A kind of room temperature curing high temperature resistant anticorrosion coating and preparation method thereof

An anti-corrosion coating, room temperature curing technology, applied in the direction of anti-corrosion coatings, fireproof coatings, coatings, etc., can solve the problems of limited temperature resistance, poor corrosion resistance, poor resistance to cold and heat, etc., to slow down high temperature oxidation corrosion, resistance Good corrosion resistance, good heat and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

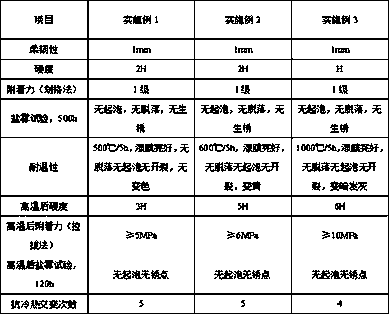

Examples

Embodiment 1

[0032] A room temperature curing high temperature resistant anti-corrosion coating, composed of A component and B component:

[0033] Component A: It is made of the following raw materials in parts by mass: 40 parts of methylmethoxysilane oligomer, 5 parts of polycarbosilane, 15 parts of silicate compound, 6 parts of ZPO, 8 parts of copper chrome black, low Melting point blend 7.5 parts, potassium hexatitanate whisker 0.6 parts, dispersant 1.2 parts, fumed silica 0.8 parts, silane coupling agent 1.6 parts, ethylene glycol butyl ether acetate 1.3 parts, xylene 13 parts.

[0034] Component B is isopropyl titanate, and the mass fraction is 1.5% of the methoxysilane oligomer.

Embodiment 2

[0036] A room temperature curing high temperature resistant anti-corrosion coating, composed of A component and B component:

[0037] Component A: made of the following raw materials in parts by mass: 28 parts of methylmethoxysilane oligomer, 12 parts of octylmethoxysilane oligomer, 5.5 parts of polycarbosilane, and 6 parts of silicate compound , 5 parts of ZPO, 5 parts of low melting point blend, 15 parts of aluminum powder, 1.8 parts of alumina whiskers, 1.2 parts of dispersant, 1.2 parts of polyamide wax, 0.3 parts of fumed silica, 1.4 parts of silane coupling agent, 1.6 parts of ethylene glycol butyl ether acetate, 16 parts of xylene.

[0038] Component B is isopropyl titanate, and the mass fraction is 1.5% of the methoxysilane oligomer.

Embodiment 3

[0040] A room temperature curing high temperature resistant anti-corrosion coating, composed of A component and B component:

[0041] Component A: made of the following raw materials in parts by mass: 16.5 parts of methylmethoxysilane oligomer, 16.5 parts of octylmethoxysilane oligomer, 6 parts of polycarbosilane, and 12 parts of silicate compound , 2 parts of barium metaborate, 6 parts of ZPO, 2 parts of aluminum powder, 6 parts of copper chrome black, 11.5 parts of low melting point blend, 3.2 parts of potassium hexatitanate whisker, 1.4 parts of dispersant, 0.5 part of montmorillonite, 0.5 parts of fumed silica, 1.6 parts of silane coupling agent, 1.3 parts of ethylene glycol butyl ether acetate, and 13 parts of xylene.

[0042] Component B is isopropyl titanate, and the mass fraction is 1.5% of the methoxysilane oligomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com