Slurry for artificial colored sand, high-wear-resistance artificial colored sand and preparation methods of the slurry and the artificial colored sand

A colored sand and artificial technology, applied in the direction of polyester coating, polyether coating, coating, etc., can solve the problems of coating coloring strength and poor dispersion of wear-resistant organic pigments, and achieve good dispersion and simple operation , good tinting strength and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

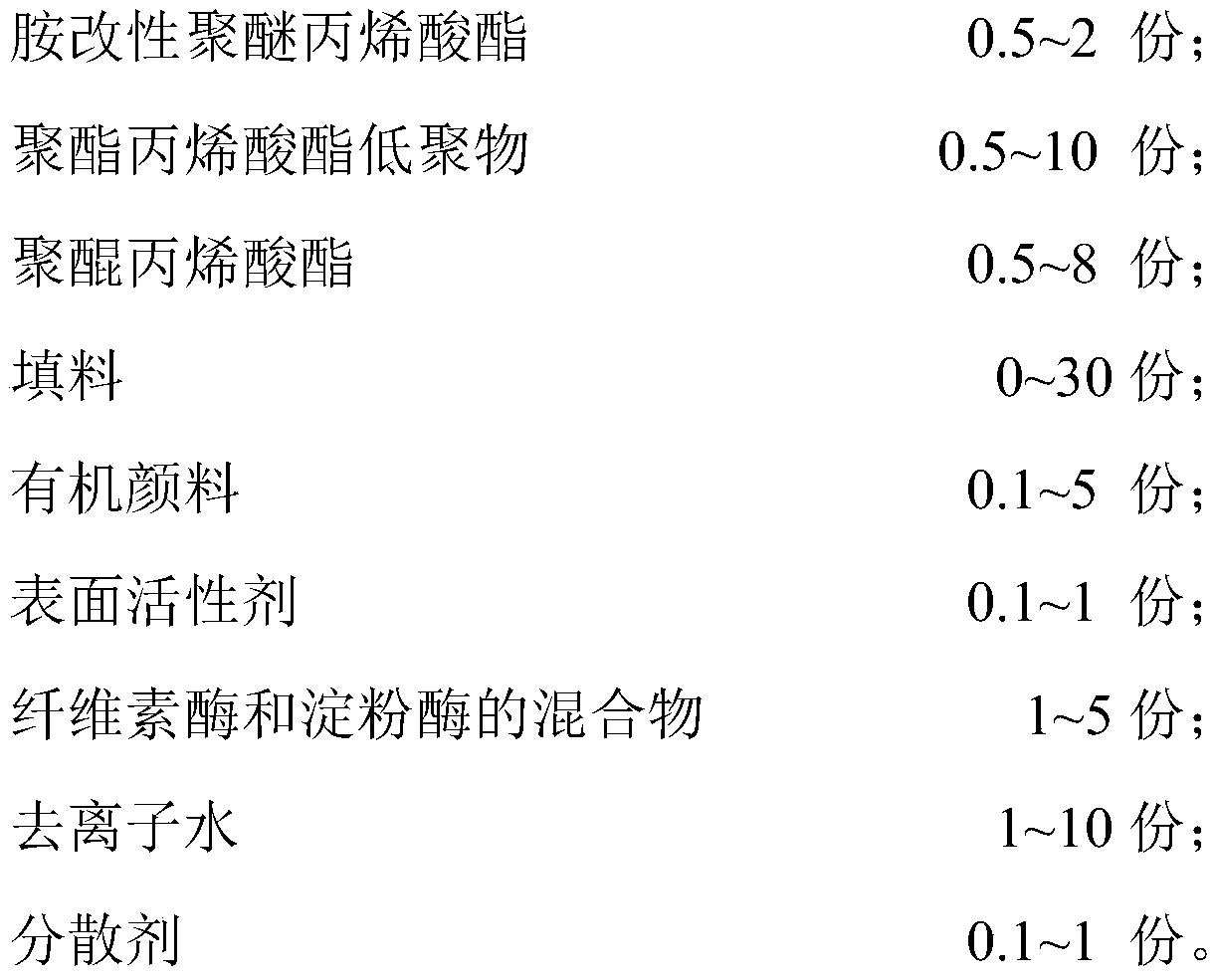

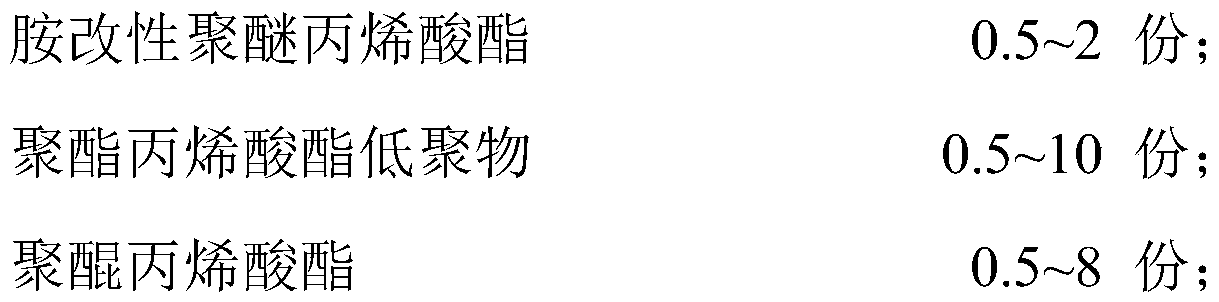

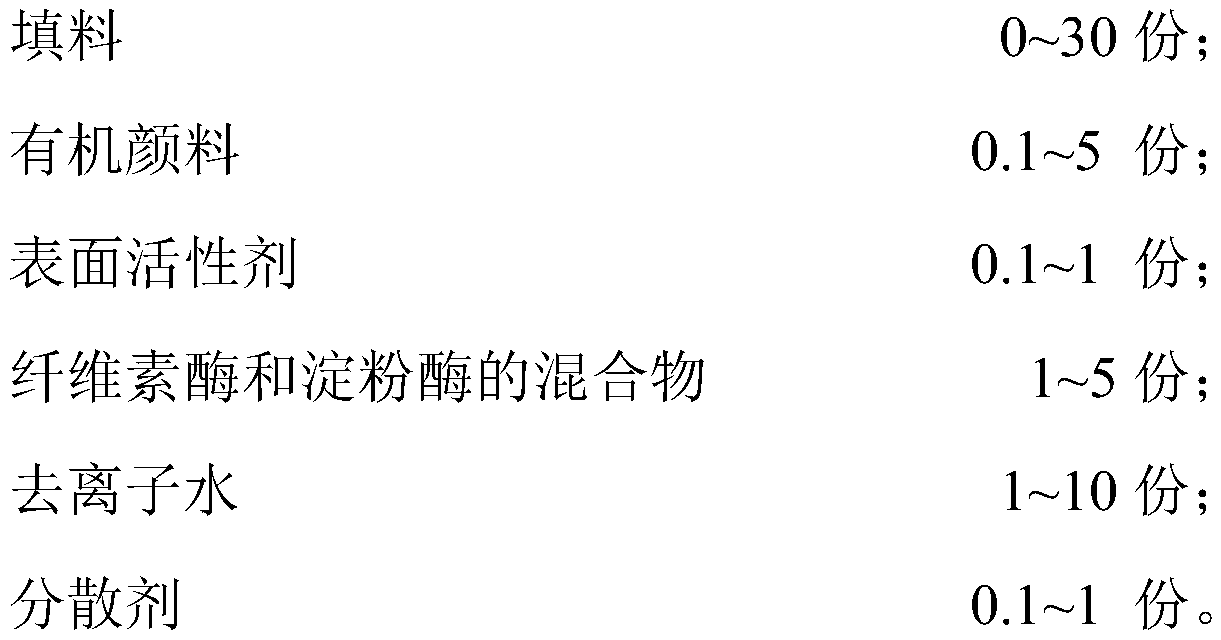

[0030] The embodiment of the present invention provides a slurry for artificial colored sand and a preparation method thereof, the slurry includes the following raw materials in parts by weight:

[0031]

[0032]

[0033] Among them, amine-modified polyether acrylate is preferably BASF's Laromer PO94F, polyester acrylate oligomer is preferably Bayer's UA VP LS2337, polyquinone acrylate is preferably BASF's Joncryl 678, and the surfactant is alkylphenol polyoxyethylene ether , the mass ratio of cellulase and amylase is 1:1, the dispersant is BYK-163 of BYK Company, and the filler is talcum powder.

[0034] The preparation method of the slurry for artificial colored sand is as follows:

[0035] Step a, uniformly mixing amine-modified polyether acrylate, polyester acrylate oligomer and polyquinone acrylate;

[0036] Step b, add 40% of the formula amount of dispersant to the mixture obtained in step a under the stirring state of 600rpm, and mix evenly;

[0037] Step c, dis...

Embodiment 2

[0040] The embodiment of the present invention provides a slurry for artificial colored sand and a preparation method thereof, the slurry includes the following raw materials in parts by weight:

[0041]

[0042]

[0043] Wherein, the preferred Laromer PO94F of BASF for amine-modified polyether acrylate, the preferred UA VP LS2337 of Bayer for polyester acrylate oligomer, the preferred Joncryl 678 of BASF for polyquinone acrylate, the surfactant is fatty alcohol polyoxyethylene ether, The mass ratio of cellulase and amylase is 1:1, the dispersant is BYK-163 of BYK Company, and the filler is titanium dioxide.

[0044] The preparation method of the slurry for artificial colored sand is as follows:

[0045] Step a, uniformly mixing amine-modified polyether acrylate, polyester acrylate oligomer and polyquinone acrylate;

[0046] Step b, add 60% of the formula amount of dispersant to the mixture obtained in step a under the stirring state of 650rpm, and mix evenly;

[0047]...

Embodiment 3

[0050] The embodiment of the present invention provides a slurry for artificial colored sand and a preparation method thereof, the slurry includes the following raw materials in parts by weight:

[0051]

[0052]

[0053] Wherein, amine-modified polyether acrylate is preferably BASF's Laromer PO94F, polyester acrylate oligomer is preferably Bayer's UA VP LS2337, polyquinone acrylate is preferably BASF's Joncryl 678, and the surfactant is polyoxyethylene amine, cellulose The mass ratio of enzyme and amylase is 1:1, the dispersant is BYK-163 of BYK Company, and the filler is an equal mass mixture of titanium dioxide and kaolin.

[0054] The preparation method of the slurry for artificial colored sand is as follows:

[0055] Step a, uniformly mixing amine-modified polyether acrylate, polyester acrylate oligomer and polyquinone acrylate;

[0056] Step b. Add 50% of the formula amount of dispersant to the mixture obtained in step a under the stirring state of 700rpm, and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com