Method for preparing crystal boundary nano-composite intensified neodymium iron boron magnet

A nanocomposite, NdFeB technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of toughness and magnetic performance decline of sintered NdFeB magnets that have not been found, and achieve suitable The effect of large-scale batch production, improving strength and toughness, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

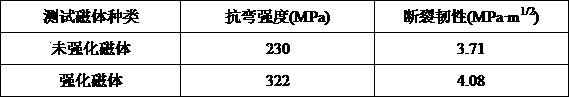

Embodiment 1

[0024] 1) Main phase alloy Nd 11 PR 2 Fe bal Zr 0.1 B 5.5 The quick-setting thin strip is made by the quick-setting strip-throwing process, the rotation speed of the copper roll is 2m / s, and the grain boundary phase alloy Nd 12 PR 20 Fe bal co 2 Cu 0.5 B 7 The quick quenching belt is made by the quick quenching process, and the quick quenching speed is 16m / s;

[0025] 2) The main phase alloy and the grain boundary phase alloy are roughly crushed by mechanical crushing, and then powders with an average particle diameter of 6 μm and 5 μm are respectively made into powders by jet milling under the protection of nitrogen;

[0026] 3) After mixing 1wt% graphene nanosheet powder and grain boundary phase alloy powder for 2 minutes, add 1wt% stearic acid for vacuum ball milling, so that it is evenly dispersed in the grain boundary phase alloy powder;

[0027] 4) uniformly mix the 7wt% graphene nano-reinforced grain boundary phase alloy powder with the main phase alloy powder...

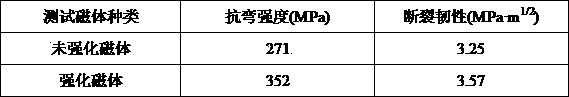

Embodiment 2

[0032] 1) Main phase alloy Nd 16 Dy 1 Fe bal Ga 0.3 B 7 Ingot made by casting process, grain boundary phase alloy Nd 30 Dy 5 Fe bal Ni 3 Al 1 Nb 0.1 B 6.5 The quick quenching belt is made by the quick quenching process, and the quick quenching speed is 18m / s;

[0033] 2) The main phase alloy and the grain boundary phase alloy are coarsely crushed by hydrogen explosion crushing respectively, and then powders with average particle diameters of 2 μm and 1 μm are respectively made by ball milling under the protection of nitrogen;

[0034] 3) After mixing 10wt% graphene nanosheet powder and grain boundary phase alloy powder for 10 minutes, add 6wt% stearic acid for vacuum ball milling, so that it is evenly dispersed in the grain boundary phase alloy powder;

[0035] 4) After uniformly mixing 3wt% graphene nano-reinforced grain boundary phase alloy powder with the main phase alloy powder, orientation pressing is made into a green body in a 1.2T magnetic field;

[0036] 5...

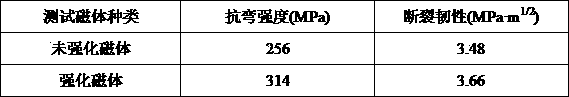

Embodiment 3

[0040] 1) Main phase alloy Nd 12 PR 10 Fe bal co 0.5 Cu 0.5 Nb 0.1 B 6 The quick-setting thin strip is made by the quick-setting strip-throwing process, the rotation speed of the copper roll is 1.6m / s, and the grain boundary phase alloy Nd 20 Dy 2 Ho 2 Fe bal Mg 2 Ti 0.5 B 5 The quick quenching belt is made by the quick quenching process, and the quick quenching speed is 18m / s;

[0041] 2) The main phase alloy and the grain boundary phase alloy are roughly crushed by mechanical crushing, and then powders with an average particle diameter of 3.8 μm and 3 μm are respectively made into powders by jet milling under the protection of nitrogen;

[0042] 3) After mixing 3wt% graphene nanosheet powder and grain boundary phase alloy powder for 5 minutes, add 4wt% stearic acid for vacuum ball milling, so that it is evenly dispersed in the grain boundary phase alloy powder;

[0043] 4) uniformly mix 1wt% graphene nano-reinforced grain boundary phase alloy powder with the mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com