Patents

Literature

54results about How to "Suitable for mass production operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370AImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneSheet steel

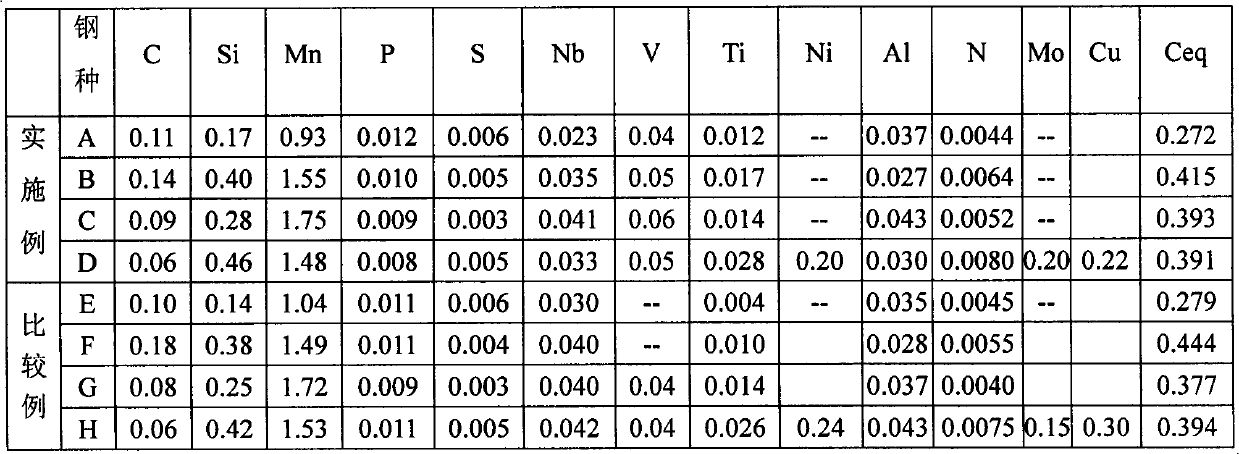

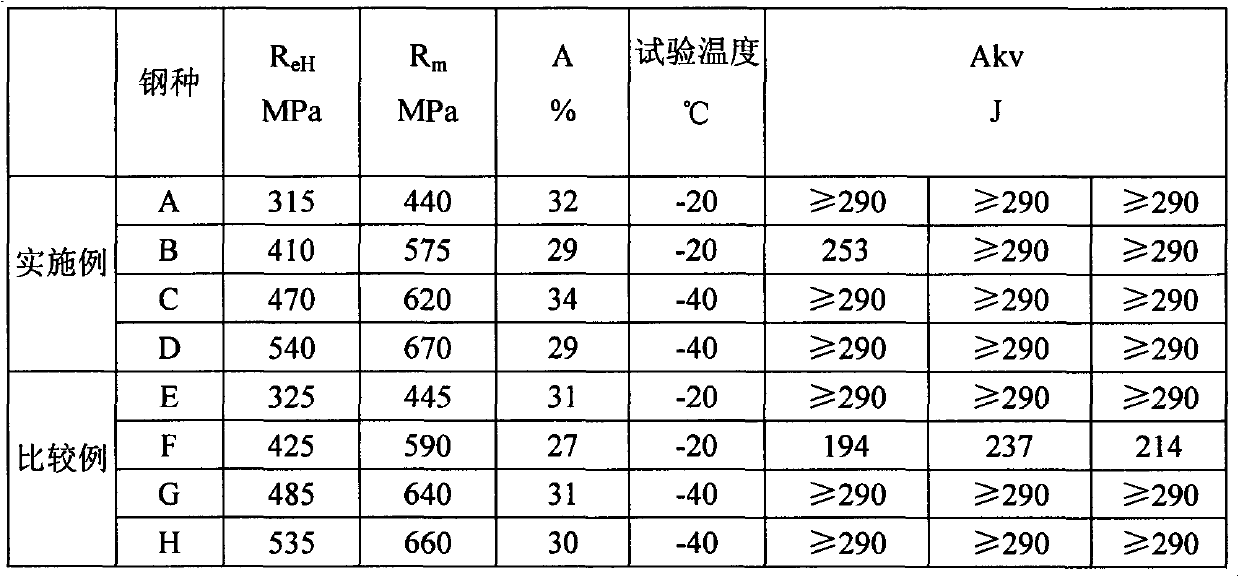

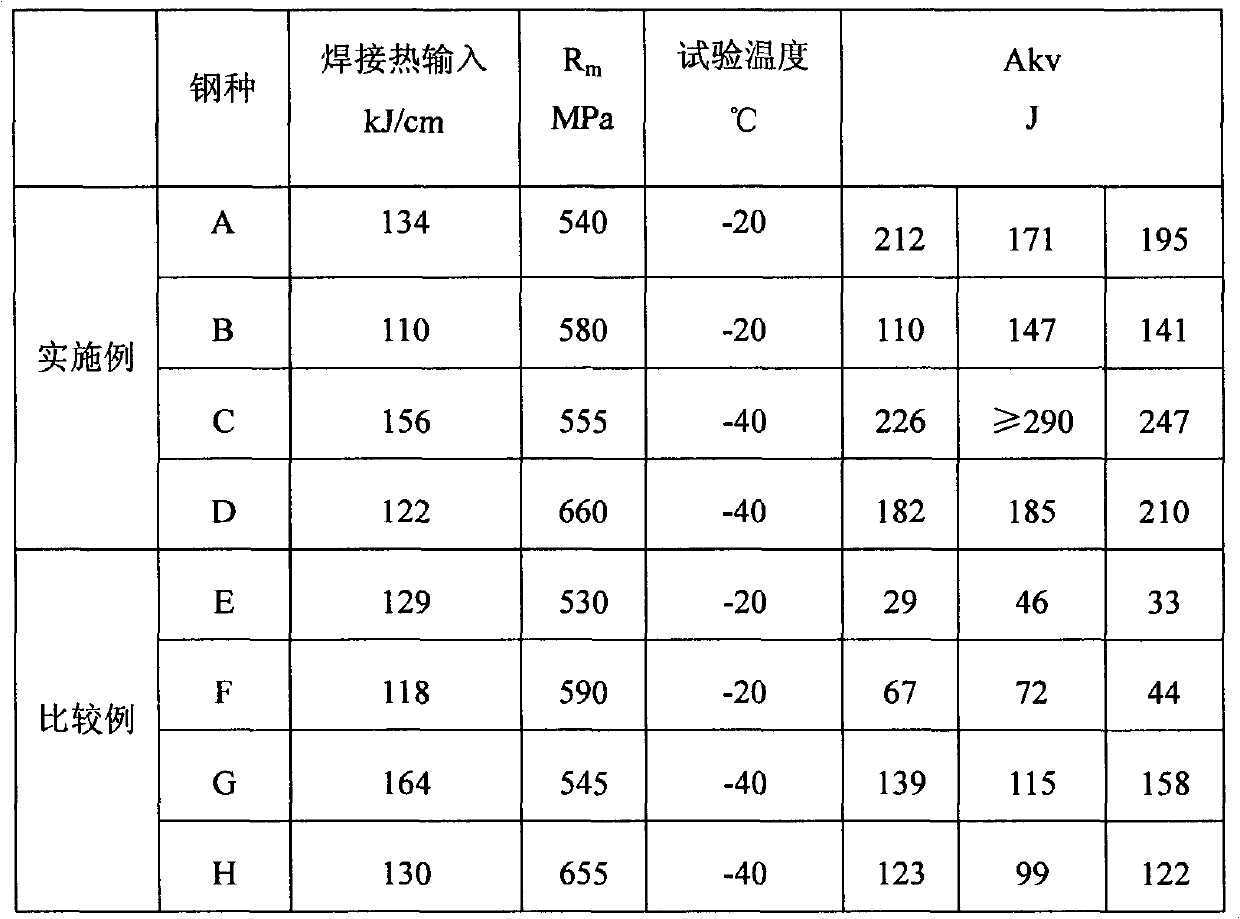

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

Hull structural steel adapting to high heat input welding and smelting method thereof

The invention discloses hull structural steel adapting to high heat input welding, which comprises the following chemical components in percentage by mass: 0.06 to 0.14 percent of C, 0.10 to 0.50 percent of Si, 0.80 to 1.80 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.008 percent of S, 0.020 to 0.050 percent of Nb, 0.006 to 0.030 percent of Ti, 0.0030 to 0.0100 percent of N, 0.015 to 0.045 percent of Al, 0.03 to 0.10 percent of V and the balance of Fe and inevitable impurities. The hull structural steel has the process characteristics that: the Ti is conveyed in a mode of steel wires formed by wrapping alloy powder by steel belts, and the addition process of the Ti is synchronous with the casting process, so that the alloying is more uniform, generated TiN mass points are finer and more dispersed, and the capacity of inhibiting grain growth is higher; and the production process is simple and convenient, and the method is suitable for batch production. When steel plates produced by the smelting method are subjected to high heat input welding under the condition of more than 50 kJ / cm, the toughness of welding heat affected zones is high.

Owner:ANGANG STEEL CO LTD

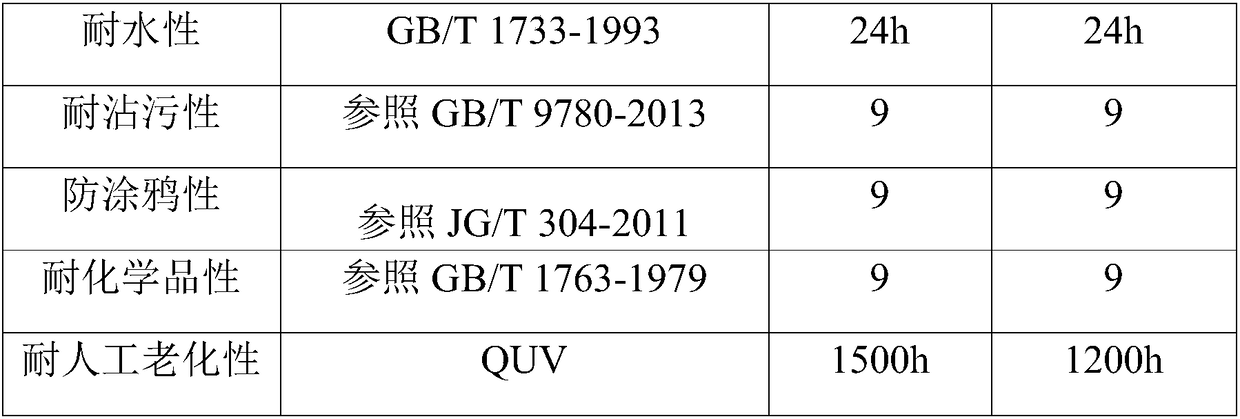

Anti-doodle anti-contamination bottom-universal aqueous woodenware white paint and preparation method thereof

InactiveCN108485421AImprove stain resistanceGood chemical resistanceAntifouling/underwater paintsPaints with biocidesSolventContamination

The invention relates to the technical field of paint, and concretely discloses anti-doodle anti-contamination bottom-universal aqueous woodenware white paint and a preparation method thereof. The aqueous woodenware white paint comprises the following components by mass percentage: 40-50% of an aqueous acrylic acid emulsion, 8-12% of an aqueous polyurethane dispersion, 0.3-0.5% of a base materialwetting agent, 0.4-0.6% of an antifoaming agent, 13-18% of deionized water, 1-3% of an environmental protection solvent, 3-5% of a wax emulsion, 1-2% of a thickening agent, 0.3-0.5% of a levelling agent, 0.5-0.8% of an anti-doodling auxiliary agent, 0.5-1% of an organosilicon surface auxiliary agent, 0.5-1% of a dispersant, and 18-20% of titanium dioxide. The aqueous woodenware white paint has high hardness, and excellent contamination resistance and doodle resistance, and a paint film has the advantages of fast drying speed, high glossiness, excellent chemical resistance, and artificial agingresistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Aqueous epoxy zinc-rich priming paint and preparation method thereof

InactiveCN108690456AGood dispersionWell mixedAnti-corrosive paintsEpoxy resin coatingsEpoxyGas phase

The invention relates to the technical field of a paint, and concretely discloses an aqueous epoxy zinc-rich priming paint and a preparation method thereof. The priming paint comprises the following raw materials in parts by weight: 10-30 parts of epoxy resin, 0.1-0.5 parts of a wetting dispersant, 0.1-0.5 parts of an antifoaming agent, 1-5 parts of a film-forming auxiliary agent, 40-70 parts of sheet zinc dust, 4-20 parts of spherical zinc dust, 0-25 parts of ferrophosphorous powder, 0.2-2 parts of graphene oxide, 0.2-2 parts of gas-phase silica, 0.1-0.5 parts of a flash rust-prevention agent, 10-30 parts of a curing agent, 0.1-1 part of magnesium lithium silicate, and 5-10 parts of deionized water. The two-component aqueous epoxy zinc-rich priming paint employs a component A and a component B, the construction is simple, the VOC content is low, the hardness is high, adhesive force, impact resistance and sag resistance are excellent, the anti-settling performance is good, the storageperformance of the priming paint is increased, and the anti-salt spray performance is excellent.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

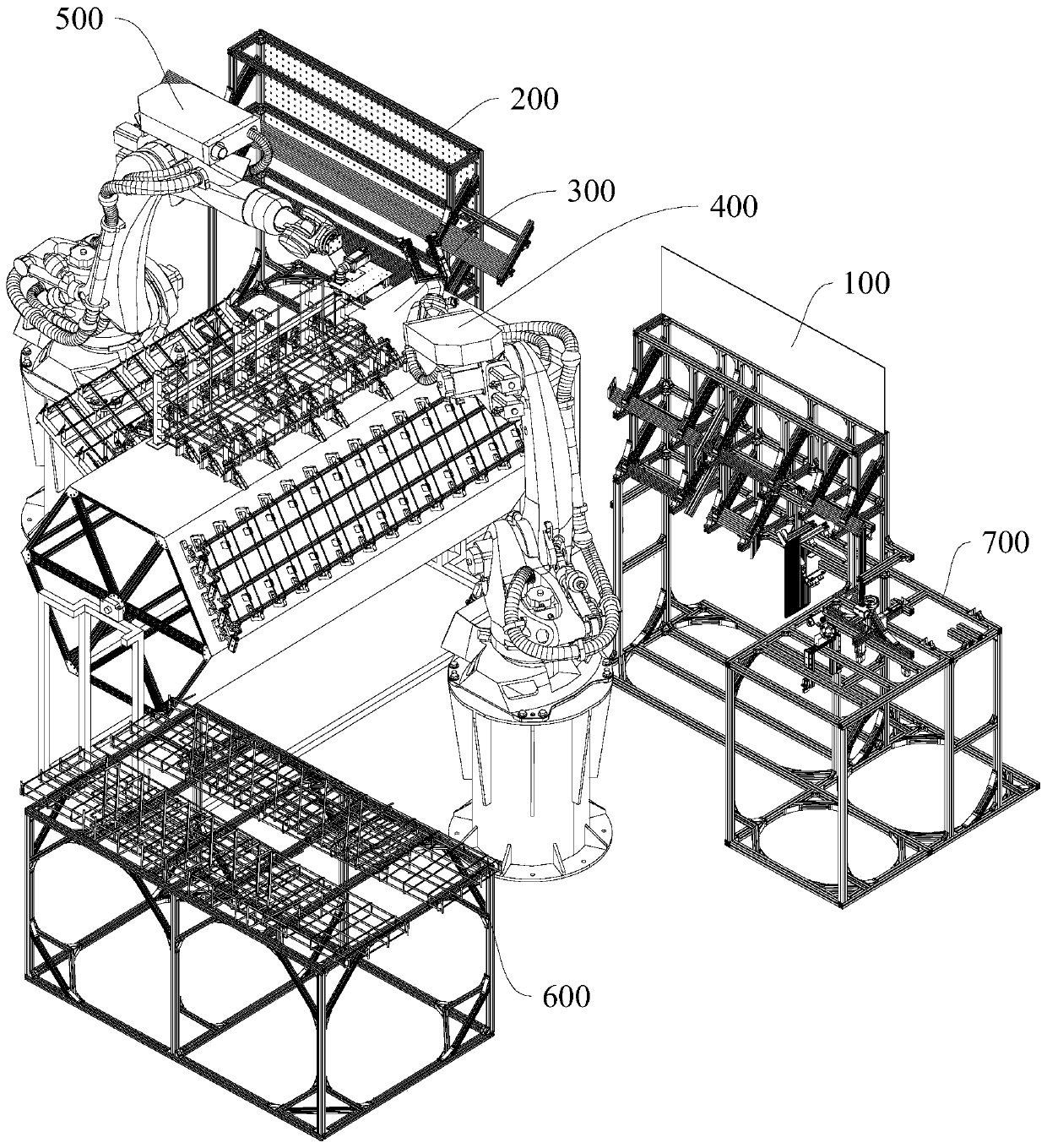

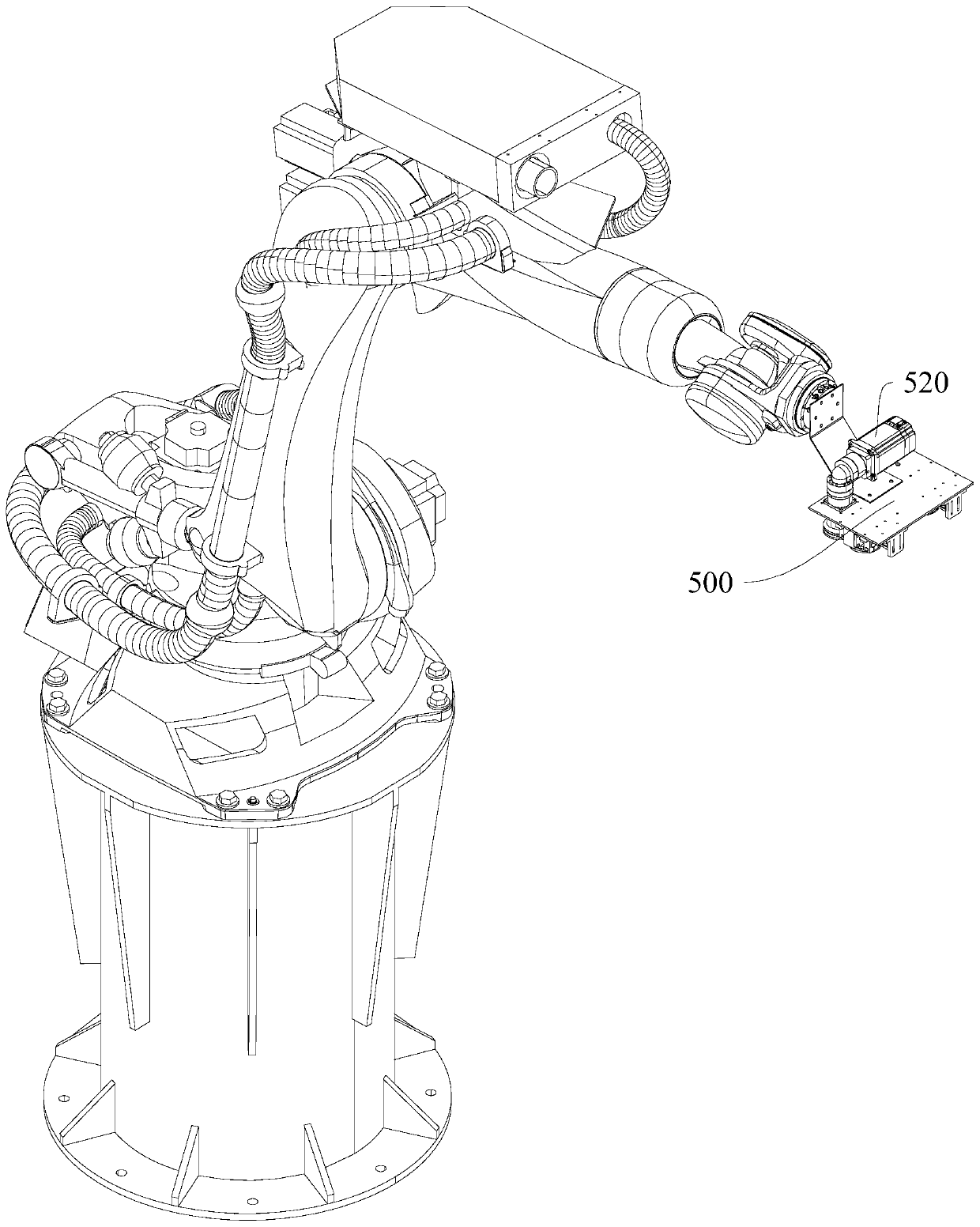

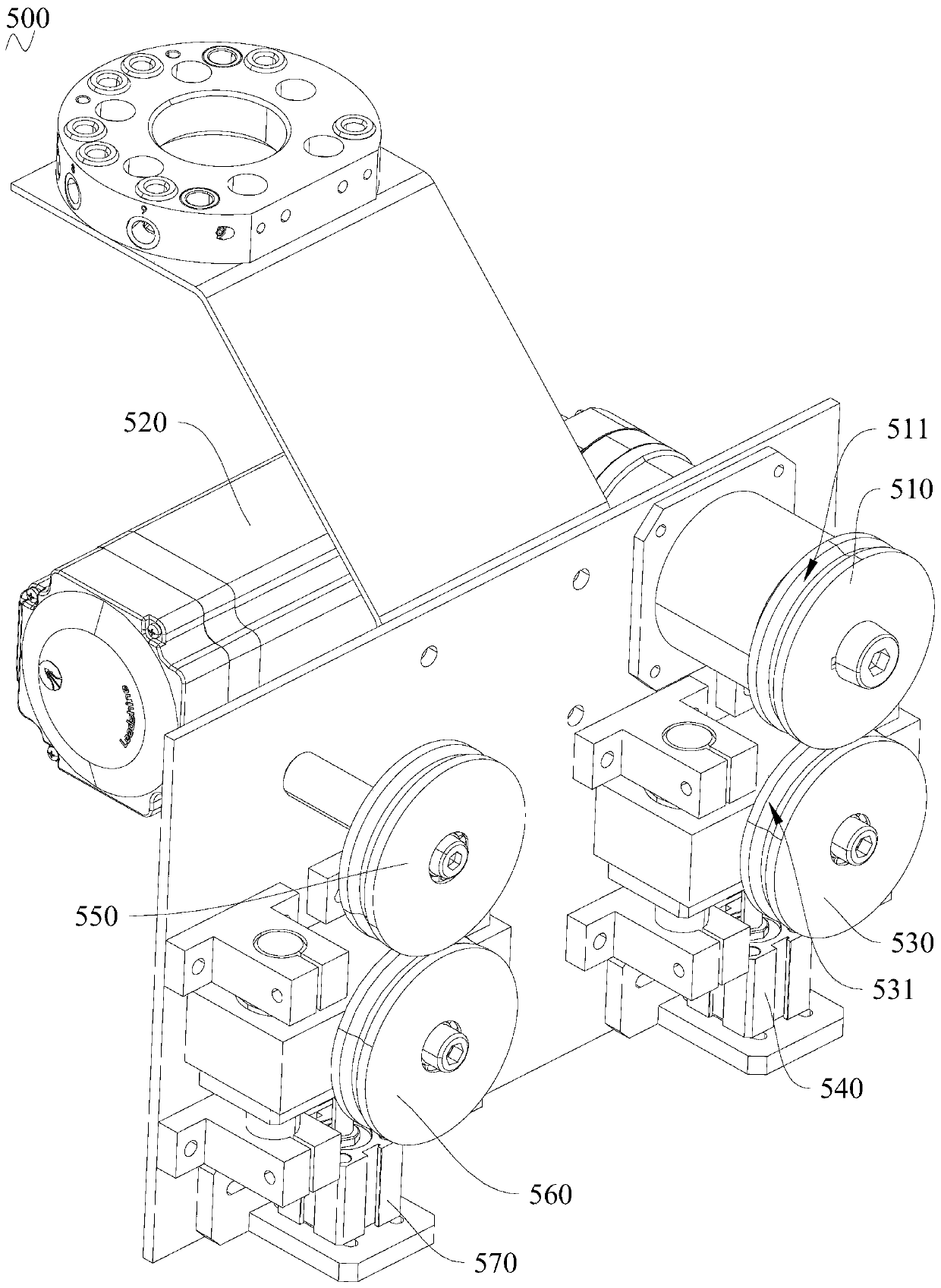

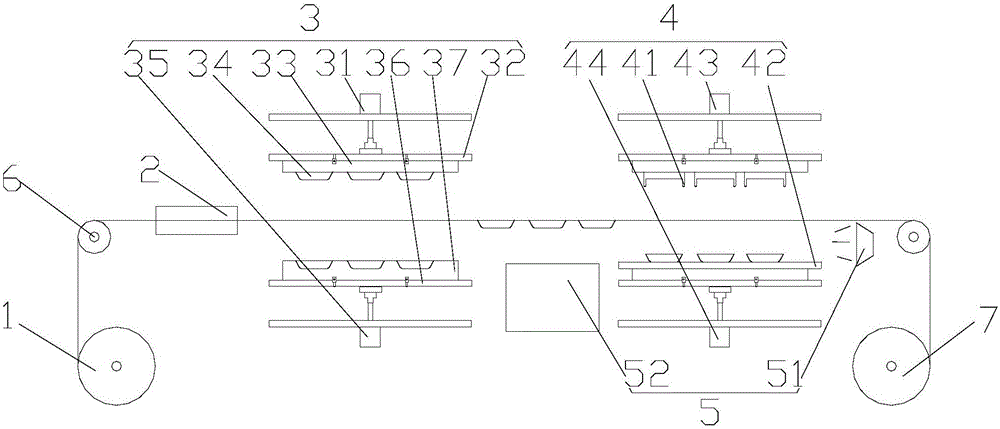

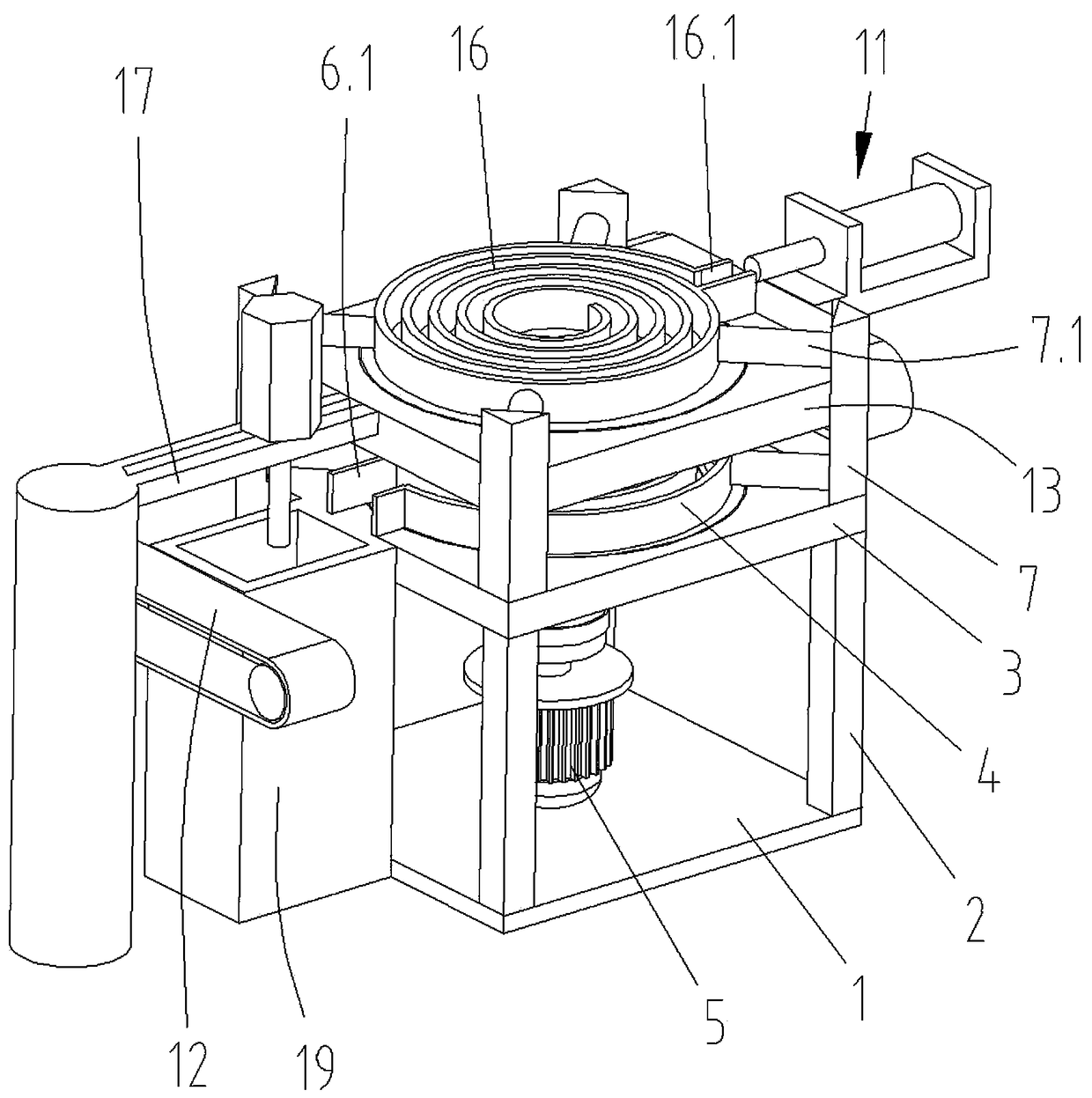

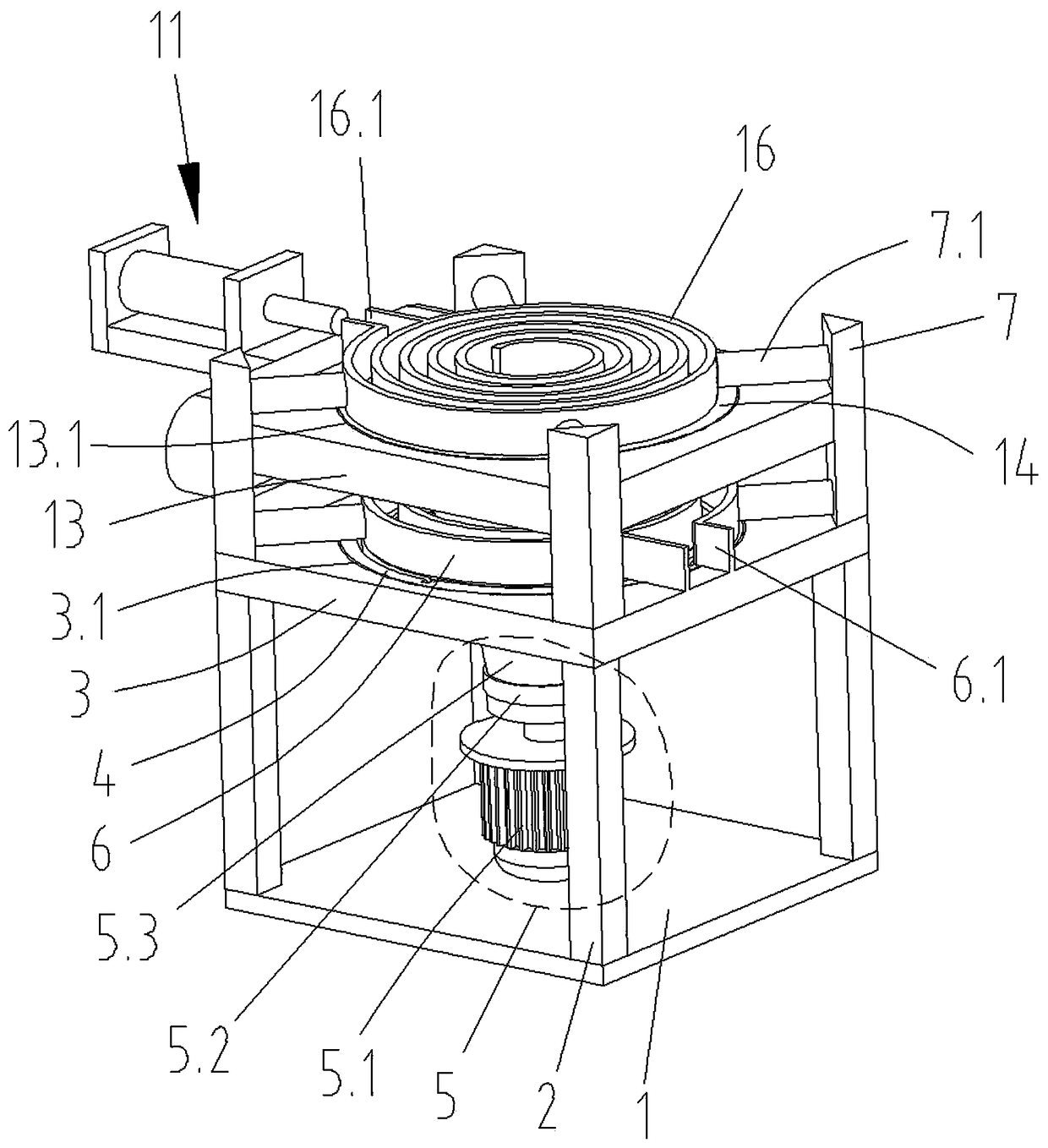

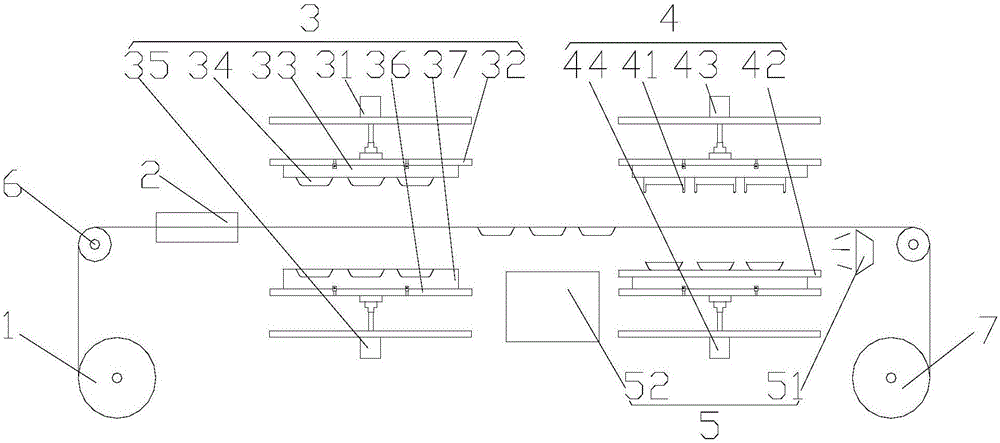

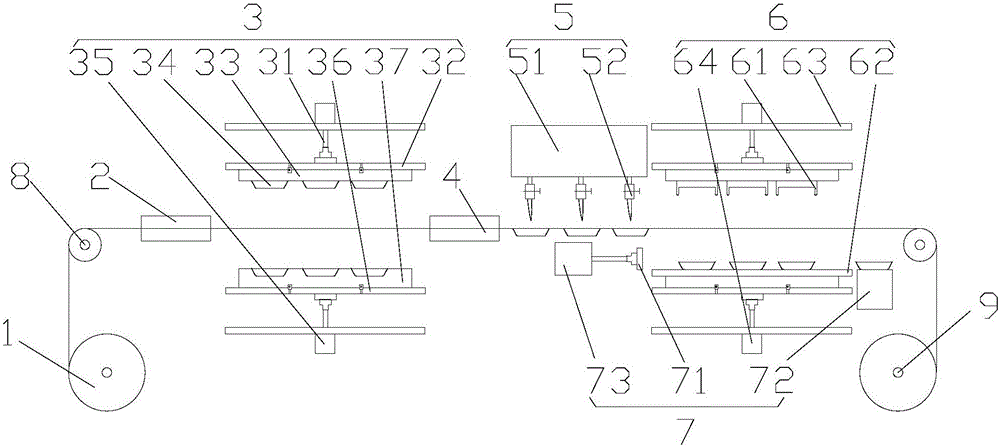

Steel reinforcement cage production line

PendingCN110814232AImprove production efficiencySuitable for mass production operationsWire networkDrive wheelStructural engineering

The invention relates to the technical field of manufacturing of steel reinforcement cages, and provides a steel reinforcement cage production line. The steel reinforcement cage production line comprises a stirrup shelf, a longitudinal bar shelf, a rotary tool assembly, a stirrup clamping robot, a longitudinal bar clamping robot and a steel reinforcement binding robot, wherein the longitudinal barclamping robot comprises a driving wheel, an active driving assembly used for driving a driving wheel to do rotary motion around a first axis, a main pressing wheel and a main press driving assemblyused for driving the main pressing wheel to move in a first direction. The outer wheel surface of the driving wheel and the outer wheel surface of the main pressing wheel can be used for clamping a longitudinal bar together, the longitudinal bar clamping robot clamps the longitudinal bar at a longitudinal bar placement position and moves the longitudinal bar to a longitudinal bar conveying position, and the driving wheel drives the longitudinal bar to penetrate through stirrups in a second direction in sequence from the longitudinal bar conveying position and fixes the longitudinal bar to a longitudinal bar clamp. The steel reinforcement cage production line can be used producing steel reinforcement cages of different specifications and dimensions, the automatic level is high, operation issimple, the steel reinforcement cage manufacturing efficiency is high, and the steel reinforcement cage production line is suitable for large-scaled production work of the steel reinforcement cages.

Owner:CHINA CONSTR SCI & TECH CO LTD

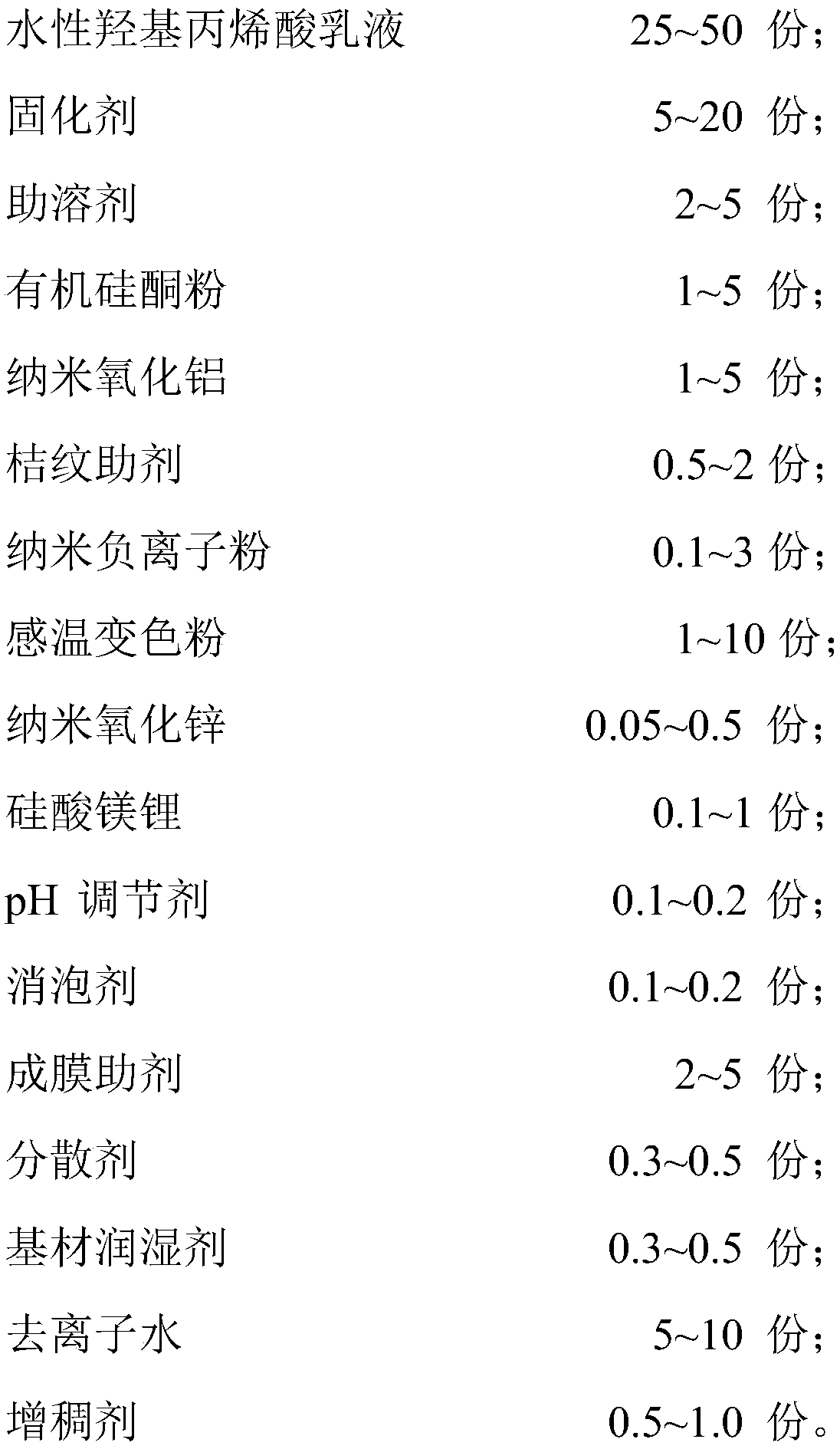

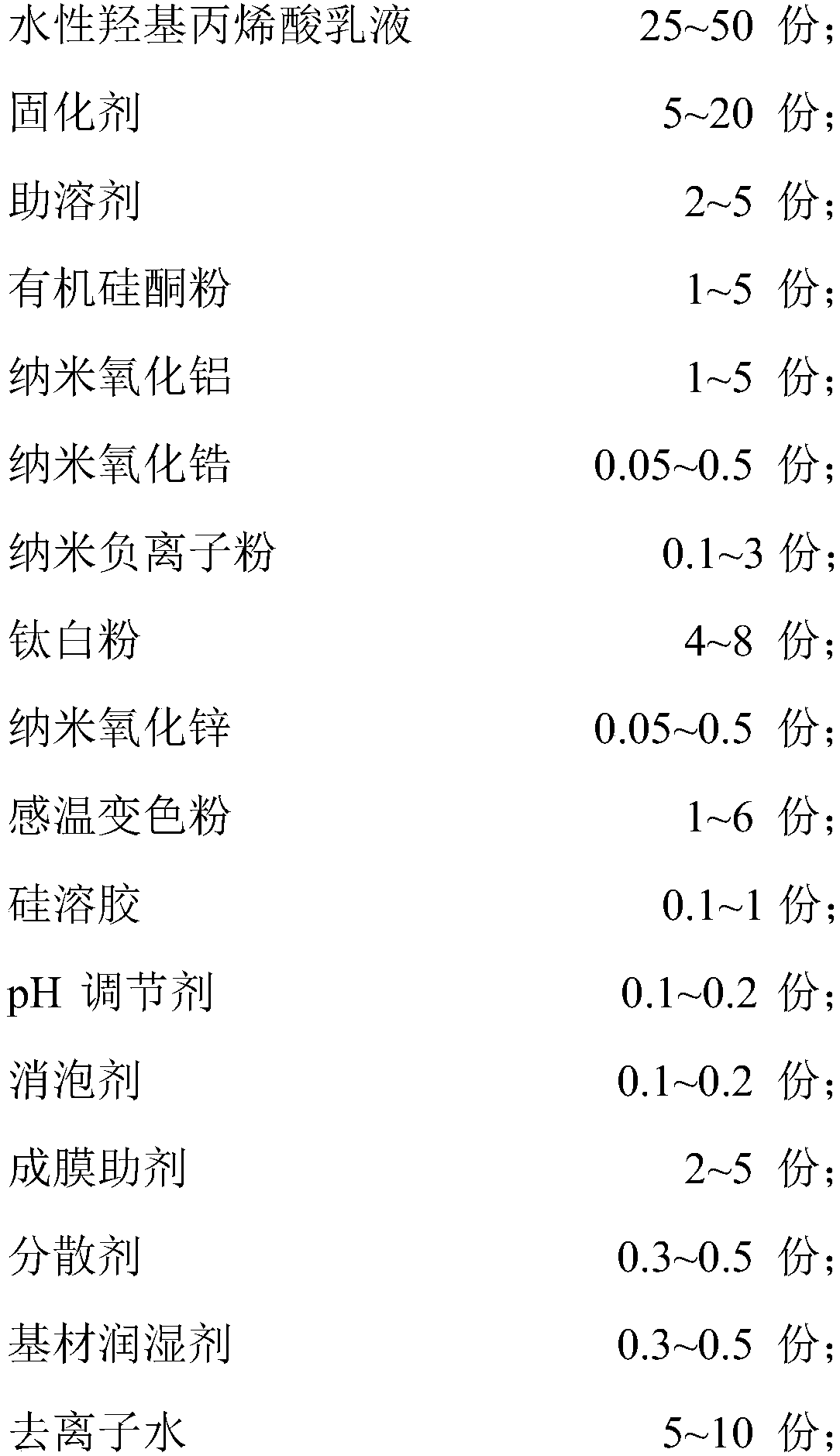

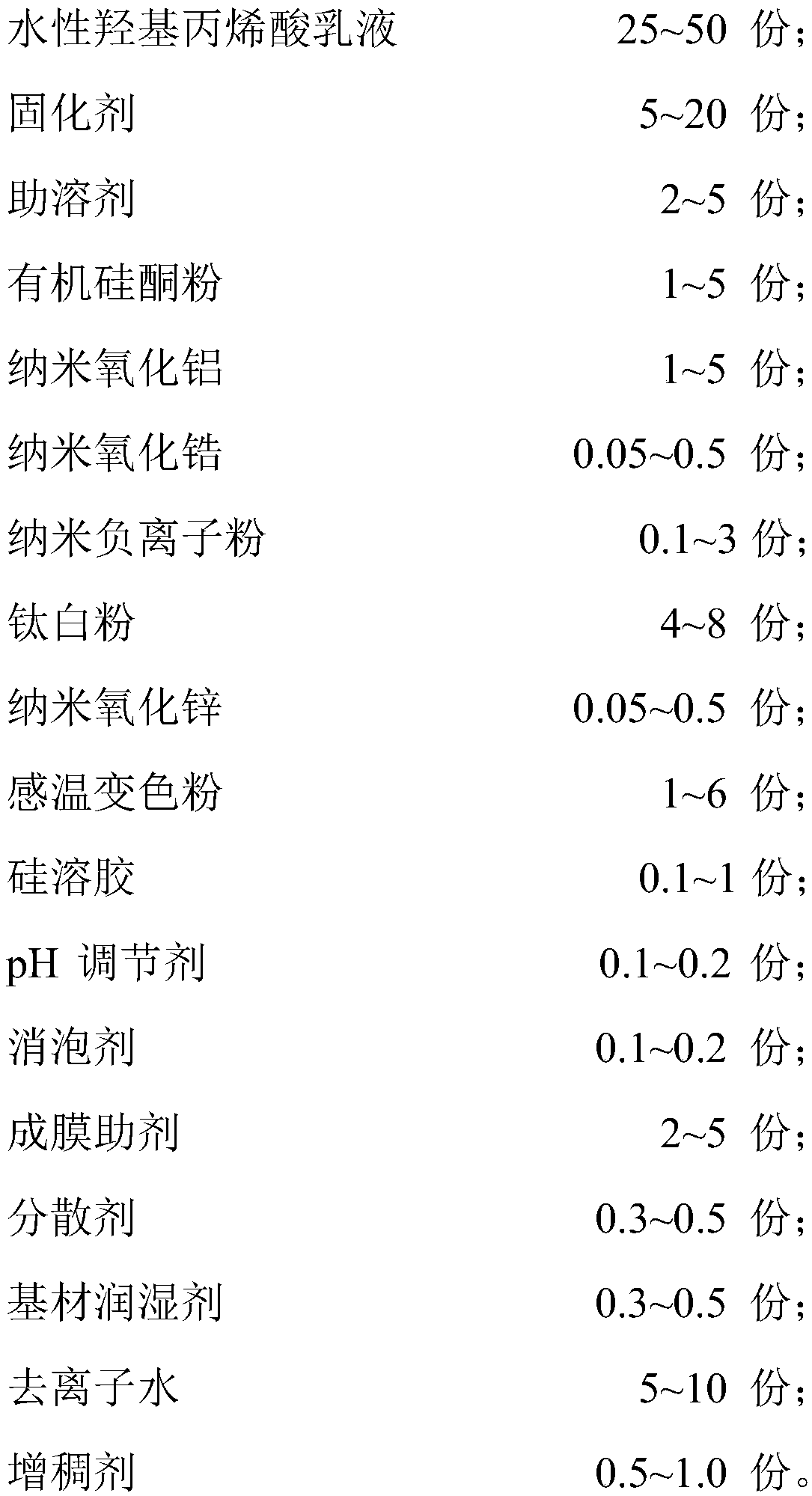

Aqueous three-dimensional effect color changing orange-peel coating material, preparation method and applications thereof

InactiveCN108753076AGood light fastnessGood chemical resistanceAntifouling/underwater paintsPaints with biocidesNano al2o3Color changes

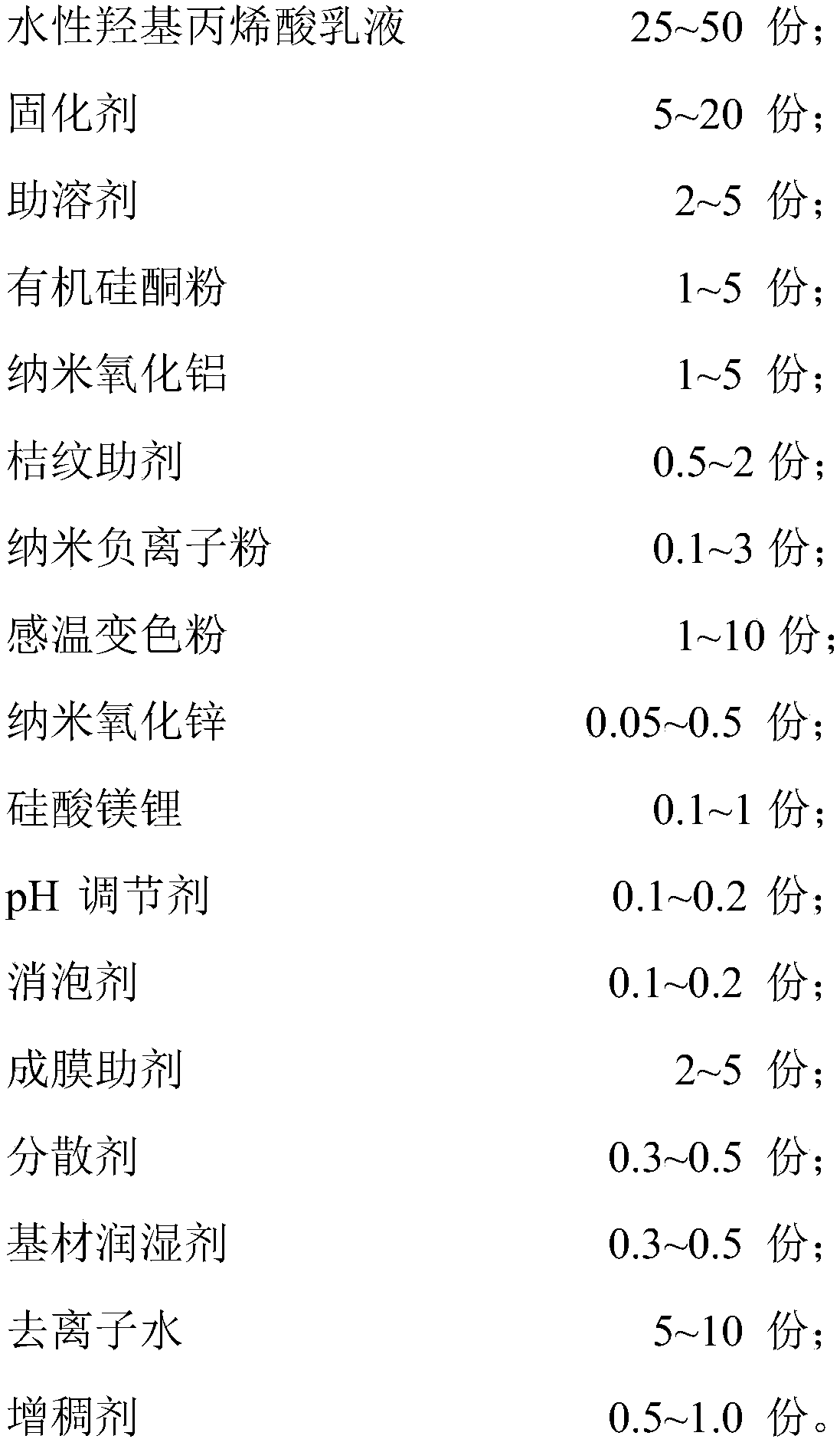

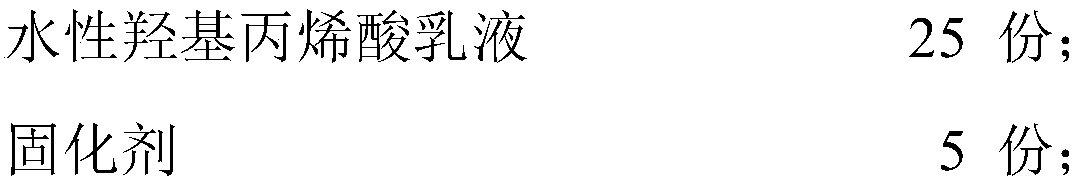

The invention relates to an aqueous three-dimensional effect color changing orange-peel coating material, a preparation method and applications thereof, wherein the aqueous three-dimensional effect color changing orange-peel coating material comprises the following raw materials by weight: 25-50 parts of an aqueous hydroxy acrylic emulsion, 5-20 parts of a curing agent, 2-5 parts of a cosolvent, 1-5 parts of organic silicone powder, 1-5 parts of nanometer alumina, 0.5-2 parts of an orange-peel auxiliary agent, 0.1-3 parts of nanometer negative ion powder, 1-10 parts of thermochromic powder, 0.05-0.5 part of nanometer zinc oxide, 0.1-1 part of lithium magnesium silicate, 0.1-0.2 part of a pH value adjuster, 0.1-0.2 part of an antifoaming agent, 2-5 parts of a film forming aid, 0.3-0.5 partof a dispersant, 0.3-0.5 part of a base material wetting agent, 5-10 parts of deionized water, and 0.5-1.0 part of a thickener. According to the present invention, the obtained coating material has low VOCs content, and the coating has advantages of good light resistance, good chemical resistance, good hardness, good antibacterial property, good air purification performance, good discoloration indication and three-dimensional orange-peel effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

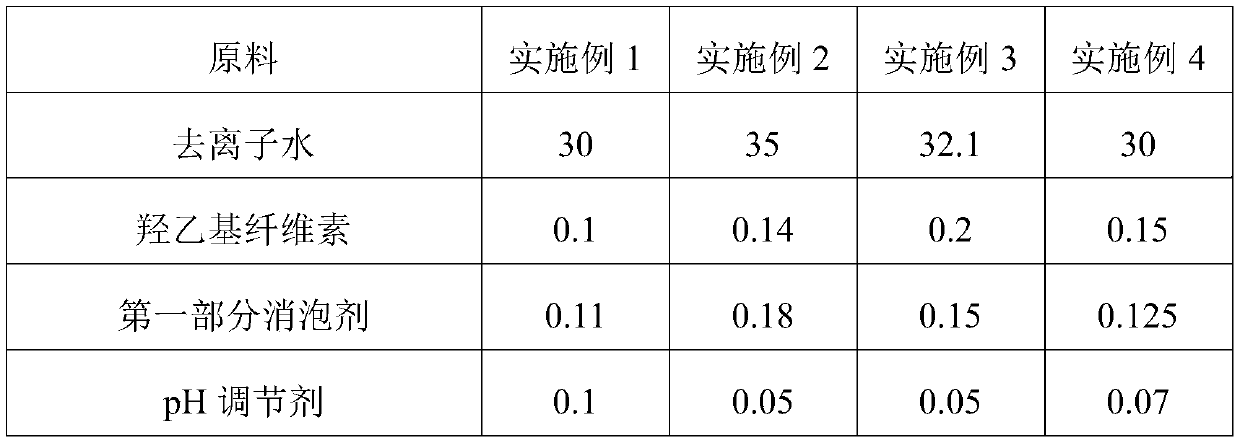

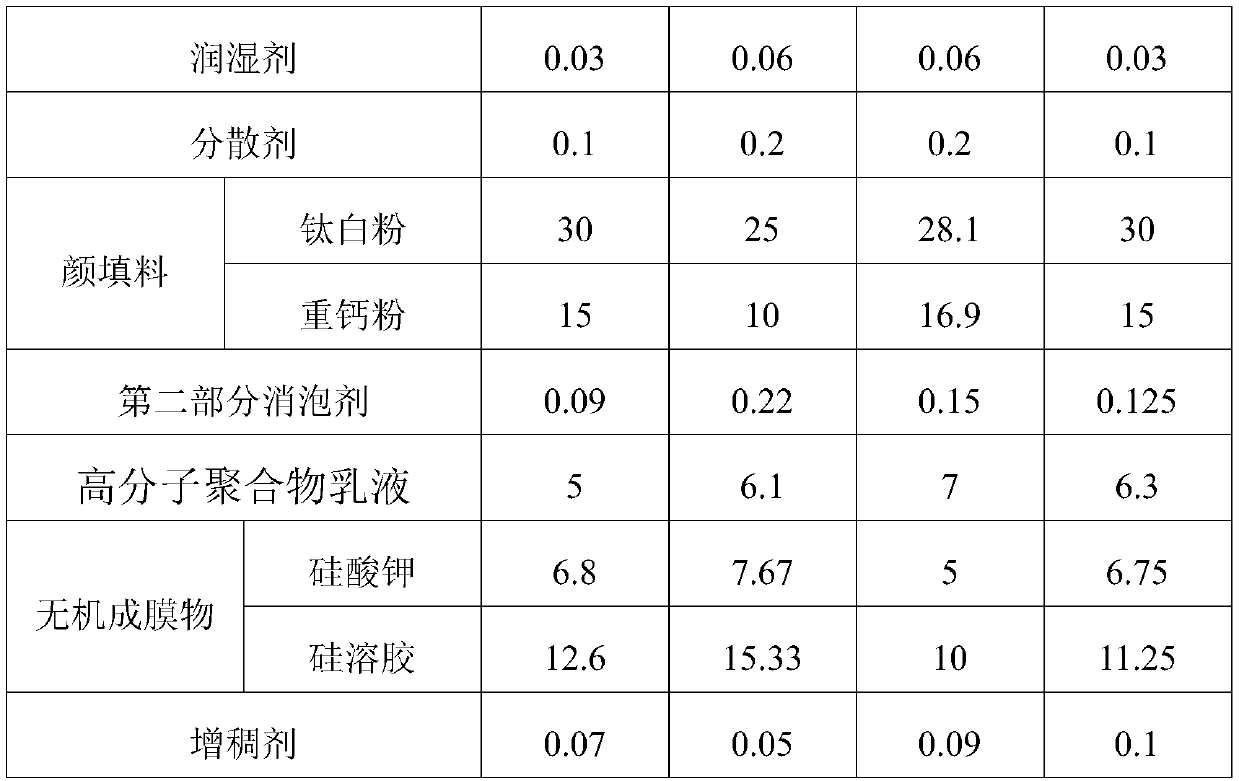

Inorganic interior wall coating and preparation method thereof

The invention relates to the field of water-based coating, in particular to inorganic interior wall coating and a preparation method thereof. The inorganic interior wall coating comprises the following components: deionized water, hydroxyethyl cellulose, a defoaming agent, a pH regulator, a wetting agent, a dispersing agent, a pigment filler, a high-molecular polymer emulsion, an inorganic film forming matter and a thickening agent. The inorganic film forming matter is a mixture of potassium silicate and silica sol. The inorganic interior wall coating adopts the raw materials and limits the weight percentage of each raw material so that the inorganic interior wall coating has good adhesive force, low-temperature stability and excellent flame resistance after film formation and is suitablefor interior wall coating or spraying.

Owner:石家庄市油漆厂

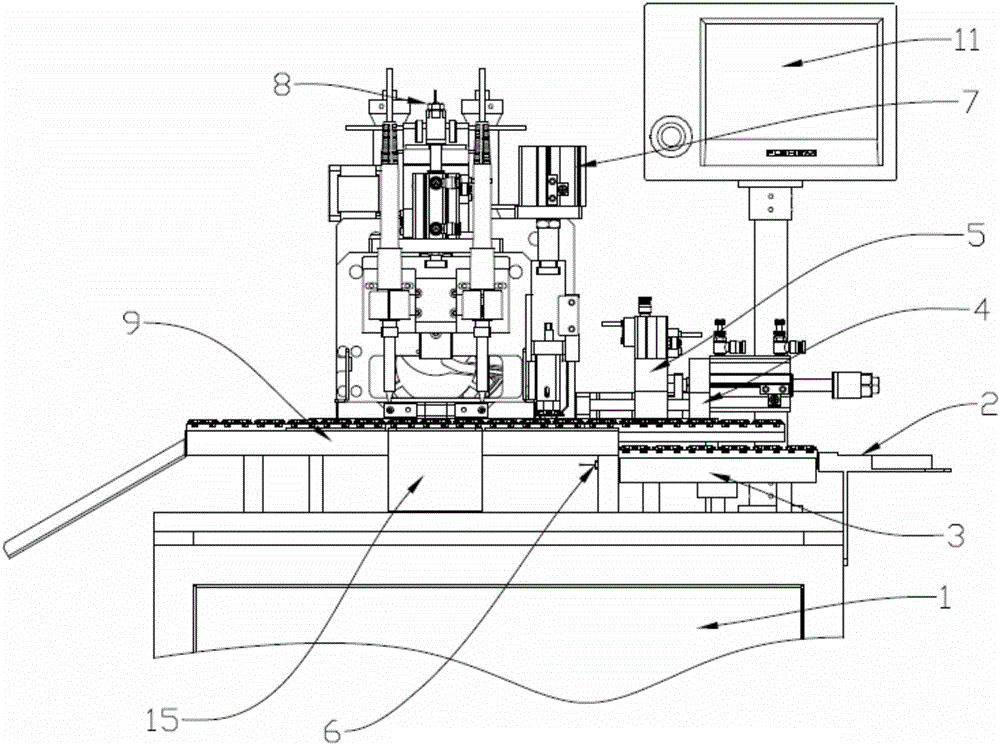

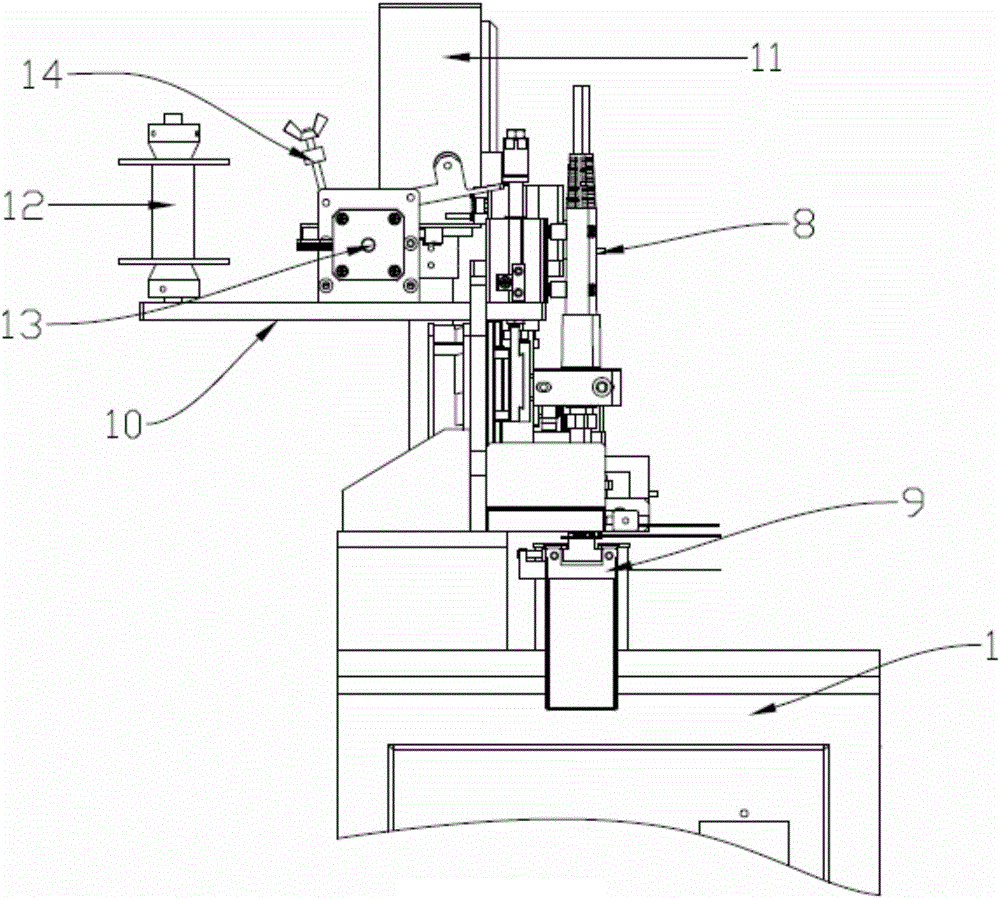

Motor-end-cover tin soldering machine

InactiveCN106001842AImprove processing efficiencySuitable for mass production operationsMetal working apparatusSoldering auxillary devicesEngineeringSoldering

The invention relates to a motor-end-cover tin soldering machine. The motor-end-cover tin soldering machine comprises a machine body, feeding rails, a feeding mechanism, a feeding pushing mechanism, a feeding pressing mechanism, a material sensor, a brush pressing mechanism, a soldering mechanism, a soldering jacking mechanism, discharging rails, a tin feeding mechanism and an PLC for controlling the mechanisms, wherein the feeding rails, the feeding mechanism, the feeding pushing mechanism, the feeding pressing mechanism, the material sensor, the brush pressing mechanism, the soldering mechanism, the soldering jacking mechanism, the discharging rails, the tin feeding mechanism and the PLC are arranged on the machine body. The feeding rails are located below the right side of the discharging rails, the feeding mechanism is located on the left side of the feeding rails, the feeding pushing mechanism and the feeding pressing mechanism are arranged over the feeding mechanism, the brush pressing mechanism and the soldering mechanism are arranged over the discharging rails, the soldering jacking mechanism is arranged at the bottom of the discharging rail located under the soldering mechanism, and the PLC is arranged at the portion, behind the feeding rails, of the machine body. According to the motor-end-cover tin soldering machine, the flow-type structural design is adopted, processes of tin welding and the like of end covers are automatically completed through the machine, machining efficiency is effectively improved, and the motor-end-cover tin soldering machine is quite suitable for batch production.

Owner:QUANNAN CHAOYA TECH

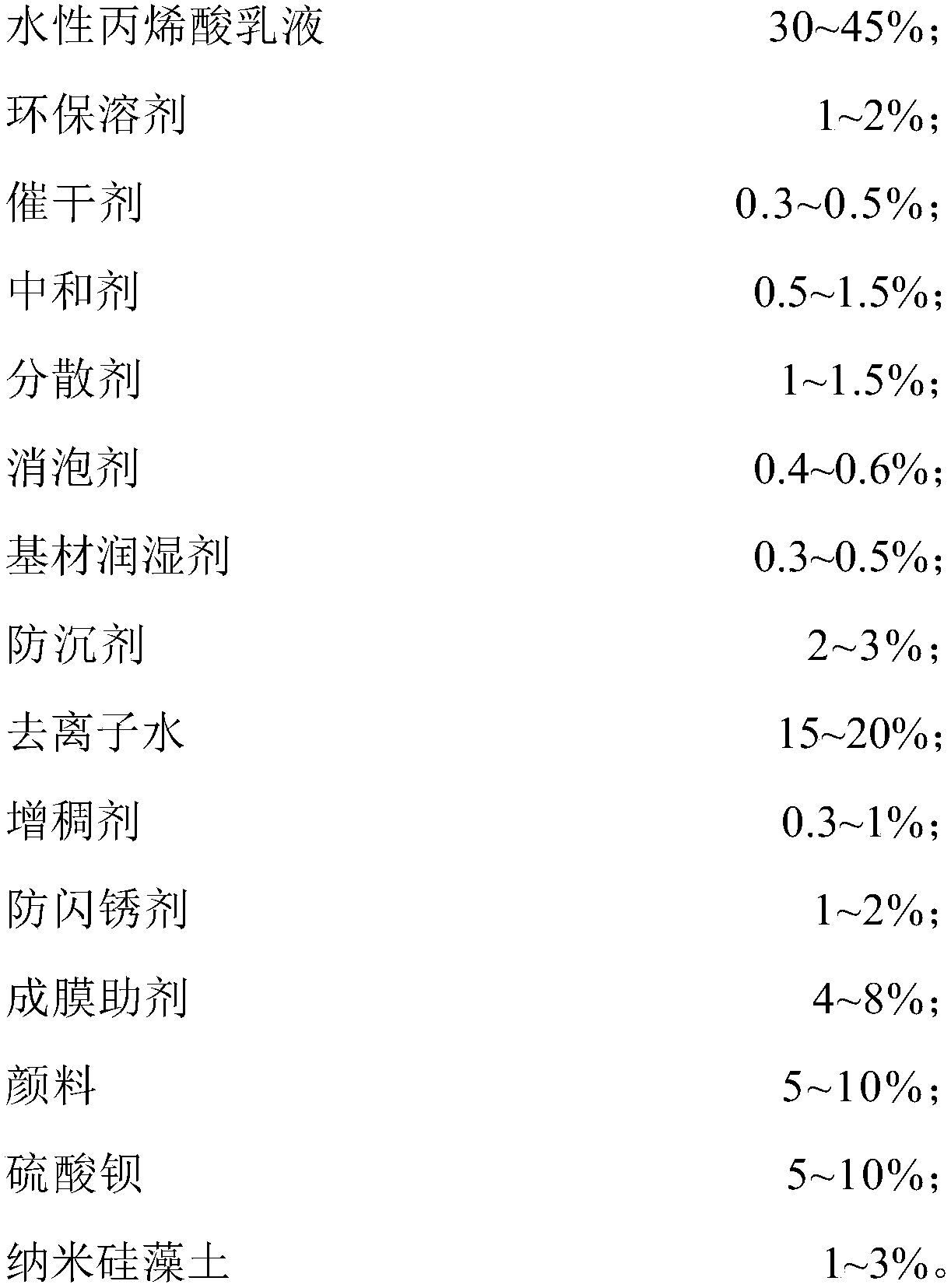

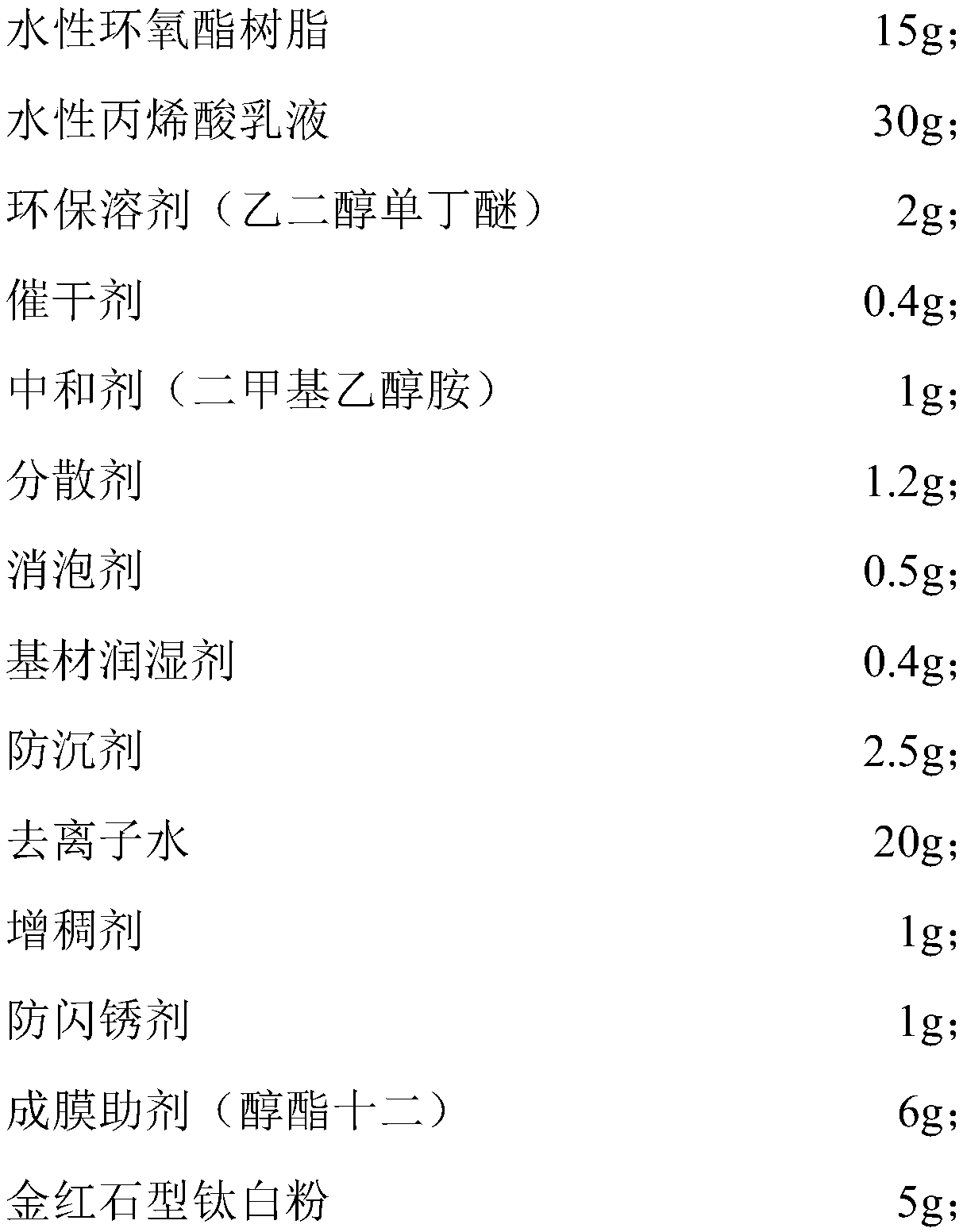

Anti-corrosion quick-drying environment-friendly water-based paint and preparation method thereof

InactiveCN109439090AEasy to operateSuitable for paintingAnti-corrosive paintsEpoxy resin coatingsWater basedEmulsion

The invention relates to anti-corrosion quick-drying environment-friendly water-based paint and a preparation method thereof. The finish paint comprises the following raw materials: water-based epoxyester resin, water-based acrylic emulsion, an environment-friendly solvent, a dryer, a neutralizer, a dispersant, a defoamer, a base material wetting agent, an anti-settling agent, deionized water, athickener, an antirust agent, a film coalescing aid, pigment, barium sulfate, and nano kieselguhr. The water-based paint is selected from a water-based system, VOC is less than or equal to 100 g / L, asmell is very low, environmental pollution is reduced, injury to a human body is reduced, construction is easy, and the water-based paint has a higher anti-corrosive property and a rapid drying speed,and each requirement of coating a water pump can be satisfied.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

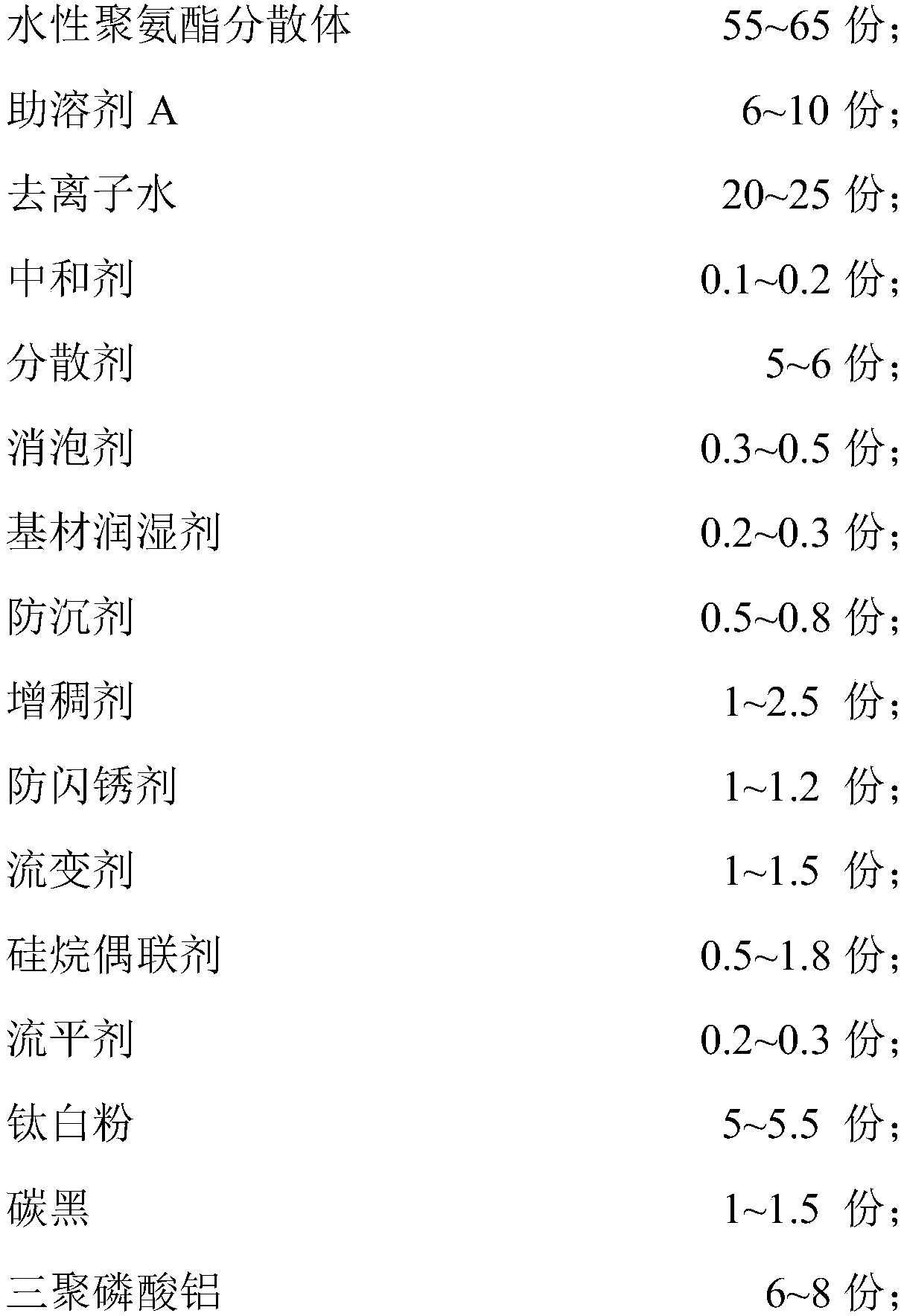

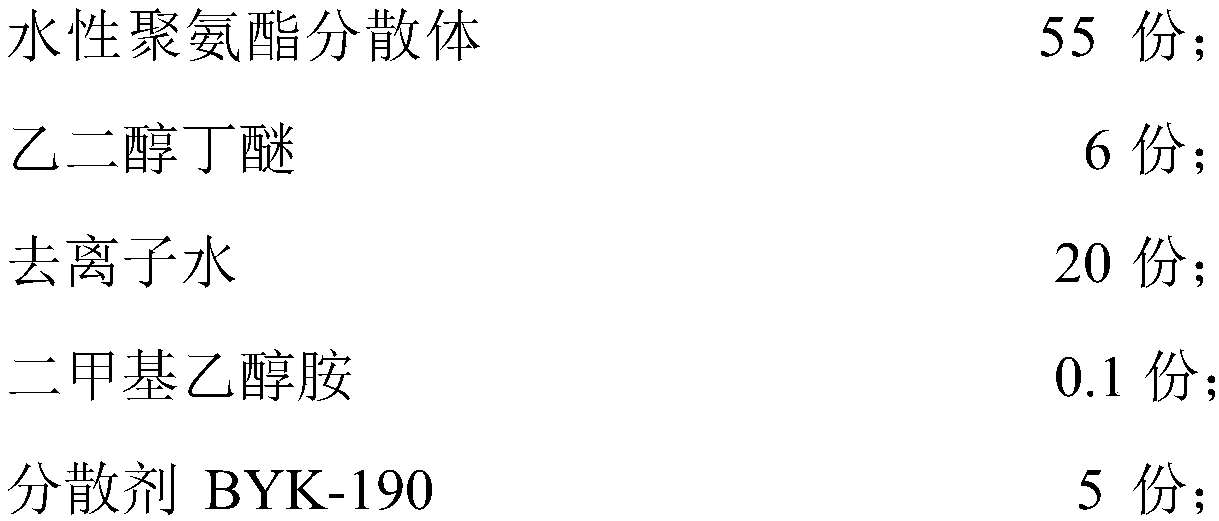

Two-component waterborne top coating for outdoor pipeline and preparation method thereof

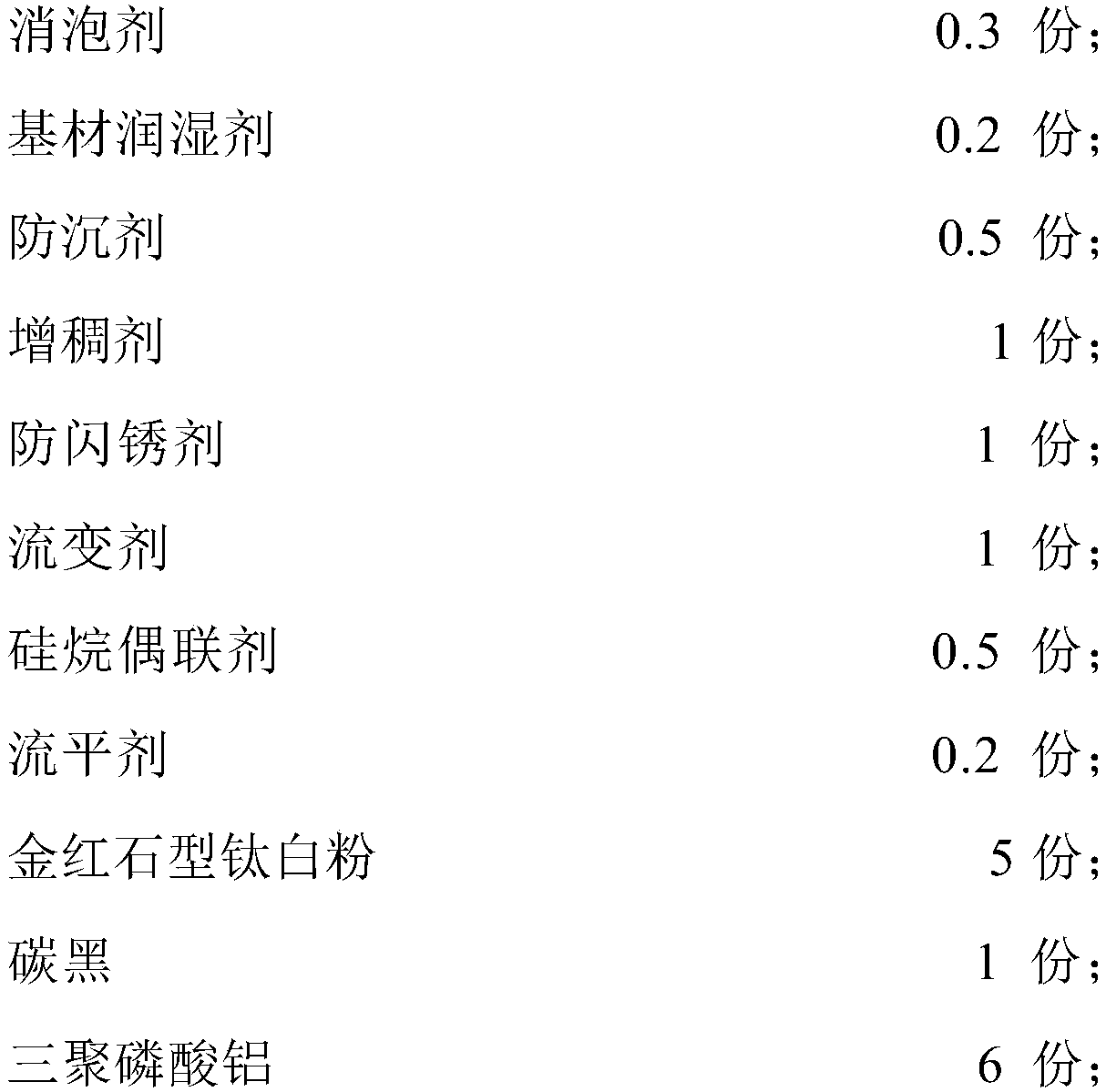

InactiveCN109535962AImprove water resistanceHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsALUMINUM PHOSPHATERutile

The invention relates to two-component waterborne top coating for an outdoor pipeline and a preparation method thereof. The top coating consists of a component A and a component B, and comprises the following raw materials: waterborne polyurethane dispersion, a co-solvent, deionized water, a neutralization agent, a dispersant, a defoamer, a substrate wetting agent, an anti-settling agent, a thickener, an anti-flash rust agent, a rheological agent, a silane coupling agent, a leveling agent, rutile titanium dioxide, carbon black, and trimeric aluminum phosphate. The top coating has high corrosion resistance, weather resistance, abrasion resistance, water resistance and acid and alkali resistance, can fully meet requirements of outdoor pipeline coating and is environmentally friendly.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

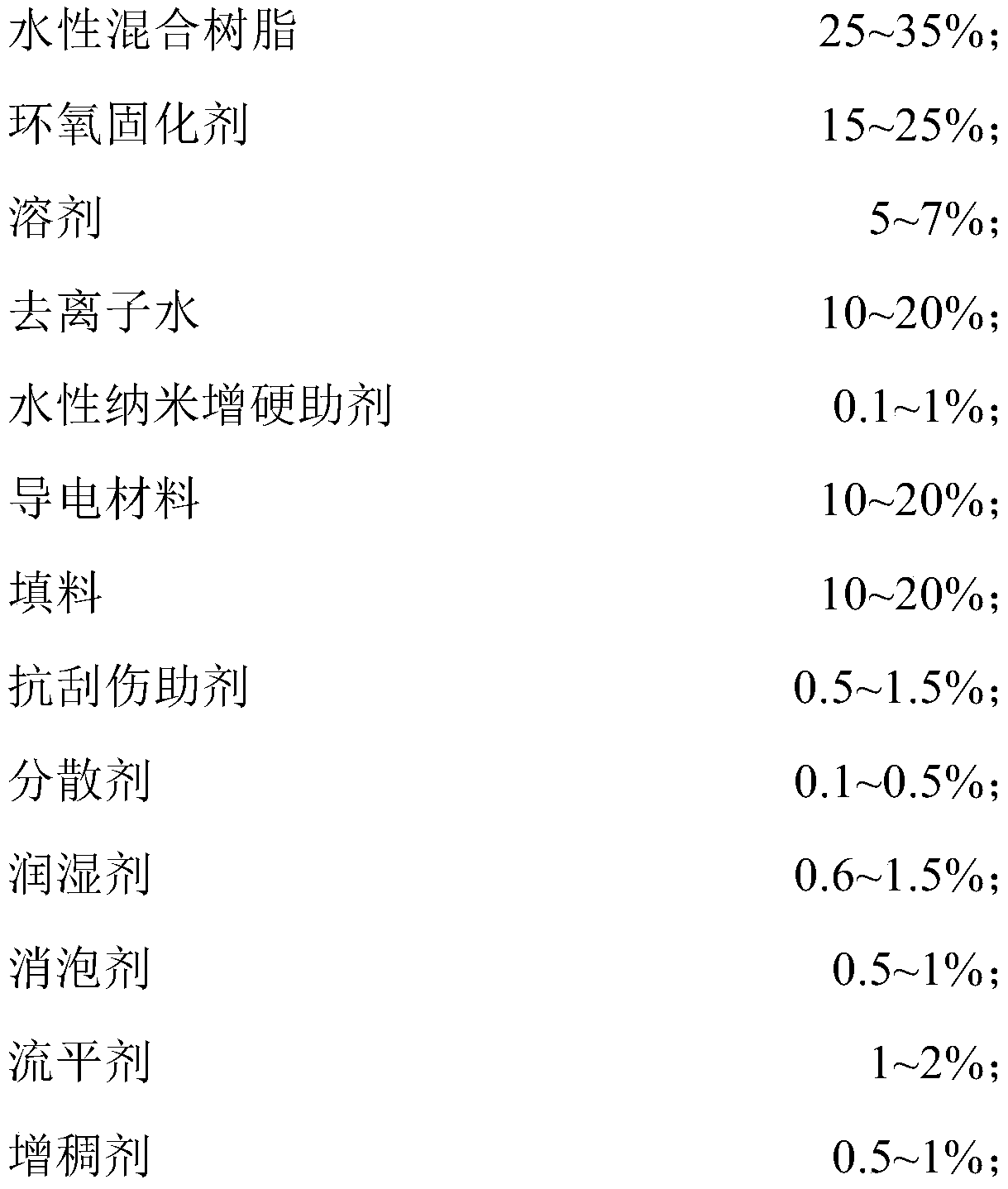

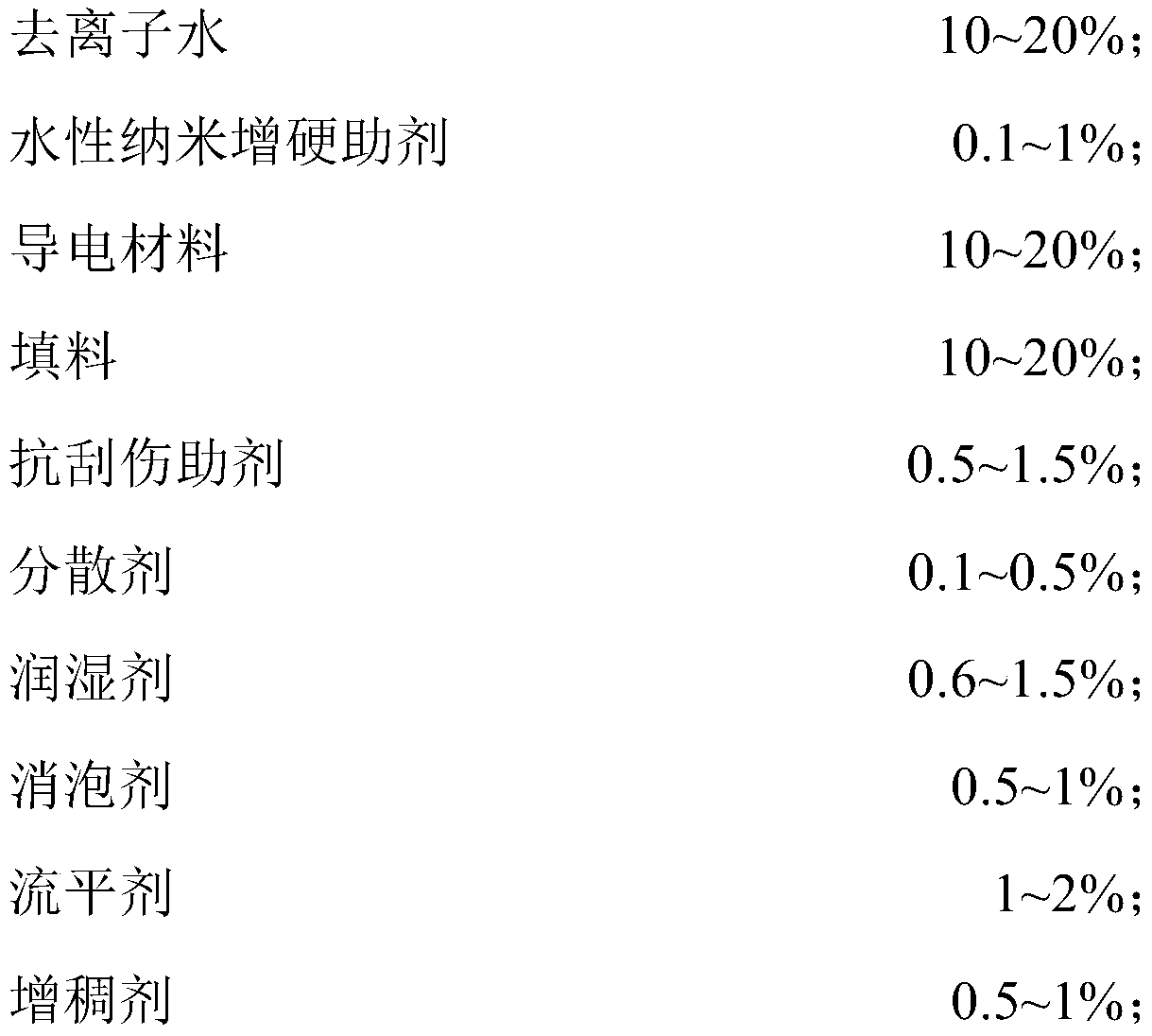

Anti-static terrace water-based paint and preparation method thereof

InactiveCN110669371AEasy to operateSuitable for mass production operationsAntifouling/underwater paintsPaints with biocidesSolventWeather resistance

The invention relates to the field of water-based paint, in particular to an anti-static terrace water-based paint and a preparation method thereof. The anti-static terrace water-based paint comprisesthe following components: a water-based mixed resin, an epoxy curing agent, a solvent, deionized water, a waterborne nano hardening powder, a conductive material, a filler, an anti-scratching aid, adispersing agent, a wetting agent, an antifoaming agent, a leveling agent and a thickener, has good antistatic performance, good weather resistance and impact resistance, high hardness, water resistance, oil resistance and extremely low VOC content, and contains no benzene series substances, free formaldehyde, or heavy metals.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

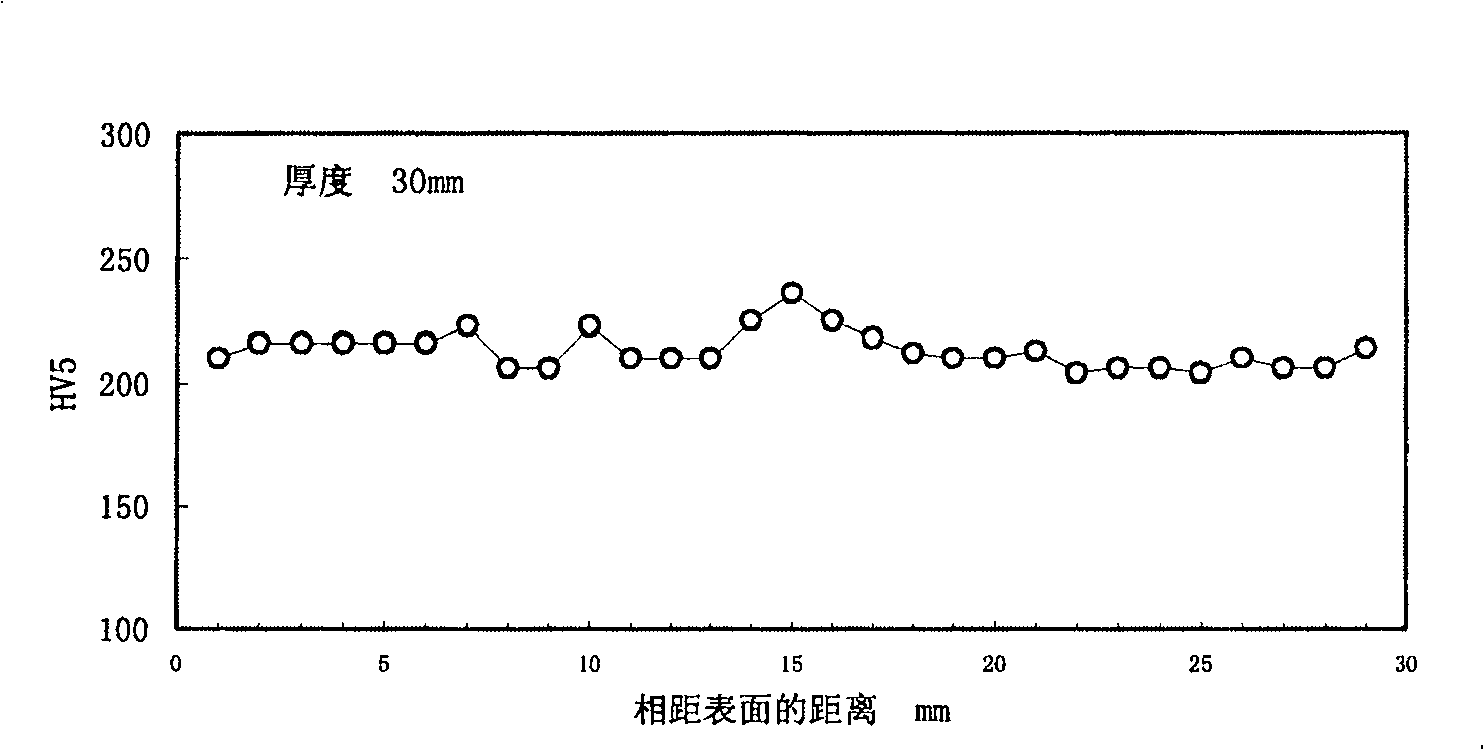

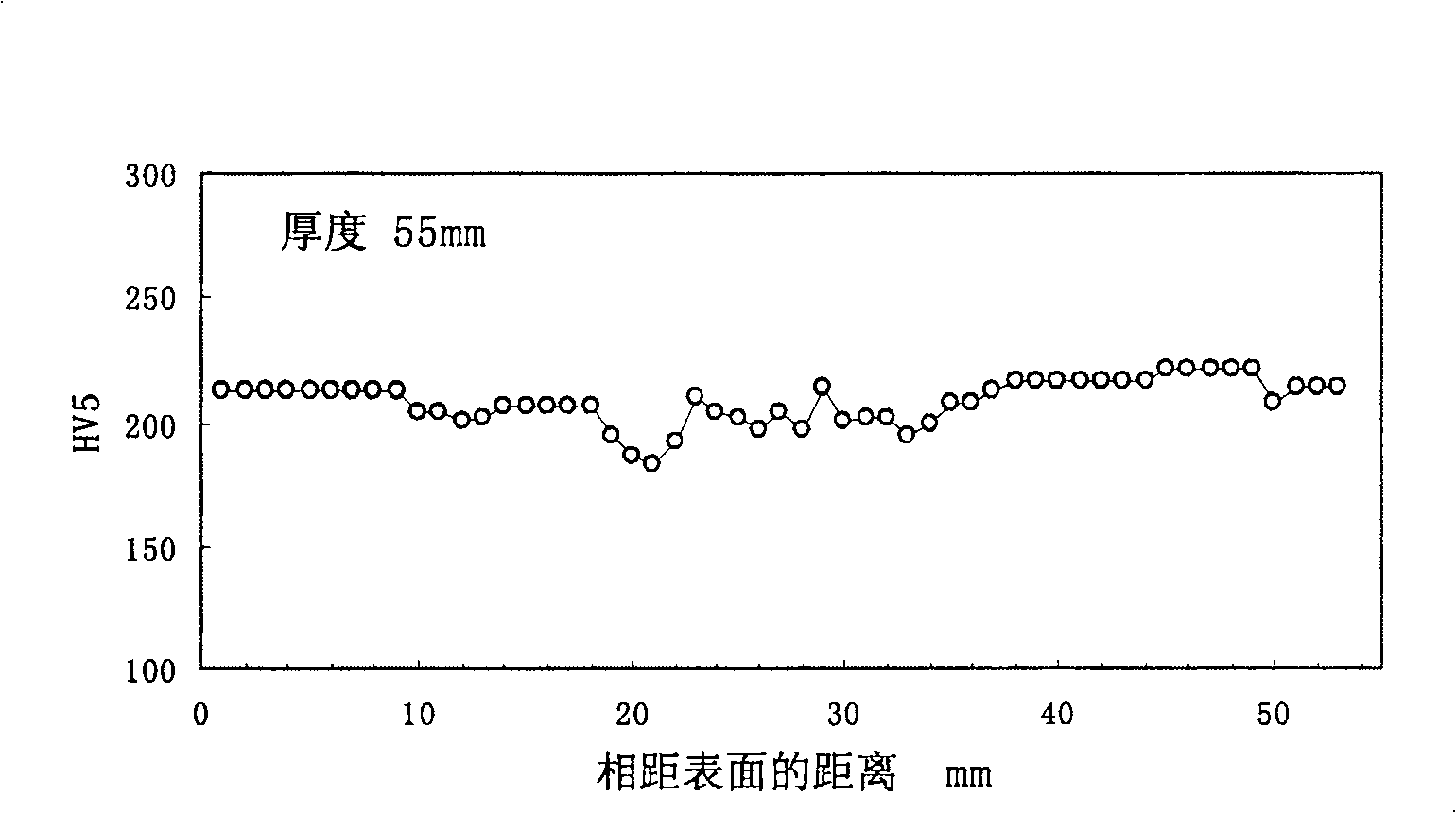

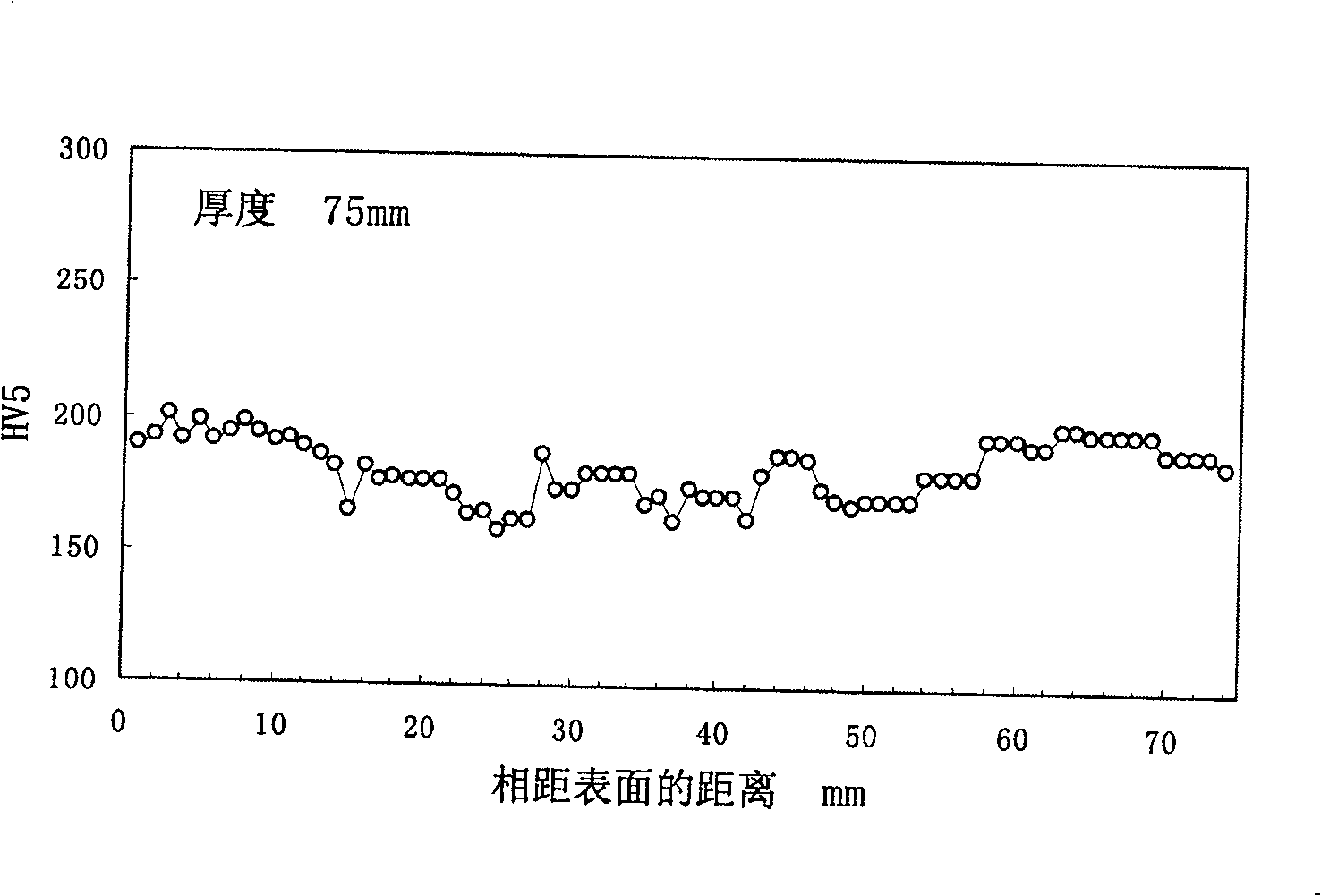

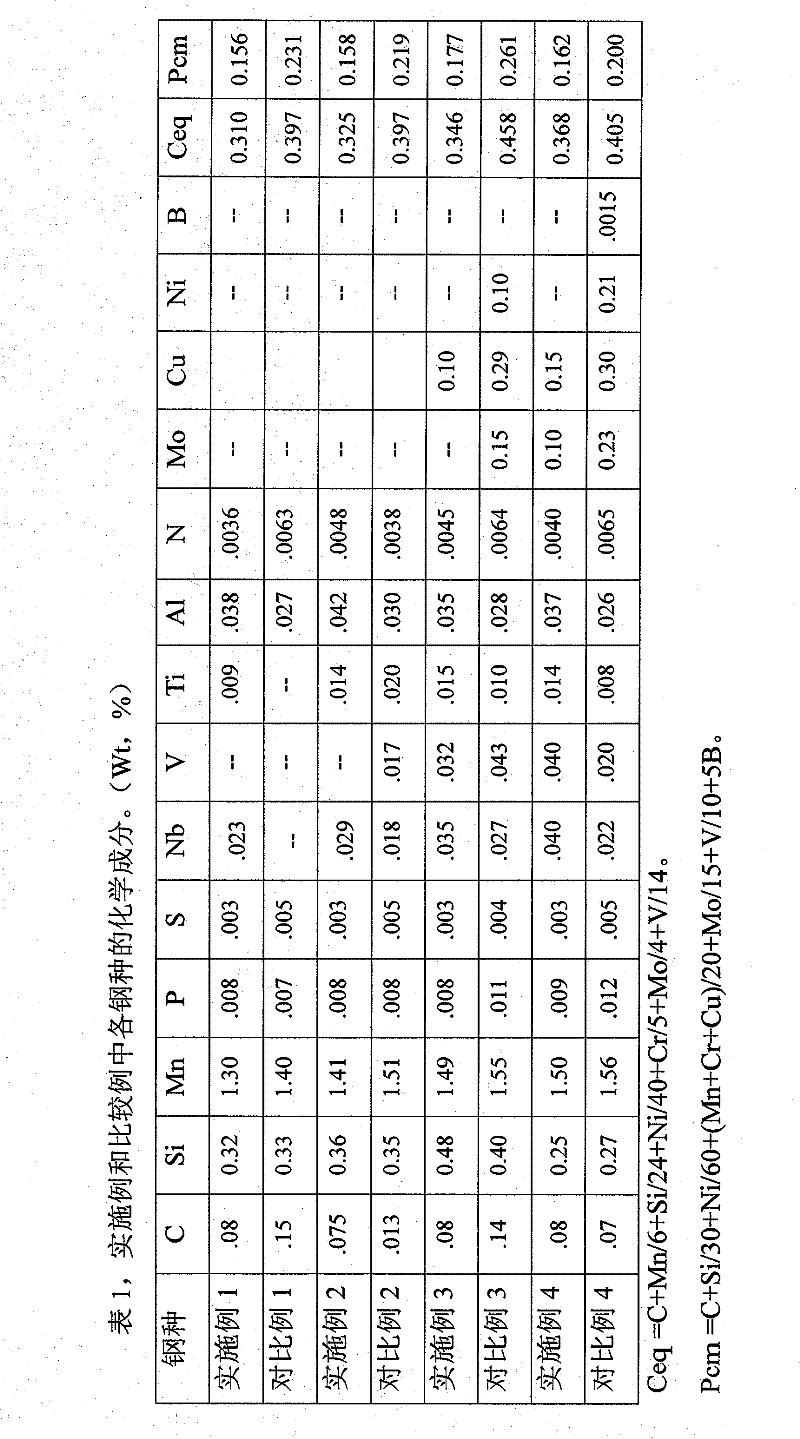

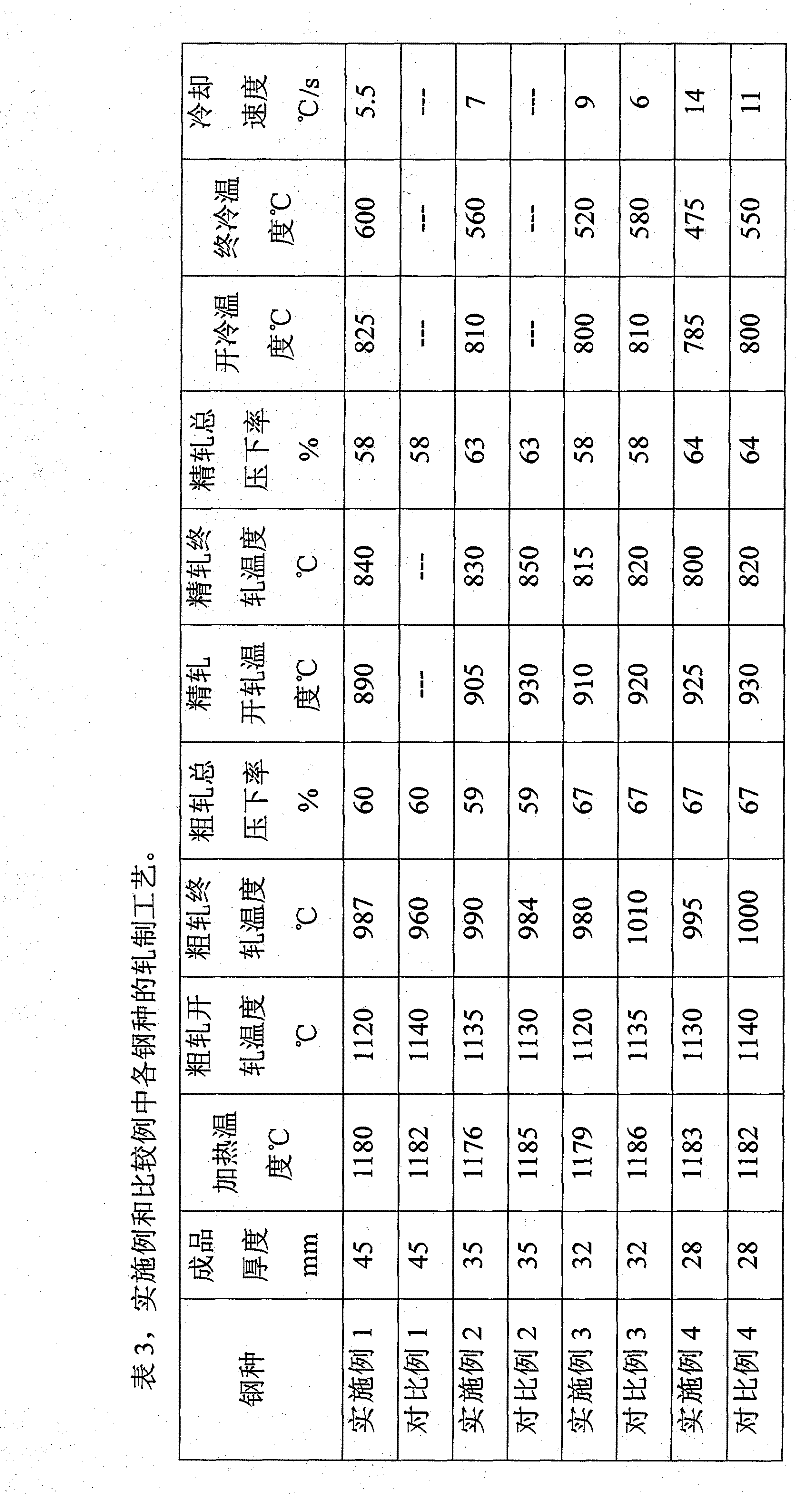

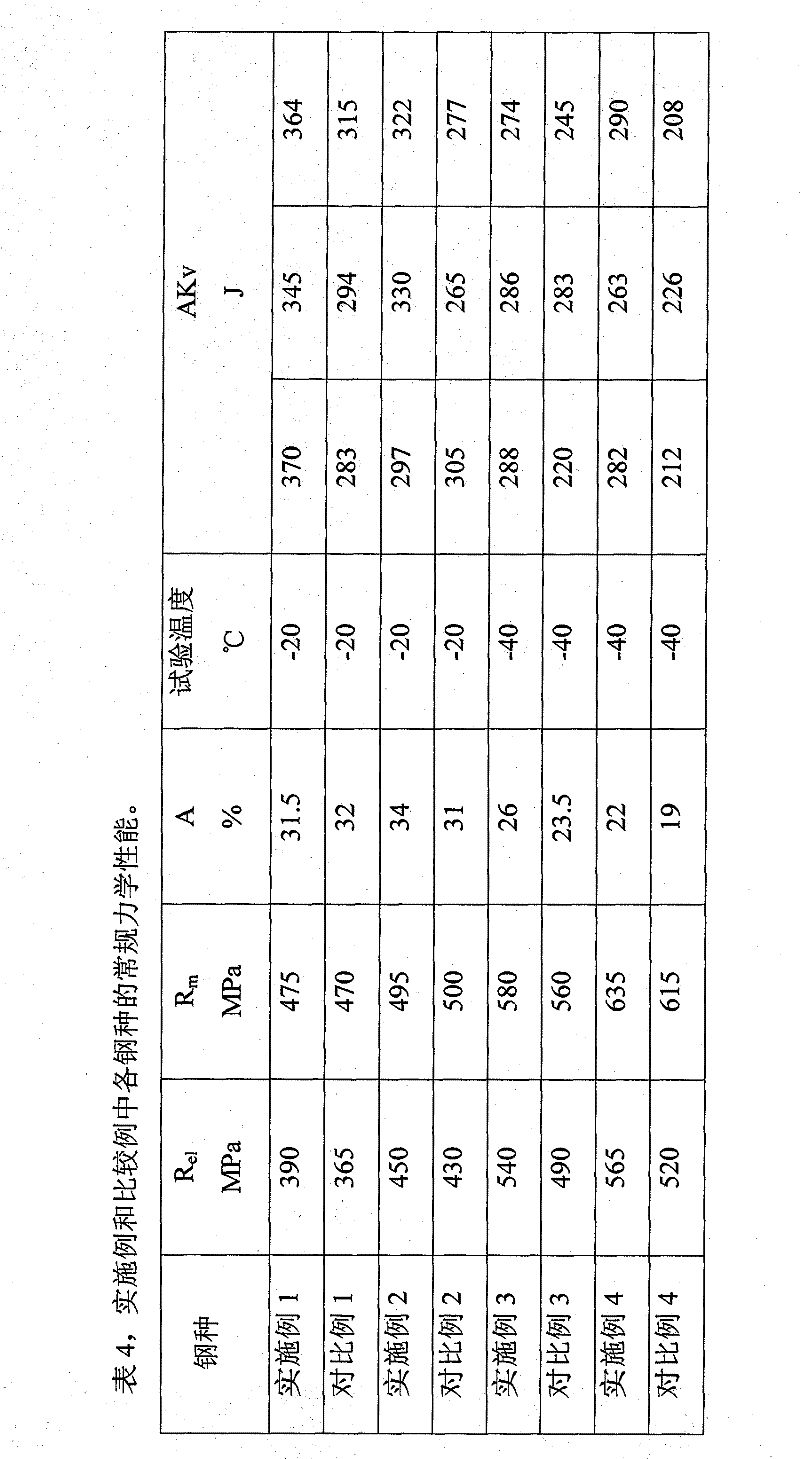

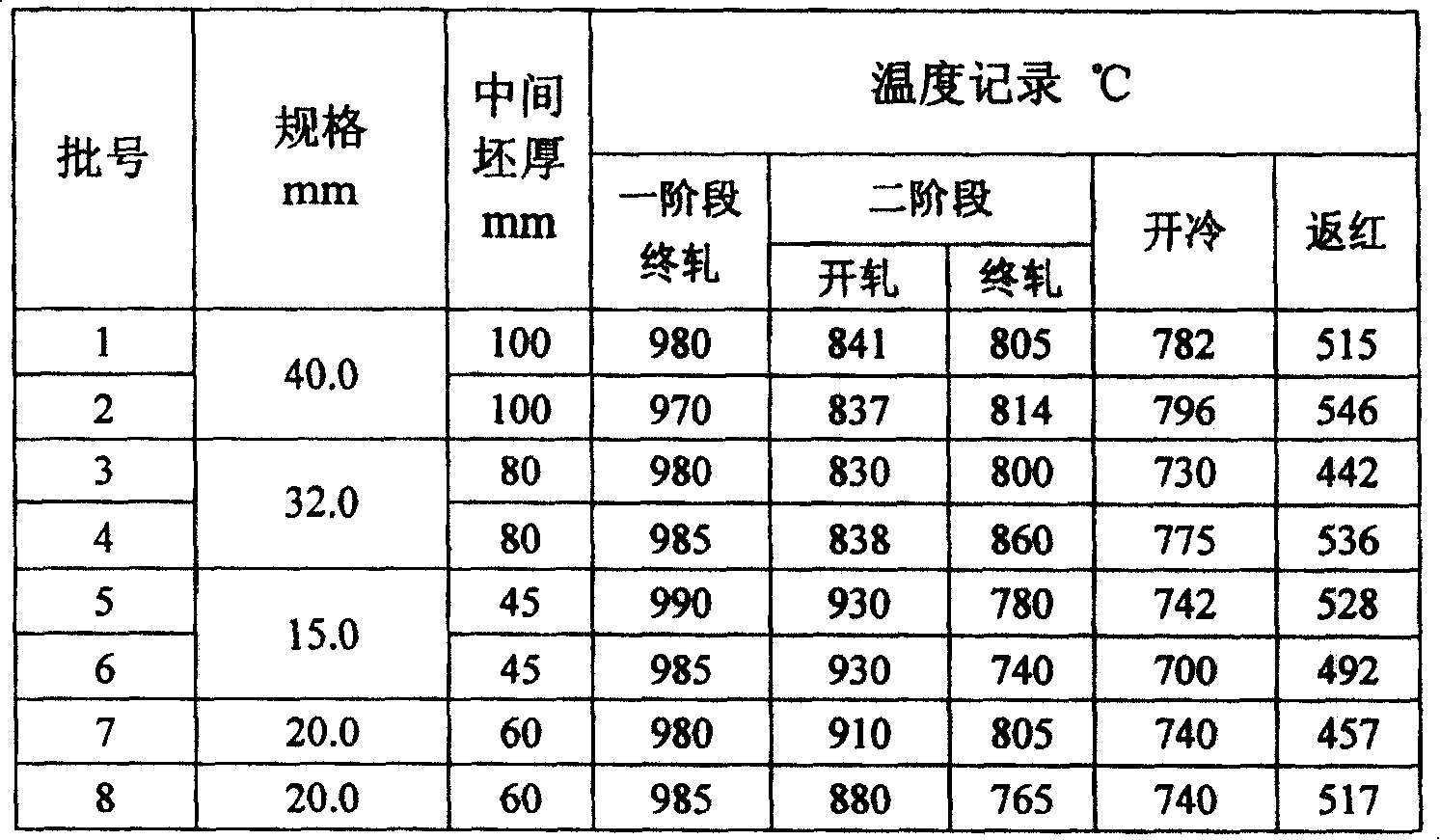

Thick steel plate with high strength and low welding crack sensitivity and its production process

InactiveCN100516270CSimple designGuaranteed performanceTemperature control deviceSheet steelChemical composition

The present invention discloses one kind of thick steel plate with high strength and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.09 wt%, Si 0.15-0.55 wt%, Mn 1.00-1.60 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo not more than 0.30 wt%, Cu not more than 0.30 wt%, V 0.02-0.06 wt%, Nb 0.005-0.05 wt% and Als 0.010-0.04 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 % and Ceq not higher than 0.42 %. The production process includes two stage controlled rolling, on-line laminar flow cooling, off-line tempering and other steps. The produced steel plate has thickness up to 75mm, tensile strength not lower than 610 MPa and very low welding crack sensitivity.

Owner:ANGANG STEEL CO LTD

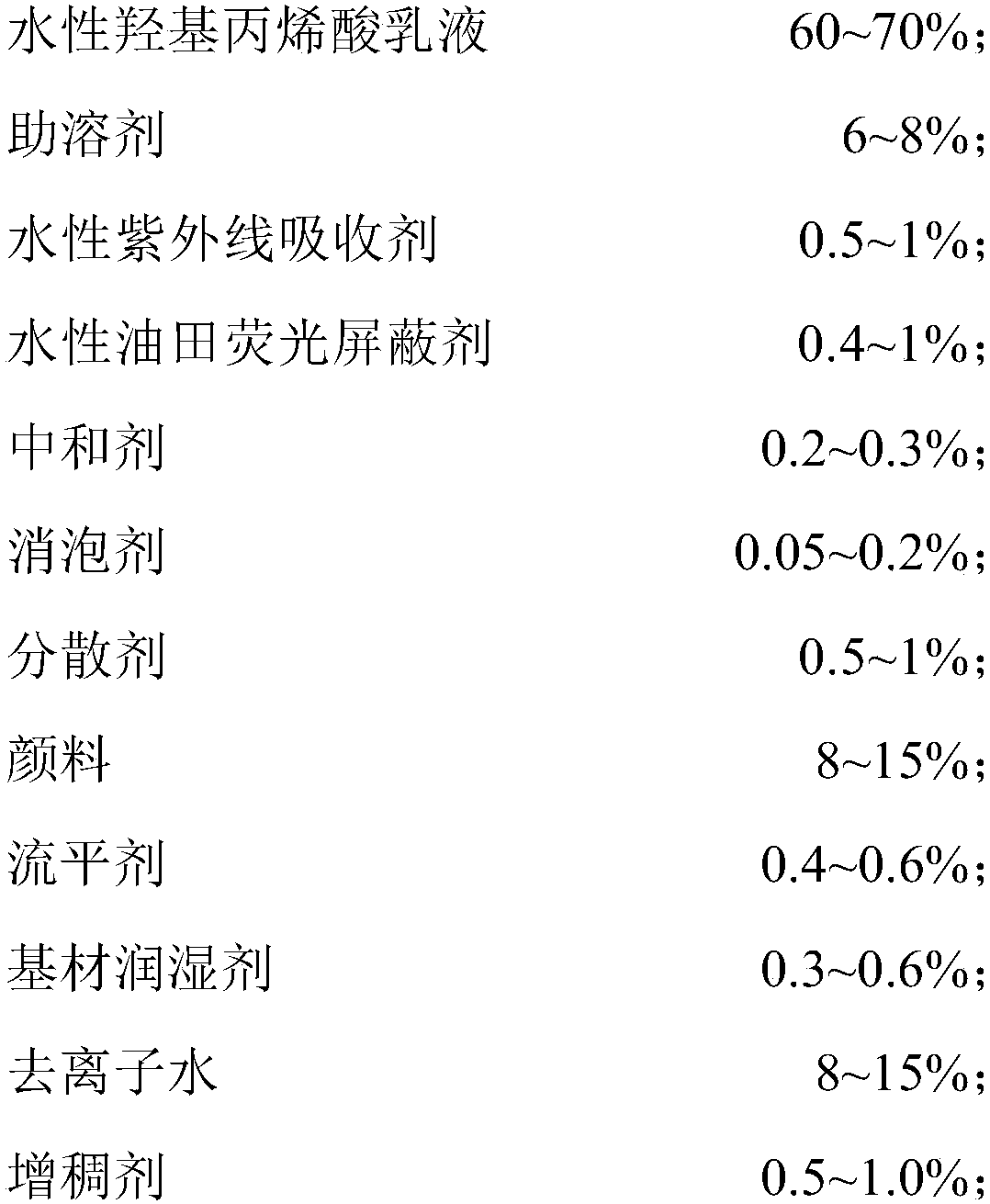

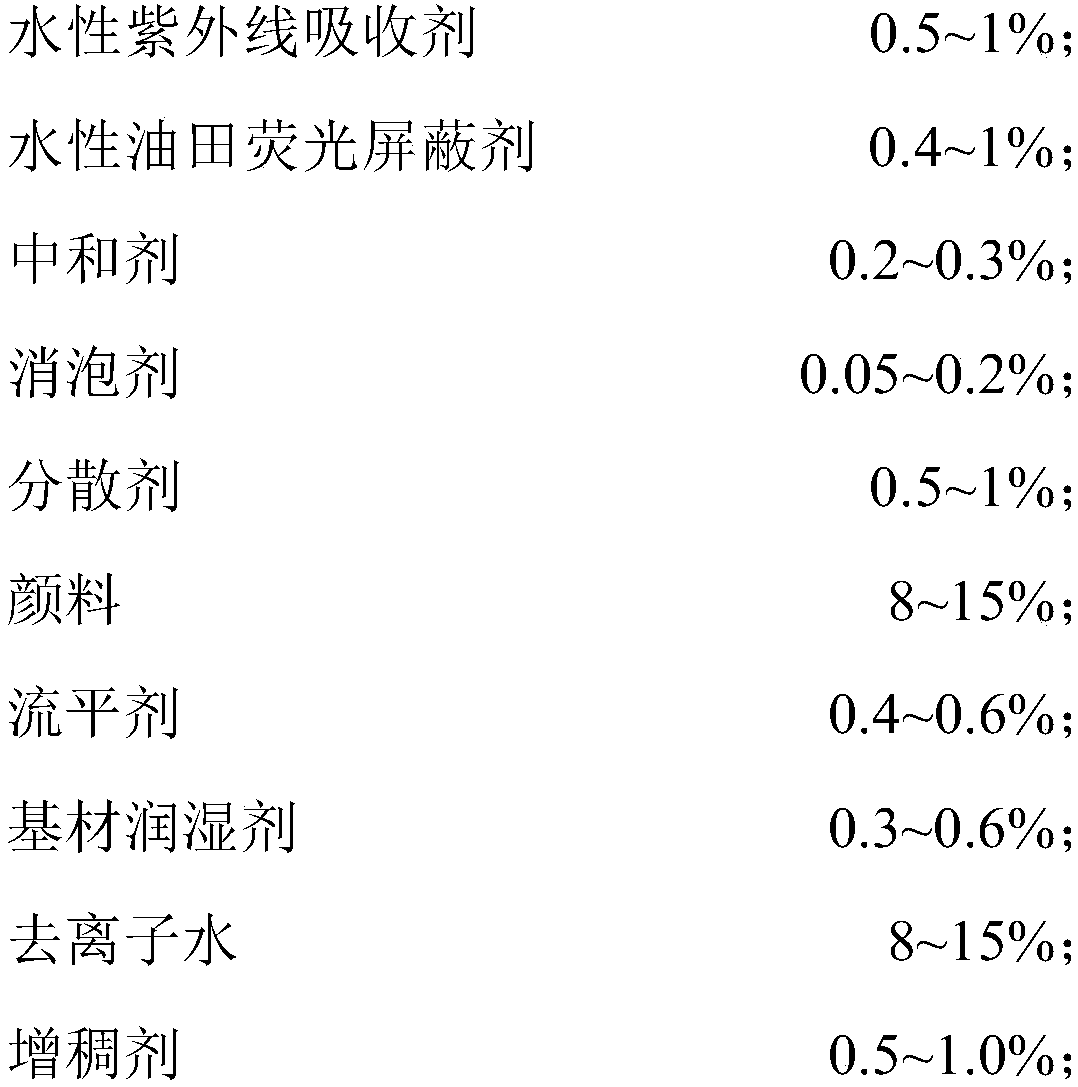

Water-based strong-weather-resistant self-repairing two-component polyurethane topcoat and preparation method thereof

PendingCN108395826AEasy to operateSuitable for mass production operationsPolyurea/polyurethane coatingsWater basedMass ratio

The invention relates to a water-based strong-weather-resistant self-repairing two-component polyurethane topcoat and a preparation method thereof. The topcoat is prepared by mixing a mixture of a group A and a mixture of a group B, wherein the mixture of the group A comprises a water-based hydroxyl acrylic emulsion, a co-solvent, a water-based ultraviolet light absorber, a water-based oilfield fluorescent shielding agent, a neutralizer, a defoaming agent, a dispersant, a pigment, a levelling agent, a substrate wetting agent, deionized water and a thickening agent; and the mixture of the groupB comprises aliphatic isocyanate and an ester organic solvent, and a mass ratio of the mixture of the group A to the mixture of the group B is (4.5-5.5):1. The preparation method comprises the following steps: mixing 50-70% of the deionized water, 40-60% of the neutralizer, the defoaming agent, the dispersant, 15-25% of the co-solvent and the pigment, performing grinding to obtain pre-stage slurry, mixing the water-based hydroxyl acrylic emulsion, and the remaining deionized water, neutralizer and co-solvent, adding the pre-stage slurry into the mixed material, performing mixing, adding the water-based ultraviolet light absorber, the water-based oilfield fluorescent shielding agent, the substrate wetting agent and the levelling agent, adjusting viscosity by using the thickening agent to obtain the mixture of the group A, preparing the mixture of the group B, and mixing the mixtures of the group A and the group B before the topcoat is used.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Compression molding device for plastic packing boxes

InactiveCN106239803ASuitable for mass production operationsIncrease productivityCompression moldingPlastic packaging

The invention brings forward a compression molding device for plastic packing boxes. The compression molding device comprises a feeding mechanism, a heating mechanism, a compression molding mechanism, a cutting mechanism and a material recovering mechanism. The heating mechanism is positioned at one side of the feeding mechanism and is used for softening strip-shaped plastics; the compression molding mechanism is positioned at one side of the heating mechanism, far from the feeding mechanism, and is used for compression molding treatment of strip-shaped plastics; the cutting mechanism is positioned at one side of the compression molding mechanism, far from the heating mechanism, and is used for separating a moulded packing box from strip-shaped plastics; and the material recovering mechanism comprises a material blowing mechanism and a collecting mechanism. The material blowing mechanism is positioned at one side of a bearing seat and is used for blowing down the packing box and collecting the packing box in the collecting mechanism. The compression molding device for plastic packing boxes has advantages of strong continuity, high production efficiency and high automation degree, and is especially suitable for batch production and operation for enterprises.

Owner:ANQING BOMEI PLASTIC CO LTD

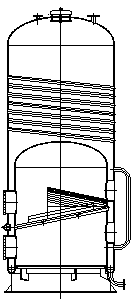

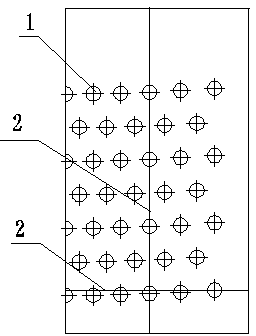

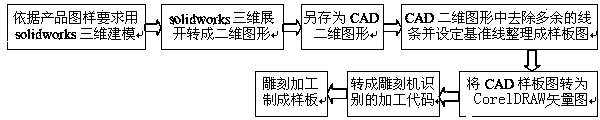

Boiler cylinder body pipe hole face mold and manufacturing method thereof

InactiveCN103624761APrecise sizeAccurate hole sizeOther workshop equipmentEngineeringSeries production

The invention provides a boiler cylinder body pipe hole face mold and a manufacturing method thereof. According to the method, by means of a computer and relative programs, a three-dimensional diagram corresponding to a boiler cylinder body is built in the computer according to requirements for design of boiler cylinder body pipe holes, then the diagram is spread to form a two-dimensional diagram, lines are revised, reference lines of regions are determined according to pipe hole distribution regions, a vector diagram is formed through conversion, a carving program is formed through conversion, hole profile lines and the reference lines are carved on a face mold material, and the pipe hole face mold is manufactured. According to the boiler cylinder body pipe hole face mold manufactured in the method, the size is accurate, the efficiency is high, the cylinder body pipe holes do not need cut for a second time, the face mold can be repeatedly used, and the face mold is suitable for large-scale production.

Owner:ZUNYI YULONG BOILER

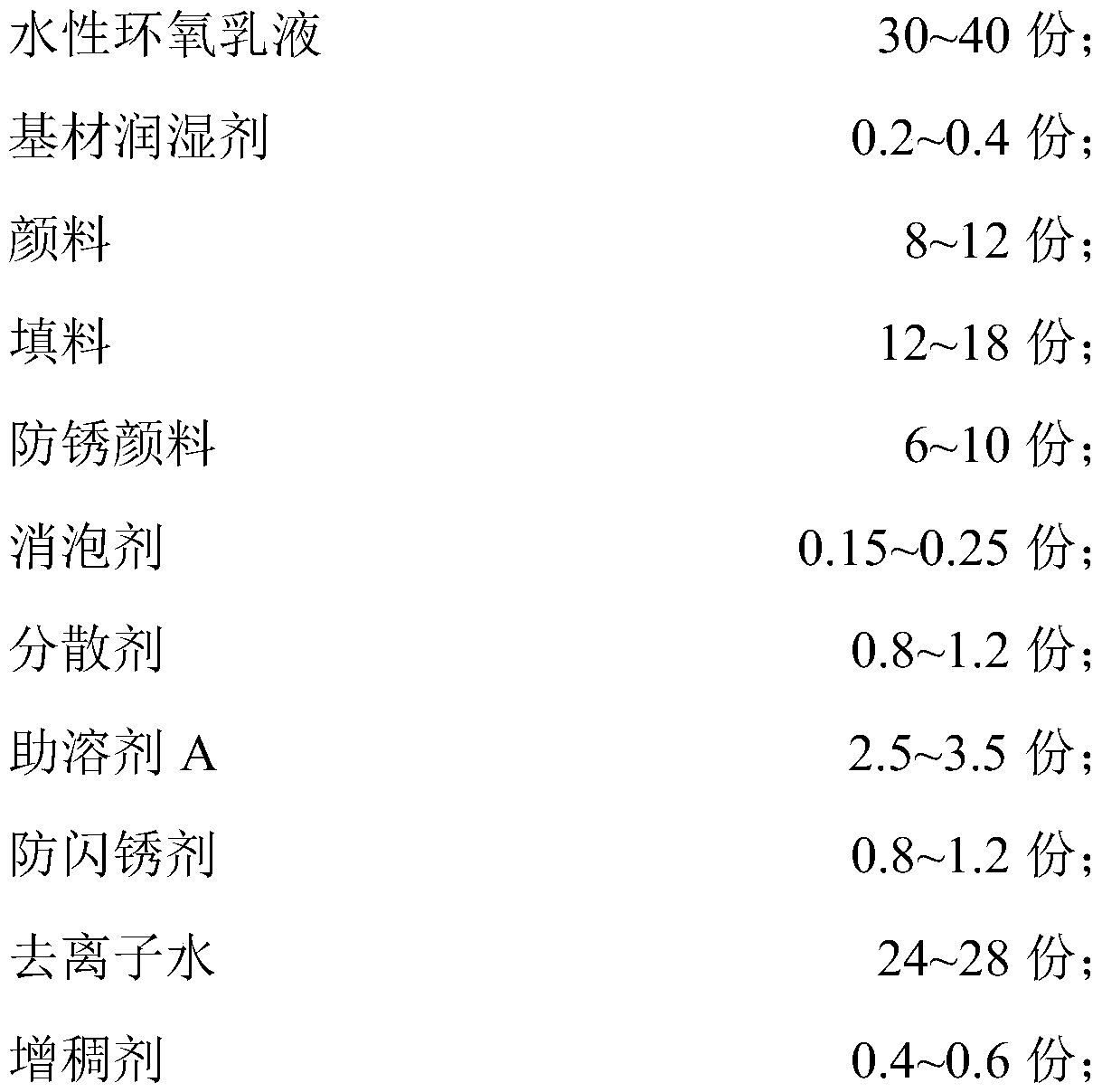

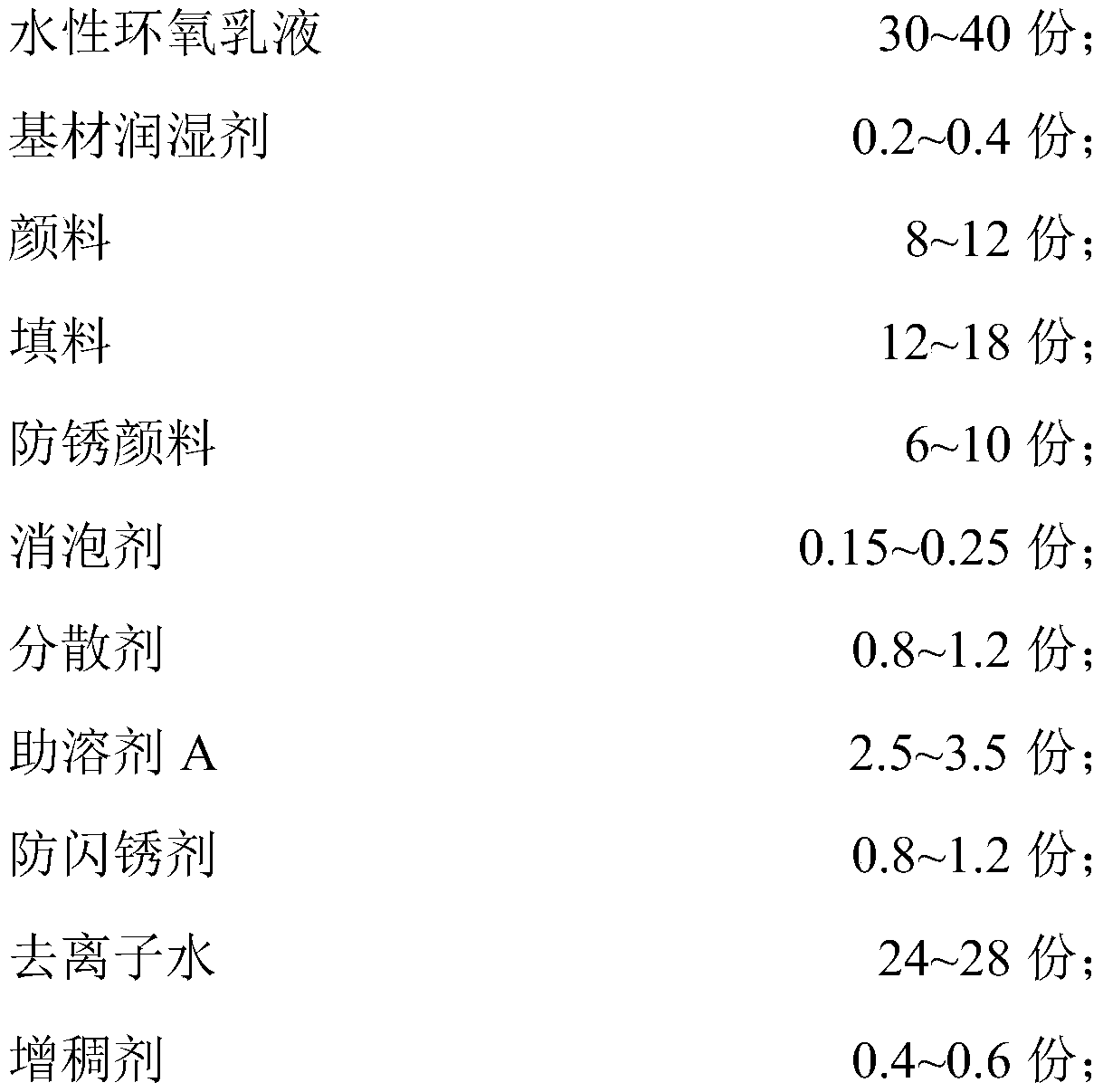

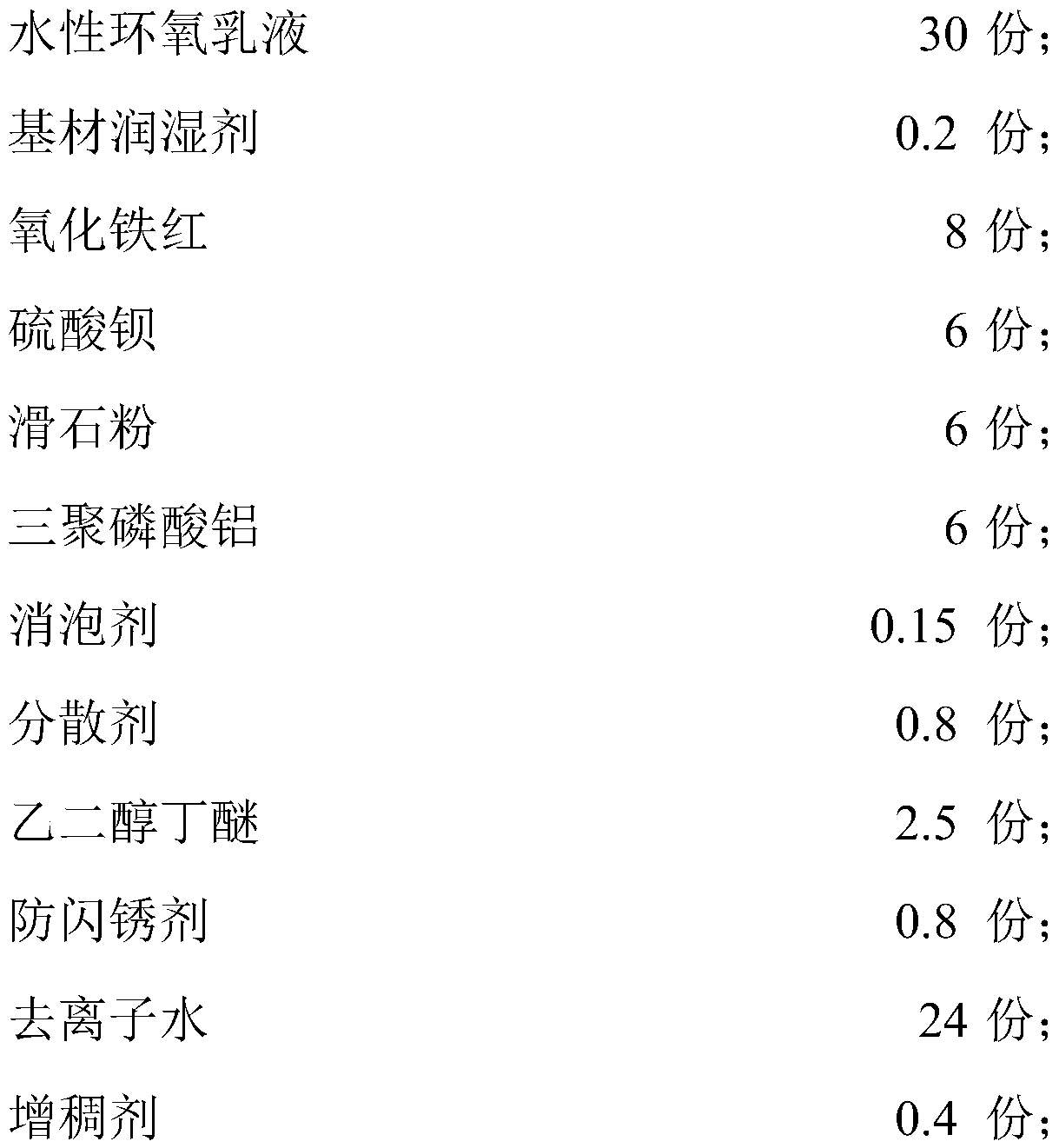

Heavy metal-free aqueous epoxy primer and preparation method thereof

InactiveCN109868033AEasy to operateImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The present invention relate to the field of aqueous primer, especially relates to a heavy metal-free aqueous epoxy primer and a preparation method thereof. The finish paint is composed of a componentA and a component B, and comprises that following raw materials: aqueous epoxy emulsion, substrate wetting agent, pigment, filler, antirust pigment, defoamer, dispersant, cosolvent A, antiflashover agent, deionized water, thickener, epoxy resin curing agent and cosolvent B. The topcoat can reduce the use of auxiliary materials containing organic solvents through the selection of the types and amounts of various components, thereby greatly reducing the VOC content, avoiding the adverse effects of a large number of toxic volatiles on human health and the environment, and being more environmentally friendly. At the same time, the film has excellent anticorrosion performance and toughness, which can meet the anticorrosion requirements of marine engineering, modern transportation, energy industry, large industrial enterprises, municipal facilities and so on.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Environment-friendly anti-blue-ray antibacterial self-drying coating and preparation method thereof

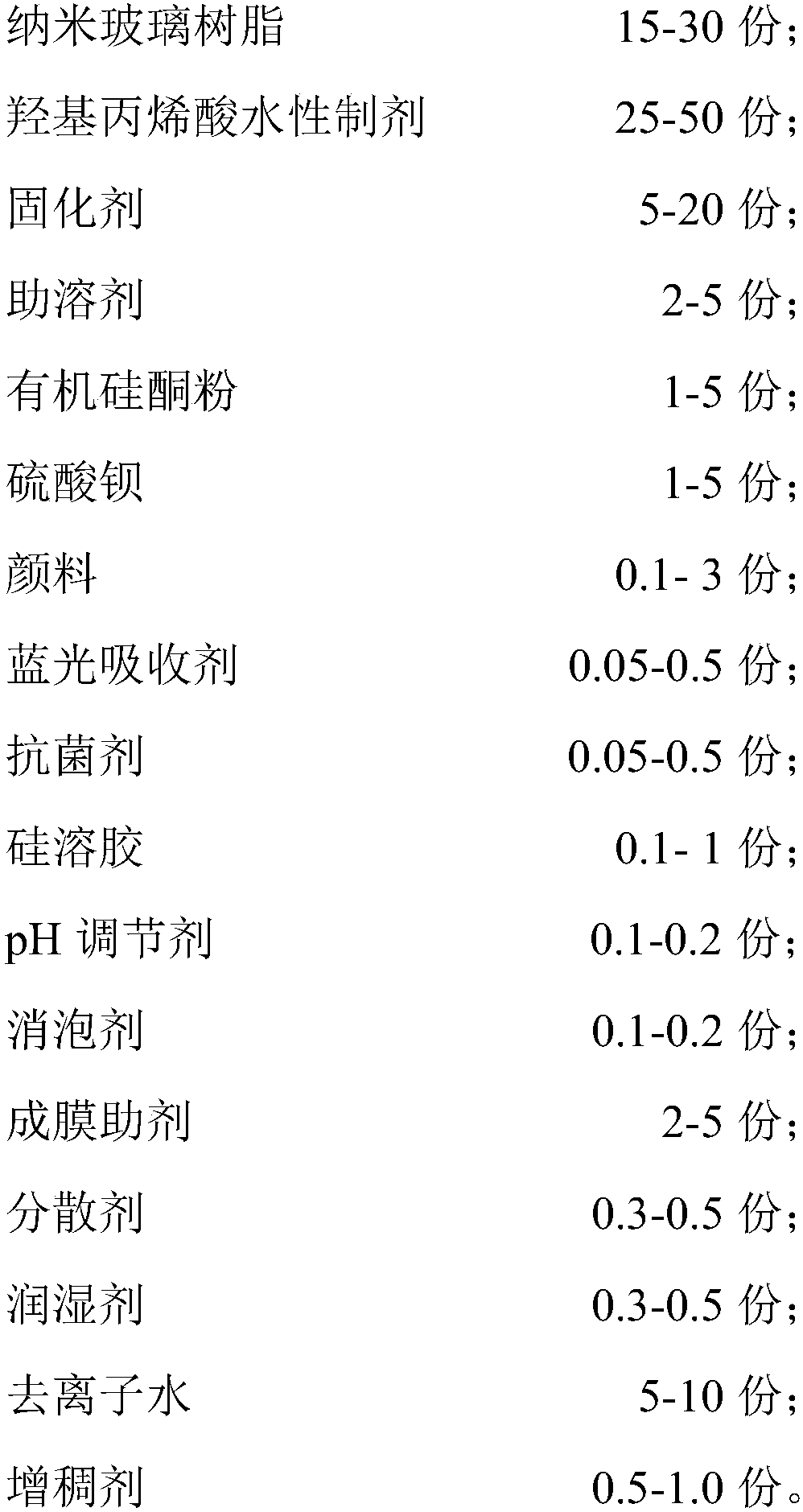

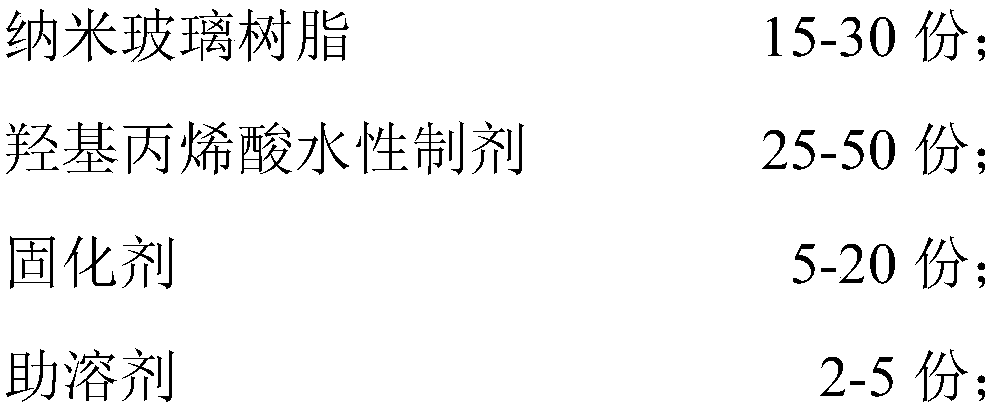

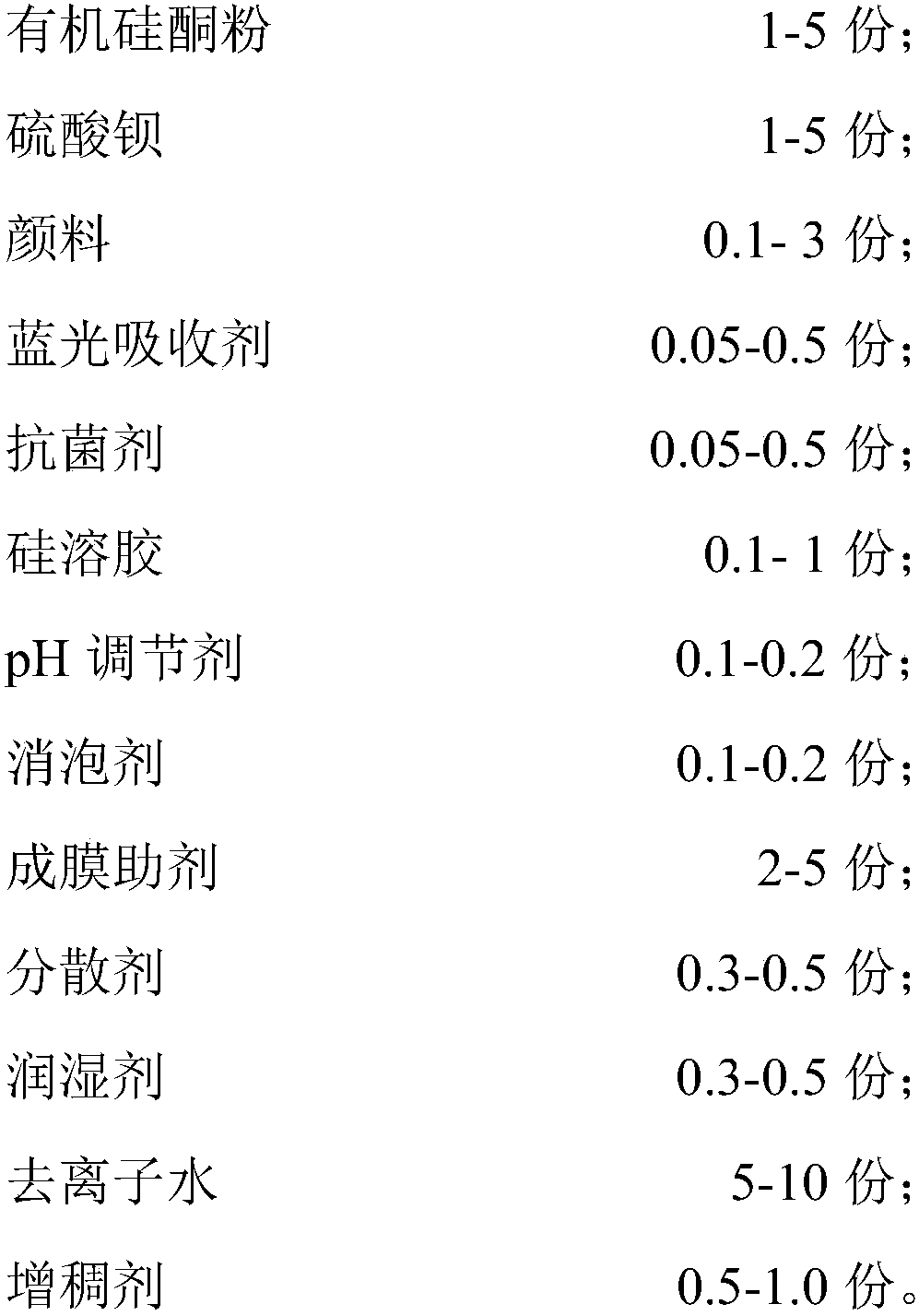

PendingCN108285674AReduce the chance of breakageExtended service lifeAntifouling/underwater paintsPaints with biocidesIonSolvent

The invention relates to an environment-friendly anti-blue-ray antibacterial self-drying coating. The coating comprises, by weight, 15-30 parts of nano glass resin, 25-50 parts of hydroxyl acrylic acid, 5-20 parts of curing agent, 2-5 parts of cosolvent, 1-5 parts of organic silicone powder, 1-5 parts of barium sulfate, 0.1-3 parts of pigment, 0.05-0.5 part of blue ray absorbent, 0.05-0.5 part ofantimicrobial, 0.1-1 part of silica sol, 0.1-0.2 part of pH conditioning agent, 0.1-0.2 part of defoamer, 2-5 parts of coalescing agent, 0.3-0.5 part of dispersant, 0.3-0.5 part of base material wetting agent, 5-10 parts of deionized water and 0.5-1 part of thickener. The coating has the advantages that the damage rate of a tempered glass screen protector can be reduced, blue ray damage can be reduced, sterilization is durable and the coating is environmentally friendly and has a colorful effect; the preparation of the coating is simple to operate, which is suitable for the operation of massive production.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Double-layer grinding machine for machining cylindrical workpiece

ActiveCN108381371AIncrease productivityEasy to operateEdge grinding machinesPolishing machinesBatch productionEngineering

The invention discloses a double-layer grinding machine for machining a cylindrical workpiece. The double-layer grinding machine for machining the cylindrical workpiece comprises a first base plate and a second base plate. A first through hole is formed at the center of the first base plate. A first grinding plate is rotationally connected into the first through hole in a matched manner. A secondthrough hole is formed at the center of the second base plate. A second grinding disk is rotationally connected into the second through hole in a matched manner. A power device is further arranged onthe lower side of the first grinding disk. A first material guide disk is arranged above the first base plate. The second material guiding disk is arranged above the second base plate. A material guide hole is arranged at the center of the second material guide disk. A material guide pipe is connected into the material guide hole in a matched manner. A feeding channel is further arranged on the edge of the upper side of the second base plate. A feeding device is further arranged at the position of the feeding channel. The double-layer grinding machine for machining the cylindrical workpiece has the advantages of being suitable for grinding the small-diameter cylindrical workpiece, capable of achieving simultaneous operation of rough grinding and fine grinding, capable of automatically conducting feeding, discharging and washing and suitable for batch production operation.

Owner:阜阳市战千里知识产权运营有限公司

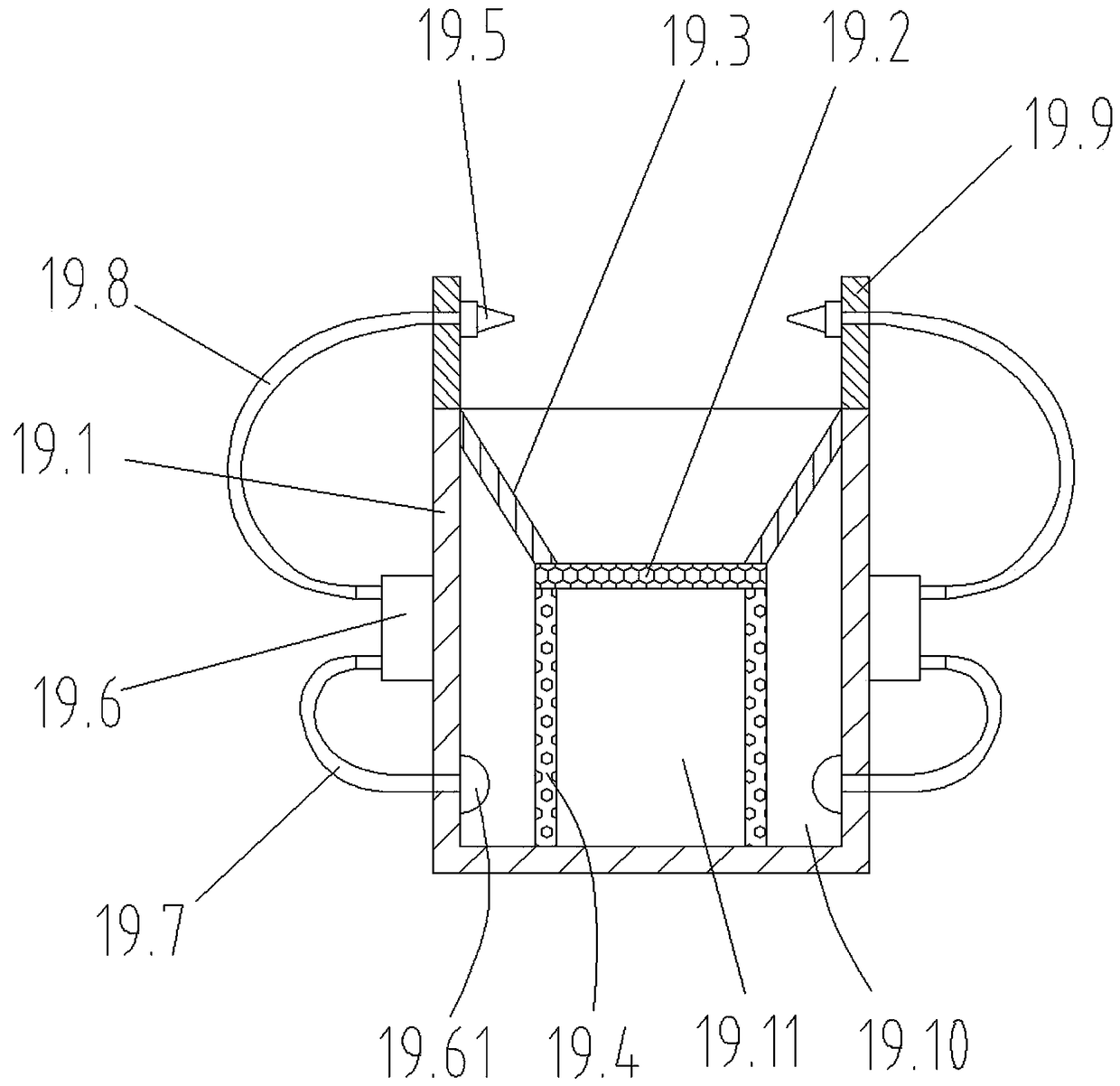

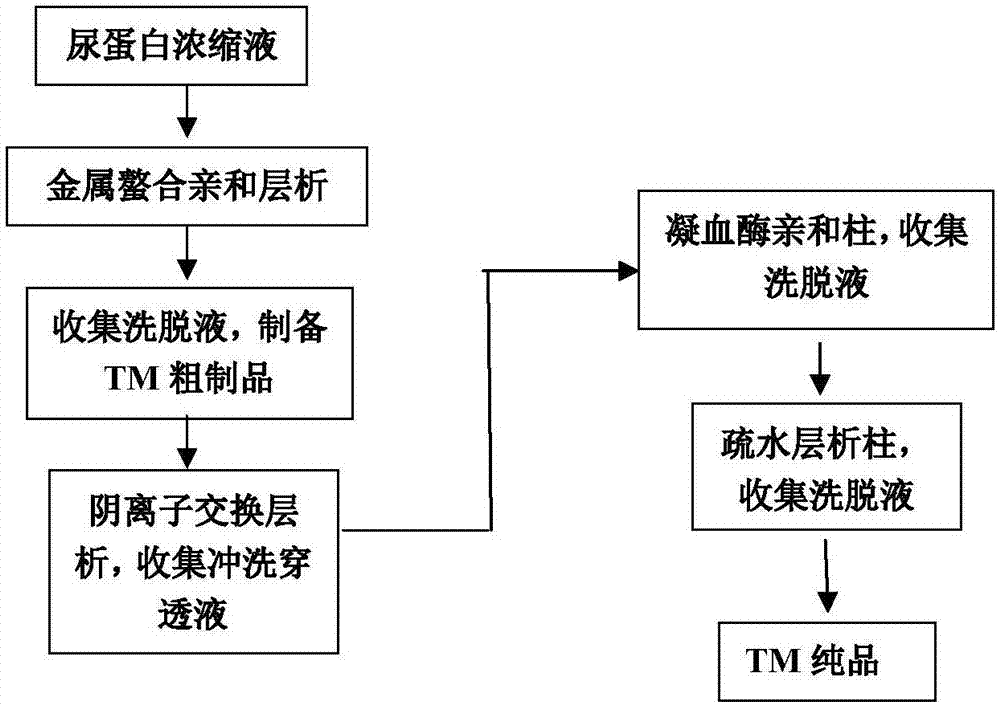

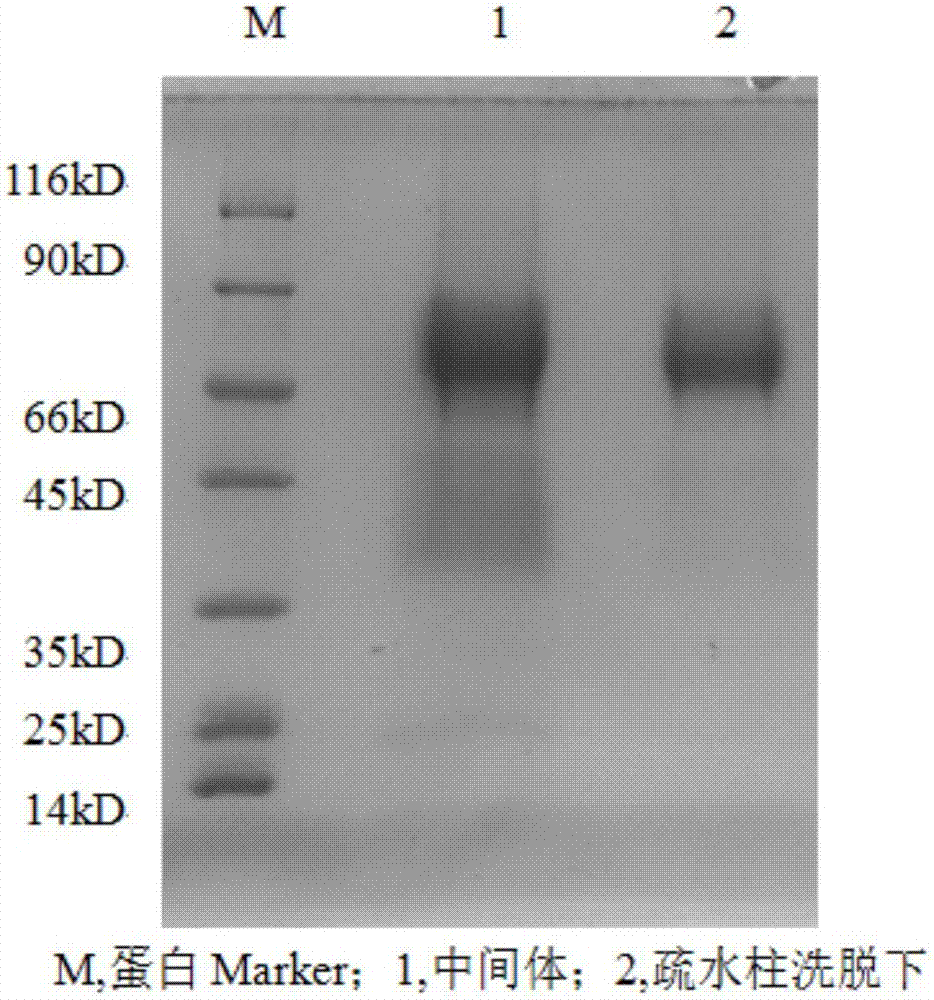

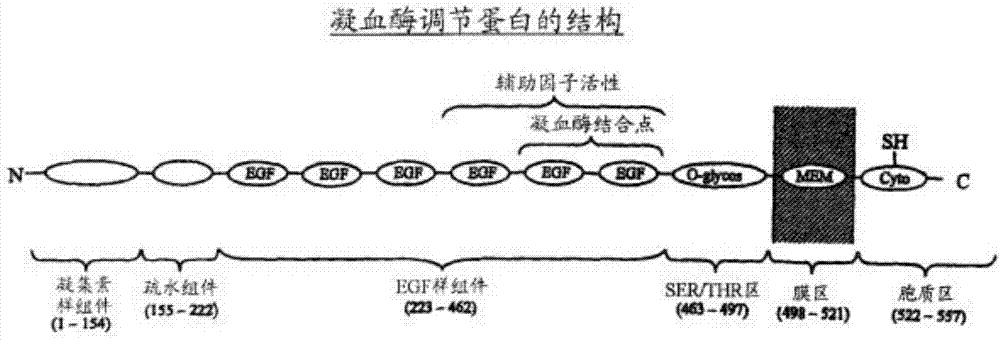

Preparation method of human derived thrombomodulin capable of being industrially produced

InactiveCN107987157AEasy to operateLow costThrombomodulinPeptide preparation methodsChromatography columnChemistry

The invention discloses a preparation method of human derived thrombomodulin capable of being industrially produced. According to the method, urine protein concentrate extracted from human urine is made to go through a metal chelate affinity chromatography column, an anion exchange column, a thrombin affinity chromatography column and a hydrophobic chromatography column so as to obtain thrombomodulin. The provided method has the advantages of simple and convenient operation, low cost, and high yield. The prepared thrombomodulin is purely human-derived, has the advantages of no foreign proteinpollution, more safety, more reliability, high bioactivity, no immunogenicity and stable quality, and is suitable for large scale production.

Owner:YANGZHOU AIDEA BIOTECH

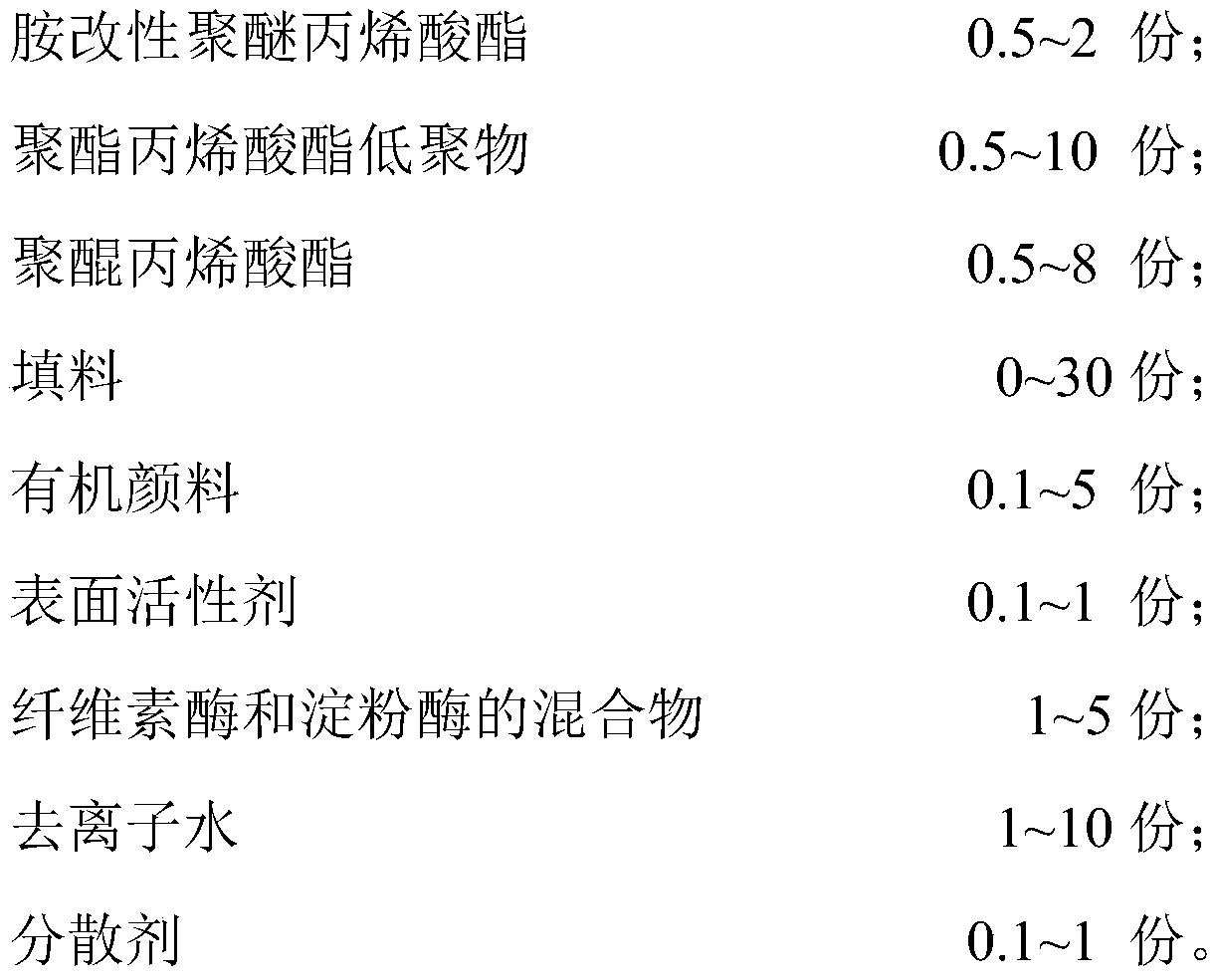

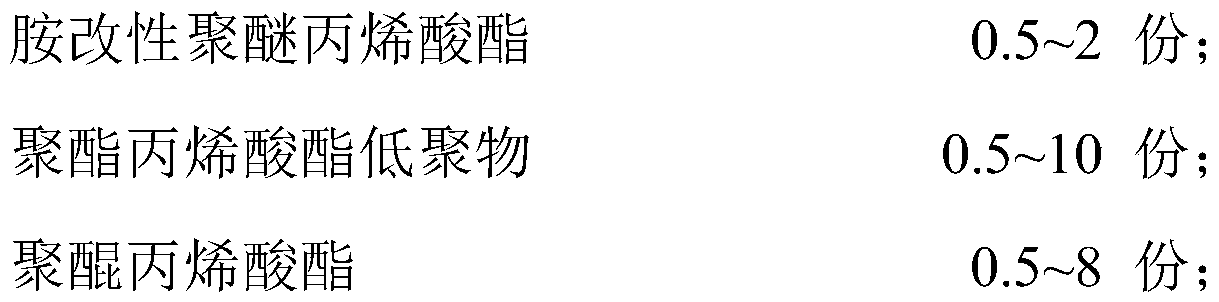

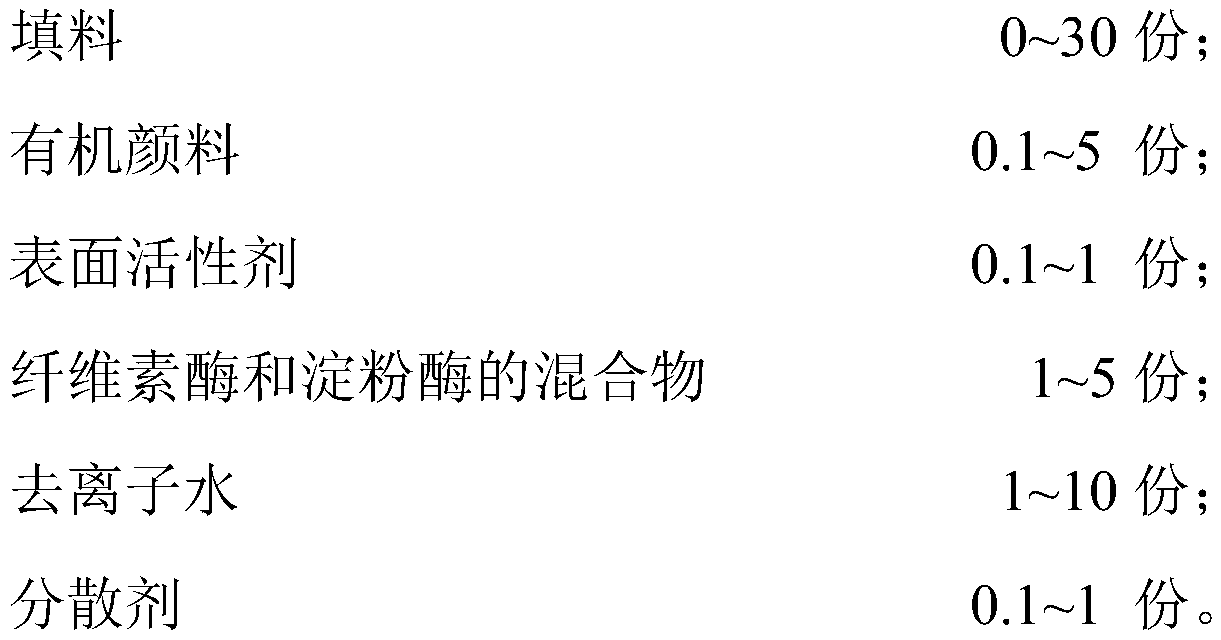

Slurry for artificial colored sand, high-wear-resistance artificial colored sand and preparation methods of the slurry and the artificial colored sand

ActiveCN110484106AHigh tinting strengthImprove wear resistancePolyether coatingsPolyester coatingsAmylasePolyester

The invention relates to the field of coating, in particular to slurry for artificial colored sand, high-wear-resistance artificial colored sand and preparation methods of the slurry and the high-wear-resistance artificial colored sand. The slurry comprises the following raw materials: amine modified polyether acrylate, a polyester acrylate oligomer, polyquinone acrylate, a filler, organic pigment, a surfactant, a mixture of cellulase and amylase, deionized water and a dispersing agent. The slurry enables good coloring power and wear resistance when used for artificial colored sand, and the organic pigment has good dispersibility in the slurry. The high-wear-resistance artificial colored sand can be prepared from the slurry and sandstone, and can meet industrial application.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Compression molding mechanism for plastic packaging box system

InactiveCN106273372ASuitable for mass production operationsImprove continuityEngineeringPlastic packaging

The invention provides a compression molding mechanism for a plastic packaging box system. The compression molding mechanism comprises an upper compression molding assembly and a lower compression molding assembly. The upper compression molding assembly comprises an upper air cylinder, an upper supporting seat, an upper die seat and multiple die cores. The upper air cylinder is connected with the upper supporting seat in a drive manner. The upper die seat is arranged on the upper supporting seat. The die cores are arranged on the upper die seat in the length direction of the upper die seat. The lower compression molding assembly is located below the upper compression molding assembly. The lower compression molding assembly comprises a lower air cylinder, a lower supporting seat and a lower die seat. The lower air cylinder is connected with the lower supporting seat in a drive manner. The lower die seat is arranged on the lower supporting seat. The lower die seat is provided with die cavities the same as the die cores in number. The die cavities and the die cores are matched in shape and arranged in a one-to-one manner. In work, the die cores can enter the corresponding die cavities. The compression molding mechanism has the beneficial effects of being high in continuity, high in production efficiency and high in degree of automation and is especially suitable for the mass production operation of enterprises.

Owner:ANQING BOMEI PLASTIC CO LTD

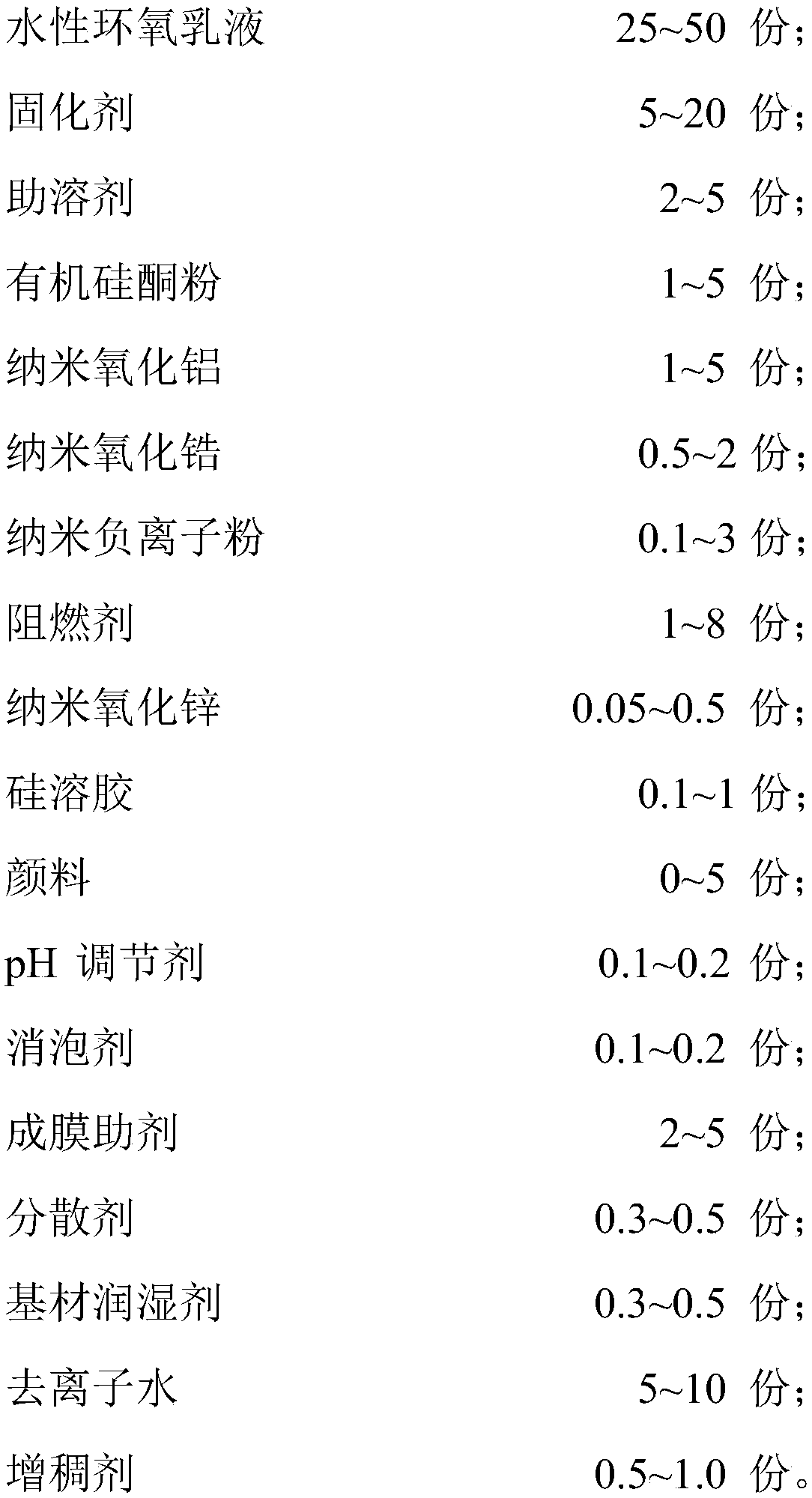

Chromotropic paint used for medical instrument and preparation method and application thereof

PendingCN108690448AGood environmental characteristicsGood light fastnessAntifouling/underwater paintsPaints with biocidesAir cleaningNano al2o3

The invention relates to a chromotropic paint used for a medical instrument and a preparation method and an application thereof. The chromotropic paint comprises the following raw materials in parts by weight: 25-50 parts of an aqueous hydroxyl acrylic emulsion, 5-20 parts of a curing agent, 2-5 parts of a cosolvent, 1-5 parts of organic silicone powder, 1-5 parts of nano alumina, 0.05-0.5 parts of nano zirconia, 0.1-3 parts of nano negative ion powder, 4-8 parts of titanium dioxide, 0.05-0.5 parts of nano zinc oxide, 1-6 parts of temperature-sensitive color-changing powder, 0.1-1 part of silica sol, 0.1-0.2 parts of a pH conditioning agent, 0.1-0.2 parts of an antifoaming agent, 2-5 parts of a film-forming auxiliary agent, 0.3-0.5 parts of a dispersant, 0.3-0.5 parts of a base material wetting agent, 5-10 parts of deionized water, and 0.5-1.0 parts of a thickening agent. The VOCs content of the paint is low, and a coating has good light resistance, chemically-resistant performance, hardness, bacterinertness, air cleaning performance, and color-changing indication effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370BImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneChemical composition

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

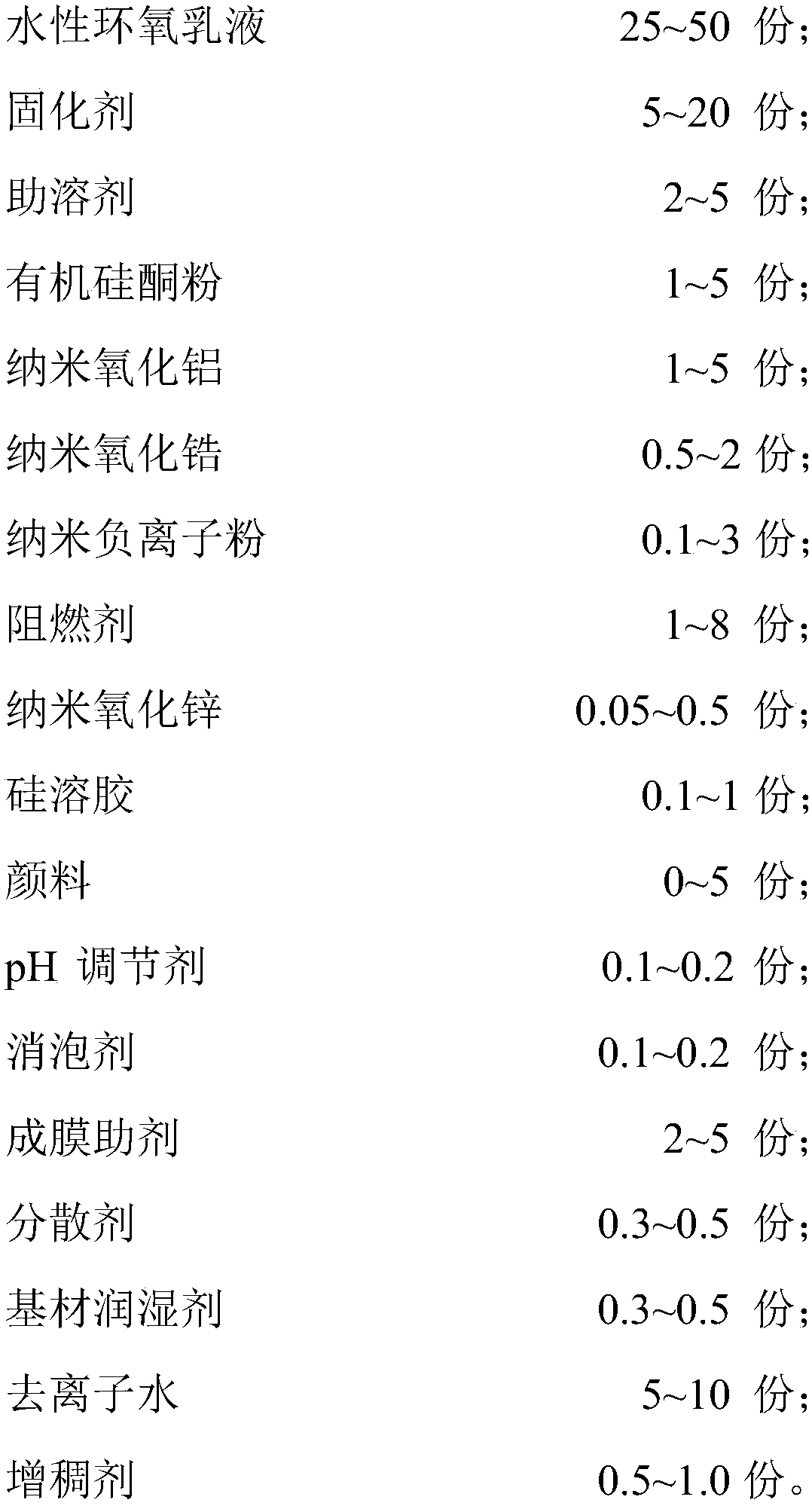

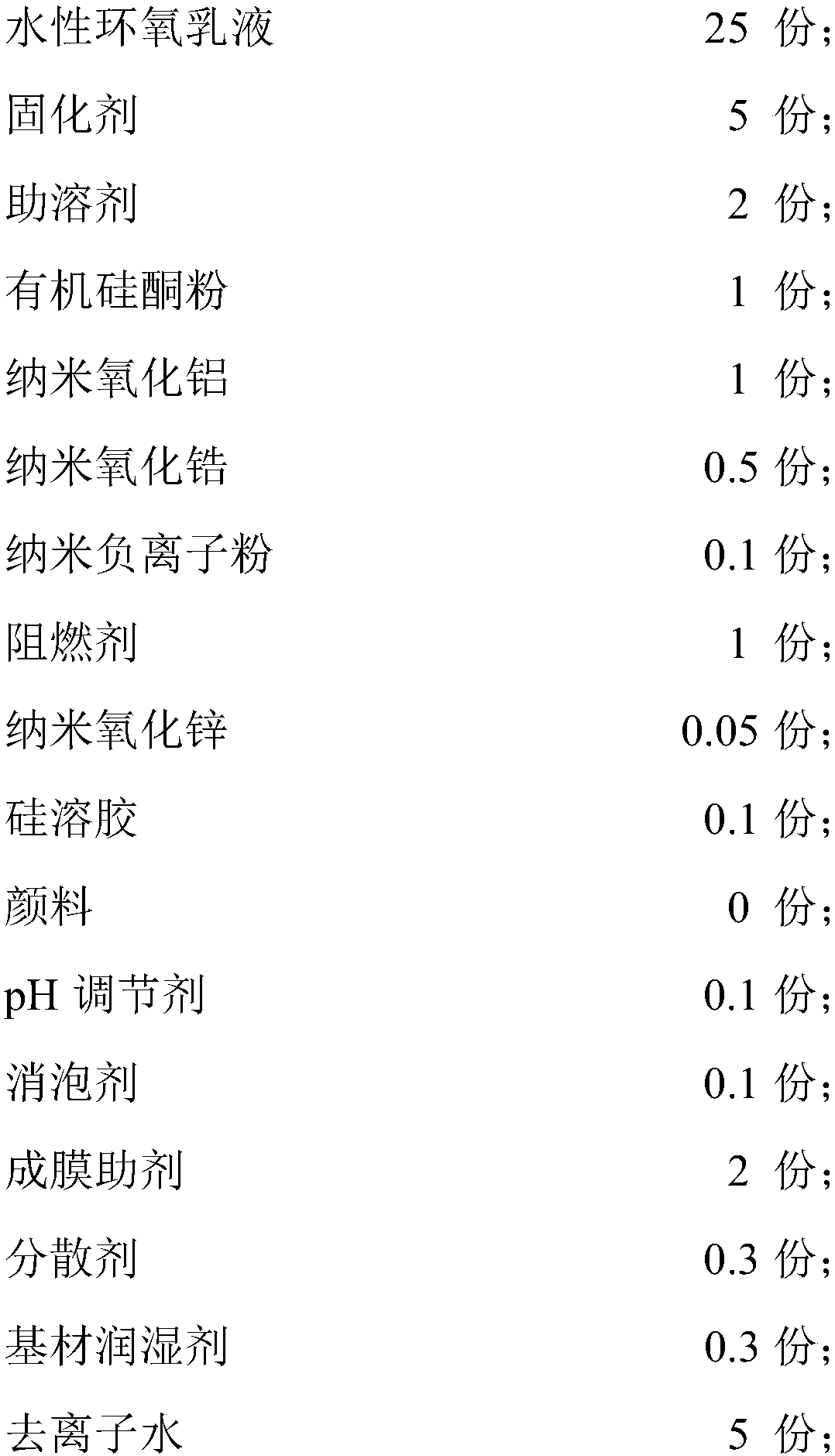

Fireproof bacteriostatic aqueous terrace paint used for bus and preparation method and application thereof

InactiveCN108690455ALow VOCs contentGood environmental protectionFireproof paintsAntifouling/underwater paintsAir cleaningIon

The invention relates to a fireproof bacteriostatic aqueous terrace paint used for bus and a preparation method and an application thereof. The paint comprises the following raw materials: an aqueousepoxy emulsion, a curing agent, a cosolvent, organic silicone powder, nano alumina, nano zirconia, nano negative ion powder, a fire retardant, nano zinc oxide, silica sol, a pigment, a pH conditioningagent, an antifoaming agent, a film-forming auxiliary agent, a dispersant, a base material wetting agent, deionized water, and a thickening agent. The preparation method is characterized in that theraw materials excepting the curing agent, the cosolvent and 1 / 3-1 / 2 formula amount of the deionized water are prepared to obtain a component A, the curing agent, the cosolvent and 1 / 3-1 / 2 formula amount of the deionized water are prepared to obtain a component B, before use, the component A and the component B are mixed to obtain the product. The VOCs content of the paint is low, and a coating hasgood light resistance, chemically-resistant performance, flame resistance and hardness, and the paint has bacterinertness and air cleaning performance, and is suitable for the bus.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Automatic compression molding and feeding device for plastic packaging box

InactiveCN106273371ASuitable for mass production operationsImprove continuityDomestic articlesCompression moldingPlastic packaging

The invention provides an automatic compression molding and feeding device for a plastic packaging box. A heating mechanism is located on one side of a feeding mechanism and softens a strip plastic material. A compression molding mechanism is located on the side, away from the feeding mechanism, of the heating mechanism and conducts compression molding on the strip plastic material. A cooling mechanism is located on the side, away from the heating mechanism, of the compression molding mechanism and hardens the strip plastic material. The feeding mechanism is located on the side, away from the compression molding mechanism, of the cooling mechanism and adds the material to the formed packaging box. A cutting mechanism is located on the side, away from the cooling mechanism, of the feeding mechanism and separates the packaging box from the strip plastic material. A discharging mechanism conveys the packaging box to the subsequent processes. The automatic compression molding and feeding device for the plastic packaging box has the beneficial effects that automatic feeding in the compression molding process is achieved, continuity is high, production efficiency is high and the degree of automation is high and is especially suitable for the mass production operation of enterprises.

Owner:ANQING BOMEI PLASTIC CO LTD

Anti-doodling interior wall water-in-water multi-colour paint and preparation method thereof

PendingCN108276849AGood stain resistanceMeet the use requirementsAntifouling/underwater paintsPaints with biocidesEmulsionMass ratio

The invention relates to the technical field of water-based paint, and particularly discloses an anti-doodling interior wall water-in-water multi-colour paint and a preparation method thereof. The anti-doodling interior wall water-in-water multi-colour paint is prepared from a dispersing phase and a continuous phase which are in the mass ratio of (1.3 to 1.5) to 1; the dispersing phase takes waterborne acrylic emulsion as a main component; the continuous phase takes odour-less styrene-acrylic emulsion and functional acrylic emulsion as main components. The product disclosed by the invention issafe and environment-friendly; a pigment and filler are not used; the surface of a paint film is flat; an anti-doodling effect is good; anti-fouling performance is excellent; the using requirements of an interior wall coating can be met; the anti-doodling interior wall water-in-water multi-colour paint has an extremely good marble simulating and decorating effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Method for recovering Li and Co in lithium battery positive electrode material by utilizing polyethylene glycol dicarboxylic acid

InactiveCN112626344AHigh recovery rateMild reaction conditionsWaste accumulators reclaimingProcess efficiency improvementHazardous substancePolythylene glycol

The invention relates to a method for recovering Li and Co in a lithium battery positive electrode material by using polyethylene glycol dicarboxylic acid. The method specifically comprises the following steps of mixing the polyethylene glycol dicarboxylic acid with the lithium battery positive electrode material, heating to carry out a complexation reaction, adding a cobalt precipitant after the reaction is completed, adding a lithium precipitant, and carrying out solid-liquid separation to obtain a solid containing Li and Co. According to the method, the polyethylene glycol dicarboxylic acid is used as a metal recovery agent to extract the Li, the Co and other metal elements, the reaction conditions are mild, high temperature and high pressure are not involved, consumed time is short, the metal recovery rate is high, other toxic and harmful substances are not introduced, the polyethylene glycol dicarboxylic acid can be recycled, and the method is environmentally friendly, easy to operate, easy to control, low in cost, and suitable for large-scale production operation.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

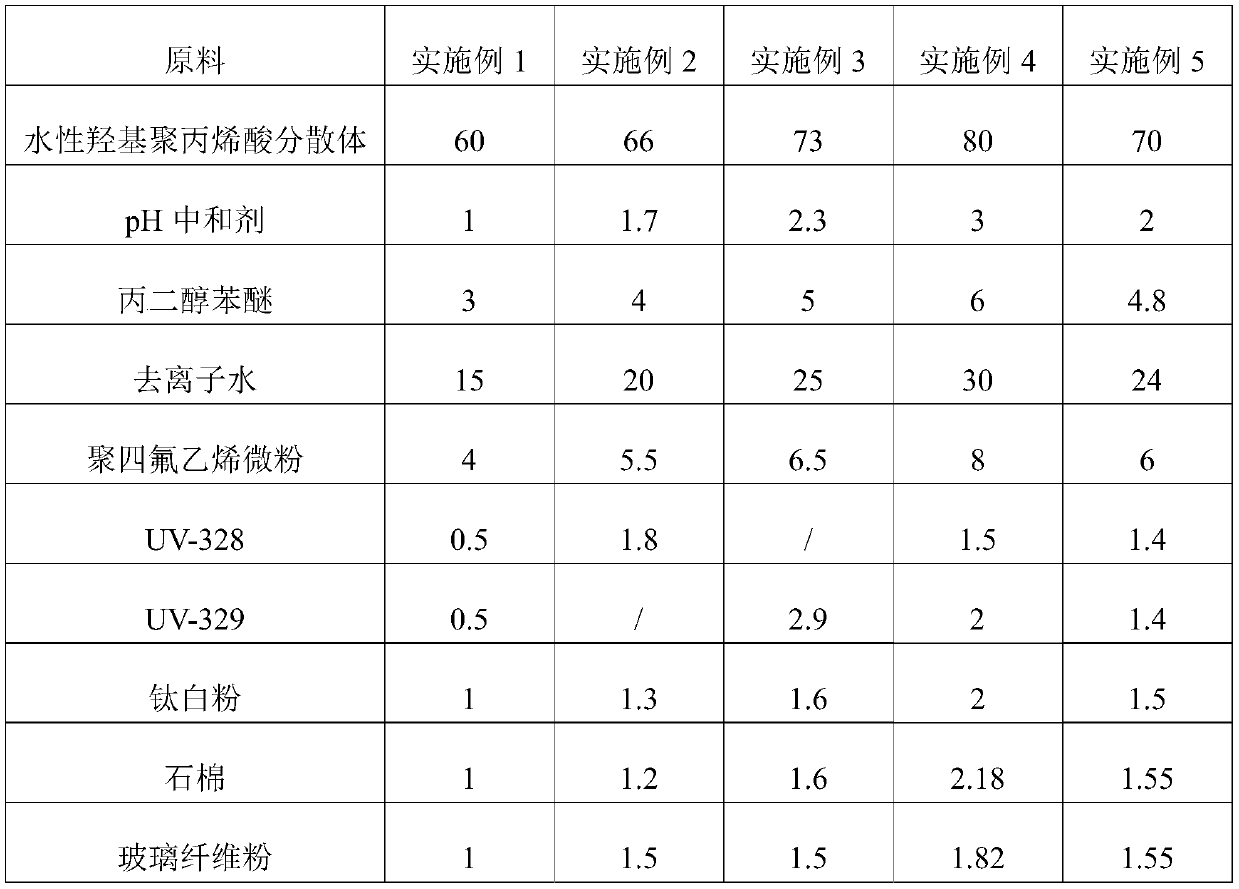

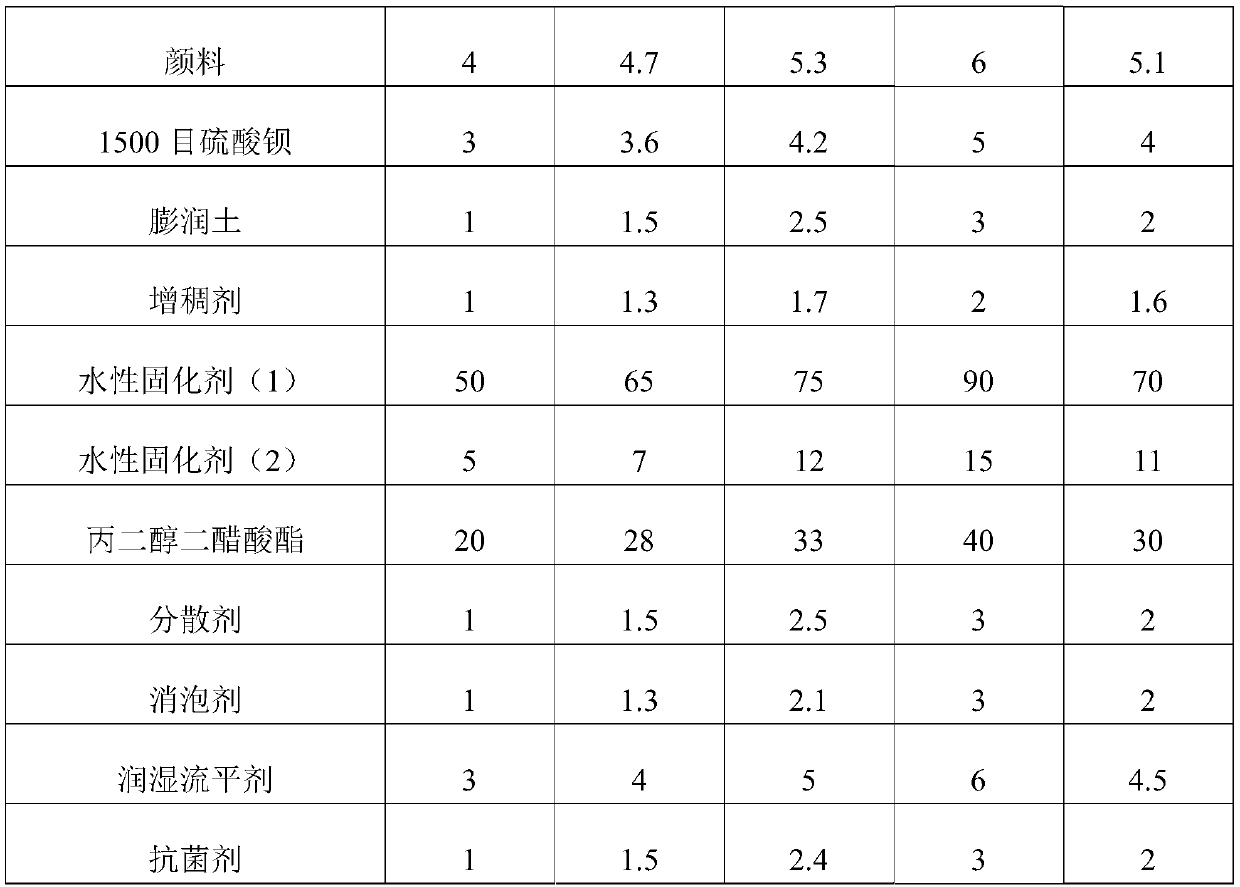

Anti-ultraviolet vehicle paint and preparation method thereof

PendingCN110964426AGood weather resistanceGood chemical resistancePolyurea/polyurethane coatingsUltraviolet lightsEthylic acid

The invention relates to the field of industrial coatings, and especially relates to an anti-ultraviolet vehicle paint and a preparation method thereof. The anti-ultraviolet vehicle paint is preparedfrom a water-based hydroxyl polyacrylic acid dispersion, a pH neutralizer, a coalescing agent, deionized water, polytetrafluoroethylene micro-powder, a benzotriazole ultraviolet light absorber, titanium dioxide, a flame retardant, pigment, barium sulfate, bentonite, a thickener, a water-based polyurethane curing agent, propylene glycol diacetate, a dispersing agent, an antifoaming agent, a wettingleveling agent and an antibacterial agent. The vehicle paint has the advantages of favorable ultraviolet resistance, favorable gloss, favorable decorativeness, favorable hydrophobicity, low VOC, lowodor and environment friendliness.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

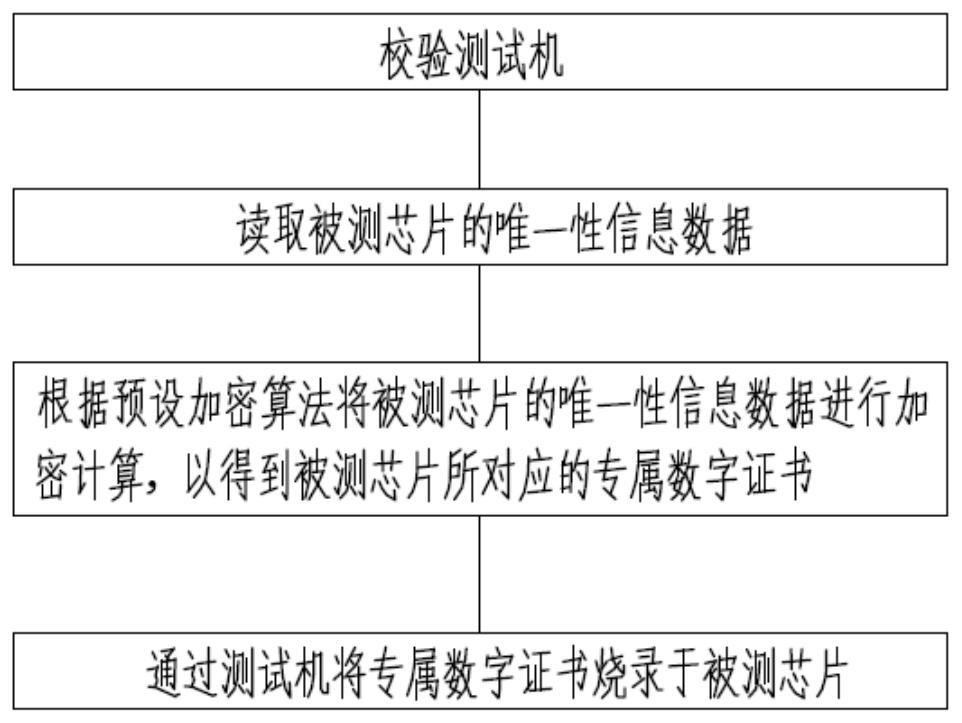

Secure chip burning method and system

InactiveCN114489695AReduce the transmission linkAvoid transmissionKey distribution for secure communicationUser identity/authority verificationPublic networkData transmission

The invention provides a secure chip burning method and system. The invention discloses a secure chip burning method. The method specifically comprises the following steps: checking a test machine; reading unique information data of the tested chip; performing encryption calculation on the unique information data of the tested chip according to a preset encryption algorithm to obtain an exclusive digital certificate corresponding to the tested chip; and burning the exclusive digital certificate on the tested chip through the test machine. According to the method, the transmission link of the burnt content of the tested chip is shortened, the burnt content is obtained through calculation by an encryption algorithm after the unique information data of the tested chip is read, the whole data transmission is completely carried out in a hardware security environment, cross-hardware public network transmission is avoided, and the transmission efficiency is improved. The problem of leakage caused by separate distribution of the burnt content and the tested chip in the prior art is solved, and the method has high safety and high convenience and is suitable for batch production operation.

Owner:嘉兴威伏半导体有限公司

Thick steel plate with great line energy and low welding crack sensitivity and its production process

InactiveCN100396809CLow weld crack susceptibilityImprove performanceTemperature control deviceQuenchingAustenite

The present invention discloses one kind of thick steel plate with great line energy and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.10 wt%, Si 0.15-0.40 wt%, Mn 1.20-1.60 wt%, P not more than 0.015 wt%, S not more than 0.007 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo 0.15-0.30 wt%, V 0.02-0.06 wt%, Al 0.015-0.045 wt%, Ti 0.010-0.034 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 %. The production process includes pre-treatment of molten iron, smelting in converter, LF furnace plus VD furnace vacuum treatment, two stage controlled rolling, on-line laminar flow cooling, tempering at 600-680 deg.c and other steps. The produced steel plate has no need of quenching and tempering treatment.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com