Direction change device

a technology of a direction change device and a change device, which is applied in the direction of vehicle maintenance, vehicle-manoeuvring devices, transportation and packaging, etc., can solve the problem that objects cannot be transported while the waiting time is over, and achieve the effect of shortening the changing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

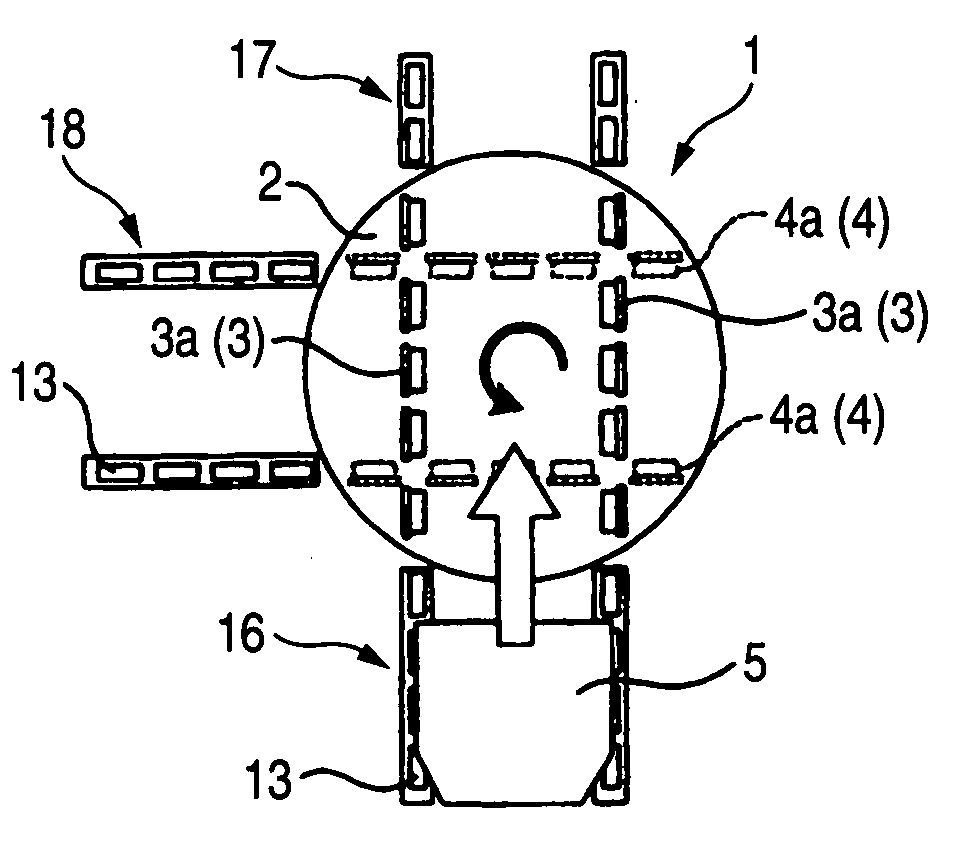

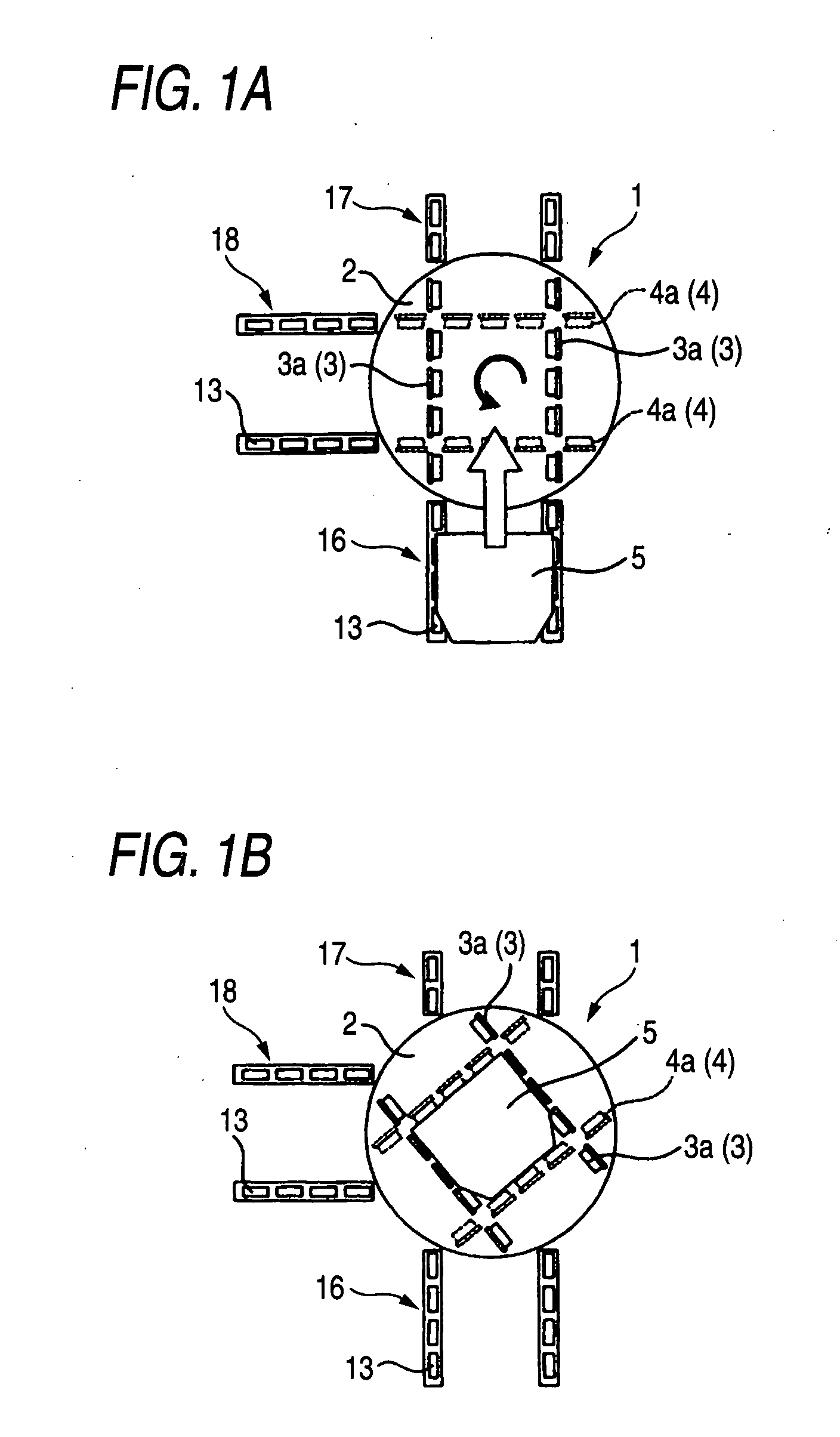

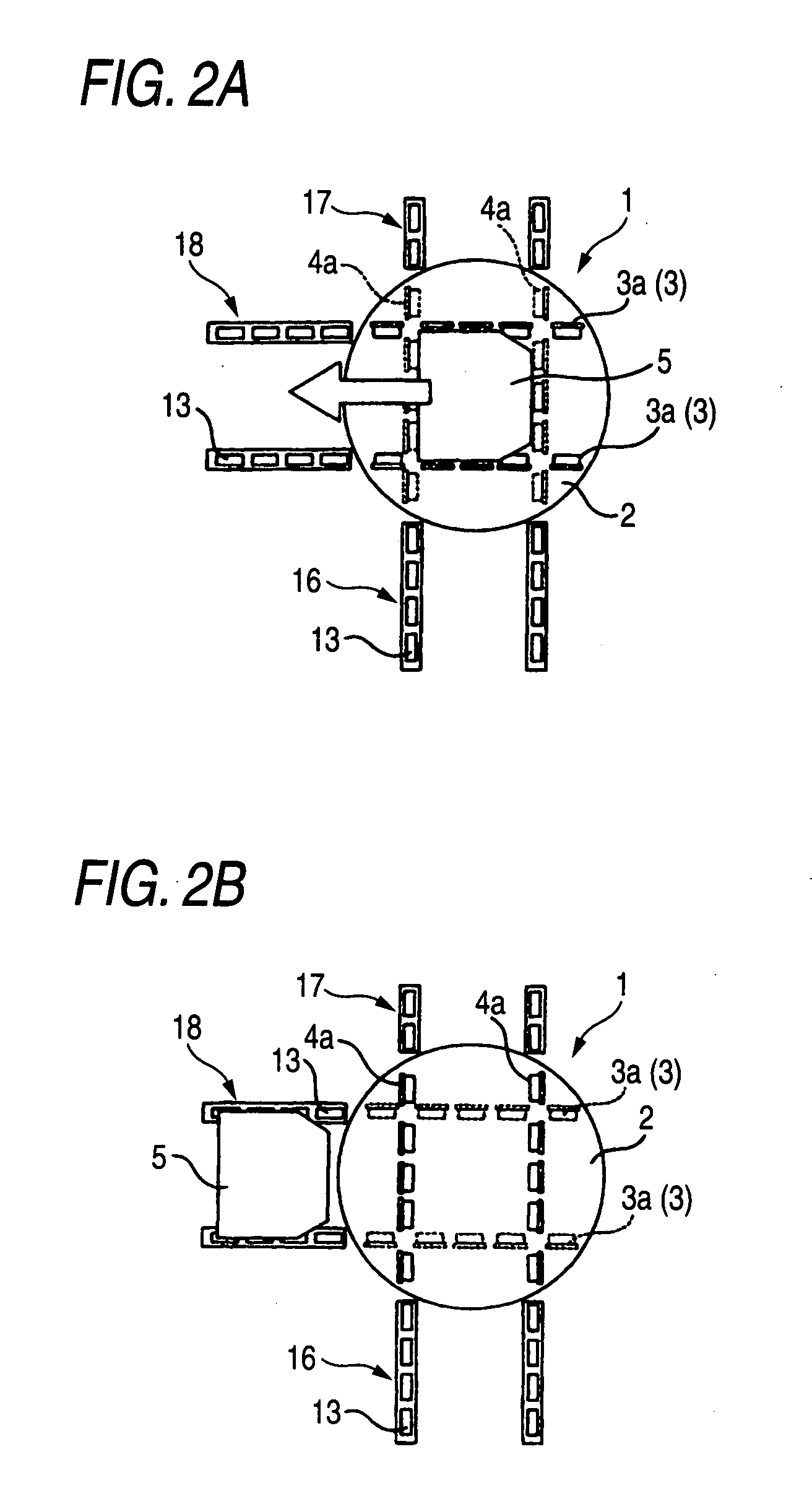

Method used

Image

Examples

modification embodiment

[0066]The above-described preferred embodiment of the invention is described, but the invention is not limited to the described embodiment. The invention may be modified in various forms without departing from the gist of the invention. Further, according to the embodiment, the operation and advantage of the configuration of the invention is described above, but the operation and advantage are just an example and the invention is not limited thereto.

[0067]For example, when the FOUP 5 is placed on the first transport passage 3, the rotation of the roller 3a of the first transport passage 3 stops and the turn table 2 rotates according to the embodiment. However, while the FOUP S is transported, the turn table 2 may rotate. In this case, since the FOUP 5 can be transported from the first transport rail 16 to the third transport rail 18 without stopping the FOUP 5 on the first transport passage 3, a time required to change the direction may be shortened more. Additionally, it is describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com