Hull structural steel adapting to high heat input welding and smelting method thereof

A technology of high heat input and smelting method, which is applied in the field of hull structural steel and its smelting, and hull structural steel. It can solve the problems of not meeting the requirements of high heat input, reducing the toughness of the base material, and large second-phase particles, so as to achieve the goal of hindering the grain size. Strong growth, simple production process, fine dispersion of TiN particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

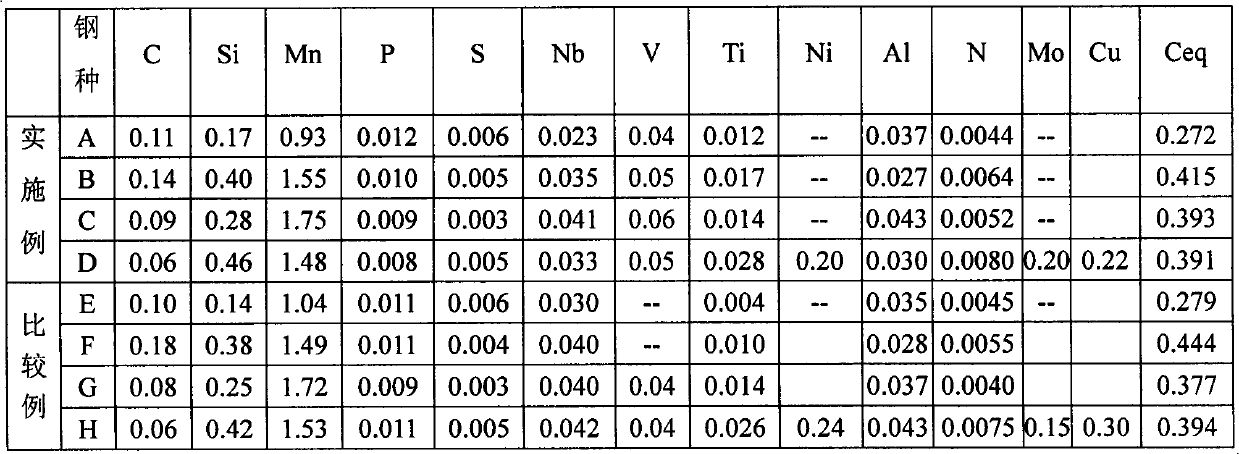

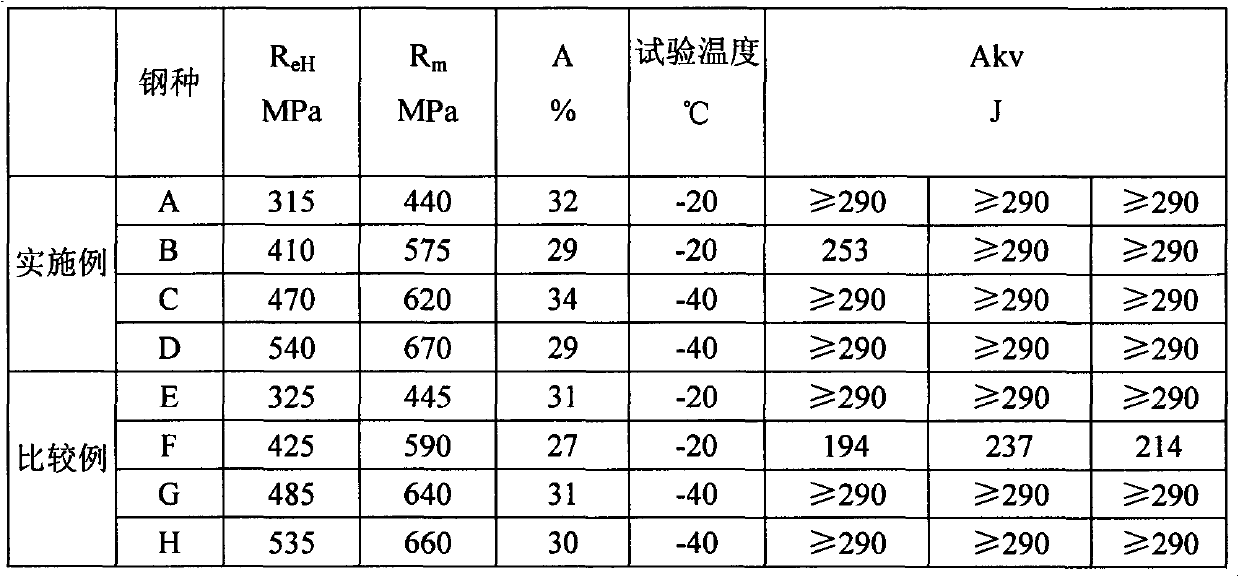

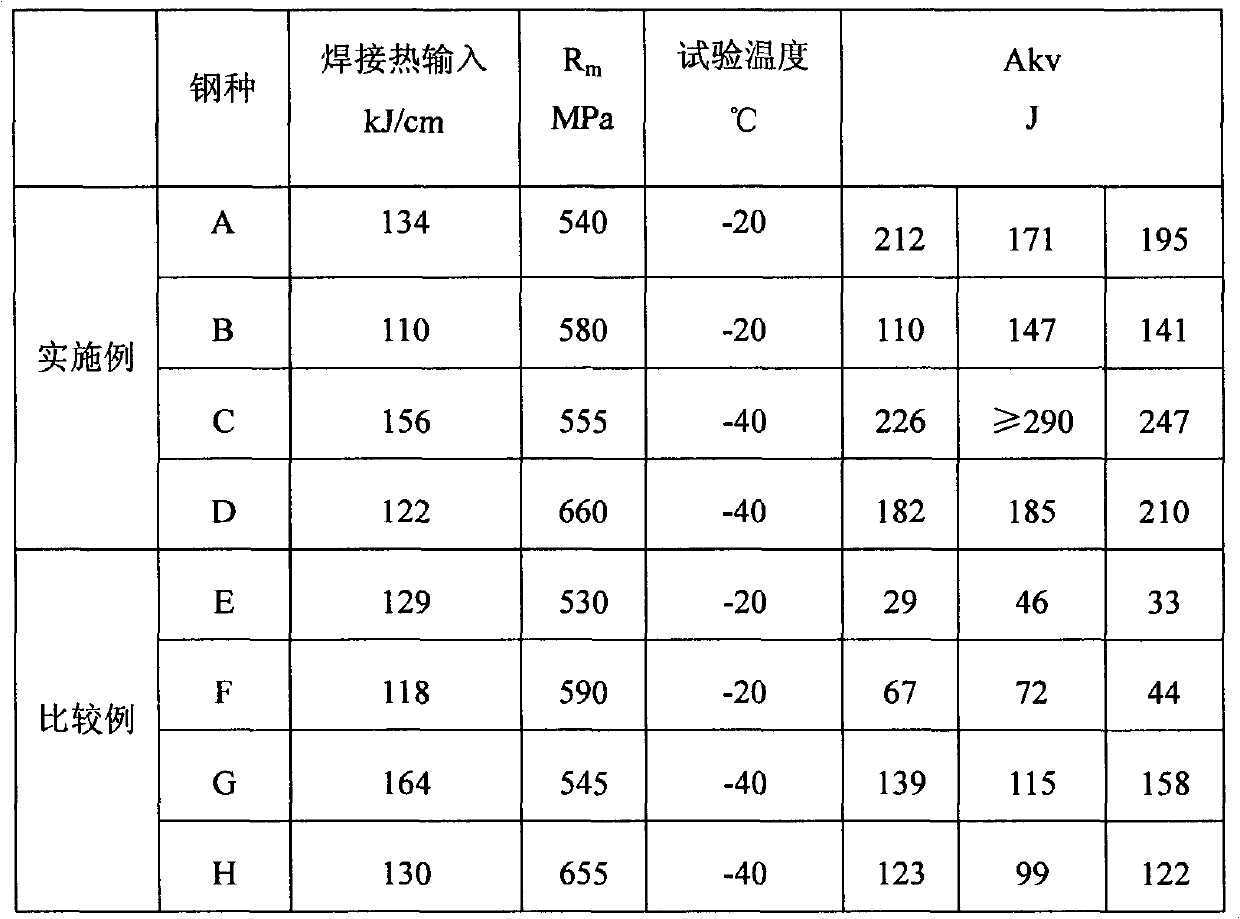

[0037] The chemical composition of the steel designed in the present invention is (mass percentage): C: 0.06% to 0.14%, Si: 0.10% to 0.50%, Mn: 0.80% to 1.8%, P: ≤0.015%, S: ≤0.008%, Nb : 0.020% to 0.050%, Ti: 0.006% to 0.030%, N: 0.0030% to 0.0100%, Al: 0.015% to 0.050%. In addition, one or more of Mo: 0.08% to 0.40%, V: 0.02% to 0.05%, Cu: 0.10% to 0.80% can be added, and Mo+Ni+Cu≤1.2% must be satisfied, and the balance is Fe and unavoidable impurities. Carbon equivalent Ceq=C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14≤0.42%.

[0038] In order to reduce the temperature of molten steel when Ti is added and shorten the residence time in molten steel after adding, the present invention adopts the method of adding Ti in the casting process of molten steel, and adopts the method of wrapping Ti alloy powder in a steel strip to form a tubular steel wire The method is fed, and the Ti microalloying is carried out simultaneously with the casting process.

[0039] In order to ensure the requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com