Spraying absorption system for waste lithium battery disassembly waste gas treatment, and applying method thereof

A waste lithium battery and exhaust gas treatment technology, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as pollution, environmental pollution, and hazards, and achieve the effects of improving safety, reducing spillage, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

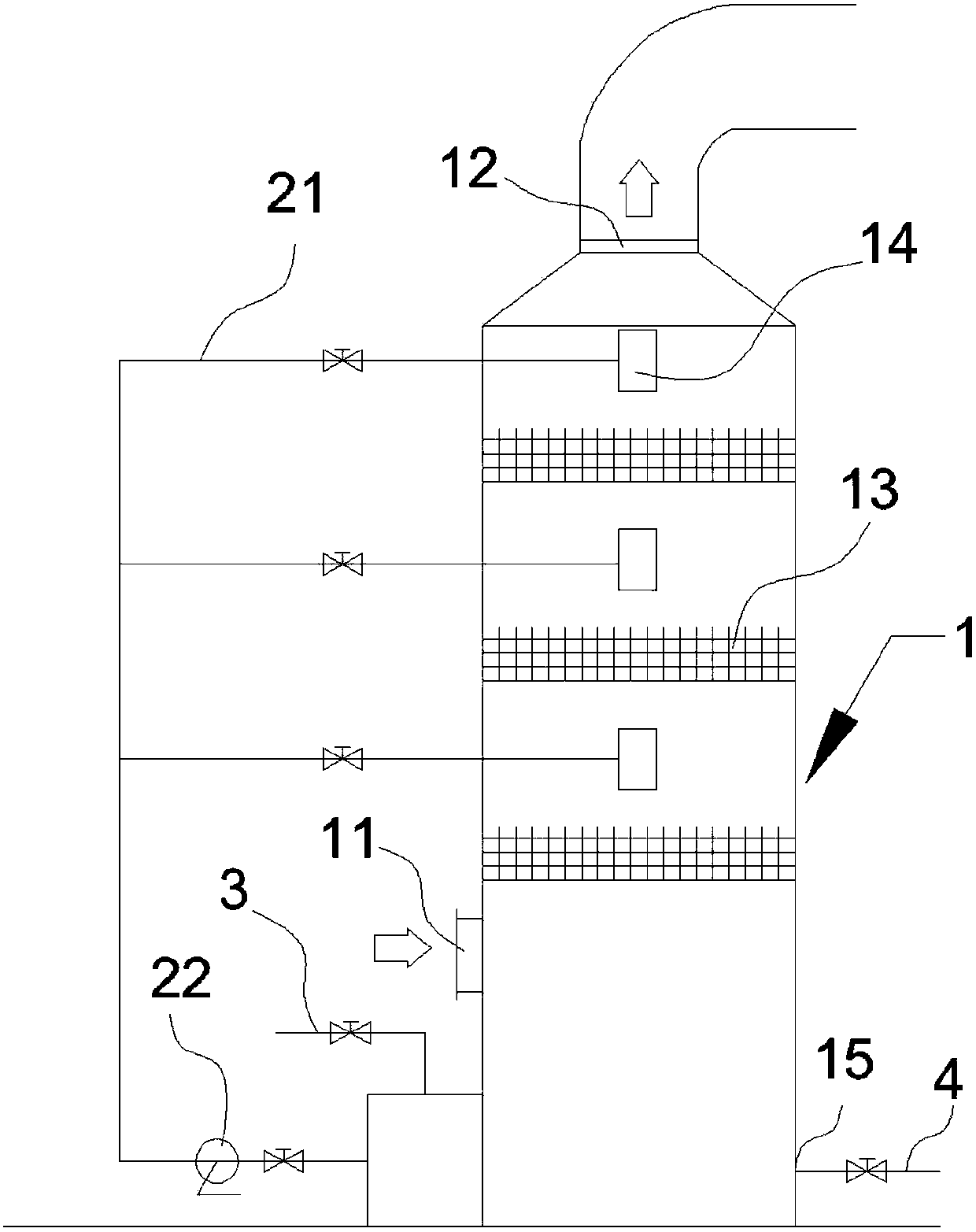

[0029] Such as figure 1 , Is the waste gas spray absorption system for waste lithium batteries of the present invention. The main structure of the system is a spray absorption tower 1, and the absorption tower is provided with an air inlet 11, an air outlet 12, a packing layer 13, a spray device 14 and a sewage outlet 15. Among them, taking the position of the air inlet 11 as the boundary, the absorption tower 1 is divided into two areas. The part above the air inlet 11 where the spray device 14 and the filler 13 are arranged is the spray area, which is located at the air inlet 11 The follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com