A method of preparing a high-performance graphene reinforced aluminium-based composite material

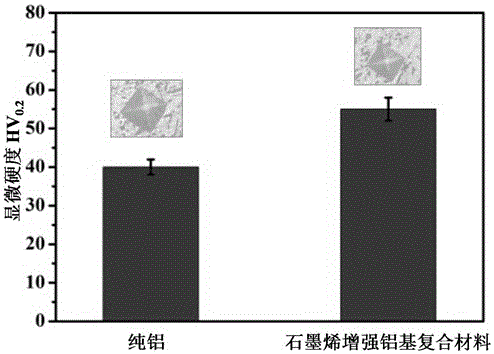

A technology for strengthening aluminum-based and composite materials, applied in the field of materials science, can solve the problems of poor graphene dispersion and interface reactions, and achieve the effects of avoiding agglomeration, improving microhardness, and making significant technological progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of graphene oxide and surface modification of aluminum powder

[0020] The preparation method of graphene oxide: 1. adopt high-purity graphite 5 g, 2.5 gNaNO 3 , added to a certain amount of H 2 SO 4 solution, stir evenly, 2. Then gradually add a certain amount of KMnO 4 , stir evenly for about 1 hour; 3. Add 200 ml of water, stir at 100°C for 1 hour, 4, add a small amount of H 2 o 2 and HCl solution. Then, graphene oxides of different sizes were centrifuged to obtain a graphene oxide solution with basically the same size (with a size between 10 μm and 20 μm).

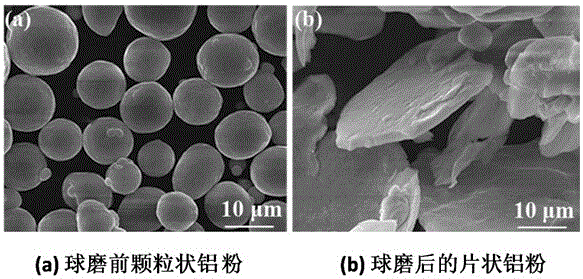

[0021] Aluminum powder surface modification method: use planetary ball mill to mill aluminum powder, firstly at low speed of 150~200 rpm, ball mill for 0.5~1 h, then at high speed of about 350~400 rpm, time of 2~4 h, so that the spherical particle aluminum powder becomes Flaky aluminum powder (microscopic morphology of aluminum powder before and after ball milling, see figure 1 ).

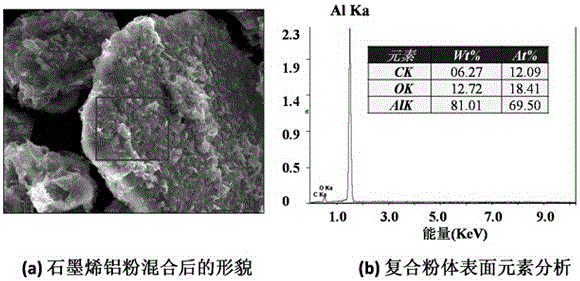

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com