Aluminum matrix composite with low expansion and high thermal conductivity reinforced by mixing graphite and silicon

An aluminum-based composite material and composite material technology, which is applied in the field of graphite/silicon hybrid reinforced aluminum-based composite materials with high thermal conductivity and low expansion, can solve problems such as poor thermal stability and thermal shock resistance, poor mechanical properties, and poor stability, and achieve Effect of improving interface, thermal conductivity and thermal expansion coefficient to maintain stable, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The graphite / silicon hybrid reinforced aluminum matrix composite material with high thermal conductivity and low expansion in this embodiment is prepared by the pressure infiltration method in the prior art.

[0024] In this embodiment, graphite particles are in the form of scales, with a volume fraction of 40%, silicon is in granular form, with a volume fraction of 20%, and the rest is aluminum alloy.

[0025] The interfacial modification additives in this embodiment are Zr (0.5% by mass) and Ti (0.2% by mass), which are blended into a commercial Al-Si alloy in the state of an intermediate alloy at 750° C. under the protection of argon.

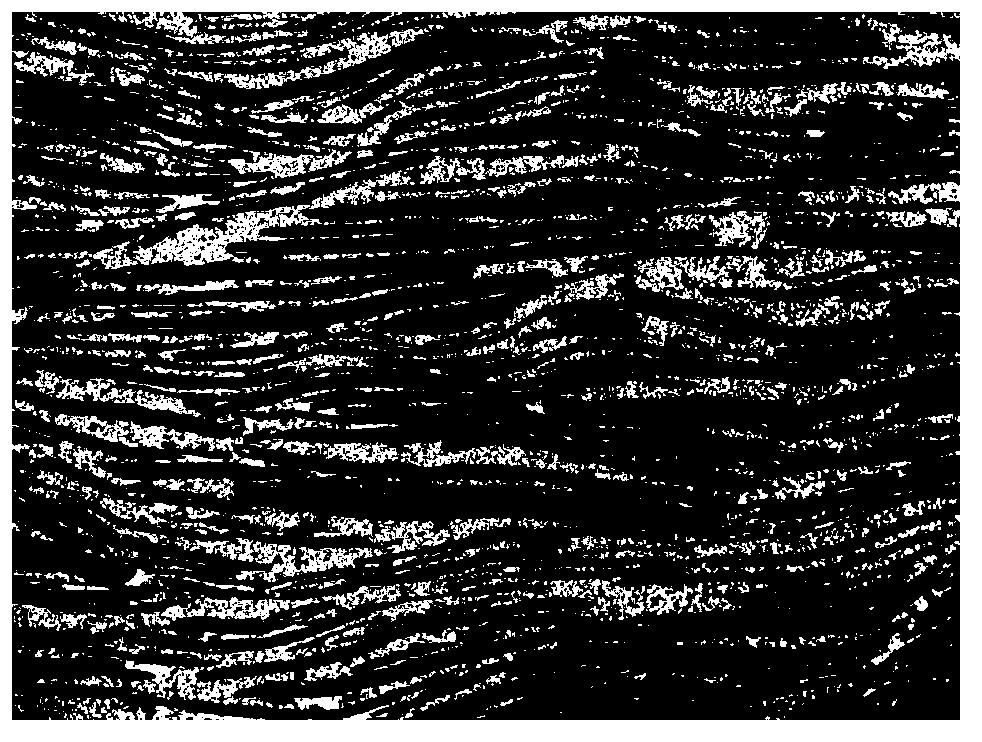

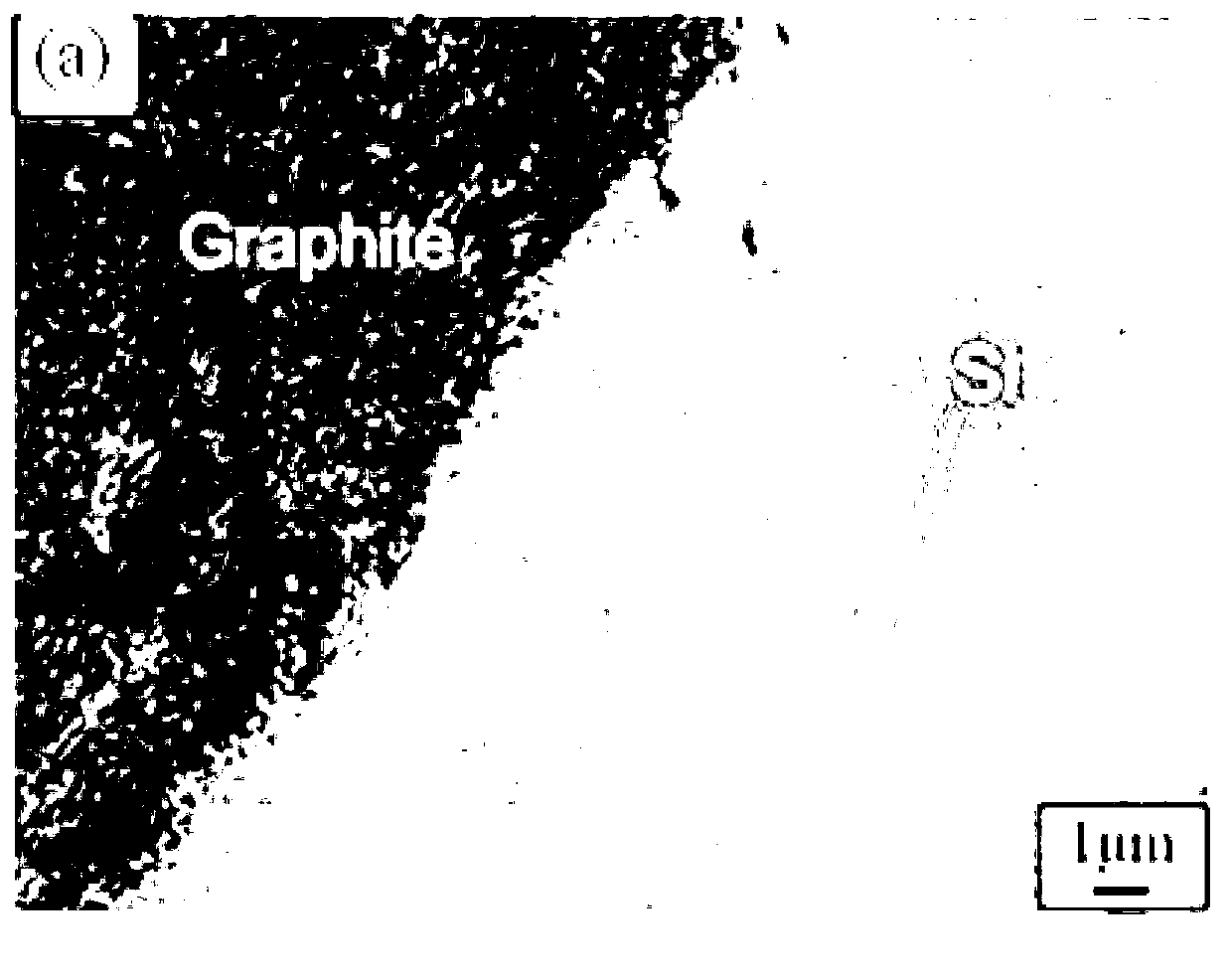

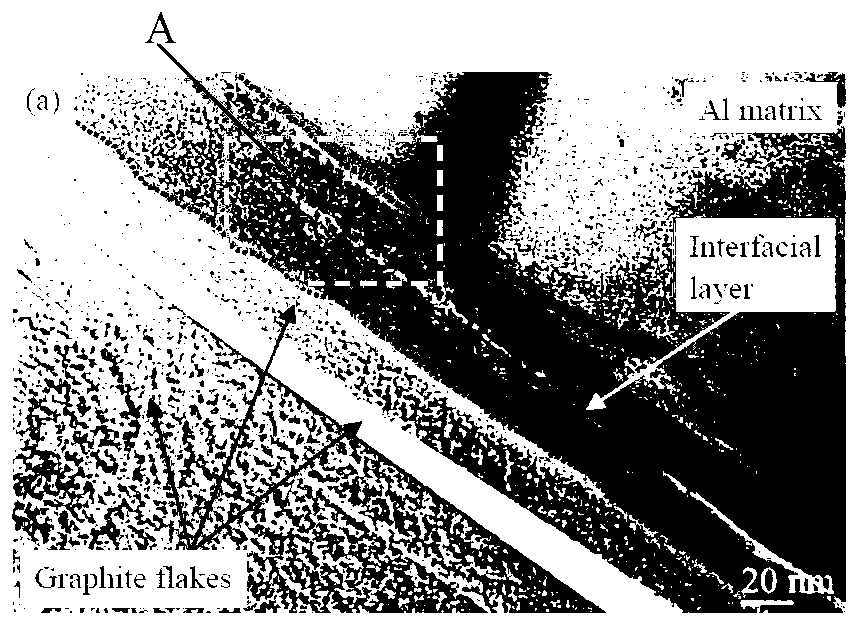

[0026] attached by figure 1 Metallographic photos of graphite / silicon hybrid reinforced aluminum matrix composites with high thermal conductivity and low expansion, attached figure 2 Graphite / silicon hybrid enhanced high thermal conductivity and low expansion aluminum matrix composite material scanning electron microscope photos, an...

Embodiment 2

[0028] The graphite / silicon hybrid reinforced aluminum matrix composite material with high thermal conductivity and low expansion in this embodiment is prepared by the pressure infiltration method in the prior art.

[0029] In this implementation example, the graphite particles are granular, with a volume fraction of 60%, the silicon is granular, and the volume fraction is 10%, and the rest is aluminum alloy.

[0030] The interface modifying additives in this embodiment are Mg (3.5% by mass) and Sc (0.1% by mass), which are blended into a commercial Al-Si alloy in the state of an intermediate alloy at 750° C. under the protection of argon.

[0031] In the prepared composite material, the graphite and silicon particles are evenly distributed in the matrix, forming a stable amorphous interface with the matrix, and the thickness is 45nm. Al was not found 4 C 3 Mutually. The structure of the composite material is dense, and its physical properties are: room temperature, thermal...

Embodiment 3

[0033] The graphite / silicon hybrid reinforced aluminum matrix composite material with high thermal conductivity and low expansion in this embodiment is produced by powder metallurgy in the prior art.

[0034] In this embodiment, graphite particles are in the form of scales, with a volume fraction of 60%, silicon is in granular form, with a volume fraction of 10%, and the rest is aluminum alloy.

[0035] The interfacial modification additives in this embodiment are Zr (3.5% by mass) and Sc (0.1% by mass), which were milled with pure aluminum powder for 10 hours under the protective atmosphere of argon. Then add graphite particles and silicon particles, and continue low-speed ball milling for 0.5 hours to carry out powder metallurgy.

[0036] In the prepared composite material, the graphite and silicon particles are evenly distributed in the matrix, forming a stable amorphous interface with the matrix, and the thickness is 50nm. Al was not found 4 C 3 Mutually. The structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com