Testing device capable of simultaneously measuring multiple SCR catalysts

A technology of SCR catalyst and test device, which is applied in the direction of measuring device, test sample preparation, instrument, etc., can solve the problems of not considering the NO removal efficiency of the catalyst, clogged pipeline, and the operation of changing the catalyst in the reaction quartz tube is not simple enough, etc. Accurate NO removal efficiency, simple operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

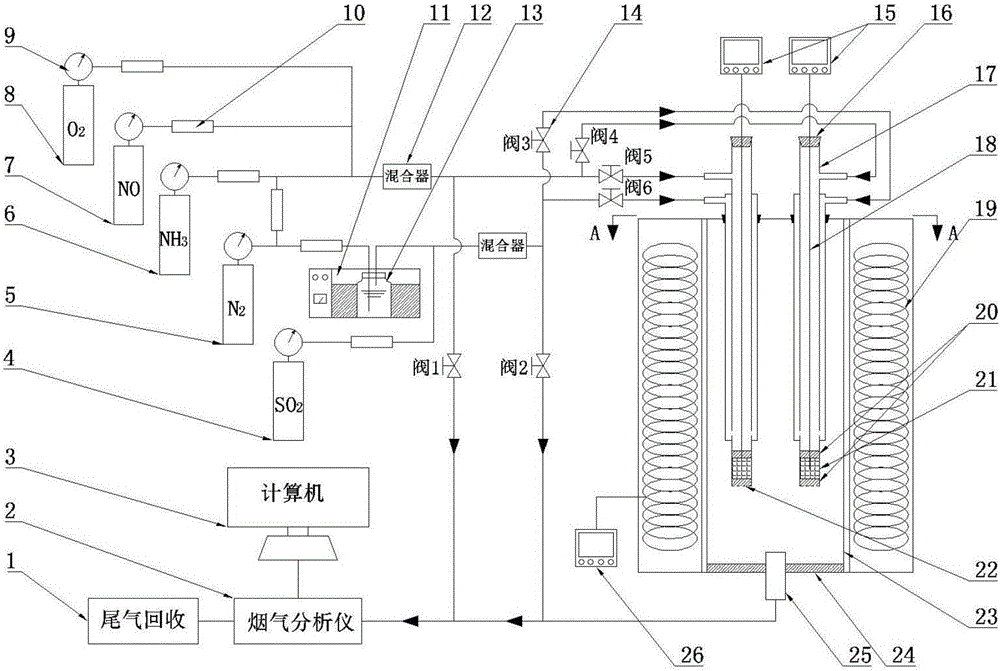

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

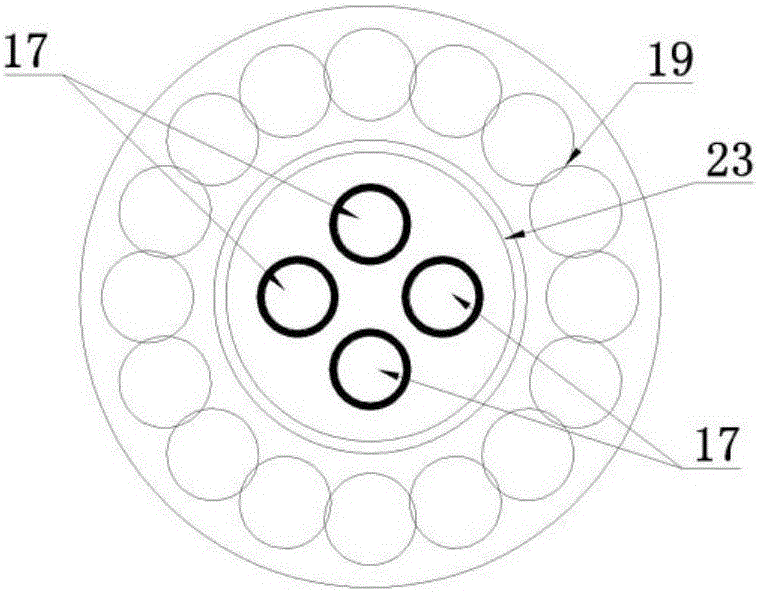

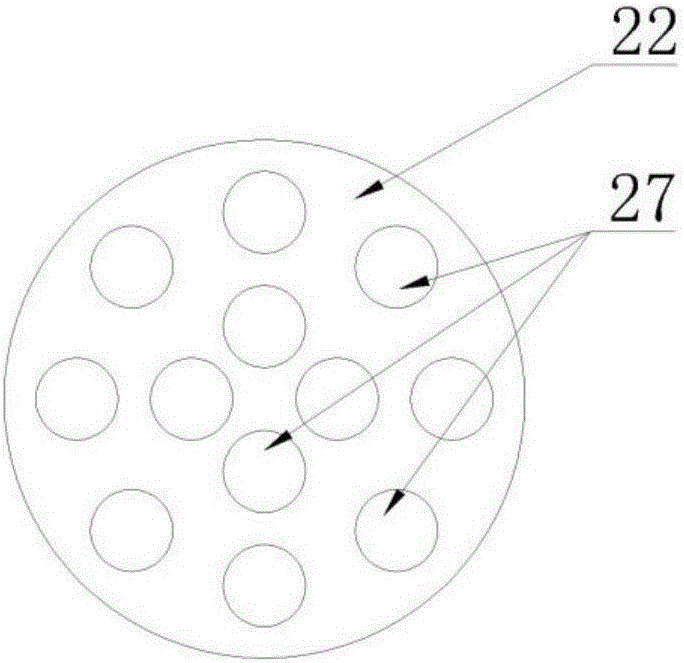

[0031] see Figure 1-Figure 3 , the present invention is composed of gas distribution system, reaction system and measurement system. Gas distribution system including SO 2 / N 2 Cylinder 4, N 2 Cylinder 5, NH 3 / N 2 Cylinder 6, NO / N 2 Cylinder 7, O 2 / N 2 Gas cylinder 8, pressure reducing valve 9, Qixing Huachuang CS200 mass flow meter 10, water bath 11, gas mixer 12, gas washing bottle 13 and valves 14 of each gas circuit. The reaction system includes a high-temperature tube furnace 19 and its temperature controller 26, a reaction tube 17, a thermocouple 18 and its temperature display instrument 15, a mullite wool layer 20 and a catalyst layer 21, an outer sleeve 23 and its sealing rubber plug 24 and outlet Trachea25. The measurement system includes a Gasmet Dx4000 flue gas analyzer 2, a computer 3 and a tail gas recovery device 1 placed at the end of the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com