Quasi-solid-state electrolyte film as well as preparation method and application thereof

An electrolyte film, quasi-solid-state technology, applied in solid electrolytes, electrolyte battery manufacturing, electrolytes, etc., can solve the problems of interface stability and affect the cycle stability of lithium anode, so as to improve interface stability and improve lithium ion conductivity. and excellent effects on migration number, mechanical properties and chemical/electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

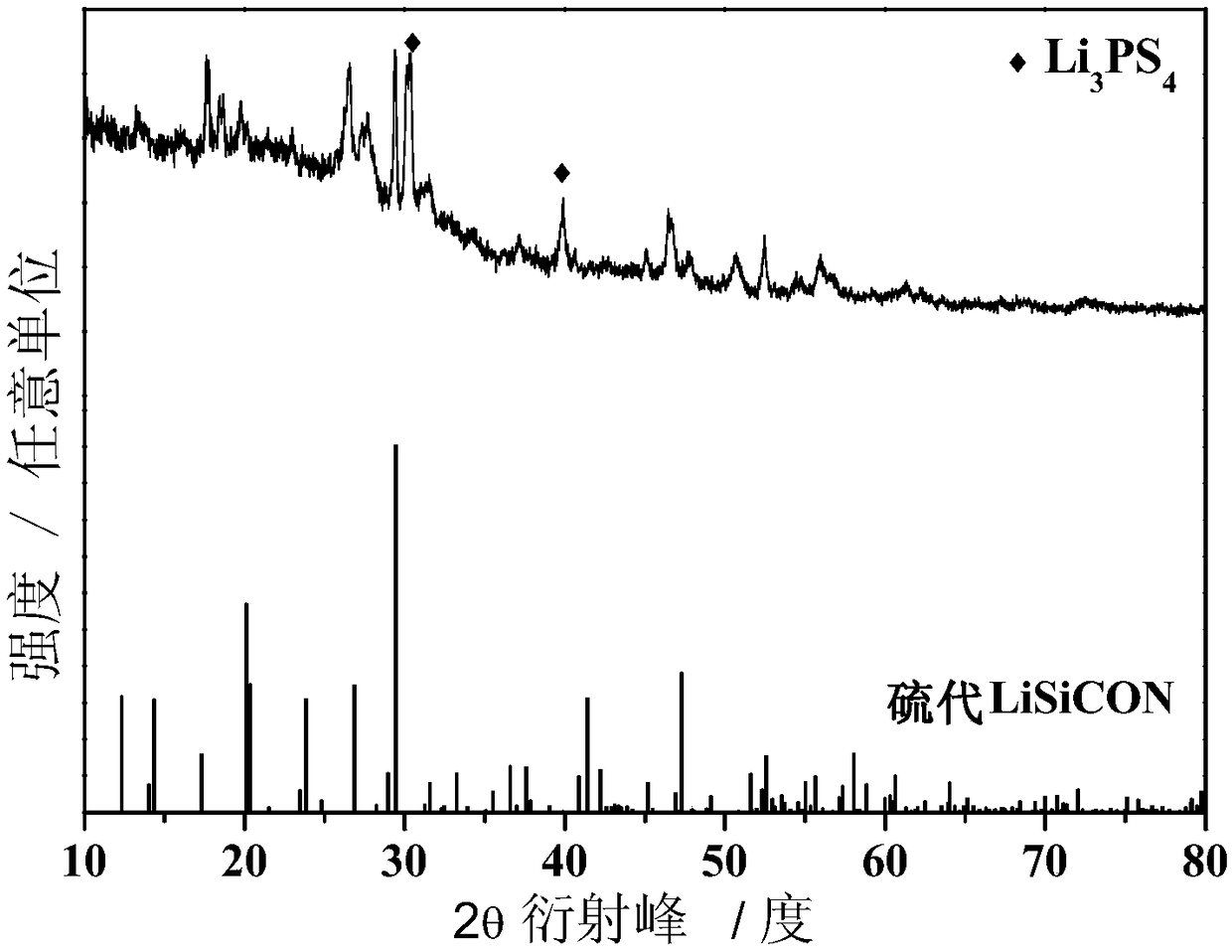

[0056] Under Ar atmosphere, 0.2123 g of Li 2 S, 0.16 g P 2 S 5 , 0.1605 g SiS 2 and 0.0127 g of LiCl were added to a container containing 10 mL of anhydrous acetonitrile, then the container was sealed, stirred magnetically for 24 h, and then left to stand for 2 h, and the supernatant was removed with a dropper to leave a white mixture, which was placed under an argon atmosphere at room temperature Evaporate and dry under reduced pressure, then grind it into powder with a mortar, put it into a quartz tube, seal the tube in vacuum, then place the sample in a tube furnace at 475°C, react for 11h, the heating rate is 5°C / min, and cool with the furnace , to obtain a ceramic electrolyte; 0.8 g of polyvinylidene fluoride-hexafluoropropylene and 0.8 g of polypropylene carbonate were placed in 50 mL of methyl pyrrolidone, and stirred at 80 ° C to obtain a uniform solution, and then 0.32 g of ceramic electrolyte and 0.32 Two grams of bistrifluoromethanesulfonylimide lithium is disper...

Embodiment 2

[0071] Under Ar atmosphere, 0.2123 g of Li 2 S, 0.1540 g P 2 S 5 , 0.1605 g SiS 2and 0.0116 g of LiCl were added to a container containing 10 mL of anhydrous acetonitrile, then the container was sealed, stirred by magnetic force for 24 h, and then left to stand for 2 h, and the supernatant liquid was removed with a dropper, leaving a white mixture, which was placed under an argon atmosphere at room temperature Evaporate and dry under reduced pressure, then grind it into powder with a mortar, put it into a quartz tube, vacuum seal the tube, then place the sample in a tube furnace at 500°C, react for 9h, the heating rate is 5°C / min, and cool with the furnace , to obtain a ceramic electrolyte; 1.12 grams of polyvinylidene fluoride-hexafluoropropylene and 0.48 grams of polypropylene carbonate were placed in 50 mL of methyl pyrrolidone, and stirred at 80 ° C to obtain a uniform solution, and then 0.32 grams of ceramic electrolyte and 0.32 Two grams of bistrifluoromethanesulfonyl...

Embodiment 3

[0074] Under Ar atmosphere, 0.2123 g of Li 2 S, 0.1623 g P 2 S 5 , 0.1605 g SiS 2 and 0.0130 g of LiCl were added to a container containing 10 mL of anhydrous acetonitrile, then the container was sealed, stirred by magnetic force for 24 h, and then left to stand for 2 h, and the supernatant liquid was removed with a dropper to leave a white mixture, which was placed under an argon atmosphere at room temperature Evaporate and dry under reduced pressure, then grind to powder with a mortar, put it into a quartz tube, vacuum seal the tube, then place the sample in a tube furnace at 450°C, react for 13h, the heating rate is 5°C / min, and cool with the furnace , to obtain a ceramic electrolyte; 0.48 grams of polyvinylidene fluoride-hexafluoropropylene and 1.12 grams of polypropylene carbonate were placed in 50 mL of methyl pyrrolidone, and stirred at 80 ° C to obtain a uniform solution, and then 0.32 grams of ceramic electrolyte and 0.32 Two grams of bistrifluoromethanesulfonylimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com