Inorganic interior wall coating and preparation method thereof

An interior wall paint and inorganic technology, applied in the field of inorganic interior wall paint and its preparation, can solve problems such as appearance and low temperature stability to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

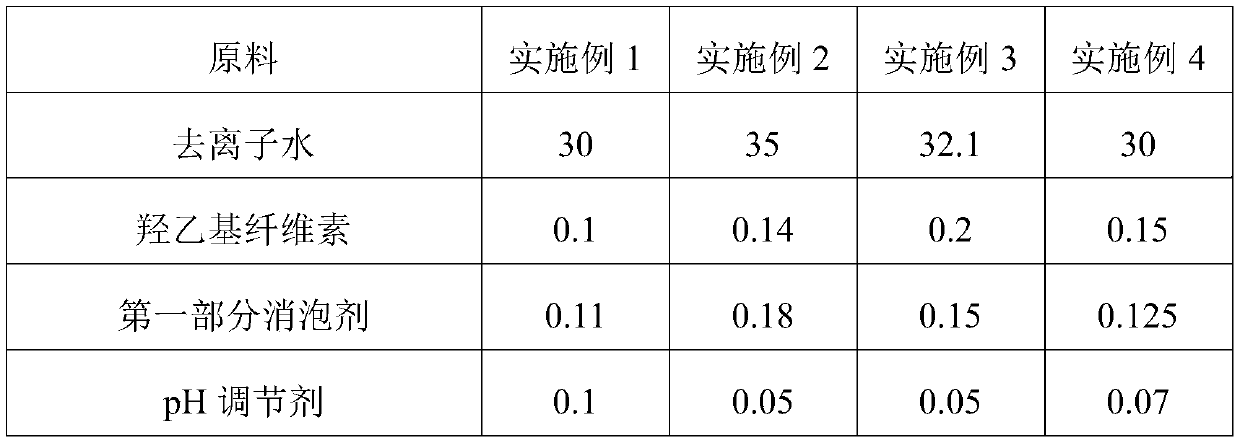

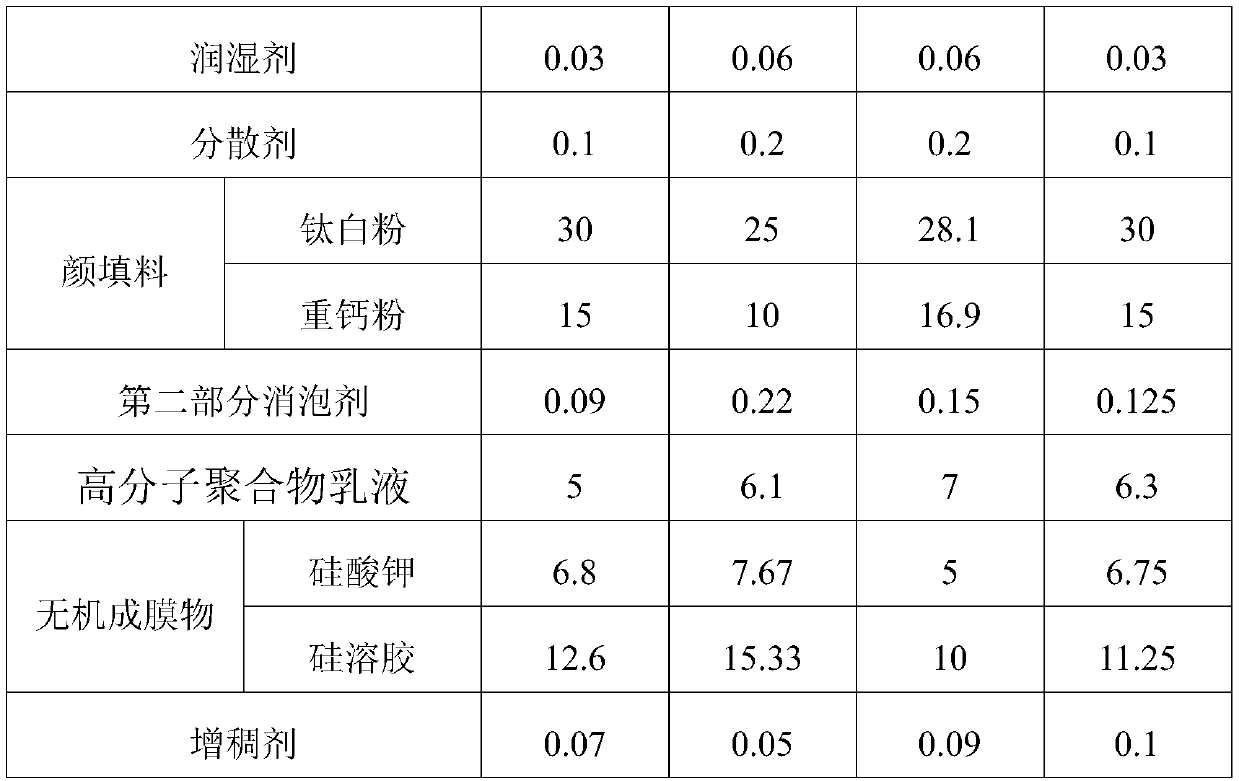

[0027] The embodiments of the present invention provide inorganic interior wall paints and preparation methods thereof, and the mass percentages of raw materials in each embodiment are shown in Table 1.

[0028] Table 1 raw material mass percent (wt%)

[0029]

[0030]

[0031] Among them, the defoamer is Hemings Dechem 7010, the pH regulator is Dow AMP-9 (AMP-95), the titanium dioxide is Dupont R706, the polymer emulsion is Dow ELASTENE 2468, and the silica sol is Jiangsu Guolian Silica sol 1306, the thickener is Dow TT-935. The inorganic film former is a mixture of potassium silicate and silica sol.

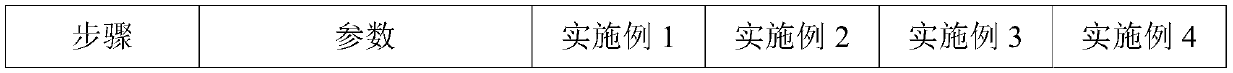

[0032] The preparation method of above-mentioned inorganic interior wall coating comprises the following steps:

[0033] ① Add the hydroxyethyl cellulose to the deionized water at a stirring rate of 300-400r / min;

[0034] ② Disperse for 20 to 30 minutes at a stirring rate of 800 to 1200 r / min;

[0035] ③ Add the first part of defoamer, pH regulator, dispersant and wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com