Method of parallel rolling by two roughing mills in the rough roll zone on hot rolling production line

A rough rolling mill and production line technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as increasing costs, affecting output, and reducing equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

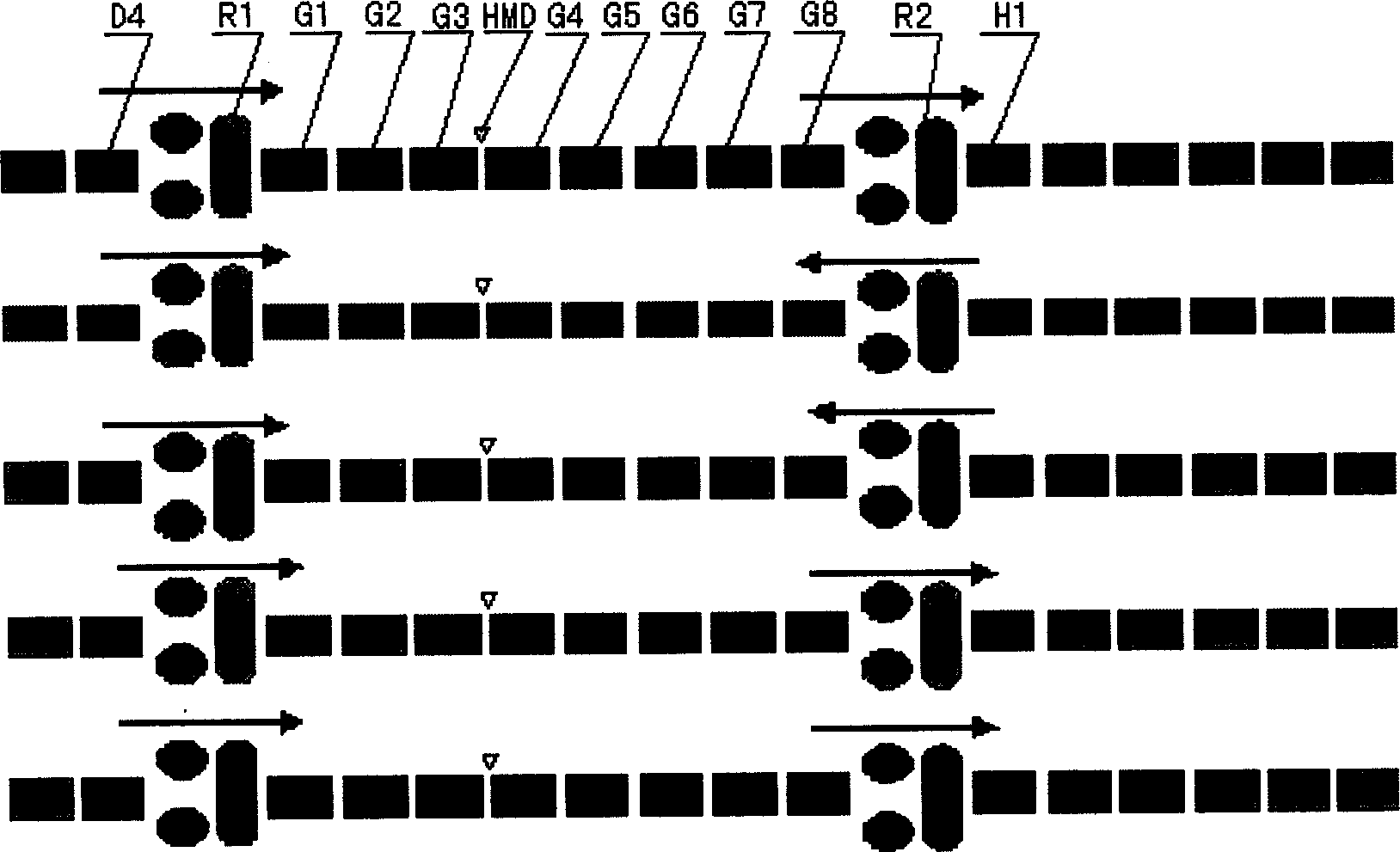

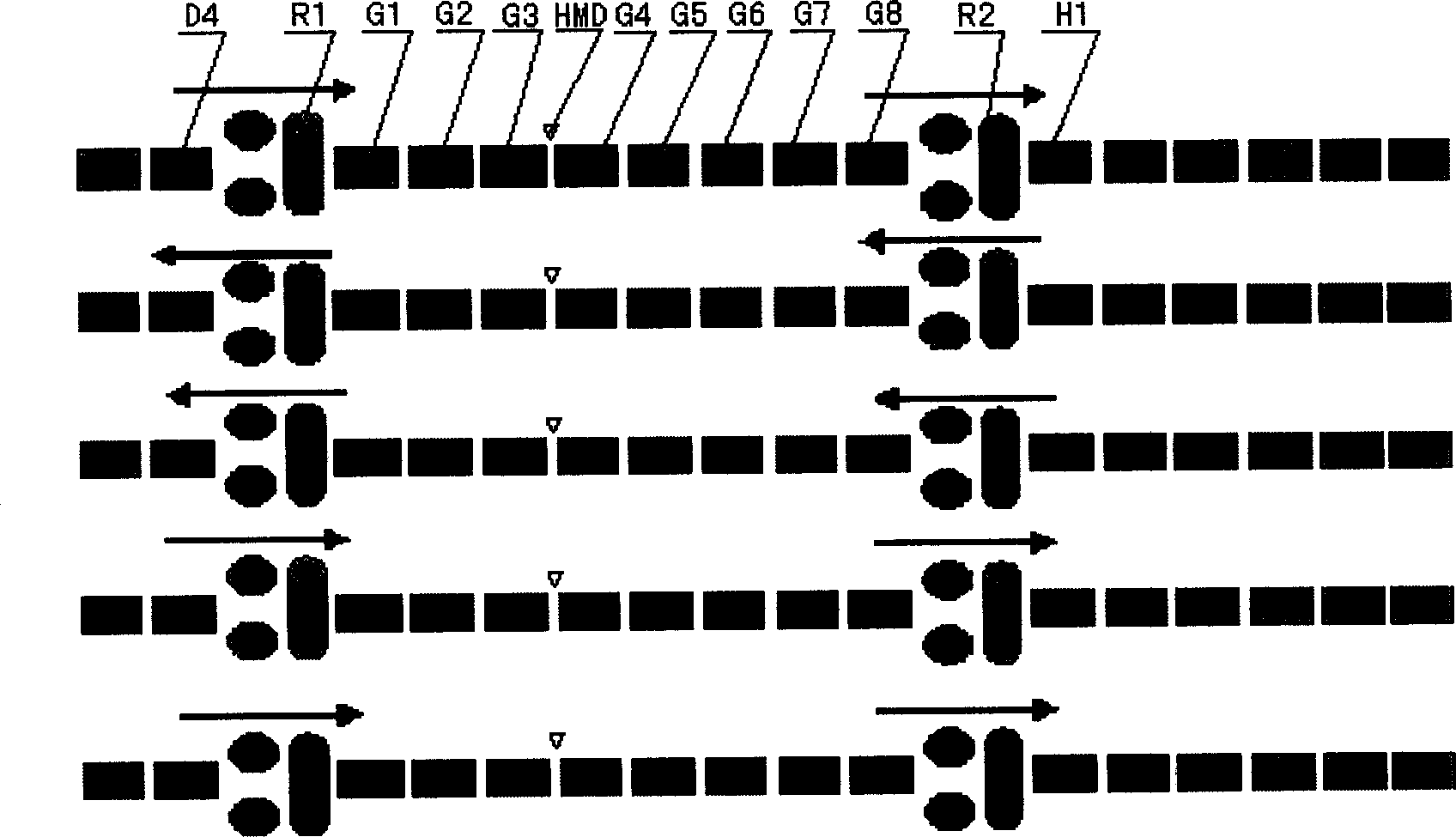

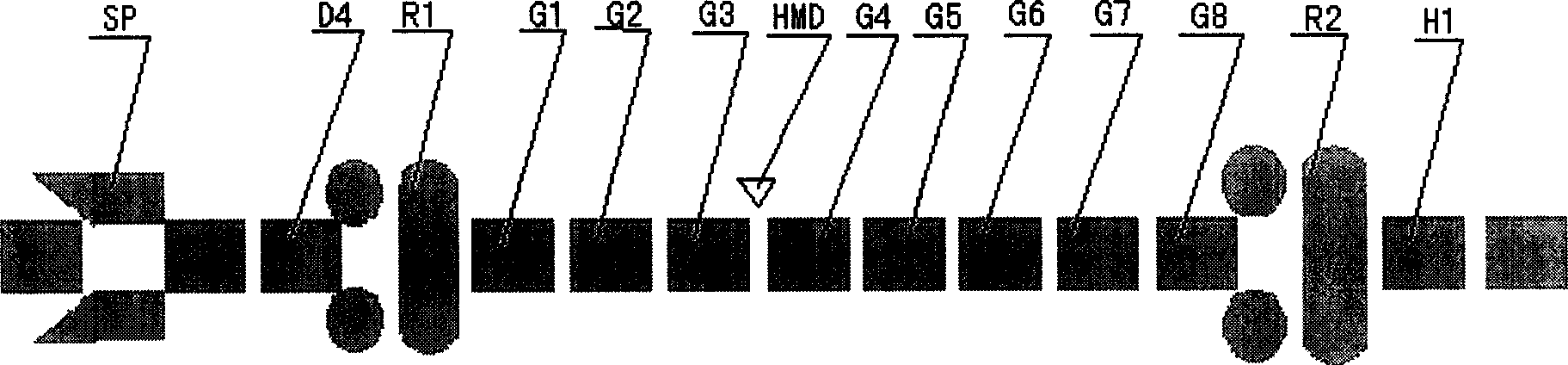

[0042] The present invention will be further described below with reference to the accompanying drawings. The parallel rolling method of the two roughing mills R1 and R2 in the rough rolling area of the hot rolling production line according to the present invention is mainly applicable to the rolling mode of 3 passes+3 passes, that is, when R1 rolling mill is 3 passes rolling, R2 When the rolling mill is also 3-pass rolling, the two roughing mills R1 and R2 can carry out forward and reverse rolling at the same time, but must meet the R1 forward requirement program and R2 reverse requirement program. attached figure 2 It is a schematic diagram of parallel rolling in the present invention, D4, G1-G8, and H1 in the figure are all roller tables, HMD is a hot metal detector, and the dark part in the figure is the position of the slab.

[0043] The present invention is equipped with anti-collision detection and priority judgment programs, that is, the R1 forward request program ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com