Heavy metal-free aqueous epoxy primer and preparation method thereof

A water-based epoxy and heavy metal technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of heavy metal content and poor corrosion resistance, and achieve improved anti-corrosion performance, fine and tight coatings, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

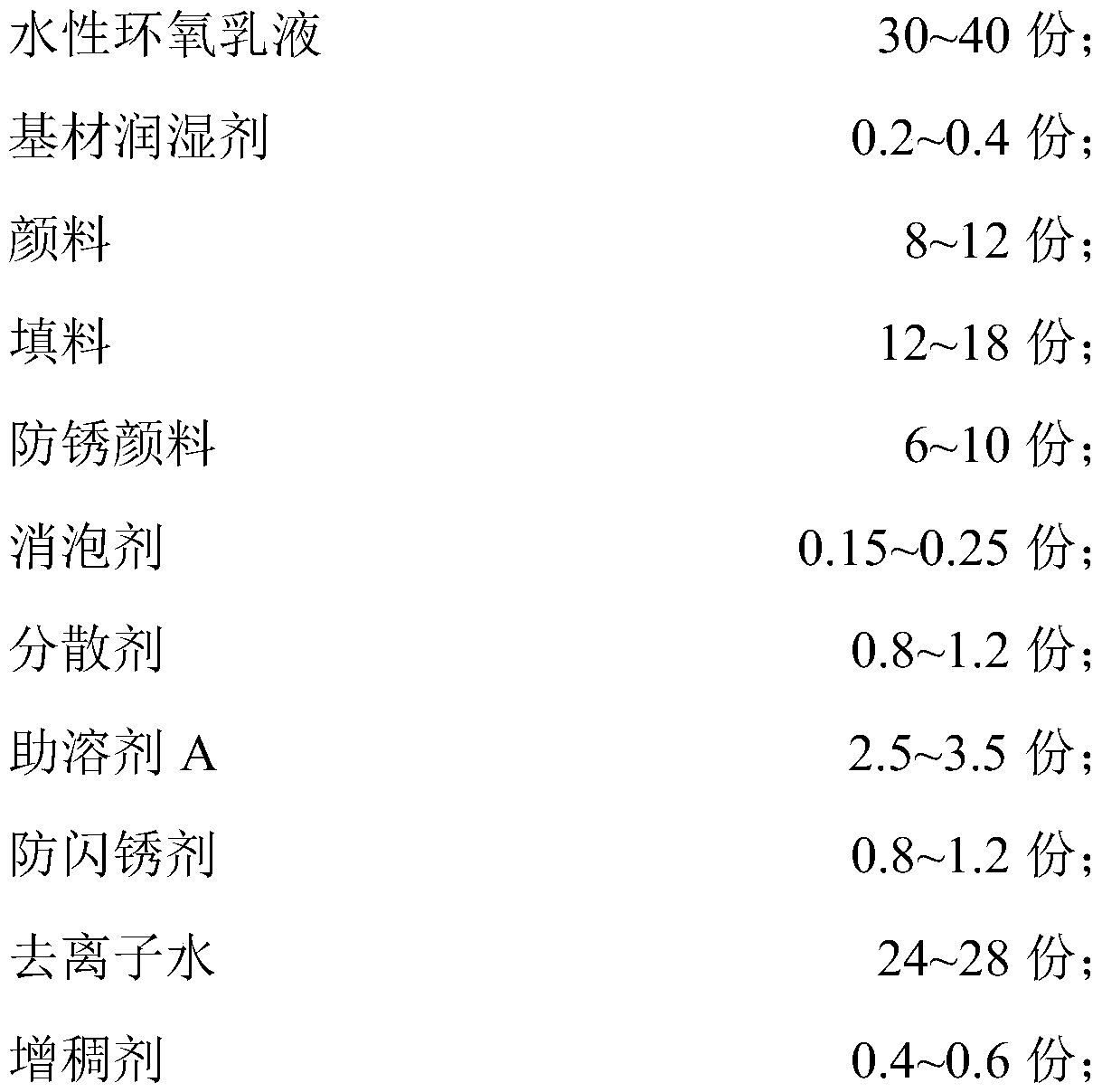

[0029] Embodiments of the present invention provide a heavy metal-free water-based epoxy primer and a preparation method thereof, comprising the following raw materials in parts by weight:

[0030] A component:

[0031]

[0032] B component:

[0033] 11.5 parts of epoxy resin curing agent;

[0034] 1.3 parts of deionized water;

[0035] 1.3 parts of propylene glycol butyl ether.

[0036] Among them, the water-based epoxy emulsion is Araldite PZ3961-1 from Huntsman Chemical Trading (Shanghai) Co., Ltd., the substrate wetting agent is tego245 from Germany Tego (TEGO), and the iron oxide red is from Henan Baihuali Chemical Products Co., Ltd. The iron oxide red and aluminum tripolyphosphate produced by the company are APW-2 type from Jiangnan Fine Chemical Factory in Nanning City, the defoamer is Foamex 810 from Germany TEGO, and the dispersant is AFCONA The company's AFCONA-4595, the anti-flash rust agent is Halox515 from the United States, the thickener is OMG's 0620, and...

Embodiment 2

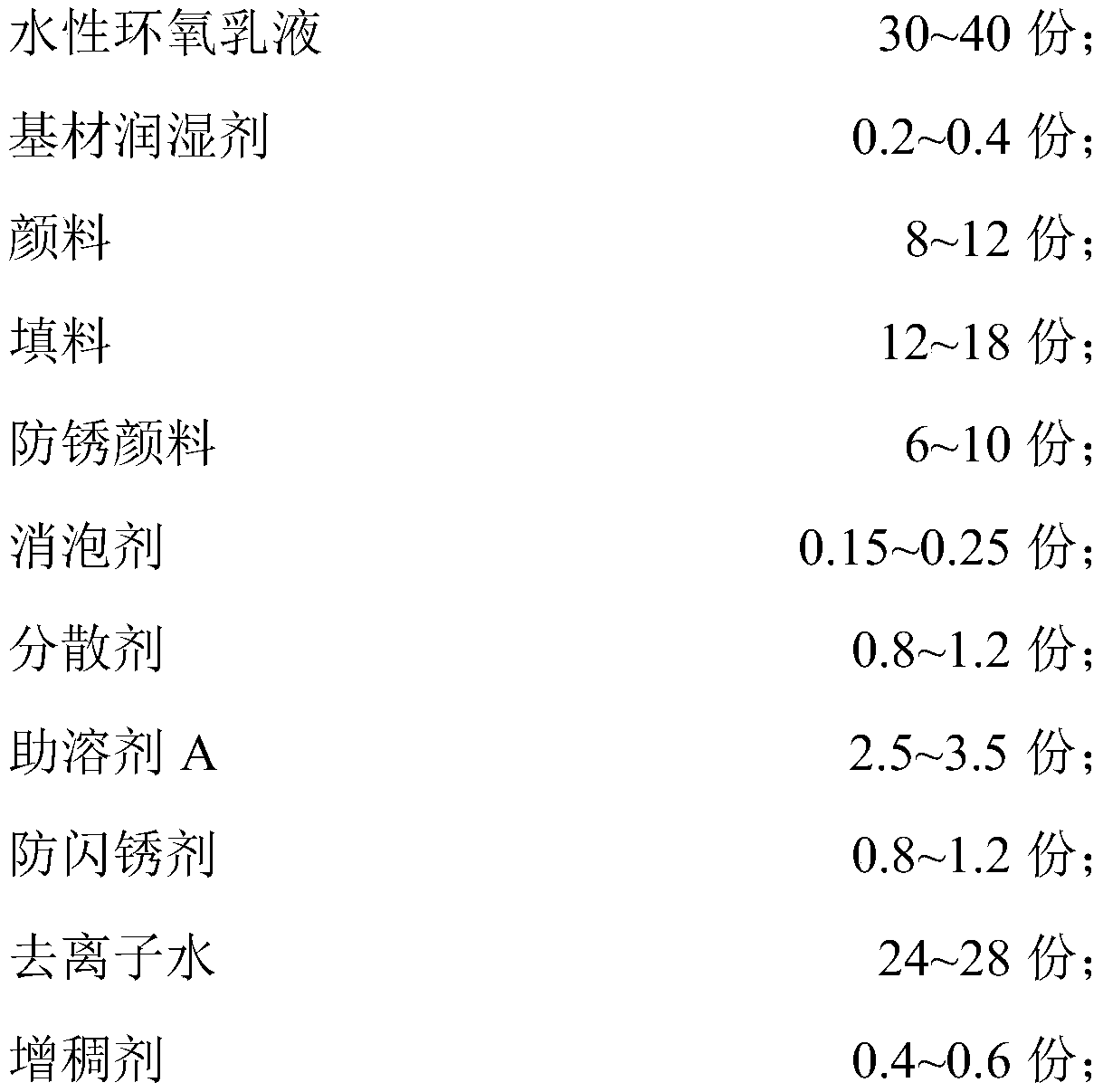

[0044] Embodiments of the present invention provide a heavy metal-free water-based epoxy primer and a preparation method thereof, comprising the following raw materials in parts by weight:

[0045] A component:

[0046]

[0047]

[0048] B component:

[0049] 11.3 parts of epoxy resin curing agent;

[0050] 1.4 parts of deionized water;

[0051] 1.4 parts of propylene glycol butyl ether.

[0052] Among them, the water-based epoxy emulsion is Araldite PZ3961-1 from Huntsman Chemical Trading (Shanghai) Co., Ltd., the substrate wetting agent is tego245 from Germany Tego (TEGO), and the iron oxide red is from Henan Baihuali Chemical Products Co., Ltd. The iron oxide red and aluminum tripolyphosphate produced by the company are APW-2 type from Jiangnan Fine Chemical Factory in Nanning City, the defoamer is Foamex 810 from Germany TEGO, and the dispersant is AFCONA The company's AFCONA-4595, the anti-flash rust agent is Halox515 from the United States, the thickener is OMG...

Embodiment 3

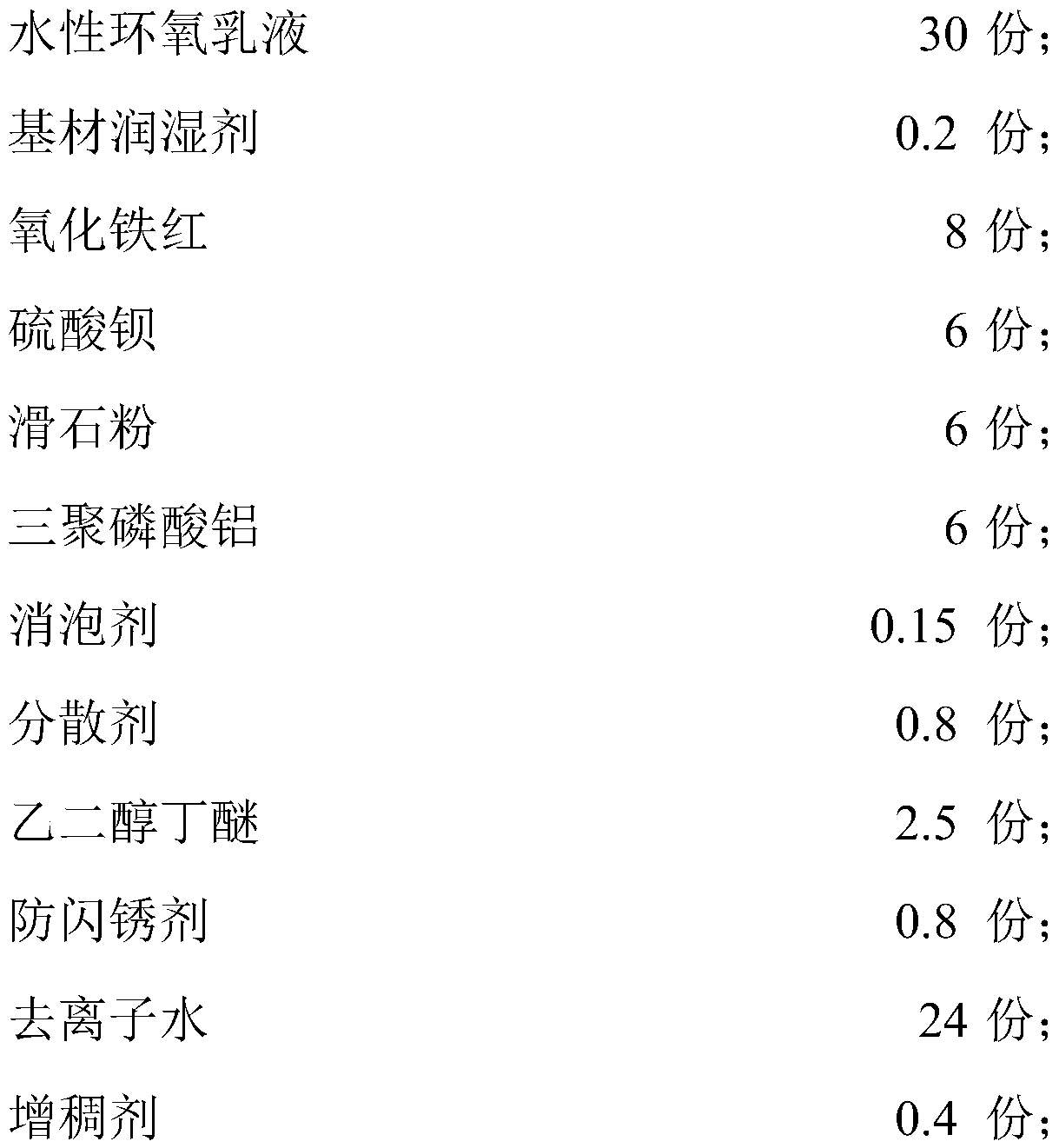

[0060] Embodiments of the present invention provide a heavy metal-free water-based epoxy primer and a preparation method thereof, comprising the following raw materials in parts by weight:

[0061] A component:

[0062]

[0063] B component:

[0064] 11.4 parts of epoxy resin curing agent;

[0065] 1.5 parts of deionized water;

[0066] 1.5 parts of propylene glycol butyl ether.

[0067] Among them, the water-based epoxy emulsion is Araldite PZ3961-1 from Huntsman Chemical Trading (Shanghai) Co., Ltd., the substrate wetting agent is tego245 from Germany Tego (TEGO), and the iron oxide red is from Henan Baihuali Chemical Products Co., Ltd. The iron oxide red and aluminum tripolyphosphate produced by the company are APW-2 type from Jiangnan Fine Chemical Factory in Nanning City, the defoamer is Foamex 810 from Germany TEGO, and the dispersant is AFCONA The company's AFCONA-4595, the anti-flash rust agent is Halox515 from the United States, the thickener is OMG's 0620, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com