Liquid nitrogen freezing system of high water pressure super-long-distance large-sectional tunnel and method of quickly changing shield tail brushes

A high-water pressure, large-section technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of long brine freezing cycle, inability to adapt to high water pressure, complex soil conditions, and large economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

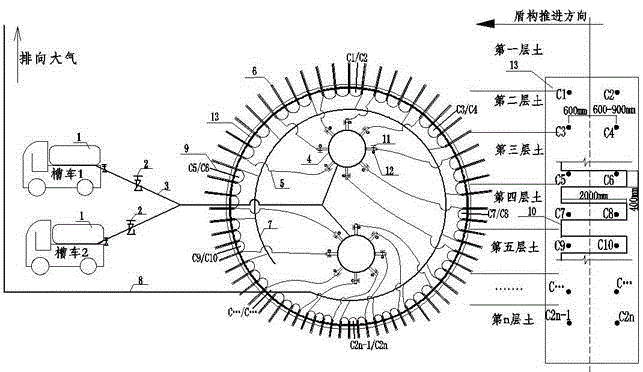

[0054] The Nanjing Weisan Road crossing channel is located between the Nanjing Yangtze River Bridge and the Nanjing Yangtze River Tunnel. Pukou District On the west side of the Dingshan turntable in Zhujiang Town, across the planned Shazihe Road and Jiangbei Binjiang Avenue, after crossing the Yangtze River and Jiangnan Binjiang Avenue in the form of a tunnel, the south tunnel connects with Dinghuaimen Street, and the north tunnel connects with Yangtze River The avenue is connected by the road, with a total length of about 7.2 kilometers;

[0055] On October 18, 2014, when the 780th ring of shield tunneling in the S line of the Weisan Road crossing channel in Nanjing was excavated, the guards on duty at the shield tail found that there was leakage at the shield tail, and then blocked it, and used the liquid nitrogen freezing system described in the manual to freeze it. and shield tail brush replacement;

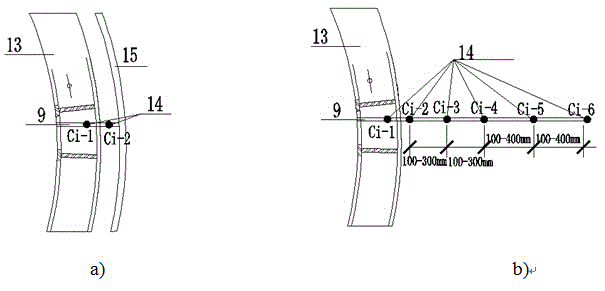

[0056] The strata within the shield range at the tail of the shield a...

Embodiment 2

[0075] A ground pump was installed at the outlet of the liquid nitrogen storage tank for pressurization, the pressure of the liquid supply pipe was 1.0 MPa, the length of the exhaust pipe was 3.5 km, and the rest were the same as in Embodiment 1.

Embodiment 3

[0077] A ground pump was installed at the outlet of the liquid nitrogen storage tank for pressurization, the pressure of the liquid supply pipe was 1.6 MPa, the length of the exhaust pipe was 5.5 km, and the rest were the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com