Phase-change constant-temperature glue preparing container

A phase change constant temperature and container technology, applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve the problems of rising solid percentage content of raw materials, waste of dilution solvent, unstable viscosity, etc., to achieve stable production quality and performance, reduce Contaminate the work site and improve the effect of poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] B. Heating the treated expanded graphite in an oven at 300° C. for 3 hours to obtain expanded expanded graphite and make particles with an average particle diameter of about 0.3 mm;

[0030] C. Prepare a solution of 5% mass concentration of sodium hydroxide solid with a purity not lower than chemical purity with distilled water and heat it to 65°C~80°C, keep it warm for use;

[0031] D. Melt the capric acid of 60 mass parts and the stearic acid of 40 mass parts in the reactor at about 70 ℃, stir for stand-by;

[0032] E. Melt 5 parts by mass of stearic acid in the reactor at about 70 °C, and add 50 parts by mass of sodium hydroxide solution at 65 °C to 80 °C dropwise to the molten stearic acid in about 10 minutes while stirring. In the fatty acid, continue to stir until a fluid white saponified liquid is formed;

[0033] F. Add 6 mass parts of expanded graphite particles with an average particle diameter of about 0.3 mm to the white saponified liquid under stirring, an...

Embodiment 2

[0041] [Example 3]

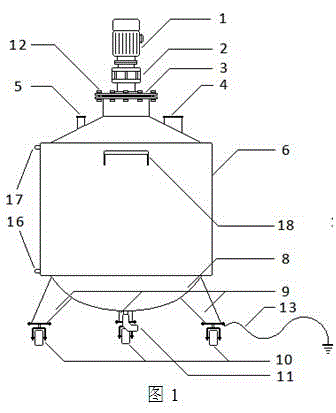

[0042] In winter conditions, the figure 1 The glue dispensing container of the present invention in the state is used for batching, and in the actual production process, the material temperature inside the glue dispensing container is tested every 0.5 hours. The test results are shown in Table 1.

Embodiment 3

[0044] Table 1 The change of material temperature in the phase change constant temperature glue mixing container with time under winter conditions

[0045] time / hour Material temperature / ℃ Workshop temperature / ℃ 0.5 21.0 12.5 1.0 20.5 12.5 1.5 20.0 13.0 2.0 20.5 12.5 2.5 19.5 12.0 3.0 16.0 12.5

[0046] It can be seen that in winter conditions, the phase change constant temperature glue compounding container of the present invention can keep the temperature of the prepared materials at 20-22°C within a certain period of time.

[0047]

[0048] 【Example 4】

[0049] Under summer conditions, the figure 1 The glue dispensing container of the present invention in the state is used for batching, and in the actual production process, the material temperature inside the glue dispensing container is tested every 0.5 hours. The test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com