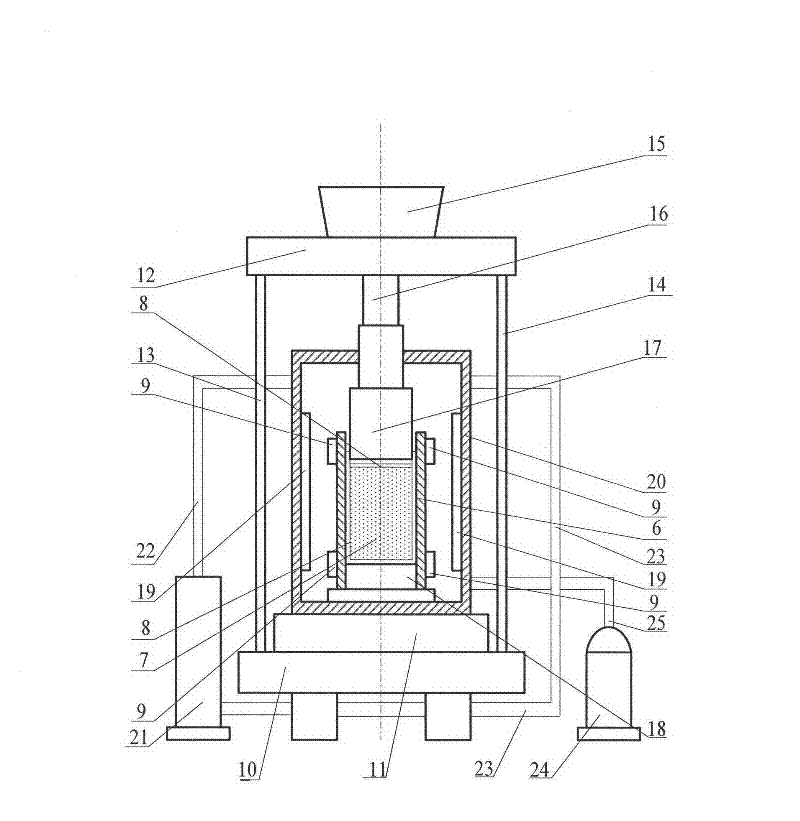

[0072] figure 1 As shown, it is the state diagram of the cold pressing of the mixed fine powder billet, and the positions of each part must be correct, and the operations should be performed in sequence.

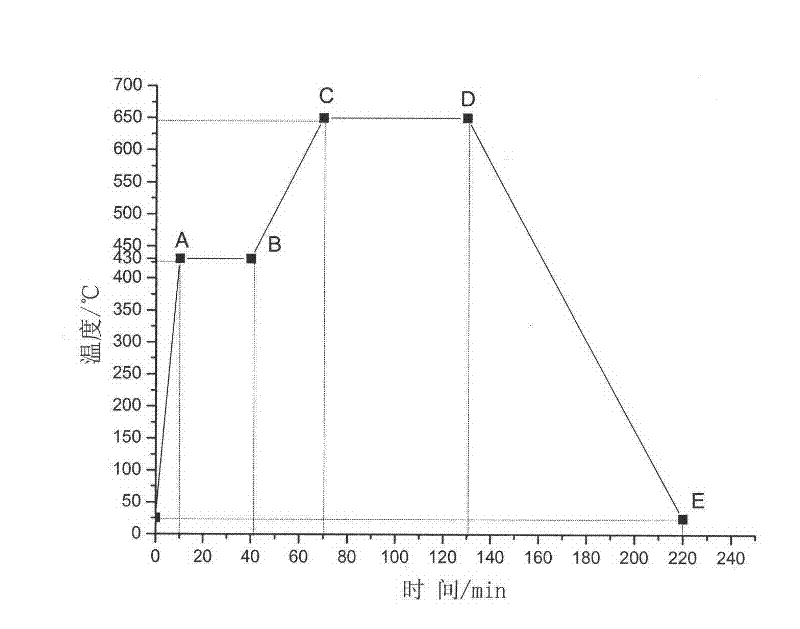

[0073] The cold pressing of mixed fine powder is carried out on a manual cold press machine, which is vertical, with an upper pressing head 3 and an upper pressing block 4 on the upper part, and the up and down movement is controlled by the control handle 5 on the side, and the lower part is equipped with There is a lower block 2, on which the open-close graphite mold 6 is placed vertically, the graphite mold 6 is assembled and formed by an open-close frame 9, graphite paper 8 is pasted on the inner periphery of the graphite mold 6, graphite cushion blocks 18 are placed on the upper and lower parts, Inside the graphite paper 8 is a mixed blank 7, and under the pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com