Two-component waterborne top coating for outdoor pipeline and preparation method thereof

A water-based topcoat, two-component technology, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor corrosion resistance and weather resistance, toxic organic volatiles, etc., to improve adhesion and reduce Environmental pollution, low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

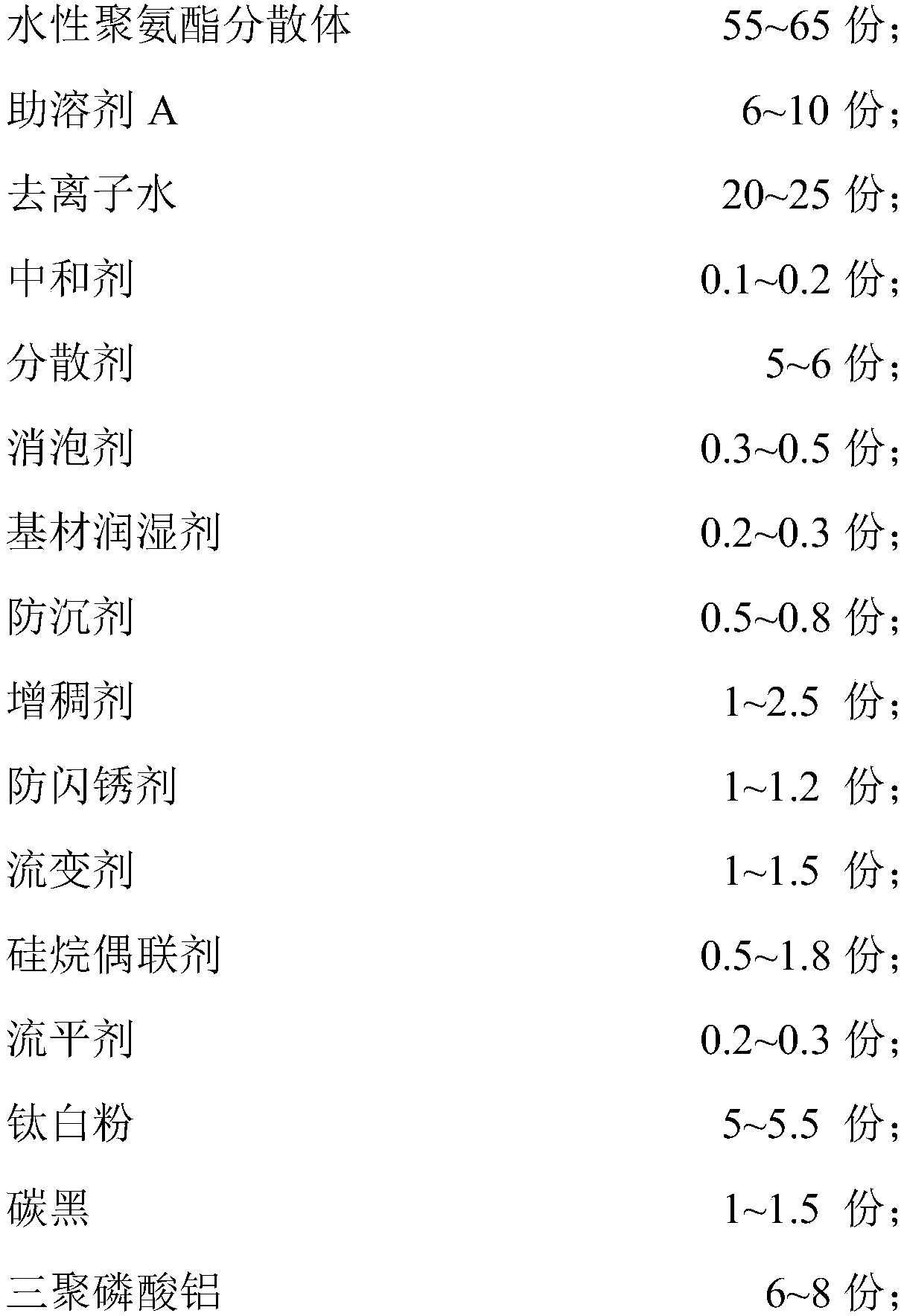

[0028] The embodiment of the present invention provides a two-component water-based topcoat for outdoor pipelines and a preparation method thereof, comprising the following raw materials in parts by weight:

[0029] A component:

[0030]

[0031]

[0032] B component:

[0033] 54.8 parts of self-emulsifying polyisocyanate;

[0034] 27.4 parts of propylene glycol methyl ether acetate.

[0035] Among them, the water-based polyurethane dispersion is A2033, the defoamer is BYK024, the substrate wetting agent is BYK-346, the anti-settling agent is LT (3%), the thickener is 0620, and the anti-flash rust agent is ED-617F. The rheological agent is 12W, the silane coupling agent is kh560, the leveling agent is Tego-100, and the self-emulsifying polyisocyanate is N3900.

[0036] The preparation method of the above-mentioned two-component water-based topcoat for outdoor pipelines is as follows:

[0037] Step a, according to the formula of two-component water-based topcoat for o...

Embodiment 2

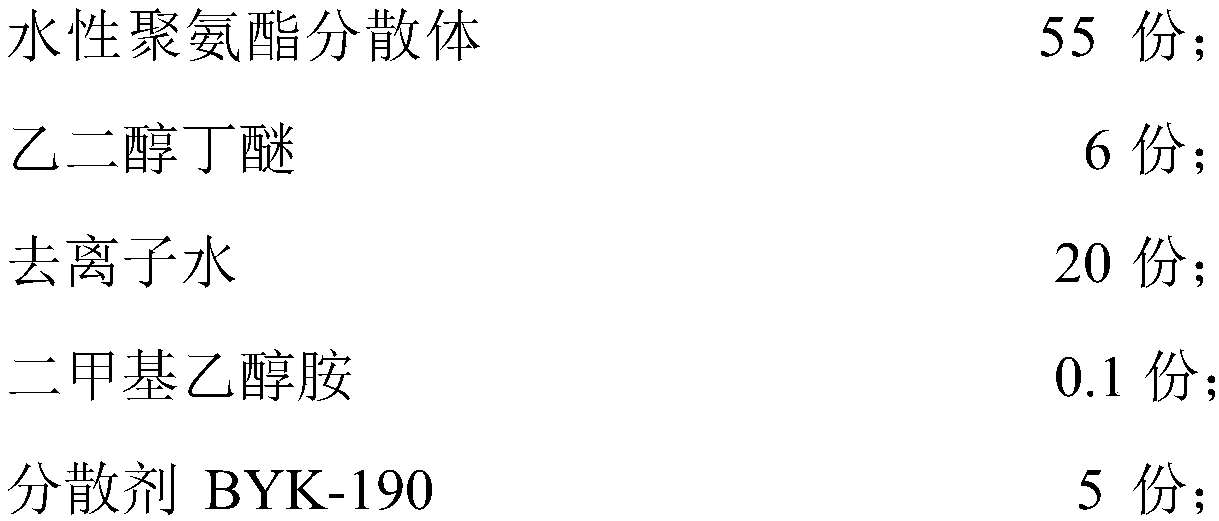

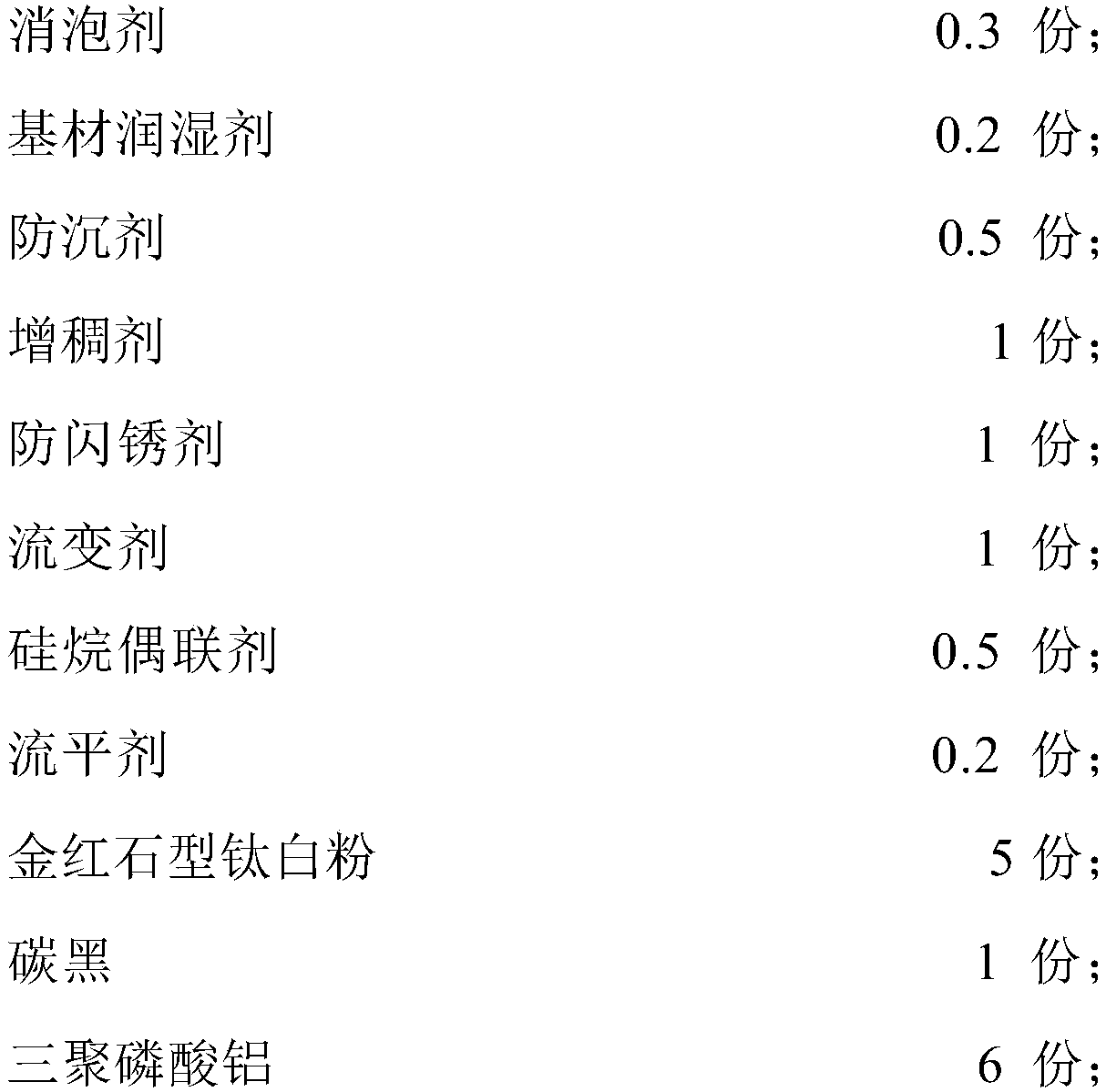

[0043] The embodiment of the present invention provides a two-component water-based topcoat for outdoor pipelines and a preparation method thereof, comprising the following raw materials in parts by weight:

[0044] A component:

[0045]

[0046]

[0047] B component:

[0048] 67.55 parts of self-emulsifying polyisocyanate;

[0049] Propylene glycol methyl ether acetate 28.95 parts.

[0050] Among them, the waterborne polyurethane dispersion is GTR6014, the defoamer is 902W, the substrate wetting agent is BYK-346, the anti-settling agent is LT (3%), the associative polyurethane thickener is 0620, and the anti-flash rust agent is ED-617F, the rheology agent is 12W, the silane coupling agent is kh560, the leveling agent is Tego-100, and the self-emulsifying polyisocyanate is N3900.

[0051] The preparation method of the above-mentioned two-component water-based topcoat for outdoor pipelines is as follows:

[0052]Step a, according to the formula of two-component water-...

Embodiment 3

[0058] The embodiment of the present invention provides a two-component water-based topcoat for outdoor pipelines and a preparation method thereof, comprising the following raw materials in parts by weight:

[0059] A component:

[0060]

[0061] B component:

[0062] 80.1 parts of self-emulsifying polyisocyanate;

[0063] 30.4 parts of propylene glycol methyl ether acetate.

[0064] Among them, the water-based polyurethane dispersion is GTR6014, the defoamer is 902W, the substrate wetting agent is BYK-346, the anti-settling agent is LT (3%), the associative polyurethane thickener is 0620, and the anti-flash rust agent is ED-617F, the rheology agent is 12W, the silane coupling agent is kh560, the leveling agent is TW336, and the self-emulsifying polyisocyanate is N3900.

[0065] The preparation method of the above-mentioned two-component water-based topcoat for outdoor pipelines is as follows:

[0066] Step a, according to the formula of two-component water-based topcoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com