Transparent conductive film and coating composition therefor

a technology of transparent conductive film and coating composition, which is applied in the direction of conductive layers on insulating supports, transportation and packaging, chemistry apparatus and processes, etc., can solve the problems of limited range of applicable substrate materials, difficult to uniformly disperse the fibers throughout the thermoplastic resin matrix, and difficulty in controlling electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthetic example 1

[0086] Carbon fibrous structures were synthesized using toluene as a raw material in a CVD process.

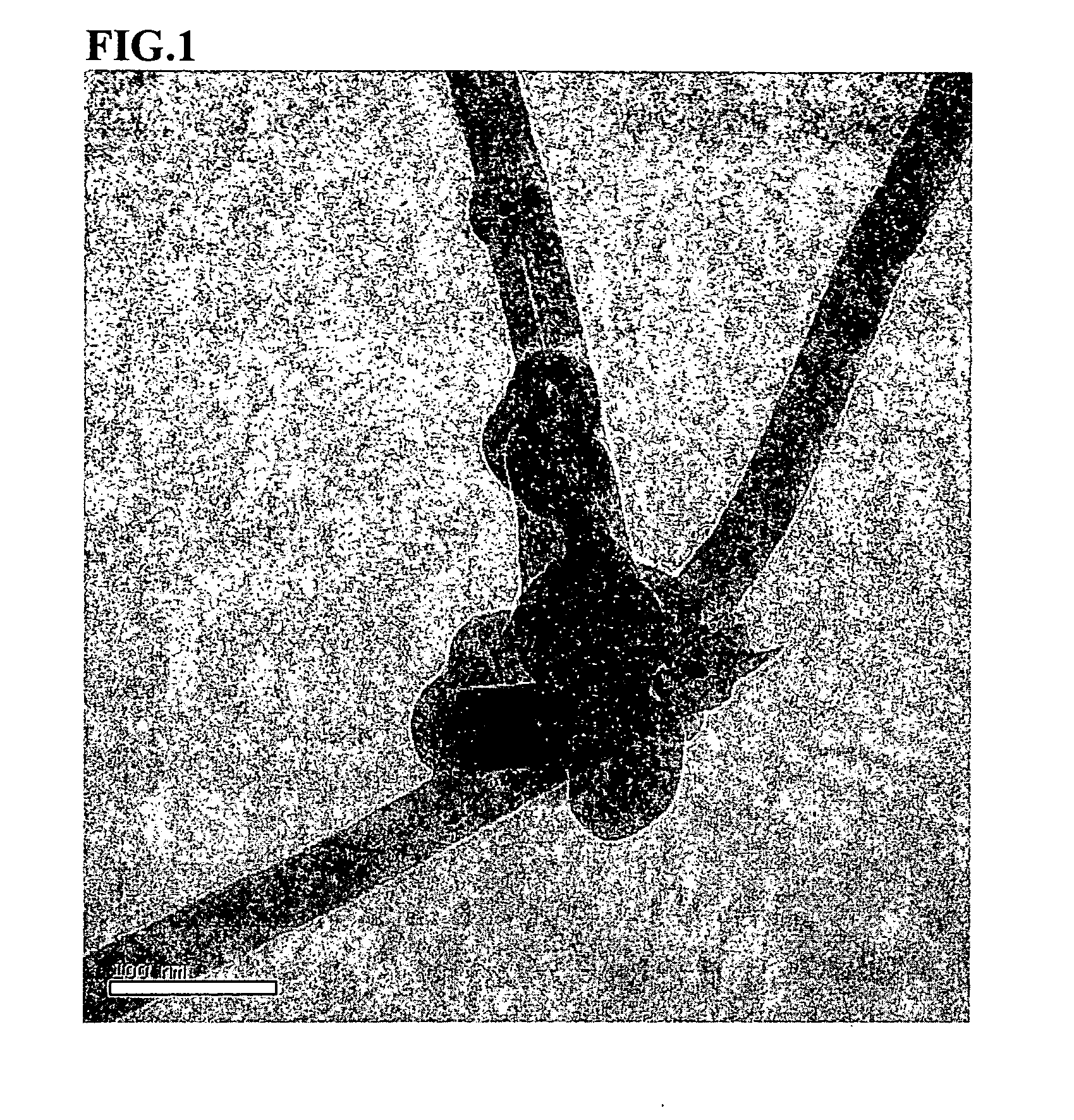

[0087] The synthesis was carried out in the presence of a mixture of ferrocene and thiophene as a catalyst, and in the reducing atmosphere of hydrogen gas. The toluene and the catalyst were heated to 380° C. along with the hydrogen gas. The heated mixture was then supplied to a generation furnace and subjected to thermal decomposition at 1250° C. in order to obtain carbon fibrous structures (the first intermediate). The synthesized first intermediate was baked at 900° C. in nitrogen gas in order to remove hydrocarbons, such as tar, to produce a second intermediate. The R value of the second intermediate, as measured by Raman spectroscopic analysis, was found to be 0.98. A sample for electron microscopy was prepared by dispersing the first intermediate into toluene. FIG. 1 shows a TEM photo of the sample.

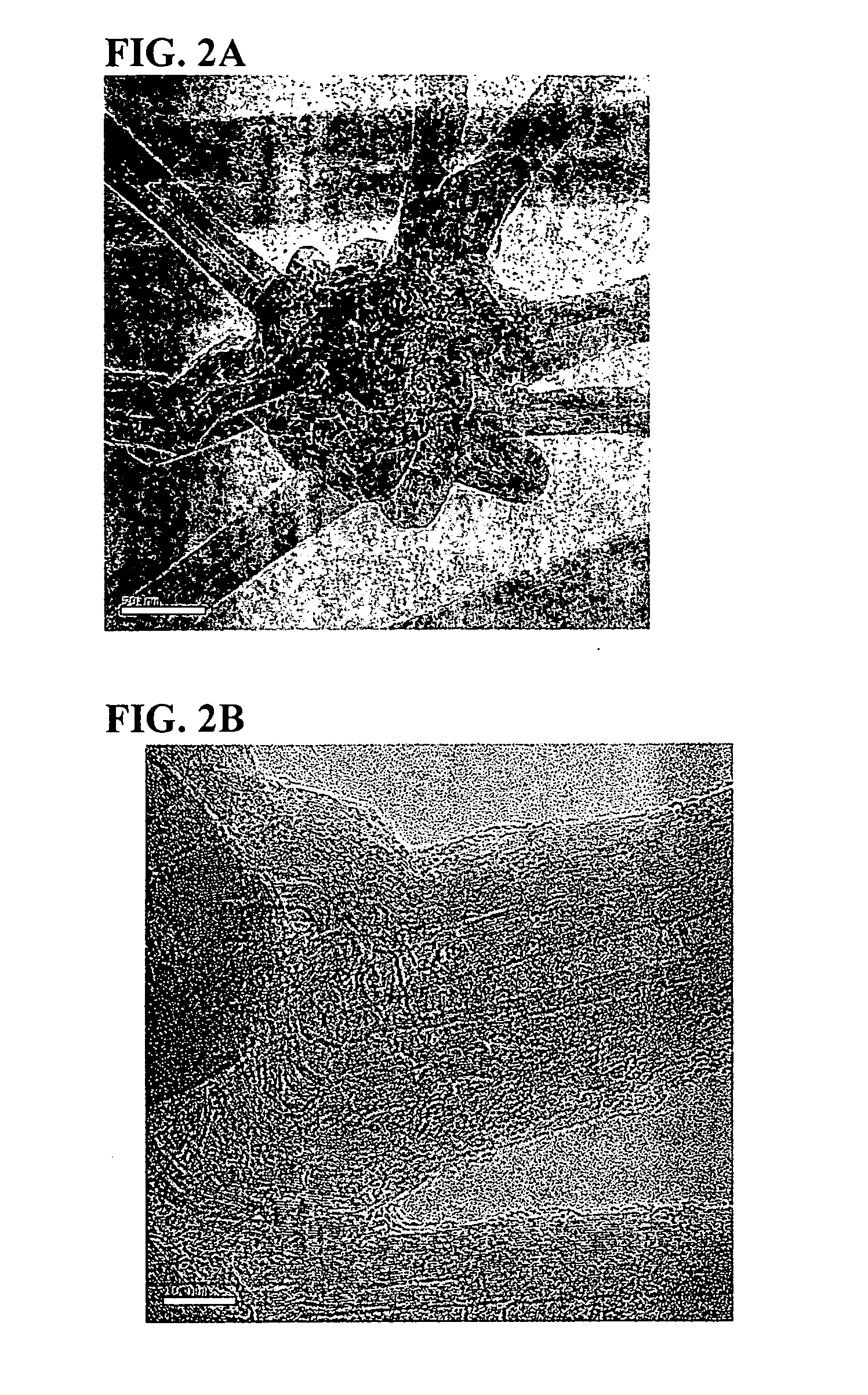

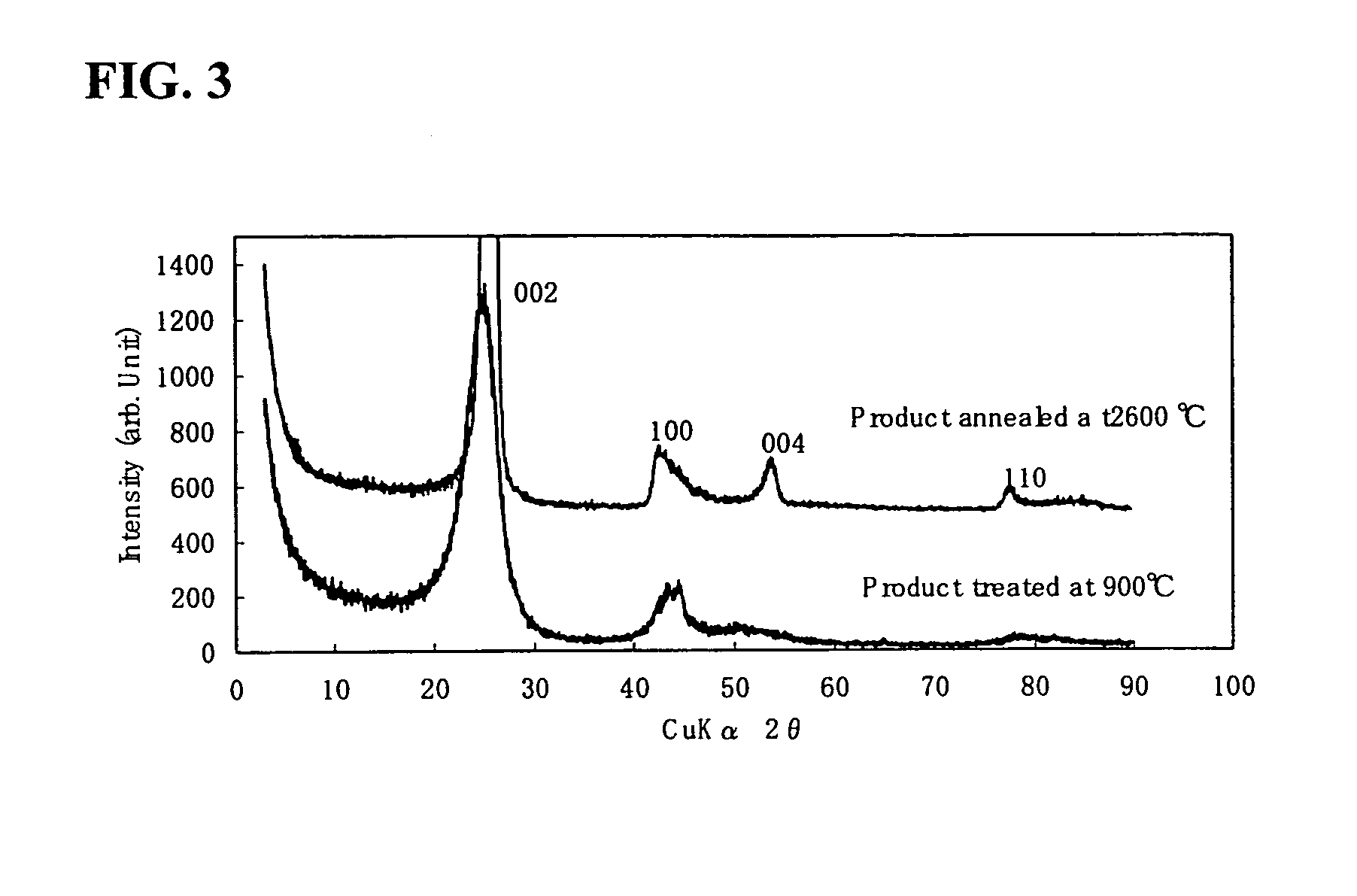

[0088] The second intermediate was further subjected to a high temperature heatin...

examples 1-9

[0091] The carbon fibrous structures obtained in Synthetic Example 1 was added to 100 parts by weight of polyurethane resin solution (non-volatile matter: 20%) at ratios shown in Table 1. The resultant mixture was pulverized and dispersed by using a bead mill (DYNO-MILL, manufactured by SHINMARU ENTERPRISES CORPORATION) with zirconium beads (0.05 mm, 0.5 mm, 1.0 mm, or 1.5 mm in diameter) at a peripheral speed of 10 m / sec, a bead filling rate of 80% by volume, and a processing time of 2 hrs. As a result, a coating composition comprising the carbon fibrous structures dispersed therein was prepared.

[0092] The liquid resinous composition obtained above was coated on a glass plate to obtain a hardened film of a prescribed thickness shown in Table 1. The hardened film was tested for coating ability, total light transmittance, and surface resistivity. The results obtained are shown in Table 1.

[0093] Furthermore, the dispersion condition of the carbon fibrous structures in the hardened c...

reference examples 1-6

[0094] To prepare the coating compositions of Reference Examples 1-6, the same procedure in Examples 1-9 was repeated except that the dispersion method and its condition were changed as shown in Table 1. Then, the same tests for coating ability, total light transmittance, and surface resistivity as in Examples 1-9 were performed. The results obtained are shown in Table 1.

Controls 1-4

[0095] Multilayered carbon nanotubes (manufactured by Tsinghua Nafine, 10-20 nm in outer diameter, several μm to several tens μm in length) were added to 100 parts by weight of a polyurethane resin solution (non-volatile matter: 20%) at ratios shown in Table 1. The resultant mixture was pulverized and dispersed by using a bead mill (DYNO-MILL, manufactured by SHINMARU ENTERPRISES CORPORATION) with zirconium beads (0.05 mm, or 1.5 mm in diameter) at a peripheral speed of 10 m / sec, a bead filling rate of 80% by volume, and a processing time of 2 hrs. As a result, a coating composition comprising the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com