Pressure resistant emulsified explosive

An emulsified explosive and pressure-resistant technology, which is applied in explosives, explosive processing equipment, offensive equipment, etc., can solve the problems of lack of systematic investigation and analysis of abnormal blasting phenomena in coal mines, limited guidance, and inability to do so

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] The pressure-resistant secondary rock-type emulsion explosive is made of the following raw materials in parts by weight

[0088] Urea 3

[0089] water 10

[0090] Complex emulsifier 3

[0091] Composite oil phase 3.6

[0092] H foaming agent 0.12

[0093] Acetic acid 0.1.

[0094] Composite emulsifier is made up of sorbitan monooleate and polyisobutylene succinimide, and its parts by weight are:

[0095] Sorbitan Monooleate: 2, Polyisobutylene Succinimide: 1.

[0096] The composite oil phase is composed of paraffin, vaseline, and mechanical oil, and its parts by weight are:

[0097] Paraffin: 1.2, vaseline: 1.2, machine oil 1.2.

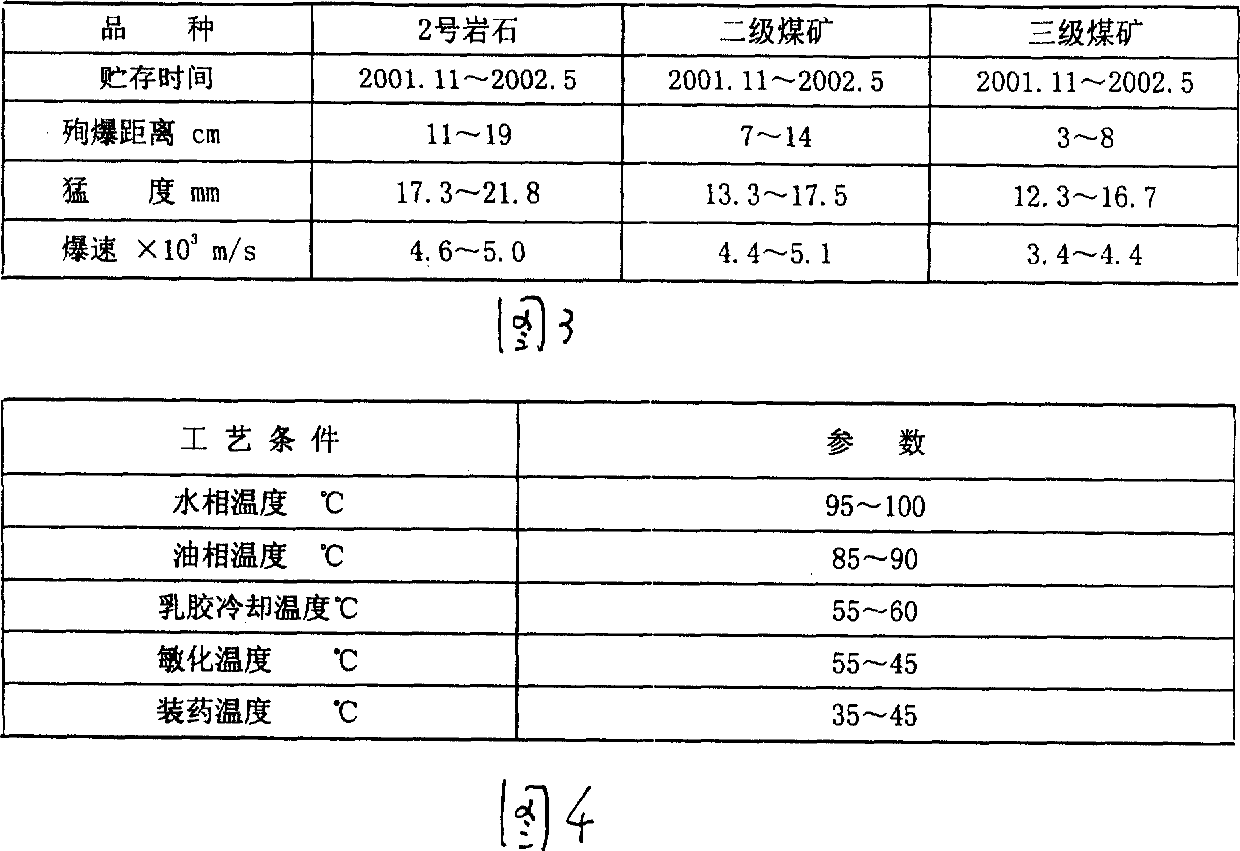

[0098] About the production method:

[0099] The preparation method of the emulsion explosive of the present invention is basically the same as the production process of the existing emulsion explosive, and will not be described in detail here, and the preparation process cond...

Embodiment 2

[0101] The pressure-resistant secondary rock emulsion explosive is made of the following raw materials in parts by weight

[0103] Sodium nitrate 10

[0104] Urea 1

[0105] water 9

[0106] Complex emulsifier 2.7

[0107] Composite oil phase 3.9

[0109] Phosphoric acid 0.1.

[0110] Composite emulsifier is made up of sorbitan monooleate and polyisobutylene succinimide, and its parts by weight are:

[0111] Sorbitan monooleate: 1.35, polyisobutylene succinimide: 1.35.

[0112] The composite oil phase is composed of paraffin, vaseline, and mechanical oil, and its parts by weight are:

Embodiment 3

[0115] The pressure-resistant secondary coal mine emulsion explosive is made of the following raw materials in parts by weight

[0116] Ammonium nitrate 65.4

[0117] Sodium nitrate 14

[0118] Urea 1

[0120]water 8

[0121] Complex emulsifier 3

[0122] Composite oil phase 3.6

[0123] H foaming agent 0.12

[0124] Sulfuric acid 0.1;

[0125] Composite emulsifier is made up of sorbitan monooleate and polyisobutylene succinimide, and its parts by weight are:

[0126] Sorbitan Monooleate: 2, Polyisobutylene Succinimide: 1.

[0127] The composite oil phase is composed of paraffin, vaseline, and mechanical oil, and its parts by weight are:

[0128] Paraffin: 1.2, vaseline: 1.2, machine oil 1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com