Anti-corrosion quick-drying environment-friendly water-based paint and preparation method thereof

A corrosion-resistant, water-based paint technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor performance of water-based protective paint and high VOCs content, achieve good protection effect, fine and dense paint film, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

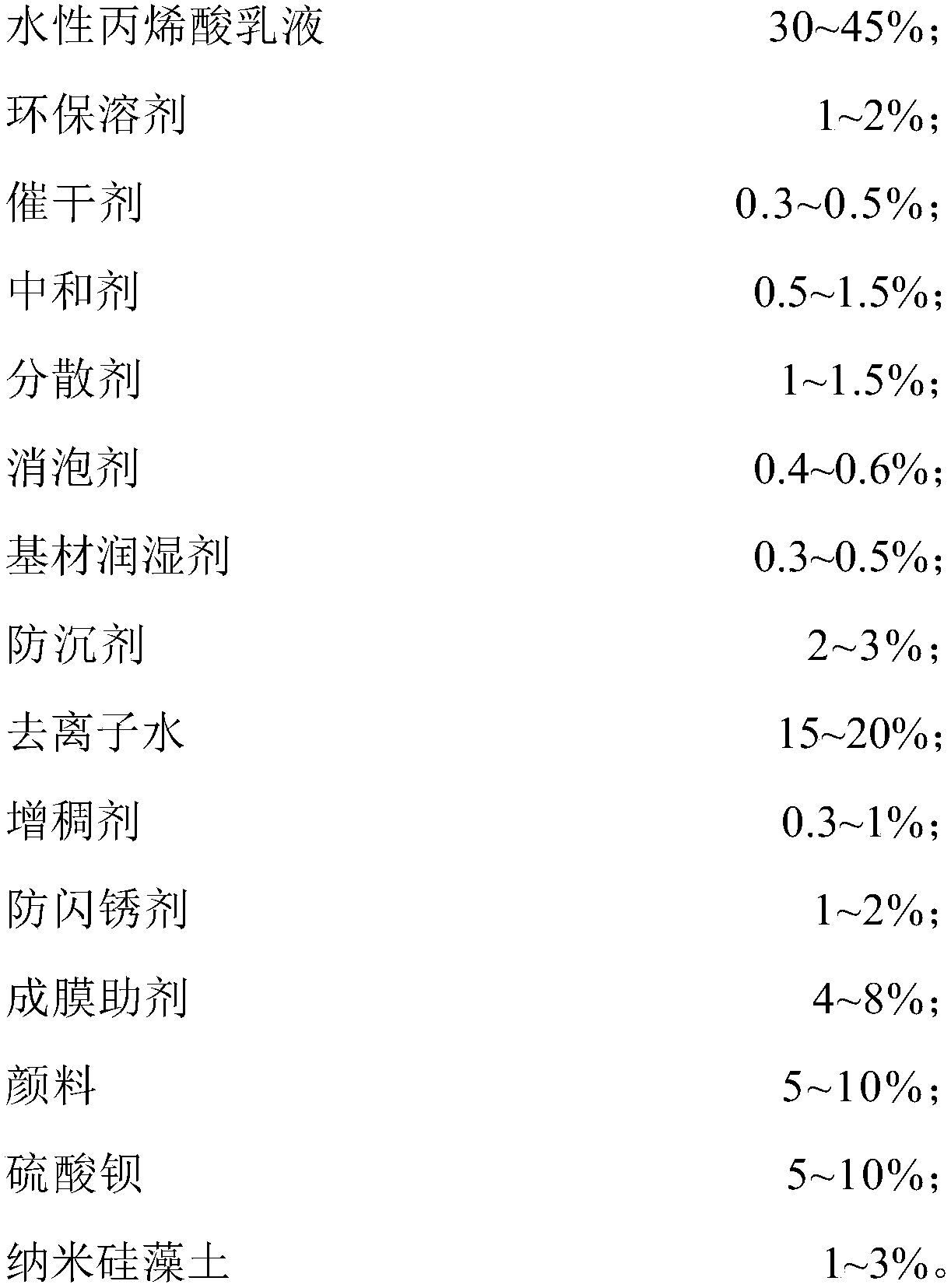

[0031] Embodiments of the present invention provide a corrosion-resistant, quick-drying, environmentally-friendly water-based paint and a preparation method thereof, comprising the following raw materials in parts by weight:

[0032]

[0033]

[0034] Among them, the water-based epoxy ester resin is GS-5000B resin from Changzhou Guangshu Chemical Technology Co., Ltd., the water-based acrylic emulsion is Wanhua Chemical Group Co., Ltd. 0612 emulsion, the dispersant is BYK-190 from BYK, Germany, and the defoamer is Di High TEGO defoaming agent Tego-902w, substrate wetting agent EFKA-3580, anti-settling agent Hemings bentonite BENTONE EW, thickener 0620 of Guangzhou Matsuo Trading Co., Ltd. The flash rust agent is D1600 from Shanghai Tianyu Chemical Technology Co., Ltd., the rutile titanium dioxide is R-818 from Jinan Yuxing, Shandong, the phthalocyanine blue is phthalocyanine blue G. type, and the phthalocyanine green is phthalocyanine green G. type.

[0035] The preparati...

Embodiment 2

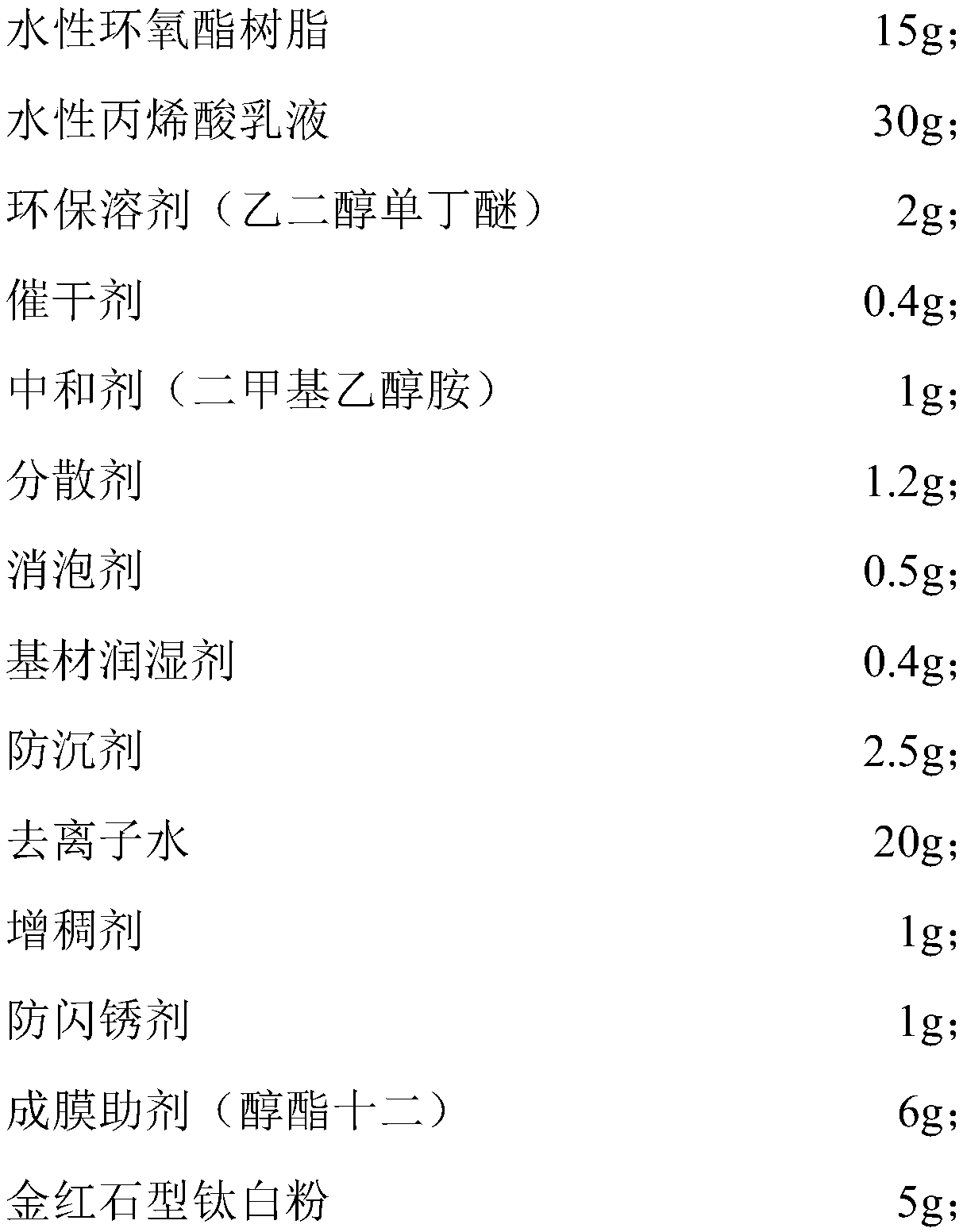

[0042] Embodiments of the present invention provide a corrosion-resistant, quick-drying, environmentally-friendly water-based paint and a preparation method thereof, comprising the following raw materials in parts by weight:

[0043]

[0044] Among them, the water-based epoxy ester resin is Changzhou Guangshu Chemical Technology Co., Ltd. GS-5000B resin, the water-based acrylic emulsion is Wanhua Chemical Group Co., Ltd. 0612 emulsion, the dispersant is Shanghai Tianyu Chemical Technology Co., Ltd. P30, and the defoamer is German. BYK's defoaming additive BYK-028, substrate wetting agent is Efka's EFKA-3580, anti-settling agent is Hemings Bentonite BENTONE EW, thickener is Guangzhou Matsuo Trading Co., Ltd. 0620, anti-settling agent The flash rust agent is D1600 from Shanghai Tianyu Chemical Technology Co., Ltd., the rutile titanium dioxide is R-818 from Jinan Yuxing, Shandong, the phthalocyanine blue is phthalocyanine blue G. type, and the phthalocyanine green is phthalocyani...

Embodiment 3

[0052] Embodiments of the present invention provide a corrosion-resistant, quick-drying, environmentally-friendly water-based paint and a preparation method thereof, comprising the following raw materials in parts by weight:

[0053]

[0054]

[0055] Among them, the water-based epoxy ester resin is GS-5000B resin from Changzhou Guangshu Chemical Technology Co., Ltd., the water-based acrylic emulsion is Wanhua Chemical Group Co., Ltd. 0612 emulsion, the dispersant is BYK-190 from BYK, Germany, and the defoamer is Di High TEGO defoaming agent Tego-902w, substrate wetting agent is EFKA-3580, anti-settling agent is Hemings bentonite BENTONE EW, thickener is Guangzhou Matsuo Trading Co., Ltd. 0620, anti-flash rust agent is Shanghai Tianyu Chemical Technology Co., Ltd. D1600, rutile titanium dioxide is R-818 from Jinan Yuxing, Shandong, phthalocyanine blue is phthalocyanine blue G. type, and phthalocyanine green is phthalocyanine green G. type.

[0056] The preparation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com