Method for preparing nanometer material@metal organic framework material

A technology of metal-organic frameworks and nanomaterials, which is applied in the field of composite materials and catalyst preparation, can solve the problems of difficult coating of nanoparticles and limited application range of MOFs, and achieve the effect of effective coating, widening application range and good packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

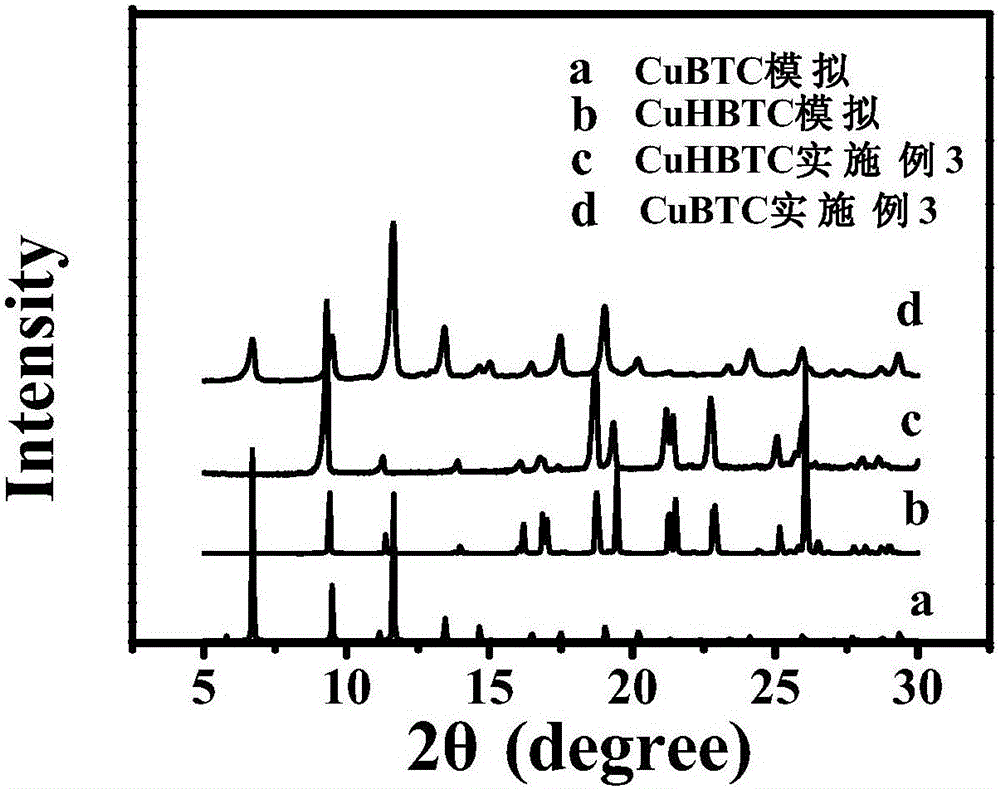

[0025] Embodiment 1: Preparation of metal-organic complex CuHBTC

[0026] Will be dissolved with 2g Cu(C 2 h 3 o 2 ) 2 ·H 2 O in 15ml deionized water and dissolved in 1g trimesic acid (H 3 BTC) in 15ml ethanol solution was mixed, stirred, reacted for 3h, filtered and dried to obtain CuHBTC.

Embodiment 2

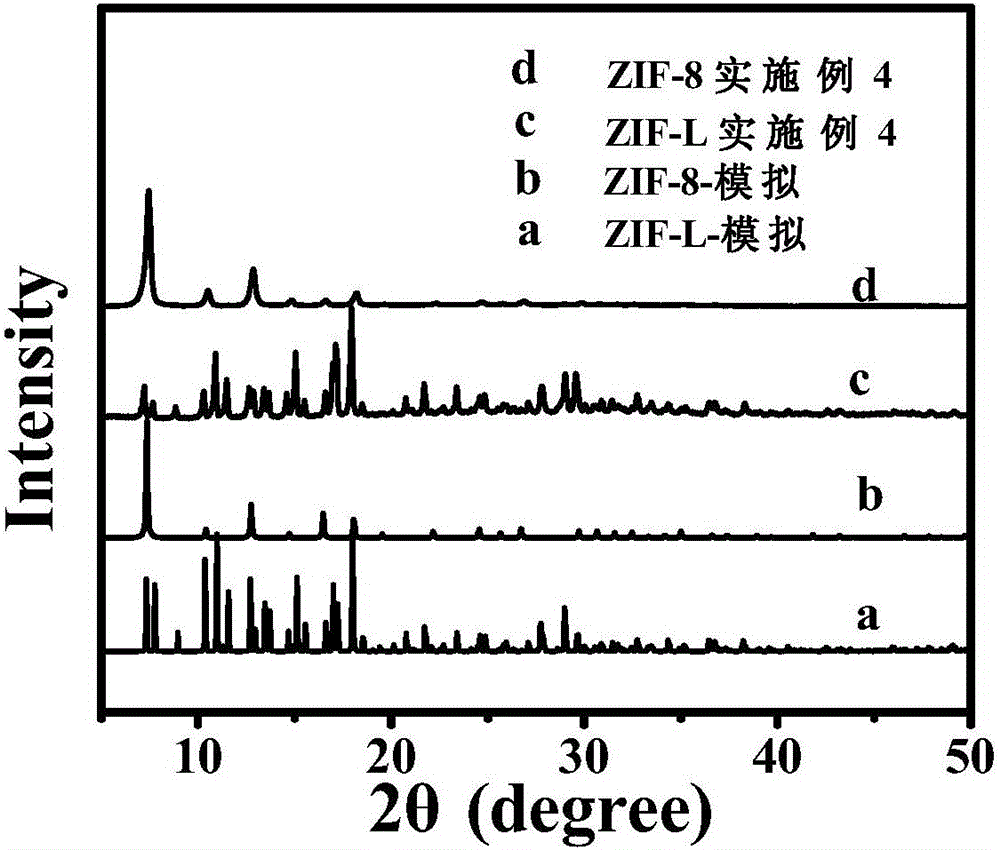

[0027] Embodiment 2: Preparation of metal-organic complex ZIF-L

[0028] Dissolve 0.059g of zinc nitrate hexahydrate and 0.13g of dimethylimidazole in 4ml of deionized water respectively, add 100μl of polyvinylpyrrolidone (molecular weight: 29000, 10mg / ml) to the aqueous solution of zinc nitrate hexahydrate, and sonicate for 1min After that, it was added into an aqueous solution of dimethylimidazole, stirred for 4 hours in an ice bath, centrifuged, washed with methanol three times, and dried to obtain ZIF-L.

Embodiment 3

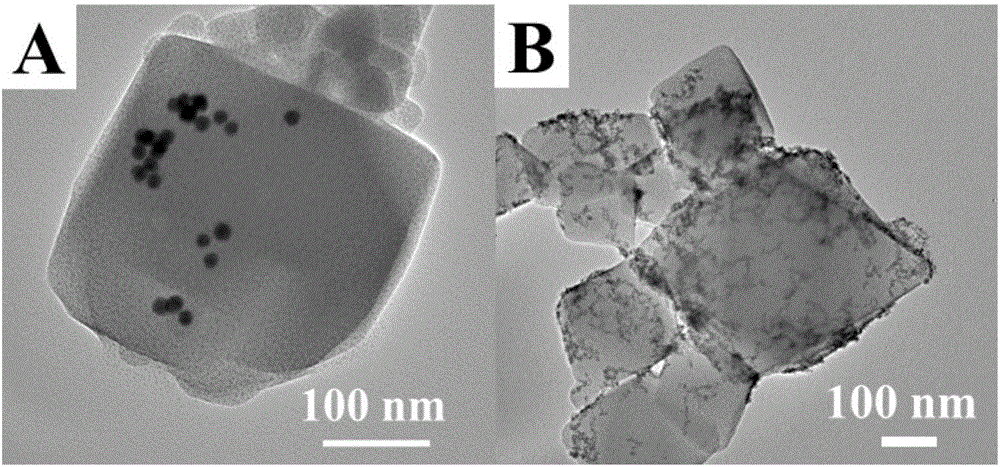

[0030] Weigh 0.02g of CuHBTC and disperse it in 5ml of deionized water, add dropwise 100μl of 2wt% 13nm Au solution pre-dispersed in N,N-dimethylformamide (DMF), stir at room temperature for 2h, and centrifuge to obtain a solid material. 3.6g / L solid-liquid ratio Add 5ml deionized water to the solid material, gradually drop 500μl N,N-dimethylformamide solution, react at room temperature for 2h, centrifuge, and dry to obtain Au@CuBTC composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com