Automatic butter connection mechanism for capstan and low-temp. fluid delivery unit

A technology for cryogenic fluids and conveying devices, which is used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., and can solve problems such as pipeline difficulties, inconvenience, temperature loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

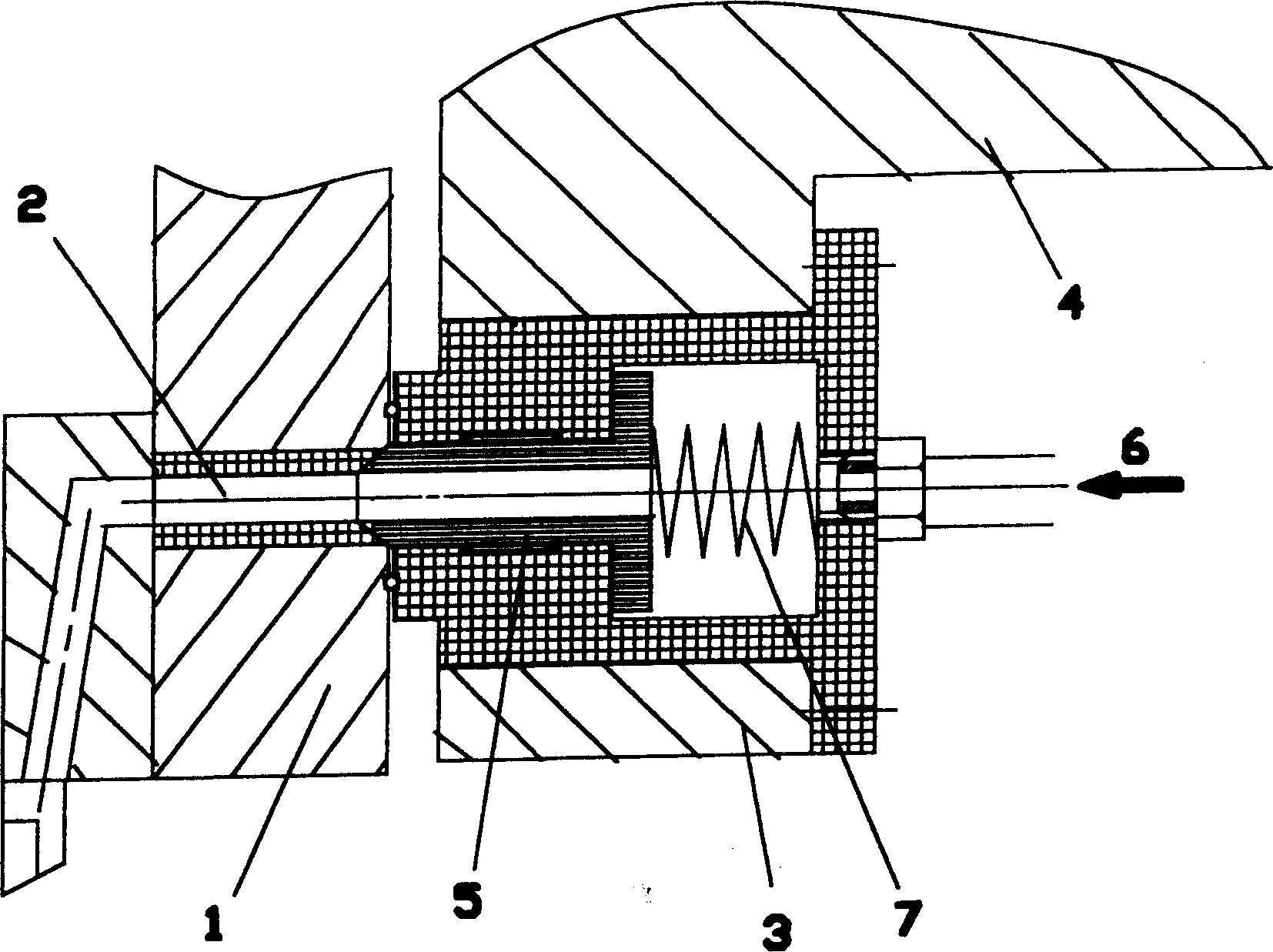

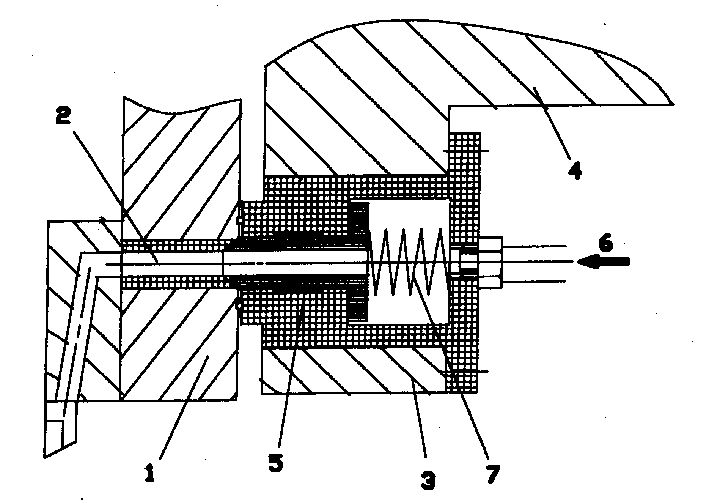

[0014] Figure 1 , is a kind of implementation plan of the low-temperature fluid conveying device that the cutter head is connected automatically. It can be seen from the figure that a transition connection seat 3 is provided on the lathe tool table 4, and a hollow elastic joint made of thermal insulation material is provided on the transition connection seat 3. Sleeve 5; one end of the hollow elastic sleeve 5 communicates with the cooling medium supply system with heat preservation measures; a spring 7 is installed inside it, so that the other end is close to the working state on the polygonal cutter head 1 under the action of elasticity The inlet end 2 of the fluid passage forms a fluid passage connected to the cooling medium supply system with heat preservation measures; when the cutter head 1 is rotated, the hollow elastic sleeve 5 automatically retracts, and the cone at the front end exits from the cone hole on the inlet end 2 After the indexing is completed, the taper hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com