Fireproof bacteriostatic aqueous terrace paint used for bus and preparation method and application thereof

A technology for floor coatings and buses, applied in fire-retardant coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of high VOCs content, easy to spread bacteria, easy to change color, etc., achieve low VOCs content, good environmental protection Characteristics, high antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] And, the embodiment of the present invention also provides a kind of preparation method of fire-resistant and bacteriostatic water-based floor paint for bus, and described preparation method comprises the following steps at least:

[0028]Step a, weigh each raw material component according to the raw material formula of the above-mentioned fire-resistant and antibacterial water-based floor coating for buses, and mix 1 / 2 to 2 / 3 of the deionized water of the formula, 1 / 2 to 2 / 3 of the formula pH regulator, dispersant, 1 / 2~2 / 3 formula amount of defoamer, nano-alumina, nano-zirconia, nano-zinc oxide, flame retardant, silica sol, organic silicone powder, anion powder, pigment mixing uniform;

[0029] Step b. Add water-based epoxy emulsion, film-forming aids, remaining pH regulator, remaining defoamer and substrate wetting agent to the mixing container in turn under stirring, pre-mix evenly and add to the mixture obtained in step a , mix evenly, add a thickener to adjust the...

Embodiment 1

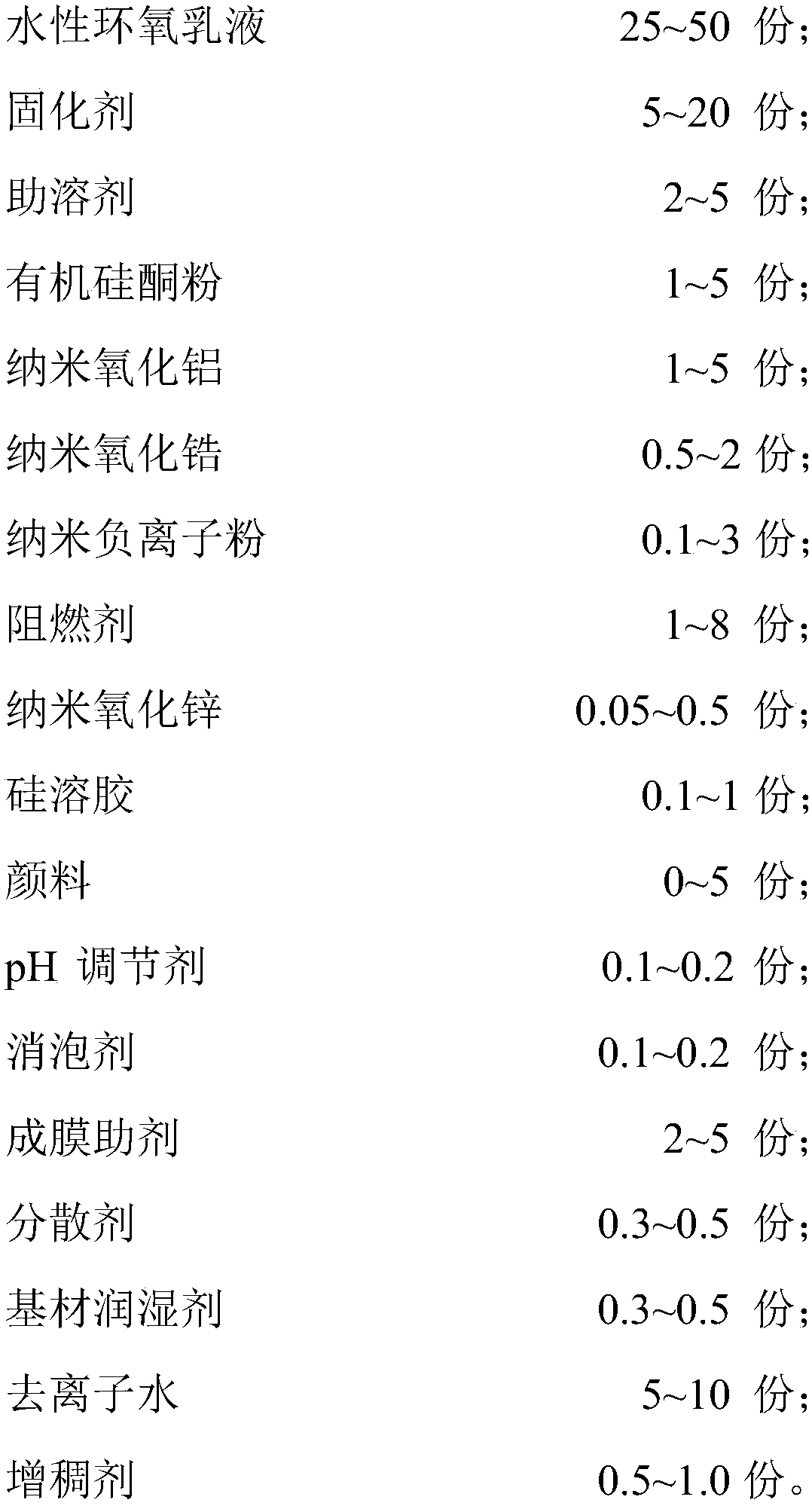

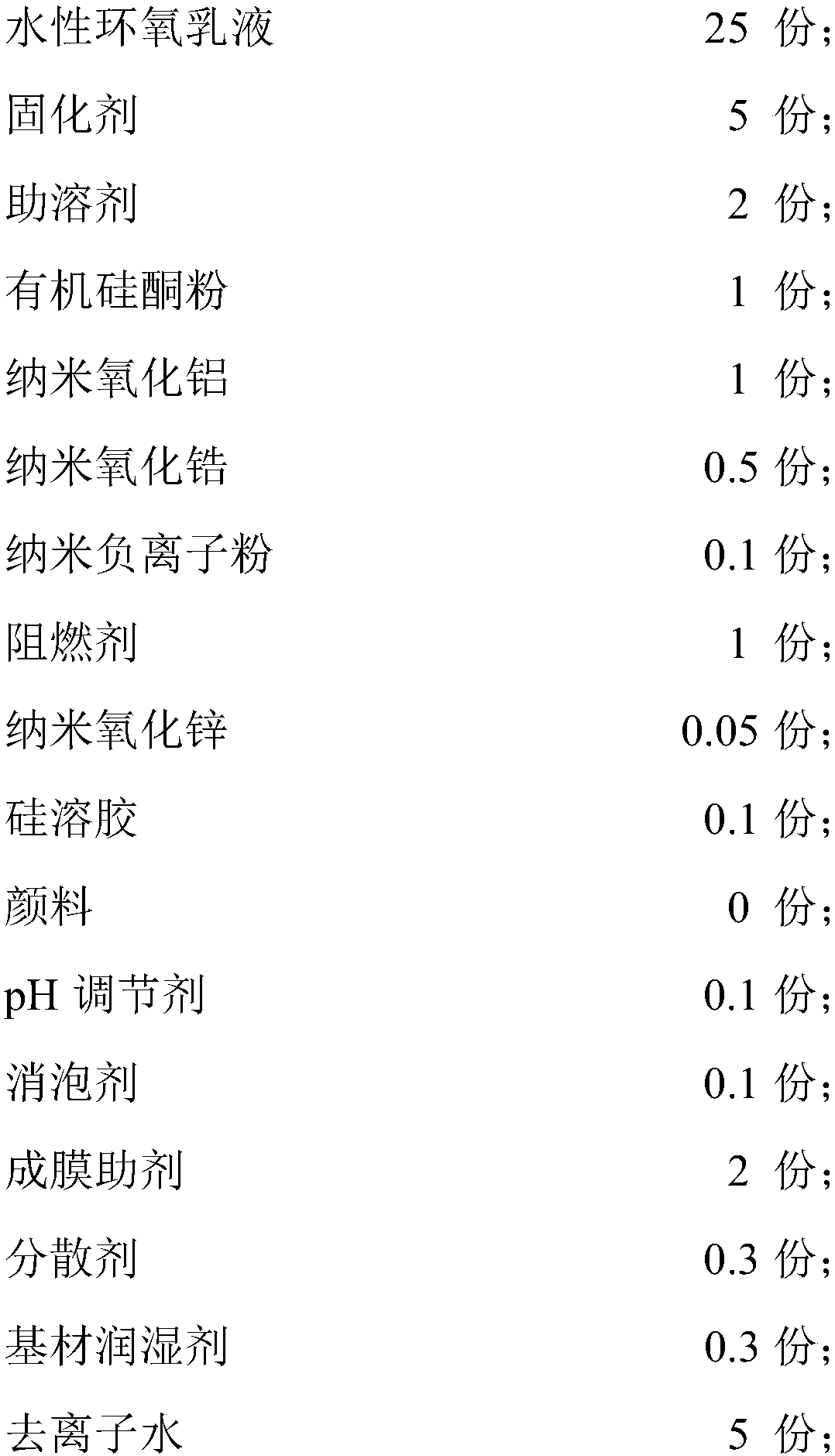

[0037] The embodiments of the present invention provide a fire-resistant and antibacterial water-based floor coating for buses, comprising the following raw materials in parts by weight:

[0038]

[0039]

[0040] Among them, the defoamer is a mixture of 941PL from MOUSSEX Company and BYK-028 from BAK Company with a mass ratio of 1.2:1, and the film-forming aids are environmentally friendly and clean-tasting film-forming aids AF and The mass ratio of Eastman's Alcohol Esters-12 is a mixture of 1:1.

[0041] Prepare as follows:

[0042] Step a, weigh each raw material component according to the raw material formula of the above-mentioned fire-resistant and antibacterial water-based floor coating for buses, and mix the deionized water of 1 / 2 formula quantity, the pH regulator and dispersant of 1 / 2 formula quantity , 1 / 2 formula amount of defoamer, nano-alumina, nano-zirconia, nano-zinc oxide, flame retardant, silica sol, organic silicone powder, negative ion powder mixed,...

Embodiment 2

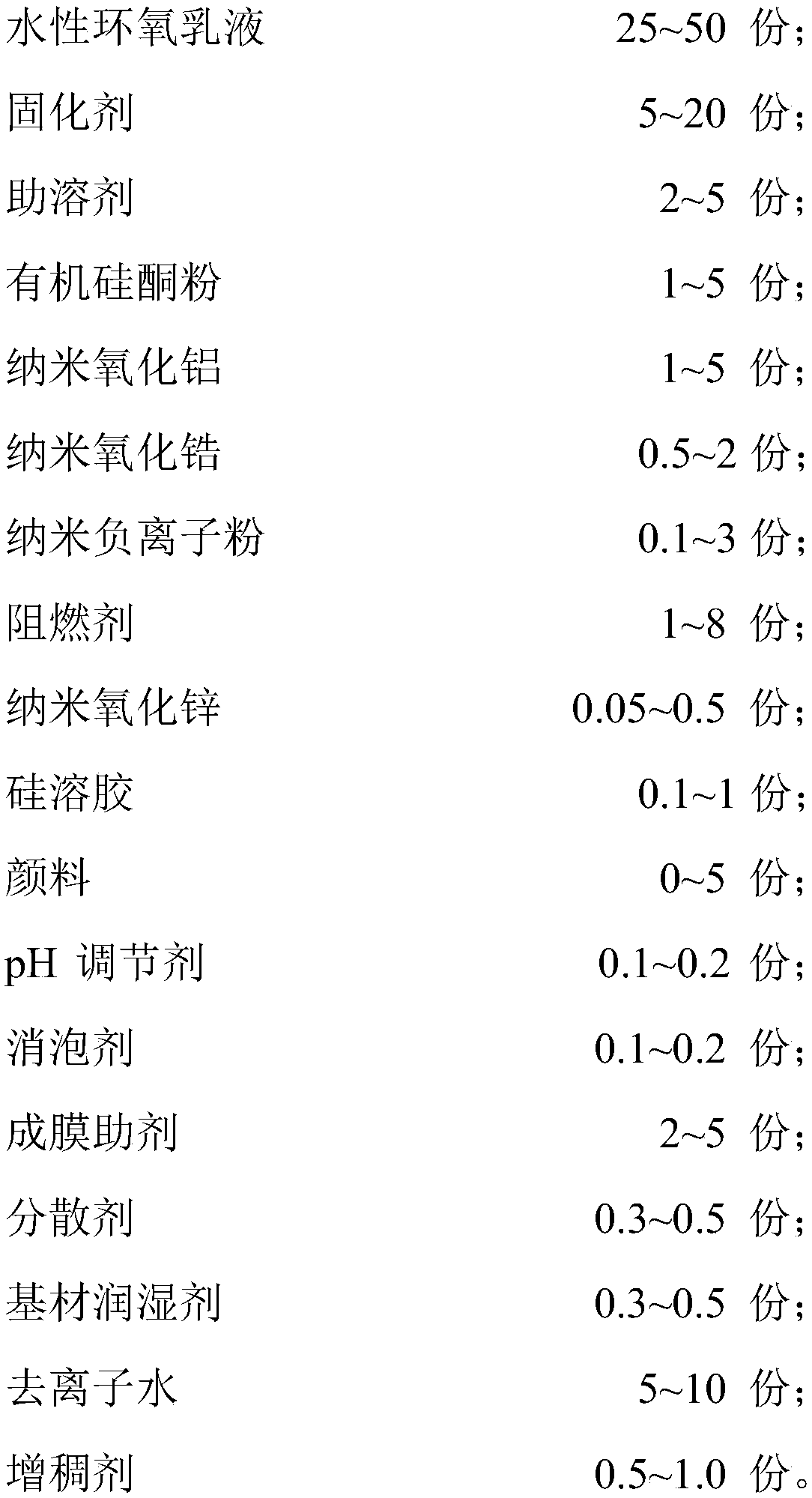

[0047] The embodiments of the present invention provide a fire-resistant and antibacterial water-based floor coating for buses, comprising the following raw materials in parts by weight:

[0048]

[0049]

[0050] Among them, the defoaming agent is a mixture of 941PL from MOUSSEX Company and BYK-024 from BAK Company with a mass ratio of 1:1, and the film-forming aids are environmentally friendly and odor-free film-forming aids AF and The mass ratio of alcohol ester-12 from Eastman of the United States is a mixture of 1:2.

[0051] Prepare as follows:

[0052] Step a, weigh each raw material component according to the raw material formula of the above-mentioned fire-resistant and antibacterial water-based floor coating for buses, and mix the deionized water of 1 / 2 formula quantity, the pH regulator and dispersant of 1 / 2 formula quantity , 1 / 2 formula amount of defoamer, nano-alumina, nano-zirconia, nano-zinc oxide, flame retardant, silica sol, organic silicone powder, ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com