Aqueous three-dimensional effect color changing orange-peel coating material, preparation method and applications thereof

A technology of three-dimensional effect and orange pattern, which is applied in the field of water-based three-dimensional effect color-changing orange pattern coating and its preparation, can solve the problems of high VOCs content, influence of coating temperature, and easy discoloration of the coating, and achieve low VOCs content and high antibacterial property , the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] And, the embodiment of the present invention also provides a kind of preparation method of water-based three-dimensional color-changing orange pattern coating, and described preparation method comprises the following steps at least:

[0039] Step a. Weigh each raw material component according to the raw material formula of the above-mentioned water-based three-dimensional color-changing orange pattern paint, and mix 1 / 2 to 2 / 3 of the deionized water and 1 / 2 to 2 / 3 of the pH regulator , dispersant, 1 / 2-2 / 3 formula amount of defoamer, nano-alumina, nano-zinc oxide, temperature-sensitive color-changing powder, magnesium lithium silicate, organic silicone powder, and nano-anion powder are mixed evenly;

[0040] Step b. Add water-based hydroxyacrylic acid emulsion, film-forming aids, remaining deionized water, remaining pH regulator, remaining defoamer, orange streaking aid and substrate wetting agent to the mixing container in a stirred state, pre- After mixing evenly, add ...

Embodiment 1

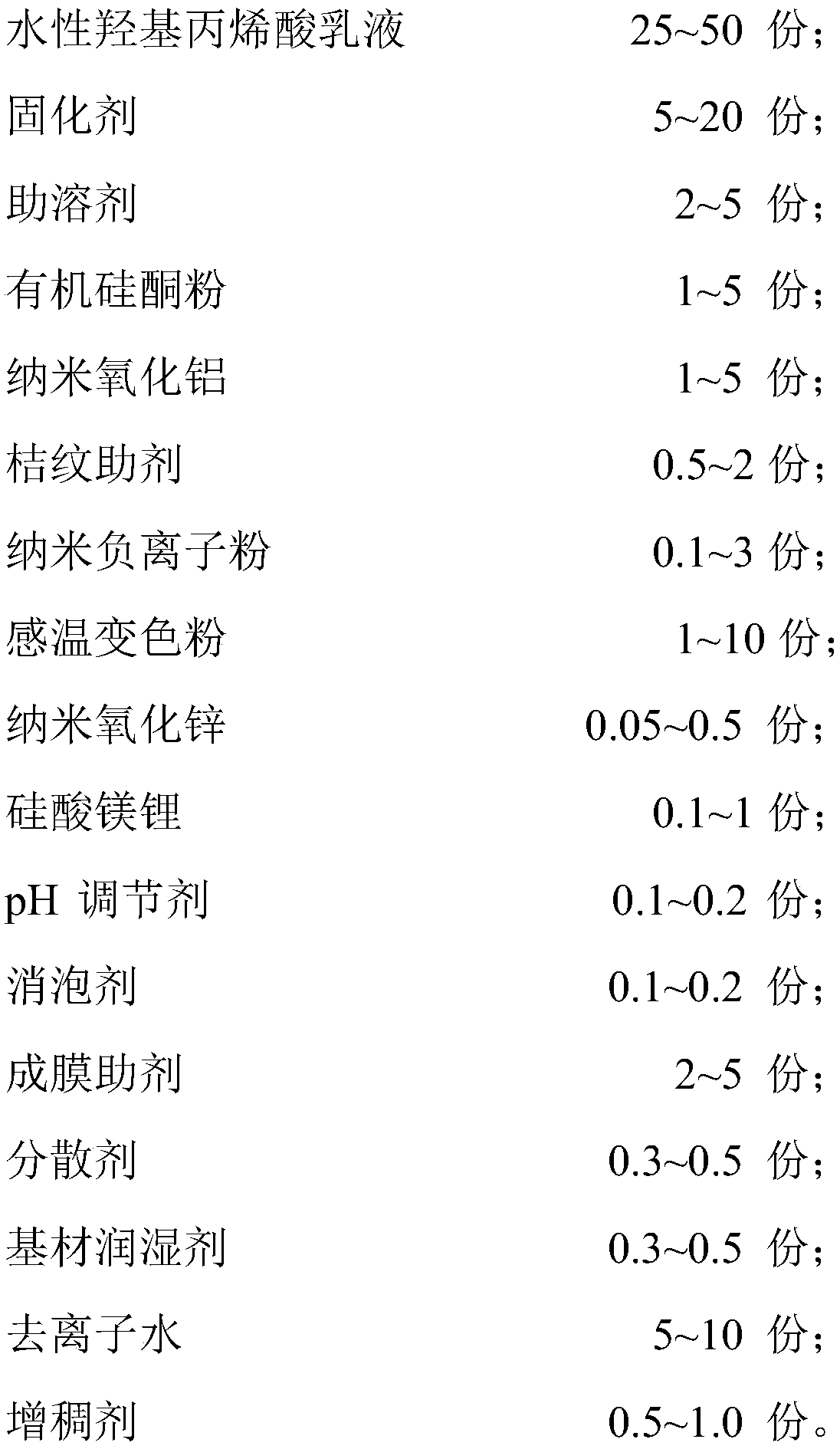

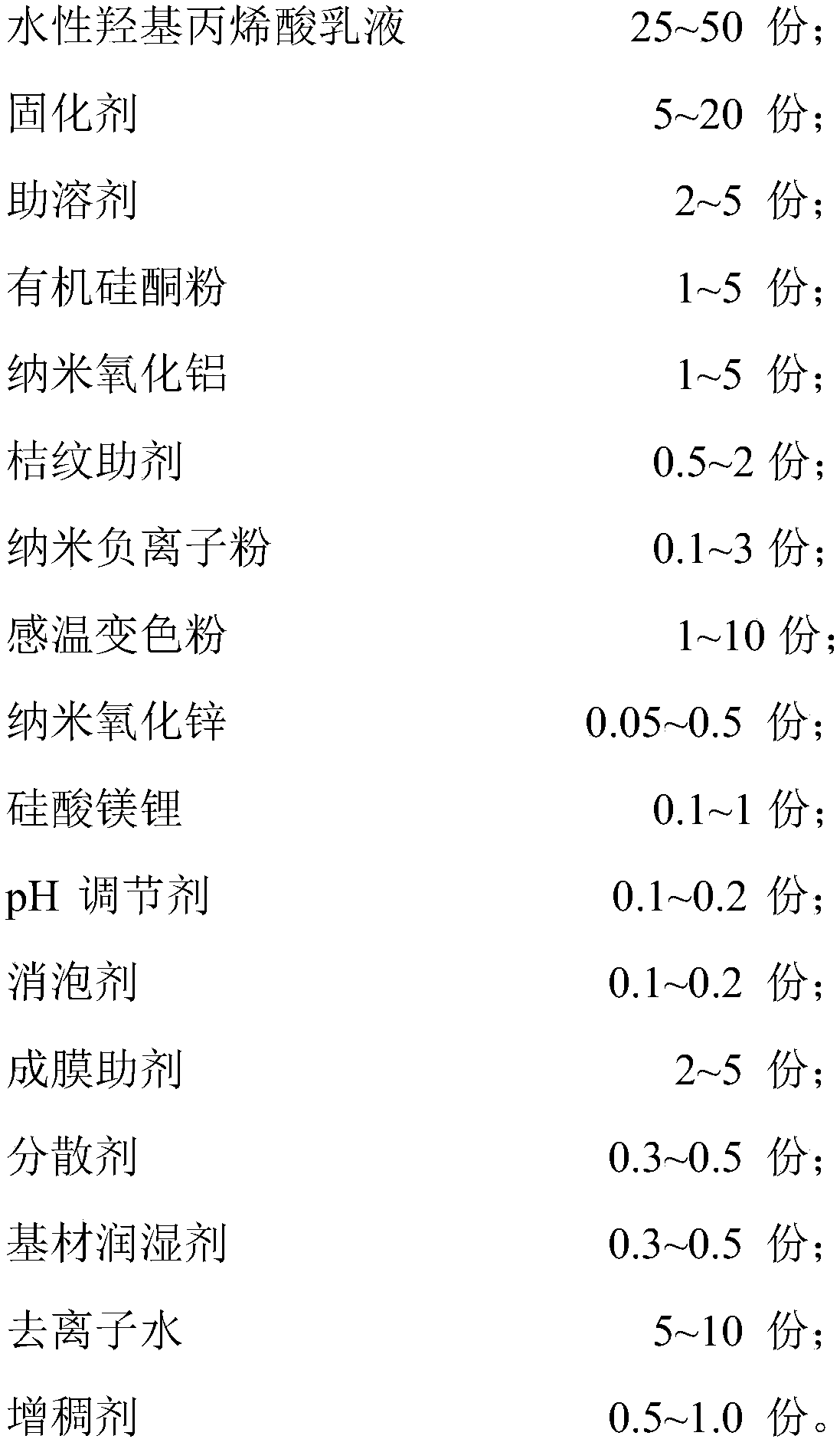

[0048] The embodiments of the present invention provide a water-based three-dimensional color-changing orange pattern paint, which includes the following raw materials in parts by weight:

[0049]

[0050]

[0051] Among them, the defoaming agent is a mixture of 941PL from MOUSSEX Company and BYK-028 from BAK Company with a mass ratio of 1.2:1, and the film-forming aids are environmentally friendly and clean-tasting film-forming aids AF and A mixture of alcohol ester-12 from American Eastman with a mass ratio of 1:1.

[0052] Prepare as follows:

[0053] Step a, weigh each raw material component according to the raw material formula of the above-mentioned water-based three-dimensional effect color-changing orange grain coating, and the deionized water of 1 / 2 formula quantity, the pH regulator of 1 / 2 formula quantity, dispersant, 1 / 2 2 Mix the defoaming agent, nano-alumina, nano-zinc oxide, temperature-sensitive discoloration powder, magnesium-lithium silicate, organic s...

Embodiment 2

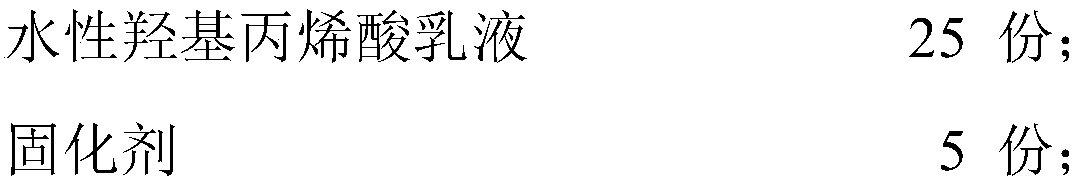

[0058] The embodiments of the present invention provide a water-based three-dimensional color-changing orange pattern paint, which includes the following raw materials in parts by weight:

[0059]

[0060] Among them, the defoaming agent is a mixture of 941PL from MOUSSEX company and BYK-024 from BAK company with a mass ratio of 1:1. A mixture of alcohol ester-12 from American Eastman with a mass ratio of 1:2.

[0061] Prepare as follows:

[0062] Step a, weigh each raw material component according to the raw material formula of the above-mentioned water-based three-dimensional effect color-changing orange grain coating, and the deionized water of 1 / 2 formula quantity, the pH regulator of 1 / 2 formula quantity, dispersant, 1 / 2 2 Mix the defoamer, nano-alumina, nano-zinc oxide, thermochromic powder, magnesium lithium silicate, organic silicone powder, and nano-anion powder in the formula, and stir for 10 minutes at a speed of 1000r / min;

[0063] Step b. Under the stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com