An alkali metal-based negative electrode and a preparation method and application thereof

An alkali metal and negative electrode technology, which is applied in the field of alkali metal-based negative electrodes and their preparation, can solve the problems of difficult large-scale preparation, low conductivity of inorganic substances, and decreased conductivity of electrodes, so as to improve safety performance and cycle stability. Effect of suppressing interface reaction and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

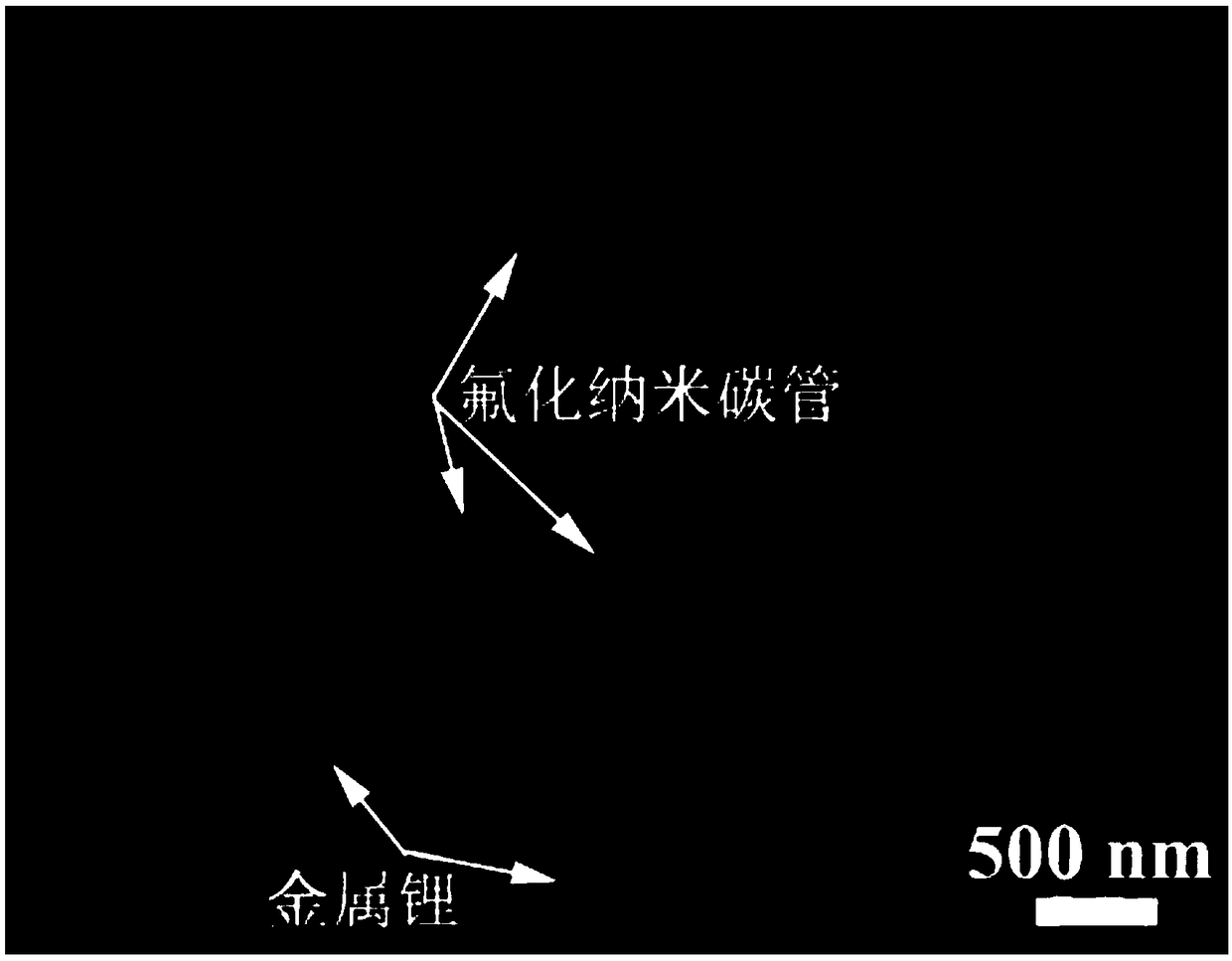

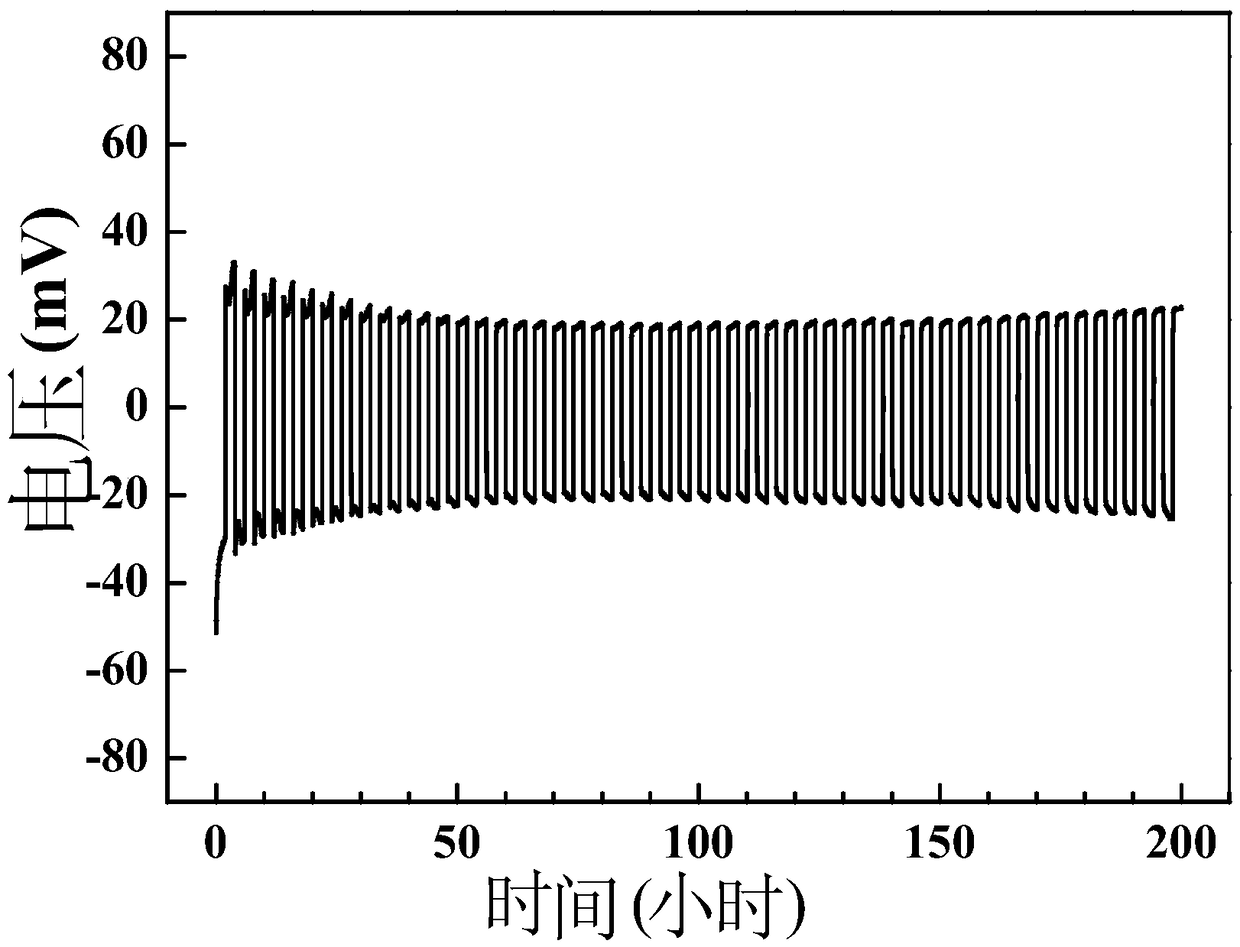

[0038] Under the protection of argon atmosphere, the metal lithium was kneaded into thin flakes; the fluorinated carbon nanotube powder was evenly loaded on the surface of the metal lithium, and pressure was applied to make the fluorinated carbon nanotube powder adhere to the metal lithium surface, and the fluorinated carbon nanotubes The weight ratio of the weight of the metal lithium to the metal lithium is 2.5%, the fluorine content of the fluorinated carbon nanotube is 50wt%, the diameter of the fluorinated carbon nanotube is 30-60nm, and the length is 500nm-2μm; the surface is loaded with fluorinated nanometer Alkali metal folding and kneading of carbon tube powder, and repeated folding and kneading to obtain metal lithium / fluorinated carbon nanotube composite negative electrode.

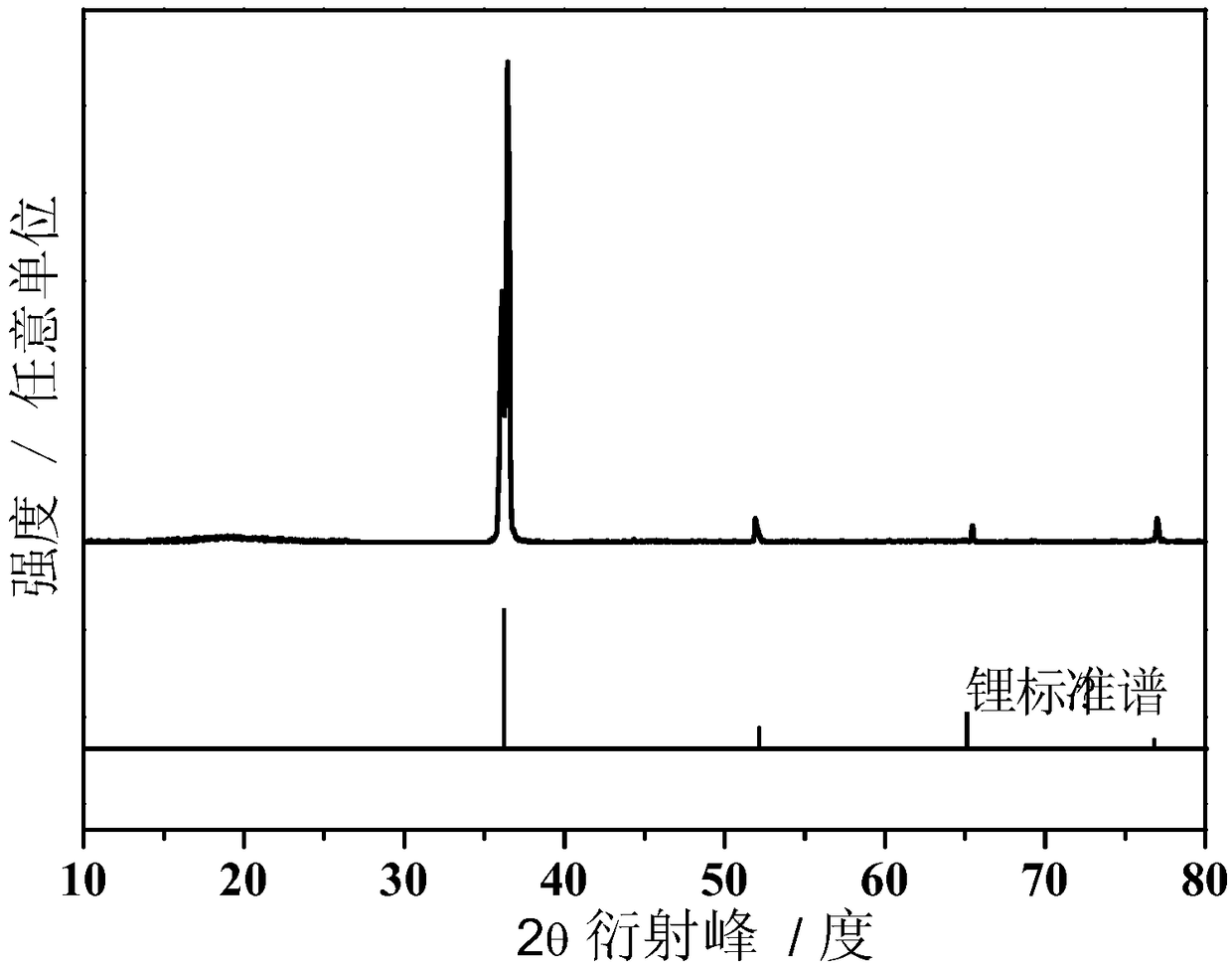

[0039] figure 1 The XRD pattern of the composite negative electrode prepared for this example shows that the diffraction peak is a lithium peak, and there is no diffraction peak in the figure d...

Embodiment 2

[0050] The preparation of the electrode and the assembly of the battery are as in Example 1, the difference is that the fluorinated carbon nanotubes are replaced with fluorinated graphite with equal additions and the same fluorine content. Electrochemical tests show that under the same test conditions Under (current density 0.5mA / cm 2 , with a capacity of 1mAh / cm 2 , after 200 hours), the polarization is 30 mV.

Embodiment 3

[0052] Under the protection of argon atmosphere, the sodium metal is kneaded into flakes; the graphene fluoride powder is evenly loaded on the surface of the sodium metal, and the pressure is applied to make the graphene fluoride powder adhere to the surface of the sodium metal. The weight of the graphene fluoride is the same as The weight ratio of metal sodium is 5%, and the fluorine content of fluorinated graphene is 50wt%; The metal sodium that the surface is loaded with fluorinated graphene powder is folded and kneaded, and then repeatedly folded and kneaded to obtain metal sodium / fluoride Graphene composite anode. The product is characterized by XRD as metallic sodium, and the fluorinated graphene does not have a diffraction peak in the figure due to its low content and low crystallinity. The product was characterized by SEM, and the fluorinated graphene was relatively uniformly dispersed in metallic sodium. Electrochemical tests show (current density 0.5mA / cm 2 , with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com