Power generation system and generating method based on same

A power generation system and generator technology, which is applied in the direction of machines/engines, steam engine devices, combined combustion mitigation, etc., can solve the problems of large heat transfer temperature difference, complicated process, and difficult control, so as to reduce effective energy loss and cold energy. The effect of high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

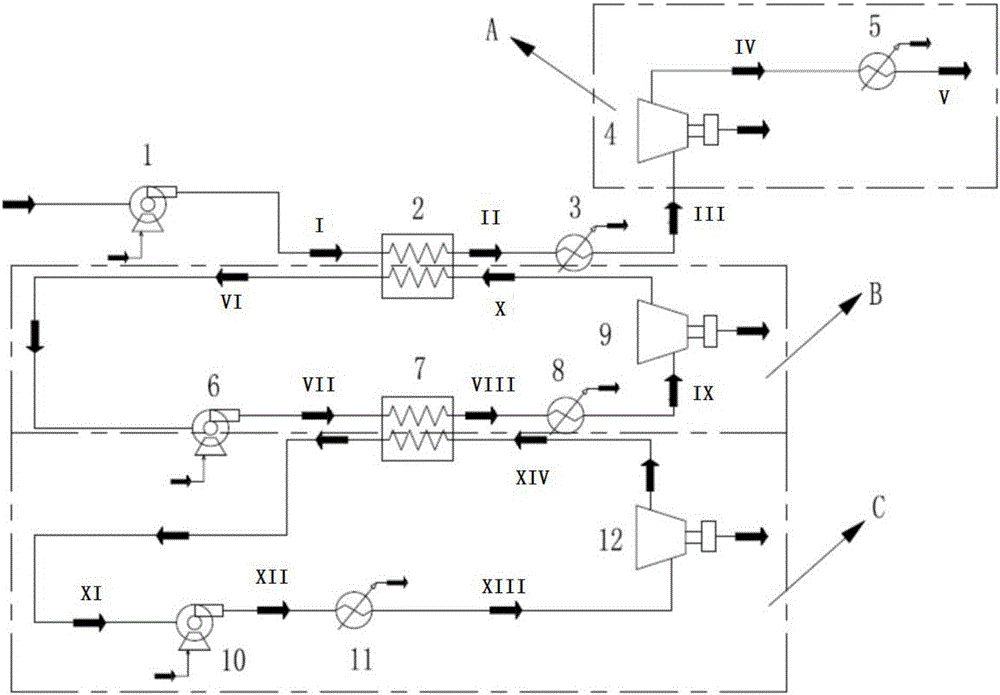

[0028] A method for cascade utilization of liquefied natural gas cold energy to generate electricity, the process flow is as follows figure 1 As shown, it includes three parts including the first-stage direct expansion A of the natural gas medium, the first-stage ternary mixed working medium Rankine cycle B, and the second-stage propane working medium Rankine cycle C.

[0029] The molar composition of liquefied natural gas (LNG) at the receiving station is: 91% methane, 5% ethane, 2.5% propane, 1% isobutane, 0.1% isopentane, and 0.4% nitrogen; The volume is 201t / h. The refrigerant selected for the first-stage Rankine cycle is a ternary mixed working medium, which is composed of methane, ethane and propane, and the flow rate is 140t / h; the refrigerant selected for the second-stage Rankine cycle is a single working medium, propane , the flow rate is 76t / h.

[0030] The LNG (first stream I) with an outlet pressure of 10.0MPa (gauge pressure) and -157.4°C from the LNG pump 1 outs...

Embodiment 2

[0035] A method for cascade utilization of liquefied natural gas cold energy to generate electricity, the process flow is as follows figure 1 As shown, it includes three parts including the first-stage direct expansion A of the natural gas medium, the first-stage ternary mixed working medium Rankine cycle B, and the second-stage propane working medium Rankine cycle C.

[0036] The molar composition of liquefied natural gas (LNG) at the receiving station is: 91% methane, 5% ethane, 2.5% propane, 1% isobutane, 0.1% isopentane, and 0.4% nitrogen; The volume is 201t / h, and the refrigerant selected for the first-stage Rankine cycle is a ternary mixed working medium, which is composed of methane, ethane, and propane, and the flow rate is 139t / h; the refrigerant selected for the second-stage Rankine cycle is a single working medium, propane , the flow rate is 96t / h.

[0037] The LNG (first stream I) with an outlet pressure of 10.0MPa (gauge pressure) and -157.4°C from the LNG pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com