Anti-ultraviolet vehicle paint and preparation method thereof

An anti-ultraviolet, car paint technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of high temperature resistance, easy aging of car paint, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

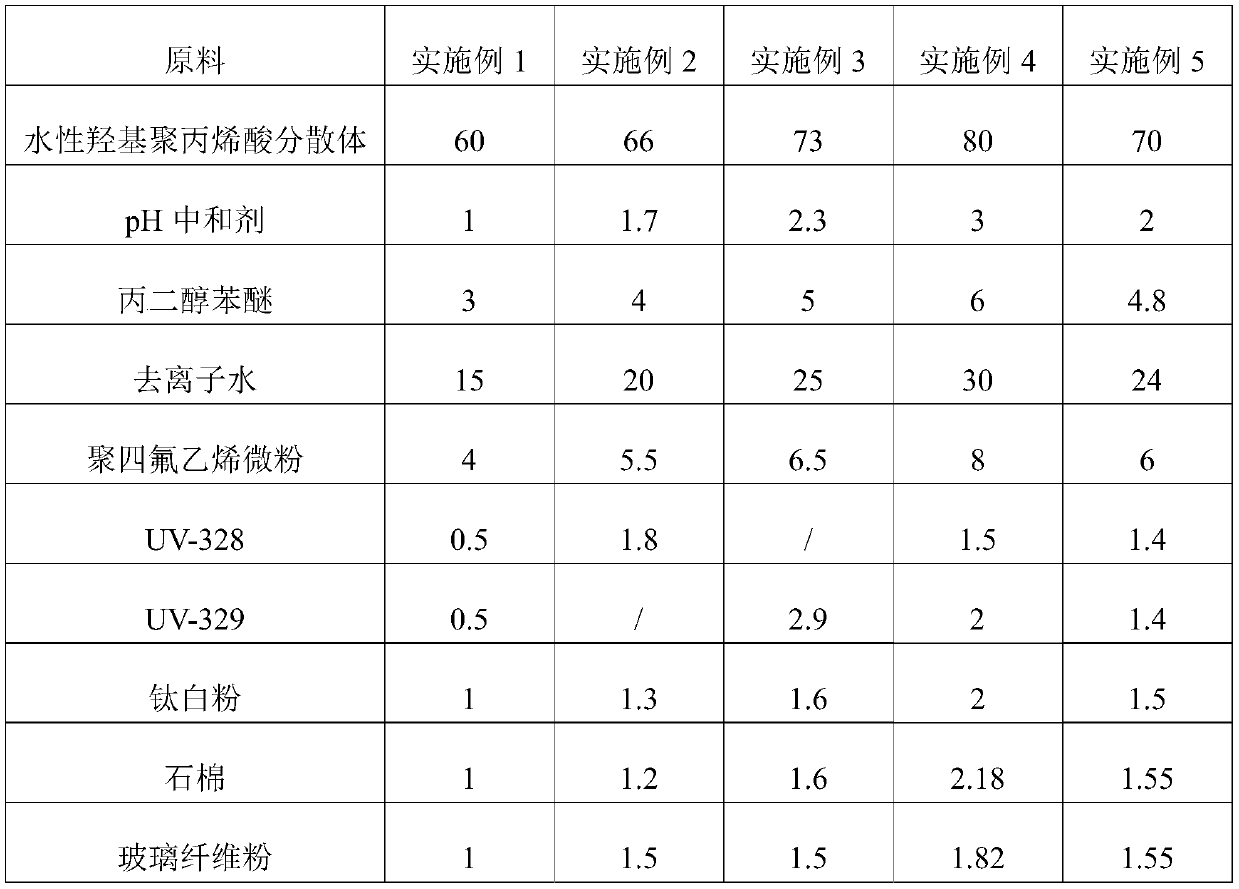

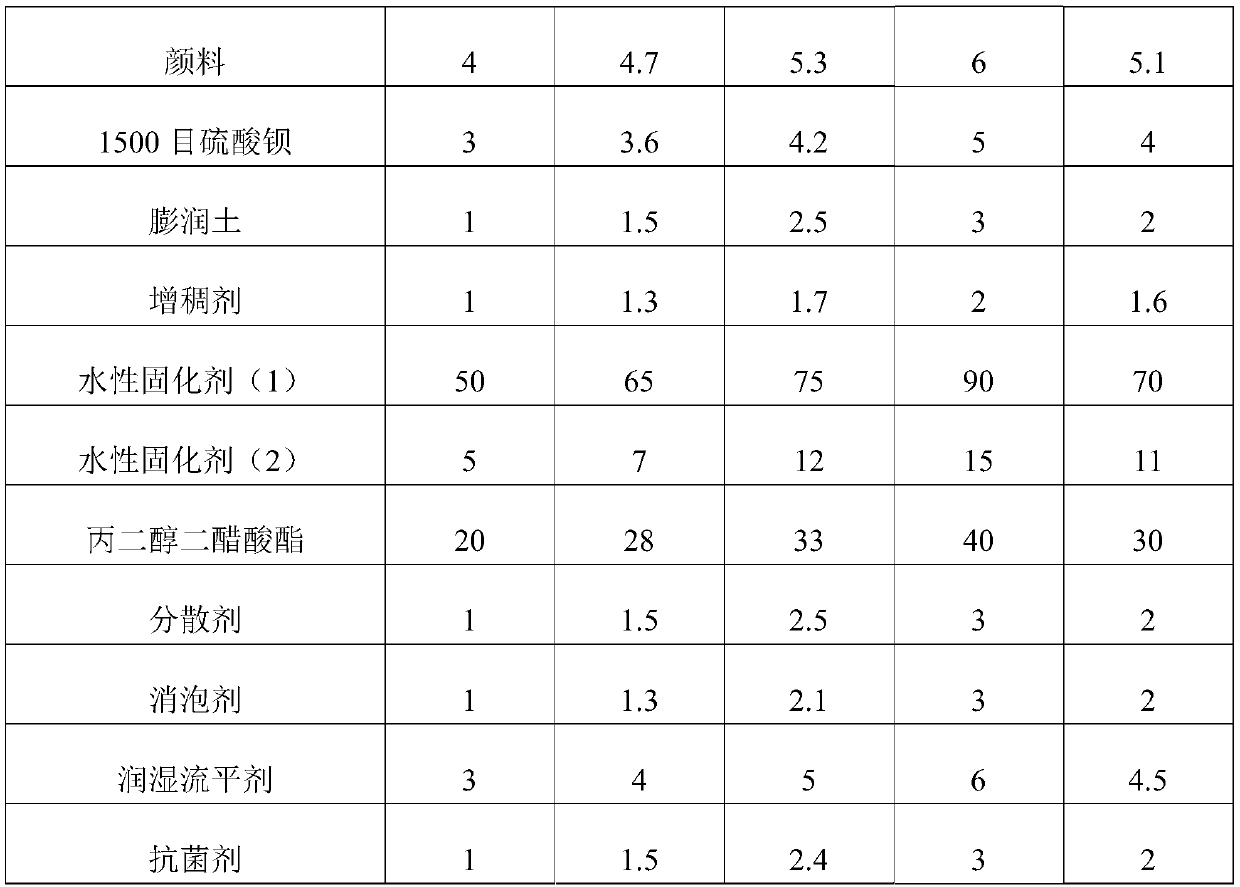

[0036] The embodiments of the present invention provide an anti-ultraviolet car paint and a preparation method thereof, and the proportions of raw materials in each embodiment are shown in Table 1.

[0037] Table 1

[0038]

[0039]

[0040] Among them, the water-based hydroxyl polyacrylic acid dispersion is 3AH0545W from Tongde Chemical, the pH neutralizer is AMP-95 from Dow, the United States, the PTFE micropowder is PTFE micropowder wax W-8006 from Patner, and titanium dioxide It is DuPont rutile titanium dioxide R706, the pigment is MH-5R red pigment, the bentonite is Hemings Deqian bentonite BENTONE LT, and the thickener is Gel 0620, water-based curing agent (1) is Japanese NPU CORONATE-HXR, water-based curing agent (2) is German Covestro Bayhydur 401-70, dispersant is 4474 of AFCONA, defoamer is 941 PL, the wetting and leveling agent is Efka EFKA-3580, and the antibacterial agent is g-C 3 N 4 / TiO 2 composite material.

[0041] where g-C 3 N 4 / TiO 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com