Pulse detonation tool, method and system for formation fracturing

a technology of formation fracturing and detonation tool, which is applied in the direction of fluid removal, earth drilling and mining, borehole/well accessories, etc., can solve the problems of low permeability, slow or difficult production, and inability to meet the needs of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Embodiments of the present invention will be explained in further detail by making reference to the accompanying drawings, which do not limit the scope of the invention in any way.

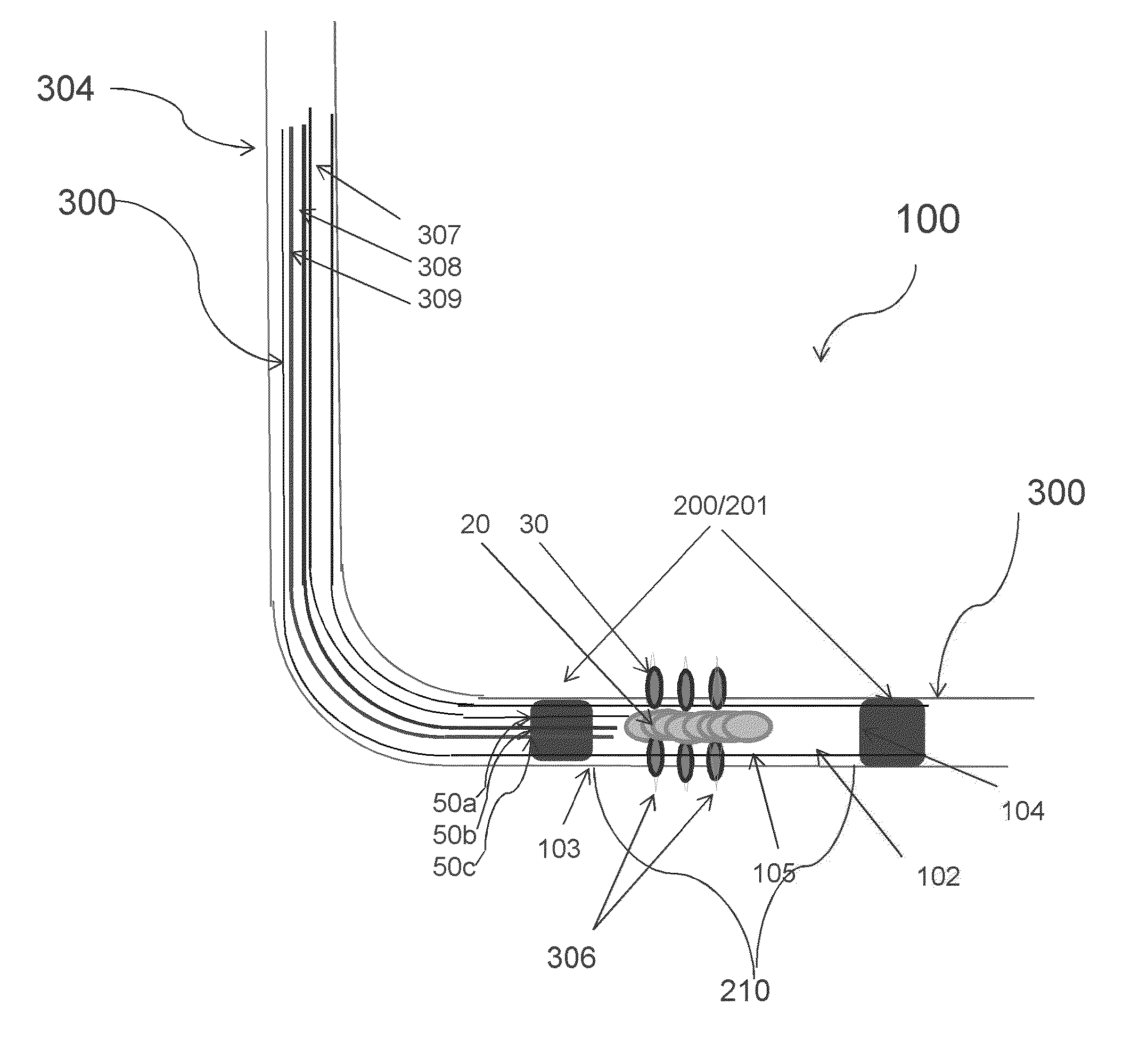

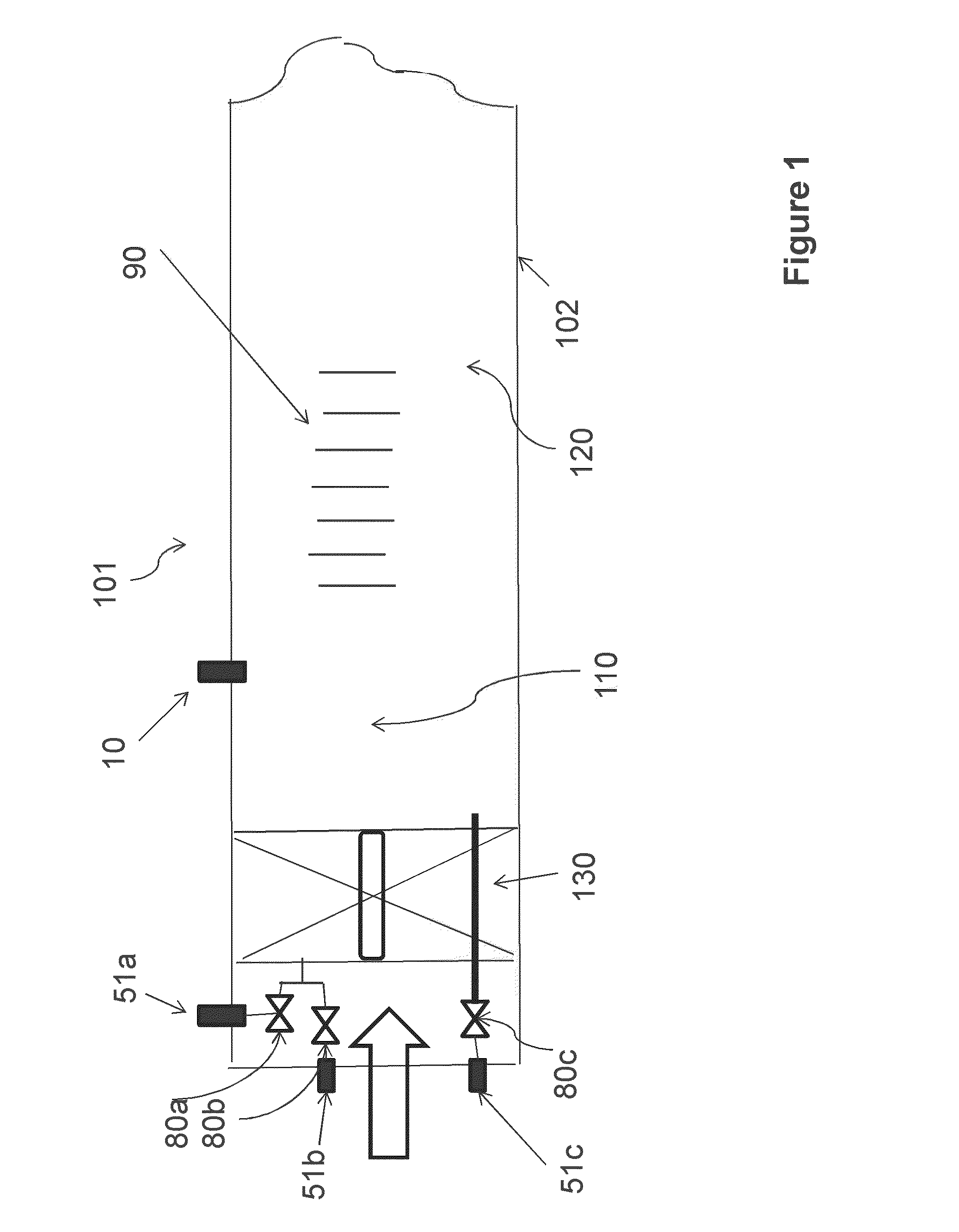

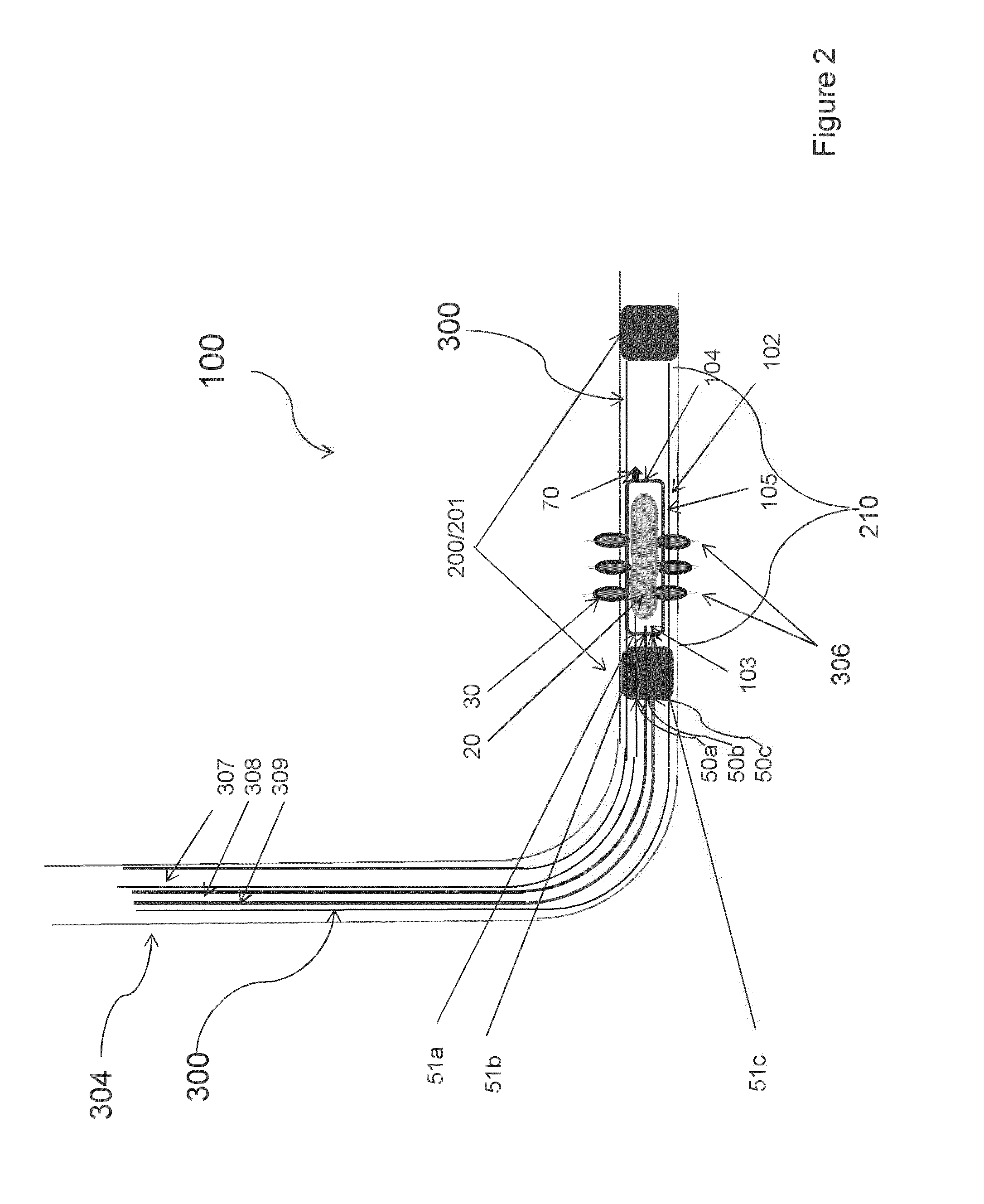

[0020]FIG. 1 depicts a cross-sectional side view of an illustrative pulse detonation tool 100, hereinafter referred to as “tool 100,” for formation fracturing according to various exemplary embodiments of the present invention. In FIG. 2, tool 100 is shown suspended within a wellbore 304 that should be understood as extending from ground level into a subterranean formation 305.

[0021]Turning now to FIG. 1 in which an embodiment of the present invention is depicted. In one or more embodiments, tool 100 contains at least one pulse detonation combustor 101. As used herein, a “pulse detonation combustor” PDC is understood to mean any device or system that produces both a pressure rise and velocity increase from a series of repeated detonations or quasi-detonations within the device. A “quasi-detonation” i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com