Method and device for dissimilar metal friction-stir welding

A technology of friction stir welding and friction stir, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve problems such as poor welding effect, reduce the generation of intermetallic compounds, reduce welding stress, Avoid the effect of prefilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

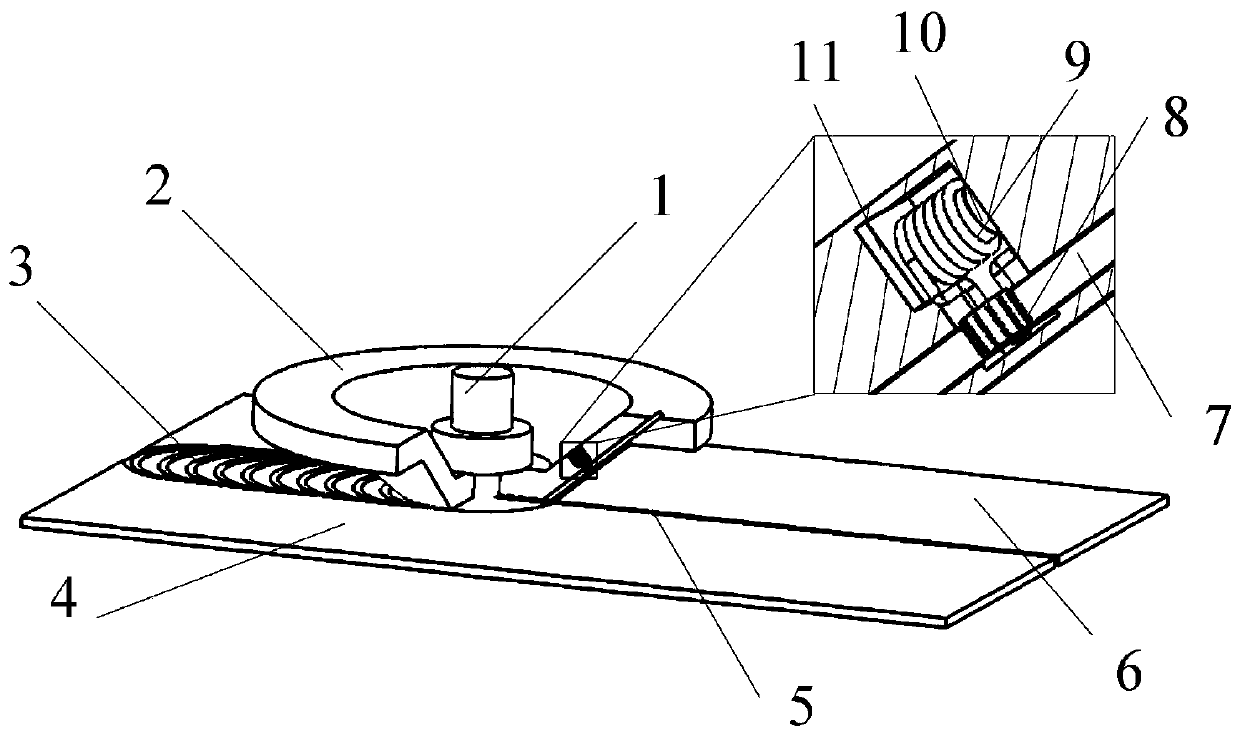

[0033] The friction stir welding method for dissimilar metals butt-filling static shaft shoulders in this embodiment specifically includes the following steps:

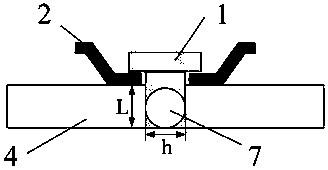

[0034] Step 1. Clamp the plate to be welded on the fixture of the friction stir welding machine, and reserve a wire filling gap between the two plates to be welded. When the welding wire is filled into the reserved gap, the welding wire is positioned and pressed by the static shoulder. , the thickness of the plate to be welded is L, and the reserved wire filling gap is h, h=0.1L.

[0035] Step 2: Install the stirring tool and the stationary shoulder, select a suitable welding wire according to the material of the plate to be welded, and send the welding wire to the reserved gap through the wire feed wheel in the stationary shoulder; a wire feeder is installed in the stationary shoulder The wire feeding mechanism sends the welding wire to the reserved gap before the stirring head arrives, and presses the welding wire i...

Embodiment 2

[0040] The friction stir welding method for dissimilar metals butt-filling static shaft shoulders in this embodiment specifically includes the following steps:

[0041] Step 1. Clamp the plate to be welded on the fixture of the friction stir welding machine, and reserve a wire filling gap between the two plates to be welded. When the welding wire is filled into the reserved gap, the welding wire is positioned and pressed by the static shoulder. The thickness of the plate to be welded is L, and the reserved wire filling gap is h, h=1.5L.

[0042] Step 2: Install the stirring tool and the stationary shoulder, select a suitable welding wire according to the material of the plate to be welded, and send the welding wire to the reserved gap through the wire feed wheel in the stationary shoulder; a wire feeder is installed in the stationary shoulder The wire feeding mechanism sends the welding wire to the reserved gap before the stirring head arrives, and presses the welding wire int...

Embodiment 3

[0047] The friction stir welding method for dissimilar metals butt-filling static shaft shoulders in this embodiment specifically includes the following steps:

[0048] Step 1. Clamp the plate to be welded on the fixture of the friction stir welding machine, and reserve a wire filling gap between the two plates to be welded. When the welding wire is filled into the reserved gap, the welding wire is positioned and pressed by the static shoulder. The thickness of the plate to be welded is L, and the reserved wire filling gap is h, h=L.

[0049] Step 2: Install the stirring tool and the stationary shoulder, select a suitable welding wire according to the material of the plate to be welded, and send the welding wire to the reserved gap through the wire feed wheel in the stationary shoulder; a wire feeder is installed in the stationary shoulder The wire feeding mechanism sends the welding wire to the reserved gap before the stirring head arrives, and presses the welding wire into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com