Environment-friendly anti-blue-ray antibacterial self-drying coating and preparation method thereof

A self-drying paint, anti-blue light technology, applied in the field of paint, can solve the problems of easily broken color of tempered film, high VOCs content, blue light damage to the screen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Further, the embodiment of the present invention also provides a preparation method of an environment-friendly anti-blue light antibacterial self-drying coating, the preparation method at least includes the following steps:

[0035]Step 1. Weigh each raw material component according to the raw material formula of the environment-friendly anti-blue light antibacterial self-drying coating, mix dispersant, barium sulfate, antibacterial agent, blue light absorber, silica sol, organic silicone powder, pigment and 1 / 2 Add the deionized water, pH regulator and defoamer in the formula quantity into the batching container, and mix evenly;

[0036] Step 2. Add hydroxyacrylic acid water-based preparation, nano glass resin, film-forming aid, wetting agent and 1 / 2 formula amount of deionized water, pH regulator, defoamer to the mixture obtained in step 1 and mix evenly, add Thickener, get A component;

[0037] Step 3, dissolving the curing agent in the co-solvent to obtain compone...

Embodiment 1

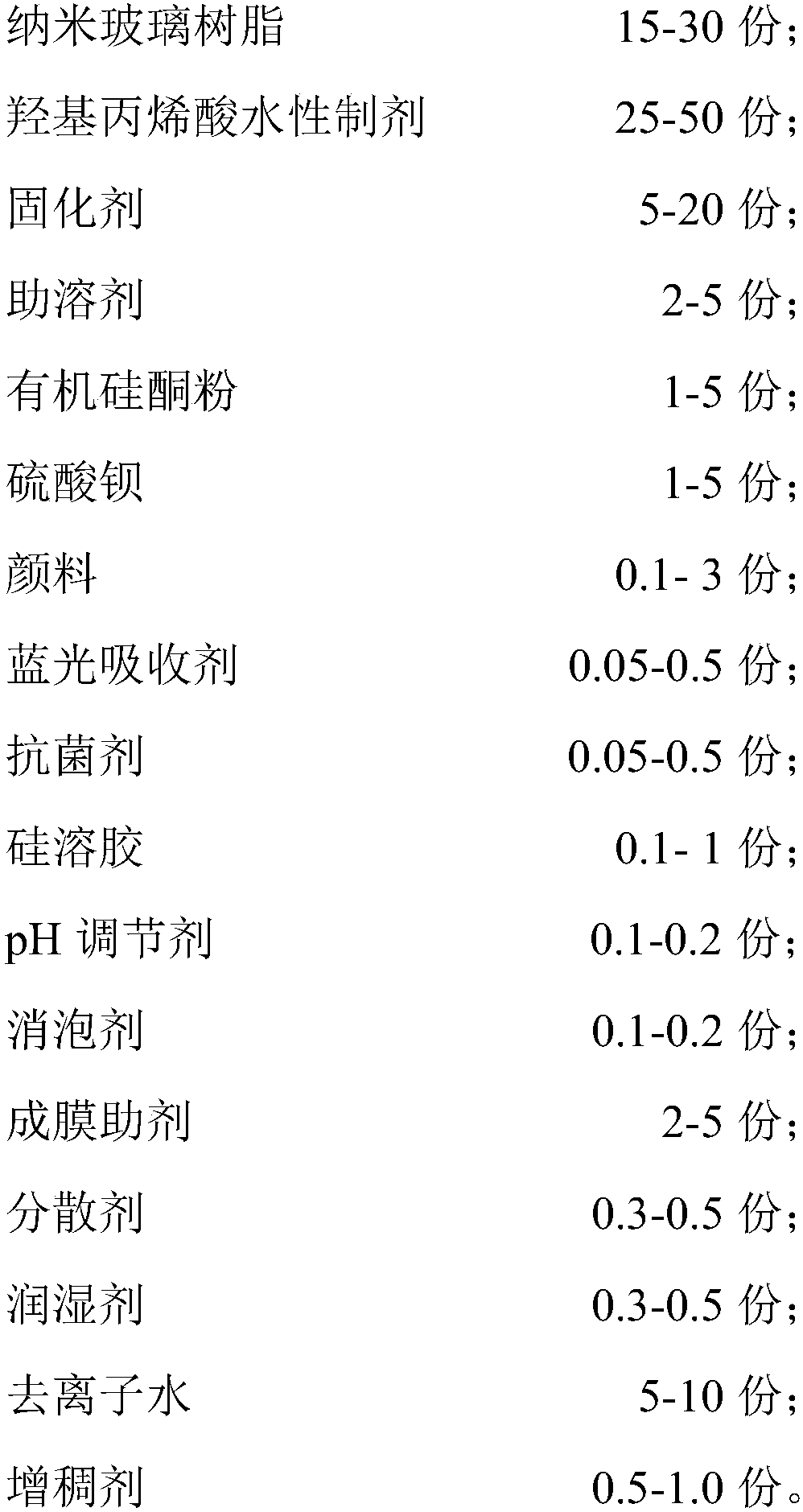

[0046] An embodiment of the present invention provides an environmentally friendly anti-blue light antibacterial self-drying coating, which includes the following raw materials in parts by weight:

[0047]

[0048]

[0049] Among them, the nano glass resin Shanghai Huzheng Nano Technology Co., Ltd. 4G-T35, the hydroxyacrylic acid water-based preparation is Bayer's A 2695, the curing agent is Bayer's 401-70, and the co-solvent is propylene glycol methyl ether acetate of Dow Chemical; The organic silicone powder is BT-9273 silicone powder from Guangzhou Batai Chemical Co., Ltd.; the barium sulfate is Micro nano barium sulfate from Sachaliben, Germany, and the pigment is BL-series laser ink from Zhongshan Liyang Nano Technology Co., Ltd. The blue light absorber is the blue light absorber LG-22 / 33 / 44 of Shanghai Huzheng Nano Technology Co., Ltd., the antibacterial agent Nantong Daxi Nong Nano Technology Co., Ltd. is the nano-zinc oxide powder, and the silica sol is Zhejiang K...

Embodiment 2

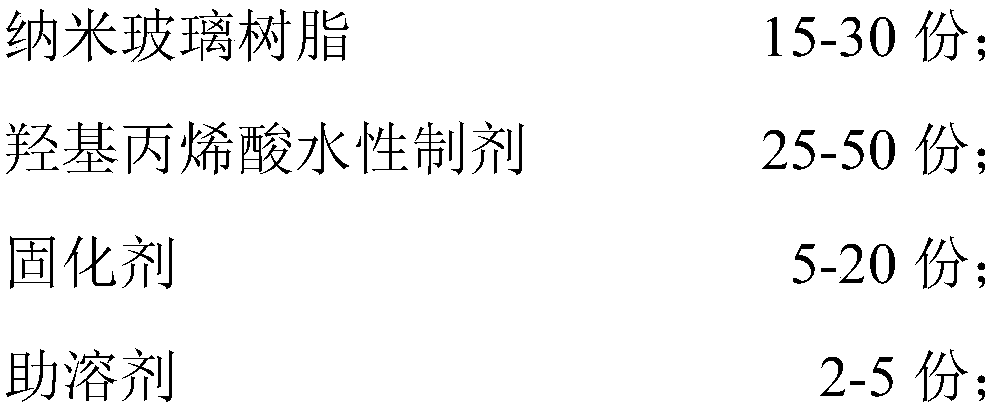

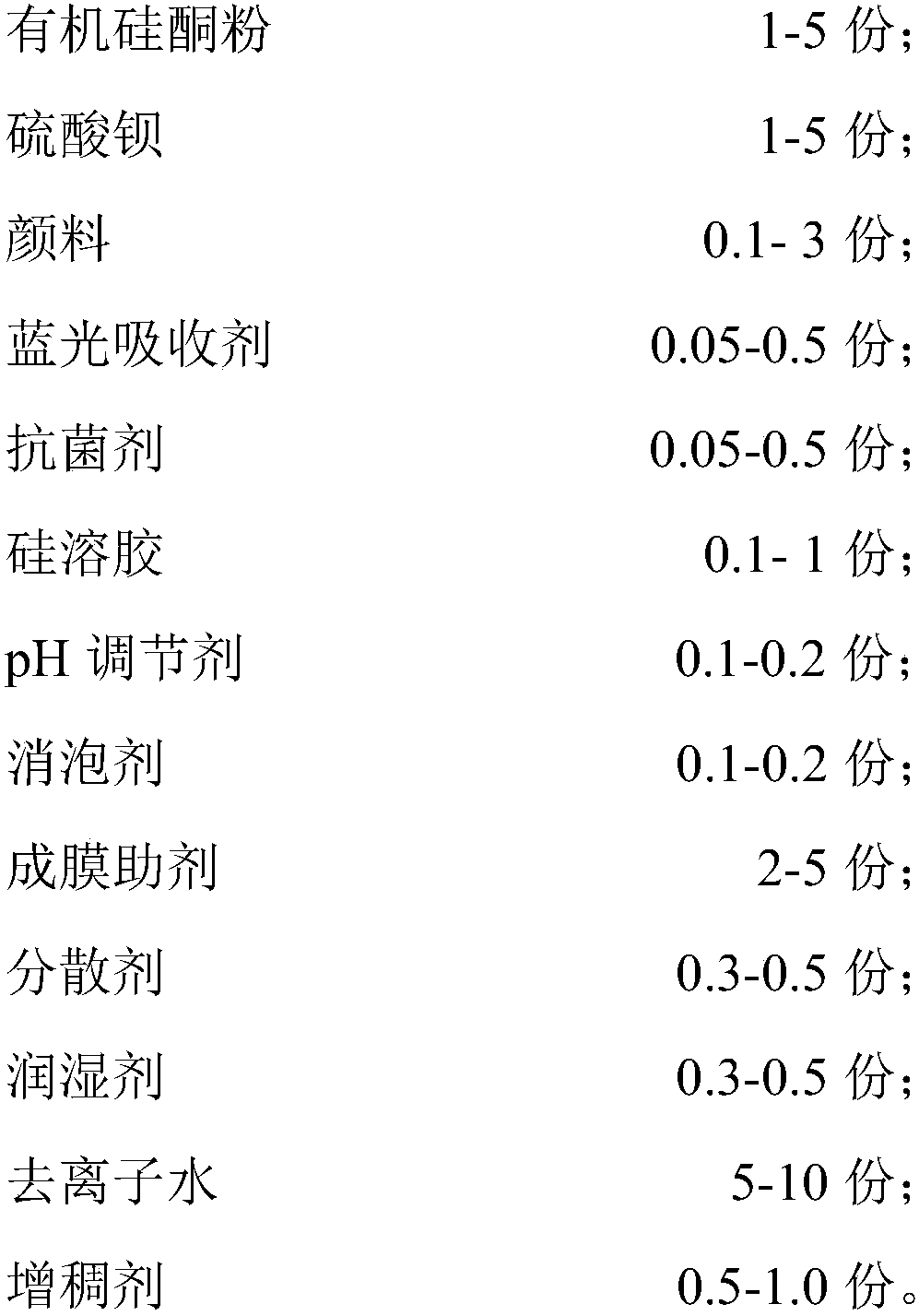

[0056] An embodiment of the present invention provides an environmentally friendly anti-blue light antibacterial self-drying coating, which includes the following raw materials in parts by weight:

[0057]

[0058]

[0059] Among them, the nano glass resin Shanghai Huzheng Nano Technology Co., Ltd. 4G-T35, the hydroxyacrylic acid water-based preparation is Bayer's A 2695, the curing agent is Bayer's 401-70, and the co-solvent is propylene glycol methyl ether acetate of Dow Chemical; The organic silicone powder is BT-9273 silicone powder from Guangzhou Batai Chemical Co., Ltd.; the barium sulfate is Micro nano barium sulfate from Sachaliben, Germany, and the pigment is BL-series laser ink from Zhongshan Liyang Nano Technology Co., Ltd. The blue light absorber is the blue light absorber LG-22 / 33 / 44 of Shanghai Huzheng Nano Technology Co., Ltd., the antibacterial agent Nantong Daxi Nong Nano Technology Co., Ltd. is the nano-zinc oxide powder, and the silica sol is Zhejiang K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com