A kind of preparation and coating method of water-based ceramic anticorrosion coating

A technology for anti-corrosion coatings and ceramics, applied in fire-resistant coatings, coatings, etc., can solve the problems of poor tensile strength, easy cracking of the coating film, and high hardness of the coating, and achieves low cracking resistance, good temperature resistance, and VOCs content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

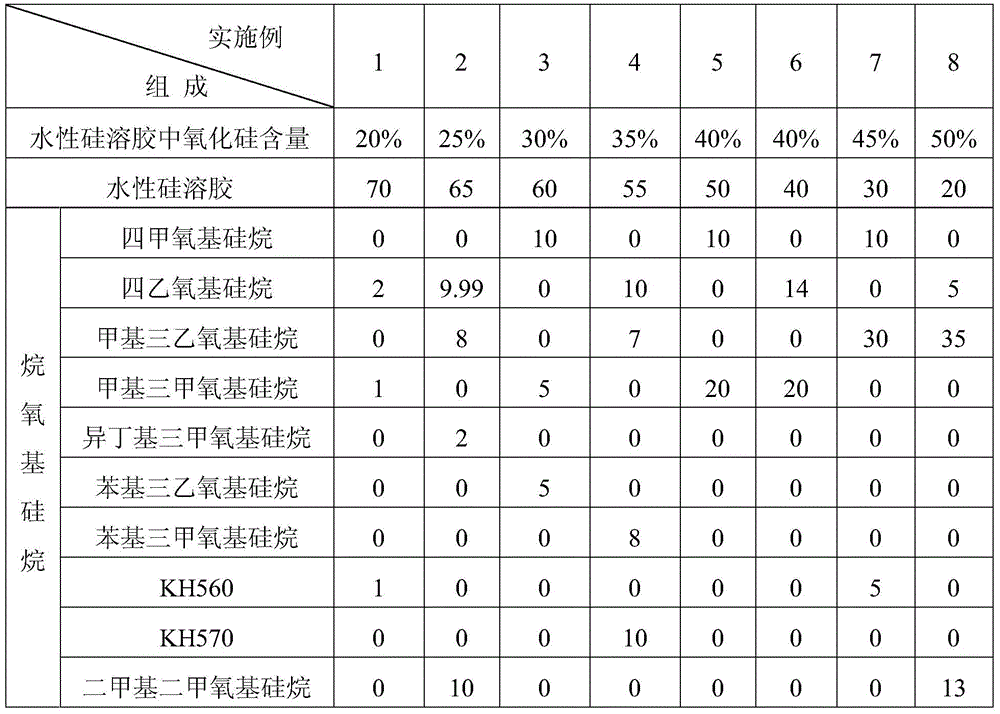

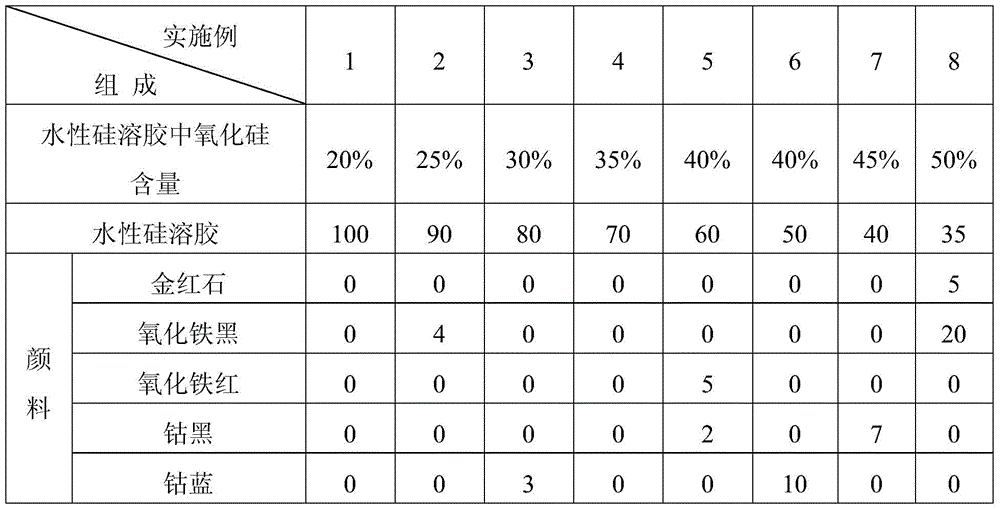

Examples

Embodiment Construction

[0031] First the raw materials used in the present invention are introduced in detail:

[0032] Aqueous silica sol

[0033] Water-based silica sol in the present invention: a dispersion liquid of nano-scale silicon dioxide particles in water with a pH of 1.5-11, a particle diameter of 10 nm-60 nm, and a solid content of 20%-50%. Water-based silica sol is used as one of the inorganic film-forming substances in the present invention, and chemically reacts with hydrolyzed alkoxysilane to obtain SiO 2 Network structure, so that the coating has hardness, corrosion resistance, temperature resistance and other properties.

[0034] Water-based silica sol is used in the A component and the B component in the present invention, reacts with the complex silane coupling agent in the A component, and obtains a mixture containing polymer sol and particle sol by sol-gel technology, There are three ways for polymer sol to exist in composite sol, the first is to bond to the surface of granula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com