Aqueous polyurethane paint and preparation method and application thereof

A technology of water-based polyurethane and coatings, which is applied in the field of coatings and can solve the problems of inability to repair, poor water resistance, poor wear resistance, high VOC content, etc., and achieve the effects of prolonging the shelf life, low surface energy of coatings, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In any embodiment, the preparation method at least includes the following steps:

[0041] (1) Take each component according to the above-mentioned raw material ratio;

[0042] (2) the deionized water of described 40-60wt%, the pH adjusting agent of 40-60wt%, dispersant, the antifoaming agent of 40-60wt%, nano-alumina, nano-zirconia, nano-zinc oxide, flame retardant Agent, silica sol, organic silicone powder, negative ion powder, carry out mixing treatment, obtain the first mixing;

[0043] (3) Add the remaining deionized water, water-based hydroxyacrylic acid emulsion, film-forming aid, remaining pH regulator, modified silicone glass resin, remaining defoamer, substrate wetting agent under stirring conditions, and then Carrying out mixing treatment to obtain the second mixing material;

[0044] (4) Mix the first mixed material with the second mixed material, disperse, add a thickener, stir, adjust the viscosity to pass, and obtain A component;

[0045] (5) Dissolving t...

Embodiment 1

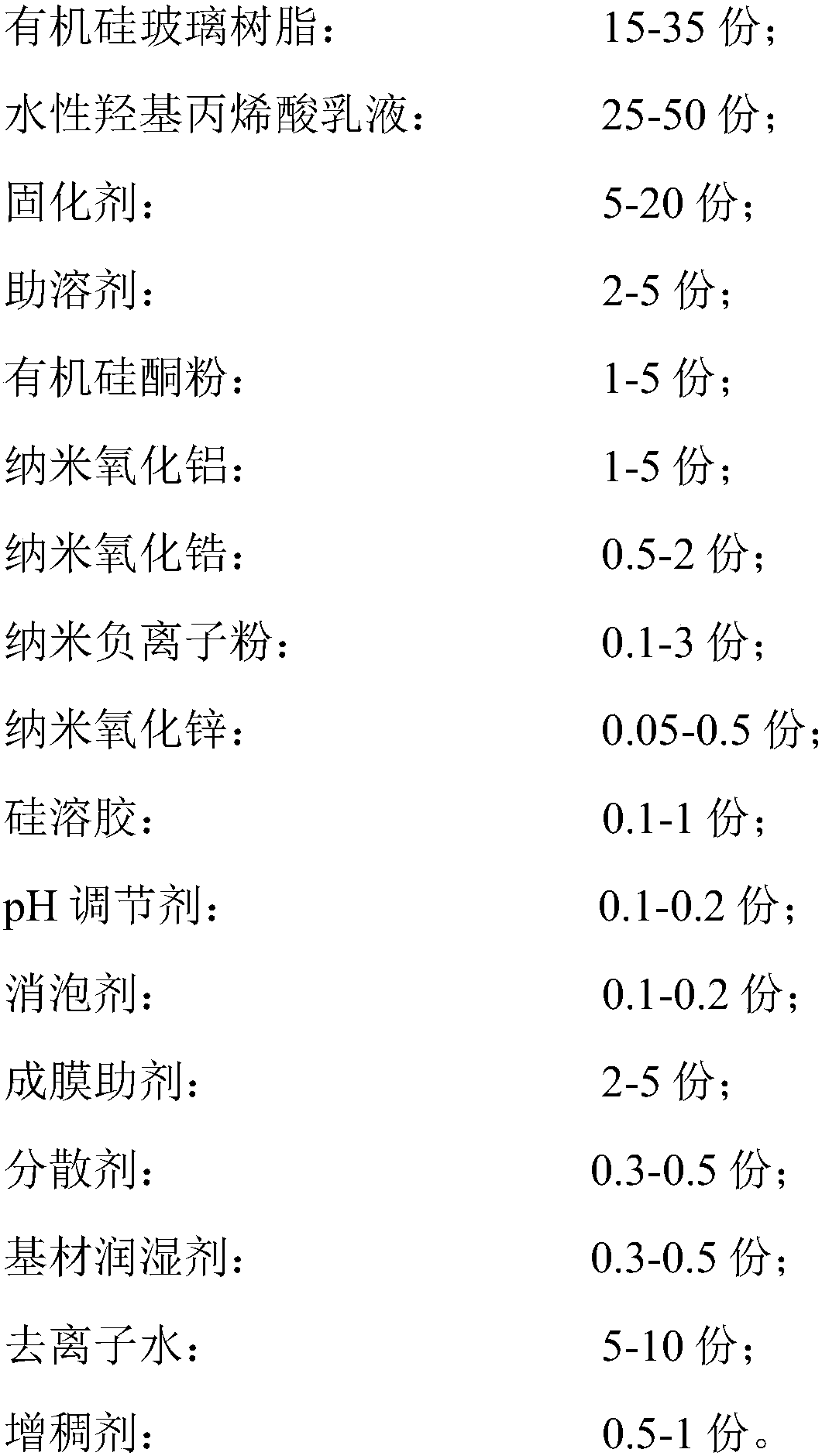

[0058] The present embodiment provides a kind of water-based polyurethane coating, and described coating comprises the following components in parts by weight:

[0059]

[0060] The silicone glass resin is selected from the SJ-35 self-drying silicone resin of Sanjin Pigment Co., Ltd.; the water-based hydroxyl acrylic emulsion is Bayhydrol A 2695 of Bayer; the curing agent is Bayhydur XP2547 of Bayer; The film-forming aid is (Guangzhou Yutai Chemical Technology Co., Ltd.) propylene glycol phenyl ethers and alcohol ester-12 film-forming aid (Eastman, U.S.) with a mass ratio of 1:1; Propylene glycol methyl ether acetate; the organic silicone powder is BT-9273 silicone powder of Guangzhou Batai Chemical Co., Ltd.; the nano-alumina is selected from Nanjing Baokete New Materials; the nano-zirconia is selected from Nanjing The TGP-M100 of Tianxing New Material Co., Ltd.; the nano-zinc oxide is selected from Nantong Daxinong Nano Technology Co., Ltd.; the nano-anion powder is the T...

Embodiment 2

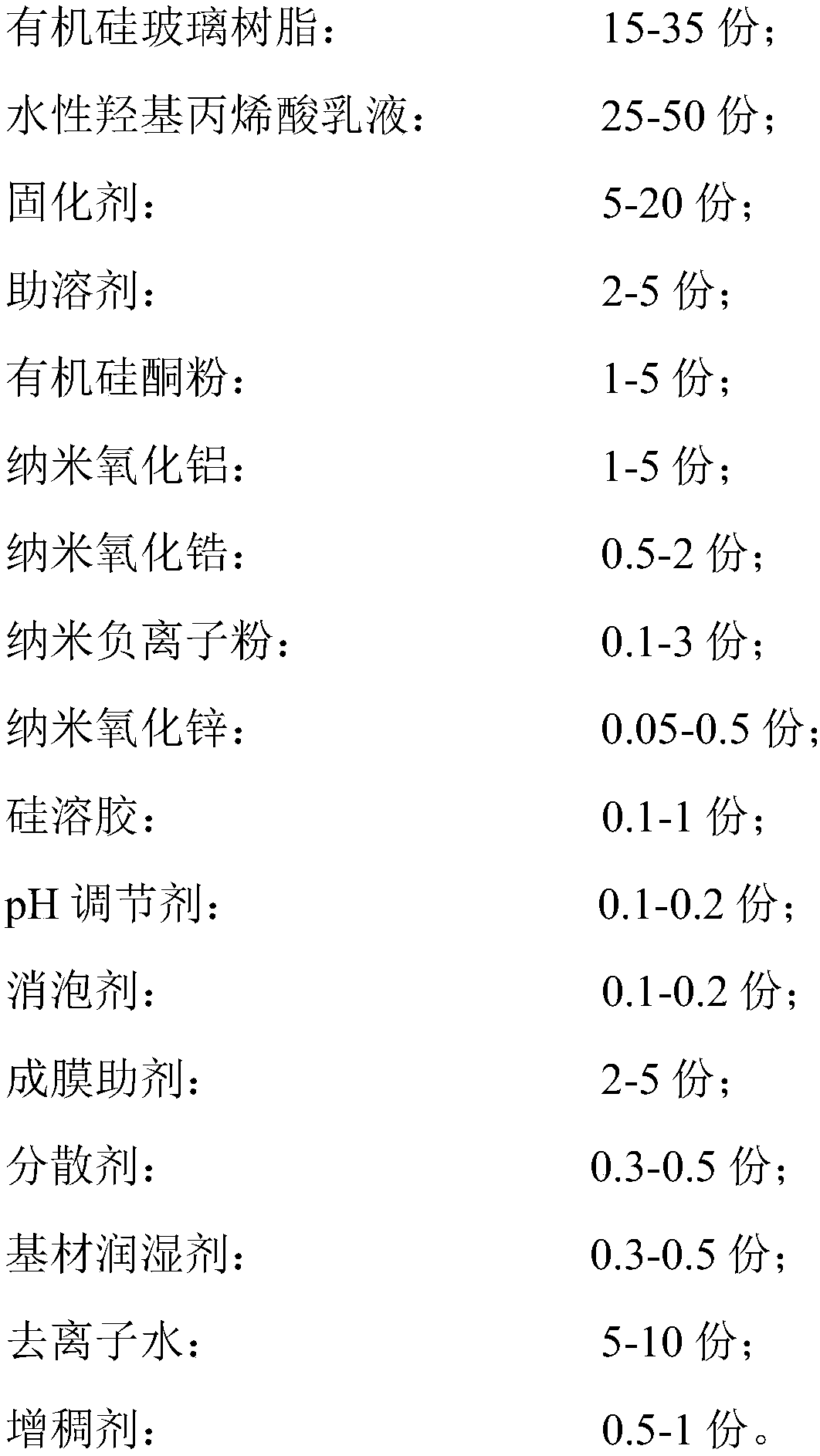

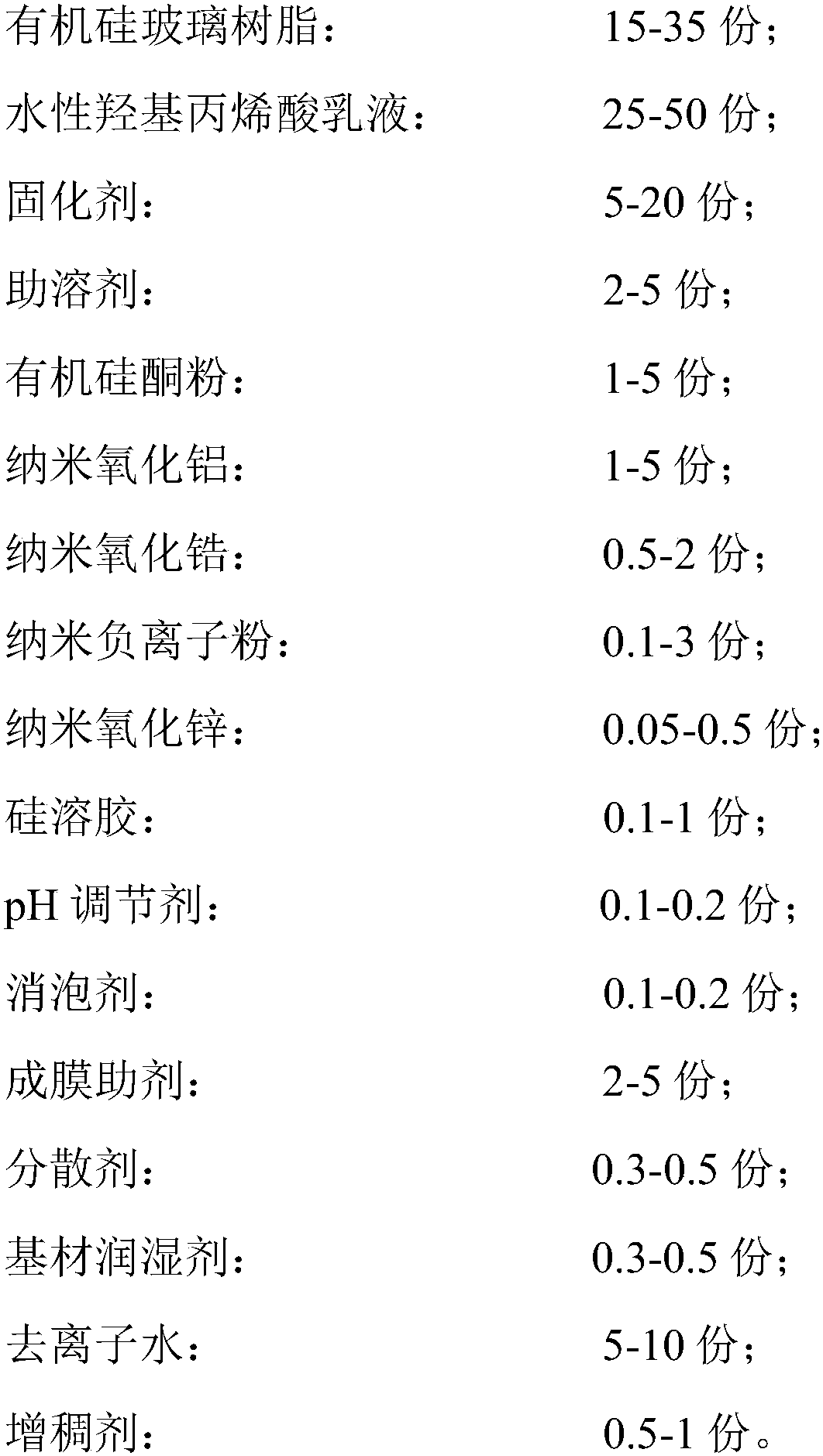

[0068] The present embodiment provides a kind of water-based polyurethane coating, and described coating comprises the following components in parts by weight:

[0069]

[0070]

[0071] The silicone glass resin is selected from the SJ-35 self-drying silicone resin of Sanjin Pigment Co., Ltd.; the water-based hydroxyl acrylic emulsion is Bayhydrol A 2695 of Bayer; the curing agent is Bayhydur XP2547 of Bayer; The film-forming aid is (Guangzhou Yutai Chemical Technology Co., Ltd.) propylene glycol phenyl ethers and alcohol ester-12 film-forming aid (Eastman, U.S.) with a mass ratio of 1:2; Propylene glycol methyl ether acetate; the organic silicone powder is BT-9273 silicone powder of Guangzhou Batai Chemical Co., Ltd.; the nano-alumina is selected from Nanjing Baokete New Materials; the nano-zirconia is selected from Nanjing The TGP-M100 of Tianxing New Material Co., Ltd.; the nano-zinc oxide is selected from Nantong Daxinong Nano Technology Co., Ltd.; the nano-anion pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com