Motor-end-cover tin soldering machine

A soldering machine and motor technology, applied in welding equipment, auxiliary devices, metal processing, etc., can solve the problems of unfavorable mass production operations, low processing efficiency of soldering machines, etc., achieve good performance, convenient operation, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

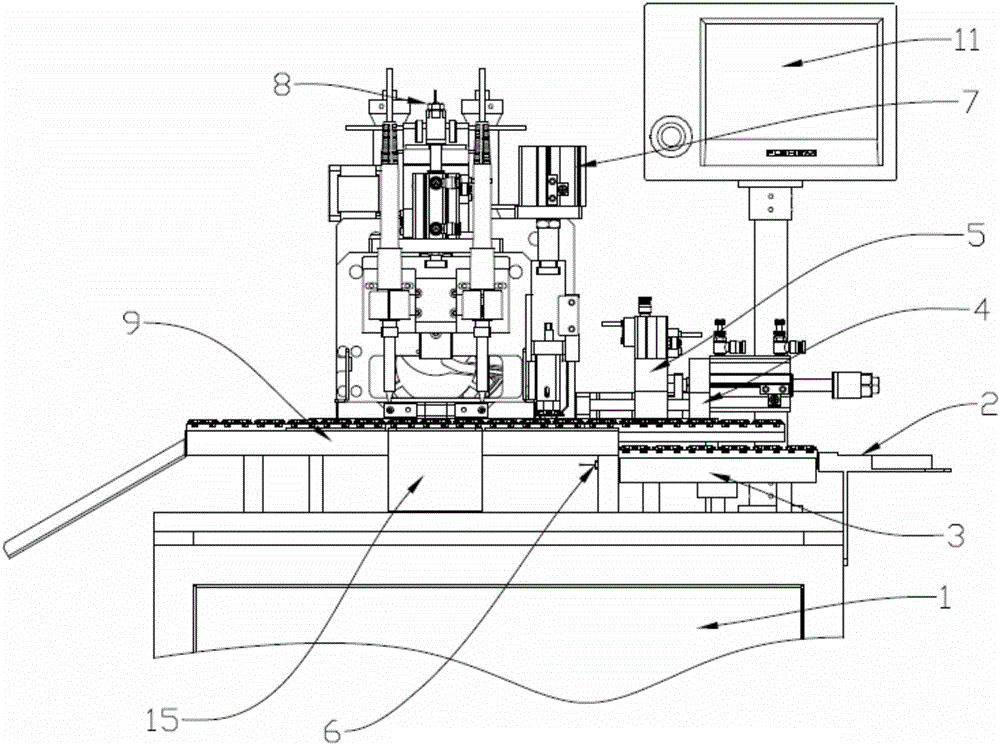

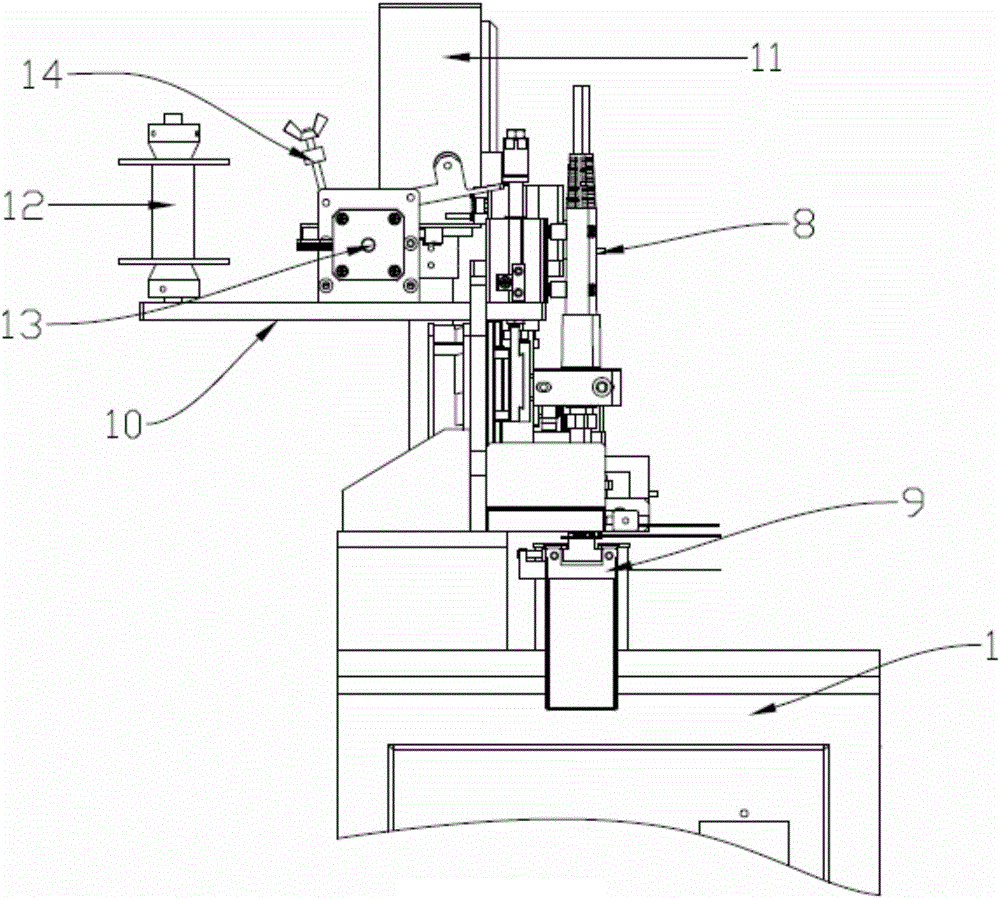

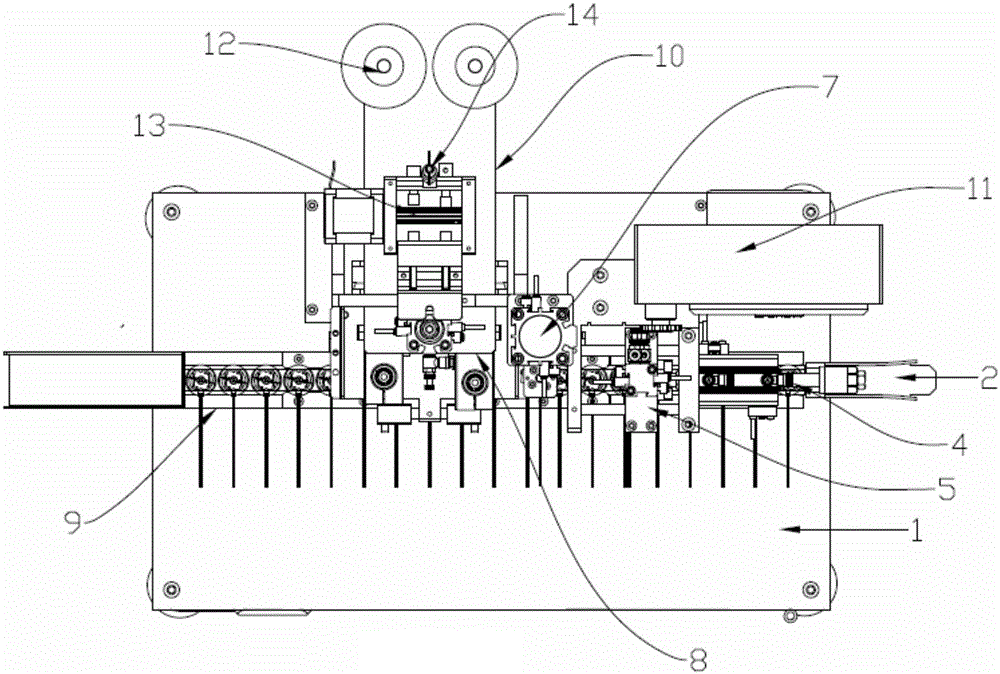

[0016] Through the following examples, combined with the attached Figure 1-3 , the technical solution of the present invention will be further specifically described.

[0017] A motor end cap soldering machine, comprising a machine body 1 and a feed track 2 arranged on the machine body 1, a feeding upper mechanism 3, a feeding pushing mechanism 4, a feeding pressing mechanism 5, a material sensor 6, a brush pressing mechanism 7, Welding mechanism 8, welding top mechanism 15, discharge track 9, tin feeding mechanism 10 and PLC controller 11 for controlling each mechanism; wherein the feeding top mechanism 3 and the feeding pressing mechanism 5 can reciprocate up and down, and the feeding The push mechanism 4 can reciprocate left and right, the feed track 2 is located below the right side of the discharge track 9, and is arranged in parallel up and down between the two, the feeding top mechanism 3 is located on the left side of the feed track 2, and The two are attached to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com