Cross-linked syndiotactic polypropylene foam and preparation method and application thereof

A polypropylene foam, polypropylene technology, applied in the field of plastic processing, can solve the problems of reduced foaming ratio, no fluidity, low melt strength, etc., and achieves low foaming difficulty, easy foaming, and improved melt strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

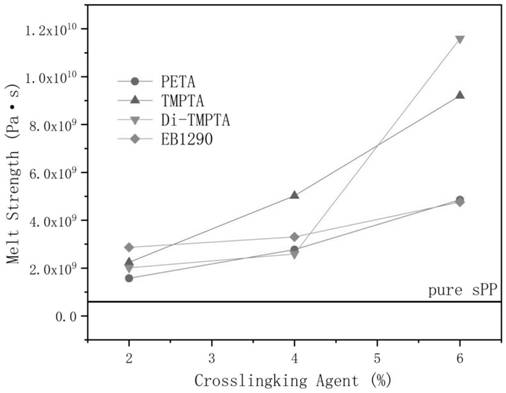

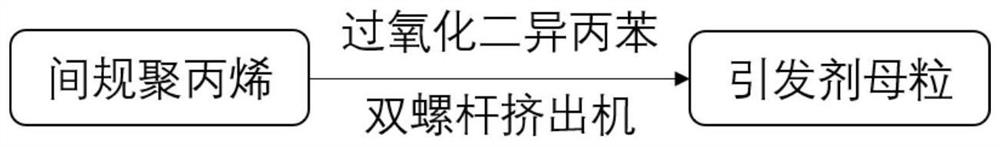

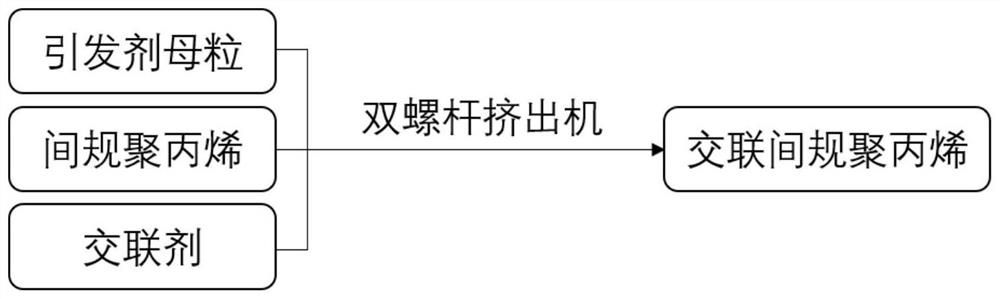

[0031] refer to Figure 1 to Figure 3 , according to the preparation method of the cross-linked syndiotactic polypropylene foam of the present invention comprises the following steps: (1) prepare initiator masterbatch for cross-linking: extrude the syndiotactic polypropylene together with the initiator in a twin-screw extruder Obtaining initiator masterbatch; (2) preparing crosslinked syndiotactic polypropylene: extruding syndiotactic polypropylene together with initiator masterbatch and crosslinking agent in a twin-screw extruder to obtain crosslinked syndiotactic polypropylene; (3) Preparation of cross-linked syndiotactic polypropylene foam: Extrude and foam the cross-linked syndiotactic polypropylene and foaming agent masterbatch in a single-screw extruder to obtain cross-linked syndiotactic polypropylene foam. In step (1), the mass fraction of the initiator is 1%, and the rest is syndiotactic polypropylene. In step (1) and step (2), initiator is dicumyl peroxide. In the ...

Embodiment 1

[0037] Extrude 49.5g of syndiotactic polypropylene and 0.5g of dicumyl peroxide in a miniature conical twin-screw extruder to obtain initiator master batches. At 120°C, extrude 40g of the above-mentioned initiator masterbatch, 336g of syndiotactic polypropylene and 24g of Di-TMPTA in a micro-conical twin-screw extruder to obtain cross-linked syndiotactic polypropylene, and the temperature of each section is 180 ℃, 185℃, 180℃, 350g of the above-mentioned syndiotactic polypropylene and 17.5g of AC foaming agent masterbatch were extruded and foamed in the single-screw extruder module of the Harp rheometer, using a sheet die, each The heating section temperatures were 100°C, 150°C, and 215°C, respectively, and the die head temperature was 130°C to prepare crosslinked syndiotactic polypropylene foam with an expansion ratio of about 2.06.

Embodiment 2

[0039] Extrude 49.5g of syndiotactic polypropylene and 0.5g of dicumyl peroxide in a miniature conical twin-screw extruder to obtain initiator master batches. Extrude 20g of the above-mentioned initiator masterbatch, 168g of syndiotactic polypropylene and 12g of Di-TMPTA in a micro-conical twin-screw extruder at 125°C to obtain cross-linked syndiotactic polypropylene, and the temperature of each section is 180 ℃, 185℃, 180℃, 150g of the above-mentioned syndiotactic polypropylene and 15g of AC foaming agent masterbatch were extruded and foamed in the single-screw extruder module of the Harp Rheometer, using a sheet die, each heating The section temperatures were 100°C, 150°C, and 215°C, respectively, and the die head temperature was 130°C to prepare a cross-linked syndiotactic polypropylene foam with an expansion ratio of about 2.25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com