Method for wet transfer printing digital color image onto fiber fabric of cellulose, and dedicated transfer paper

A cellulose fiber and color image technology, applied in the field of textile printing and dyeing, can solve the problems of inconvenient printing of color patterns, slow promotion, popularization and application, high printing cost, etc., and achieves good color fixing effect, fast production speed, and satisfactory The effect of personalized pursuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

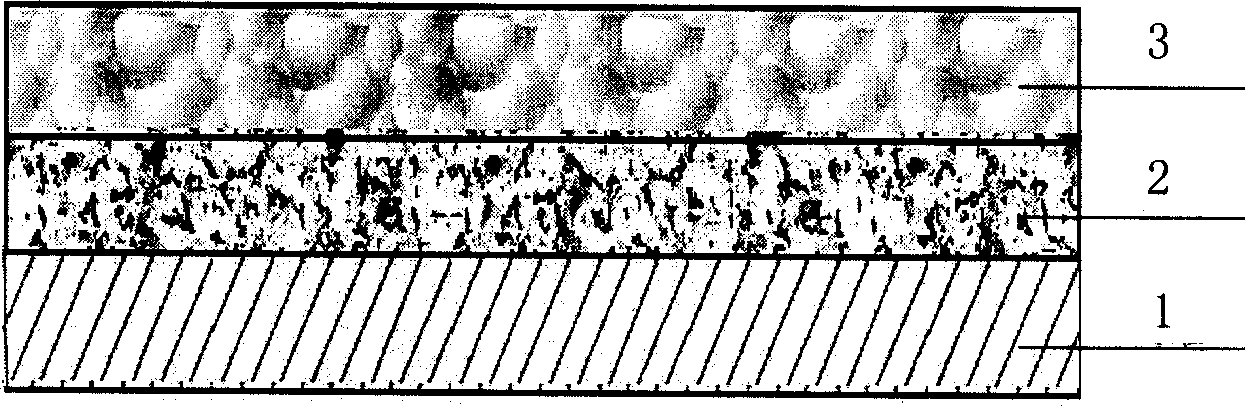

Image

Examples

Embodiment 1

[0025] After designing the pattern on the computer, use a micro-piezoelectric color inkjet printer or photo machine to print the color pattern on the special transfer paper for wet transfer printing of cotton fabrics with inkjet printing special reactive dye ink; use 3% Sodium bicarbonate (baking soda) aqueous solution soaks the part of the cotton fabric to be transferred to the pattern and dries it; in the wet state of the cotton fiber fabric, use a screen printing plate to scrape the transfer paste on the part to be transferred. Then paste the front side of the printed transfer paper on the cotton fiber fabric with the transfer paste scraped, and use a thick glass plate or other flat plate to flatten the transfer paper so that the transfer paper and the sized fabric surface are closely attached. After 3 minutes, press the dry transfer paste from the back of the transfer paper with a heat transfer machine. The printed paper is bonded together, and when the transfer paste is i...

Embodiment 2

[0028] After designing the pattern on the computer, use a micro-piezoelectric color inkjet printer, offset printing machine or the method of screen printing to print the color pattern on the special transfer paper for wet transfer printing by using reactive dye ink or ink. on the sol level. Before transfer printing, use 3% sodium bicarbonate (baking soda) and 2% aqueous solution of sodium carbonate (soda ash) to soak and dry the part to be transferred; then use the screen printing screen to transfer the cotton fiber fabric. The part of the pattern is evenly scraped and coated with sodium alginate transfer paste with only 3% sodium bicarbonate, and then the front side of the transfer paper with the pattern printed on it is pasted on the cotton fiber fabric with the transfer paste scraped, and a thick glass plate is used to or other flat plate to flatten the transfer paper so that both the transfer paper and the sized fabric side fit snugly. After 3 minutes, use a heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com