Anti-static terrace water-based paint and preparation method thereof

An anti-static and flooring technology, applied in anti-fouling/underwater coatings, conductive coatings, paints containing biocides, etc., can solve the problems of poor, easy to gather static ions, weather resistance and environmental protection, and achieve simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

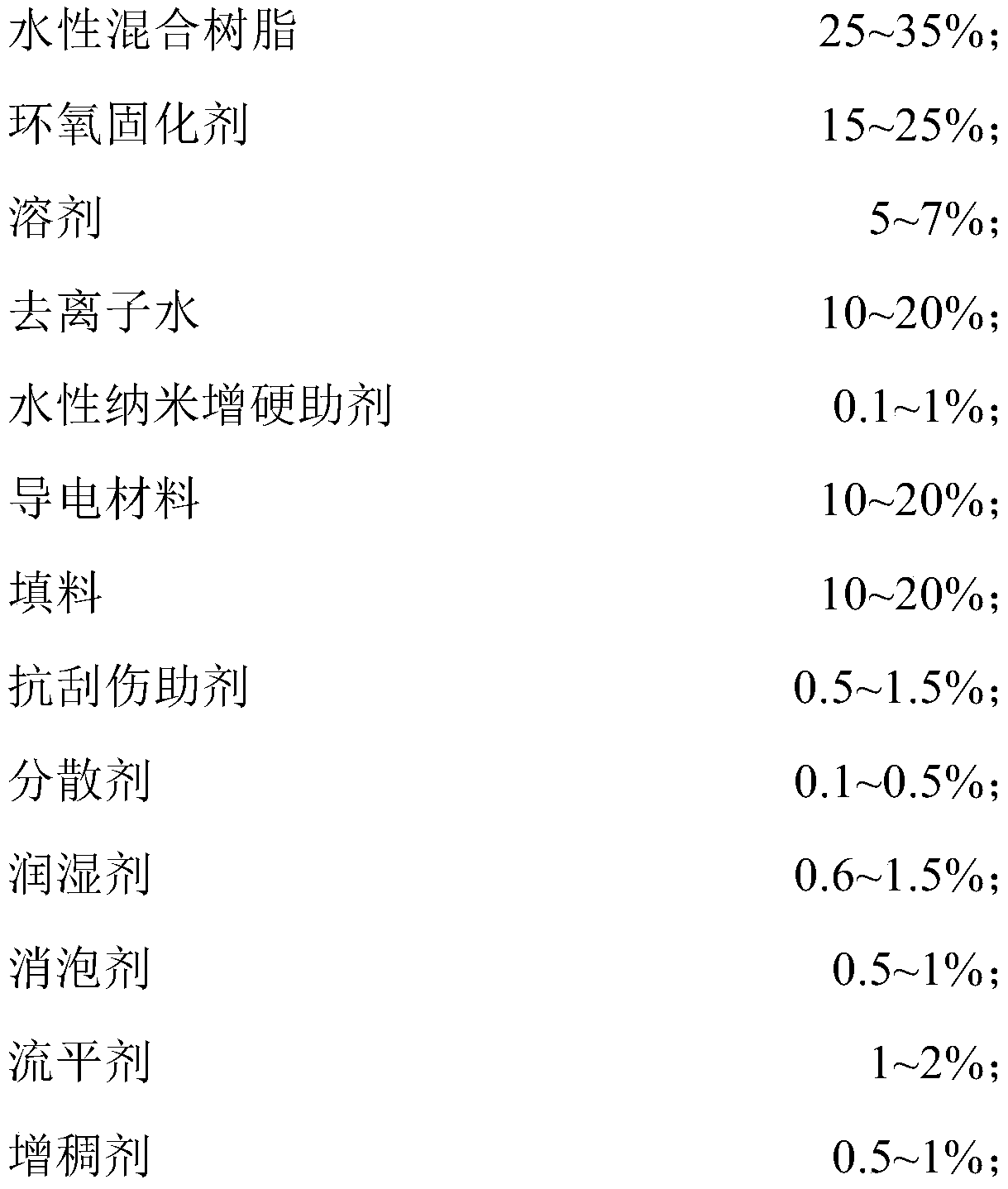

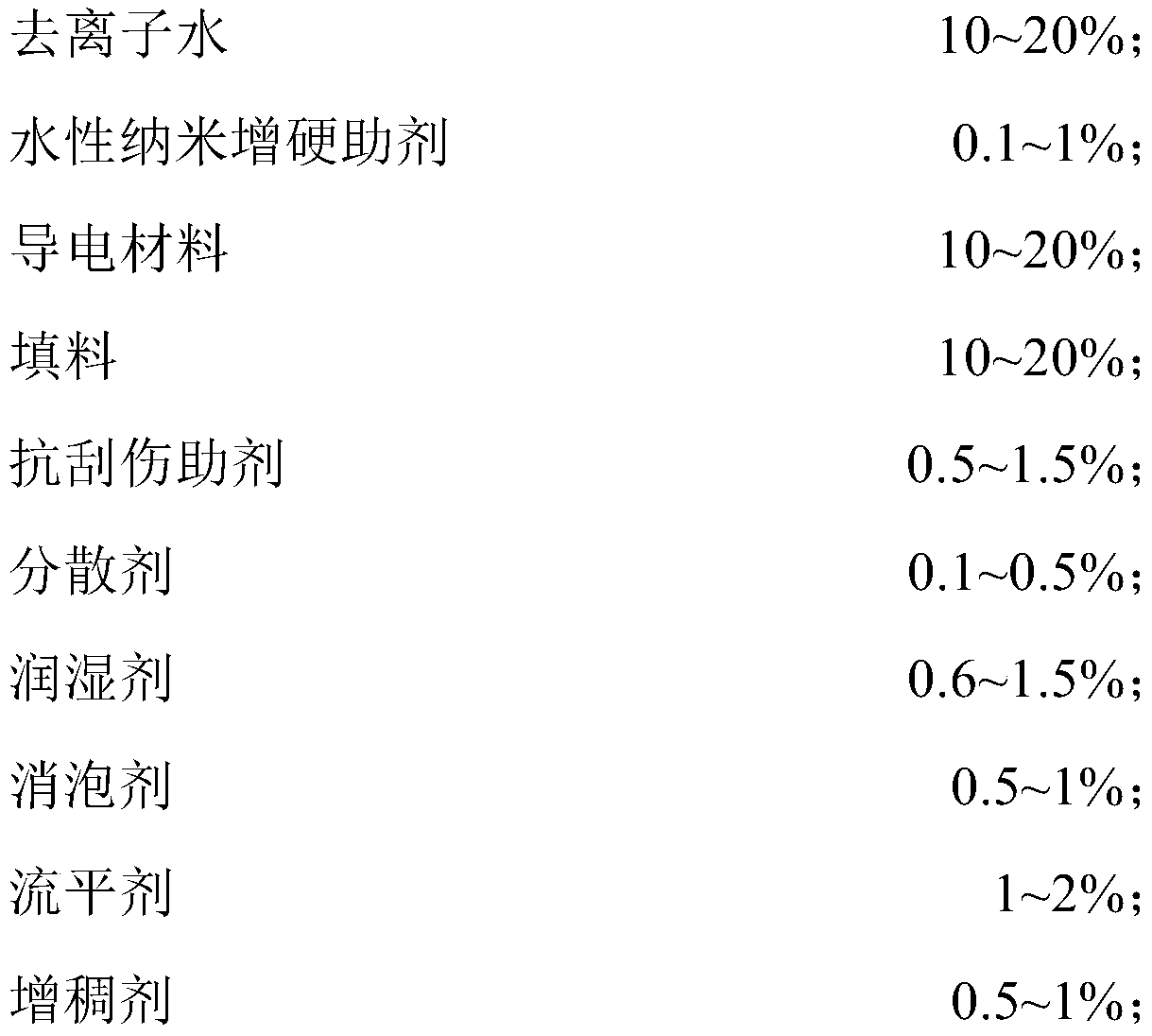

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: According to the ratio of the above-mentioned embodiment 1, in the material preparation tank, add water-based mixed resin, place it under the high-speed disperser, start the high-speed disperser, and add 65% of the formula amount evenly and slowly under 800r / min stirring Solvent, deionized water, dispersant, modified polyurethane high polymer wetting agent and 65% defoaming agent in the formulation amount, and stirred for 15 minutes. Under stirring at 1000r / min, add polyether siloxane copolymer wetting agent, leveling agent and anti-scratch additive, and stir for 10 minutes. Under stirring at 1200r / min, add water-based nano hardening powder, conductive materials, and functional fillers, and stir for 20 minutes to control the fineness below 15 μm. Add the thickener under stirring at 800r / min, and stir for 25min to make component A. According to the above ratio, add epoxy curing agent into the material preparation tank, place it under the high-speed dispers...

Embodiment 2

[0043]Embodiment 2: According to the ratio of the above-mentioned embodiment 2, in the material preparation tank, add water-based mixed resin, place it under the high-speed disperser, start the high-speed disperser, and add 70% of the formula amount evenly and slowly under 700r / min stirring Solvent, deionized water, dispersant, modified polyurethane high polymer wetting agent and 70% defoaming agent in the formulation amount, and stirred for 13 minutes. Under stirring at 900r / min, add polyether siloxane copolymer wetting agent, leveling agent, anti-scratch additive, and stir for 8 minutes. Under stirring at 1100r / min, add water-based nano hardening powder, conductive materials, and functional fillers, and stir for 18 minutes to control the fineness below 20 μm. Add the thickener under stirring at 700r / min, and stir for 20min to make component A. According to the above ratio, add epoxy curing agent into the material preparation tank, place it under the high-speed disperser, st...

Embodiment 3

[0044] Embodiment 3: According to the proportioning of the above-mentioned embodiment 3, in the material preparation tank, add the water-based mixed resin, place it under the high-speed disperser, start the high-speed disperser, and under 900r / min stirring, evenly and slowly add 75% of the formula amount Solvent, deionized water, dispersant, modified polyurethane high polymer wetting agent and 75% defoaming agent in the formulation amount, and stirred for 13 minutes. Under stirring at 800r / min, add polyether siloxane copolymer wetting agent, leveling agent, and anti-scratch additive, and stir for 8 minutes. Under stirring at 1000r / min, add water-based nano hardening powder, conductive materials, and functional fillers, and stir for 18 minutes to control the fineness below 20 μm. Add the thickener under stirring at 700r / min, and stir for 20min to make component A. According to the above ratio, add epoxy curing agent into the material preparation tank, place it under the high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com