Method for rapidly replacing belt type conveyor rubber belt

A belt conveyor and belt replacement technology, applied in the direction of conveyor, transportation and packaging, can solve problems such as asynchrony, and achieve the effect of reducing labor intensity, shortening replacement time, and reducing replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

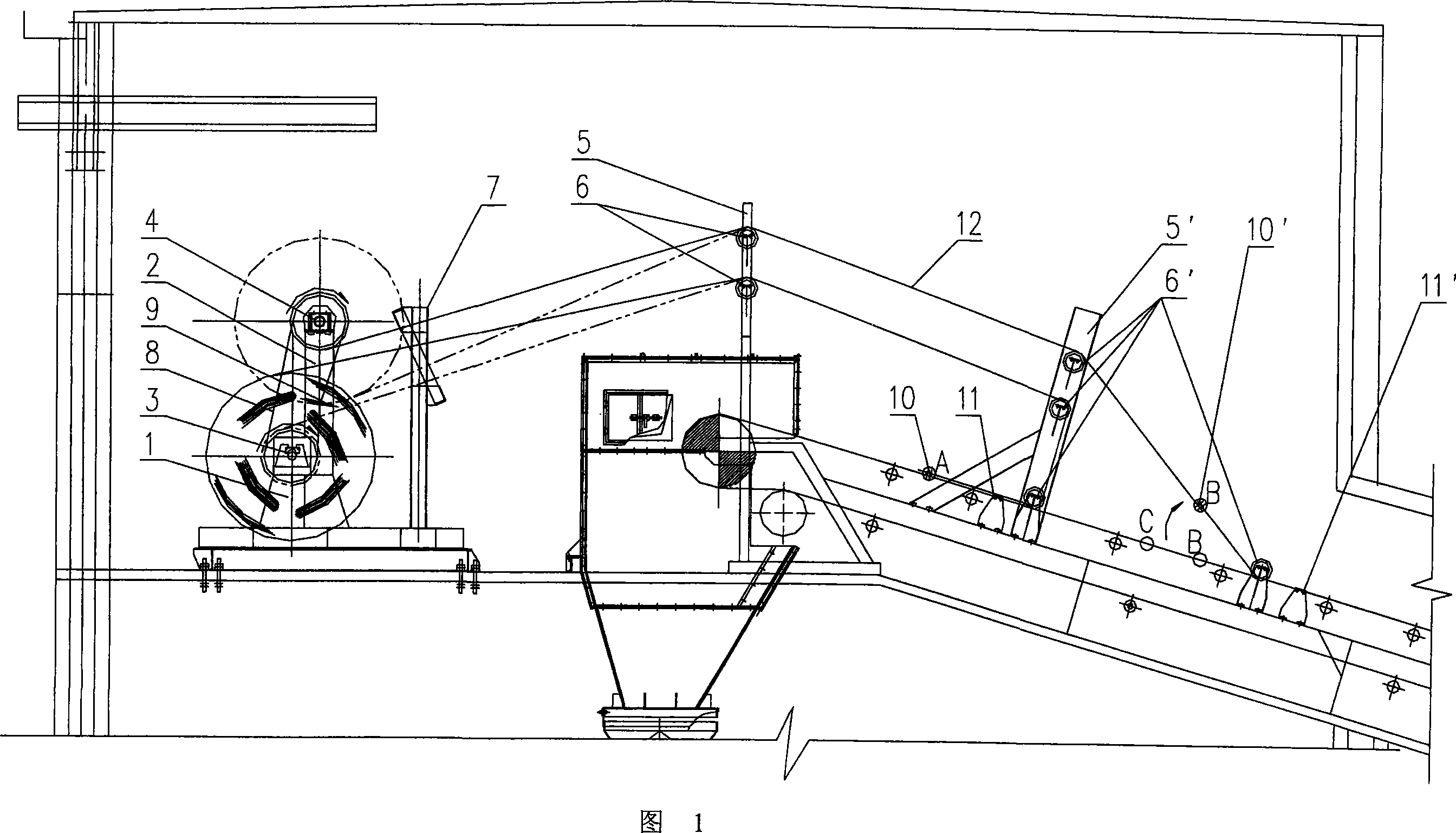

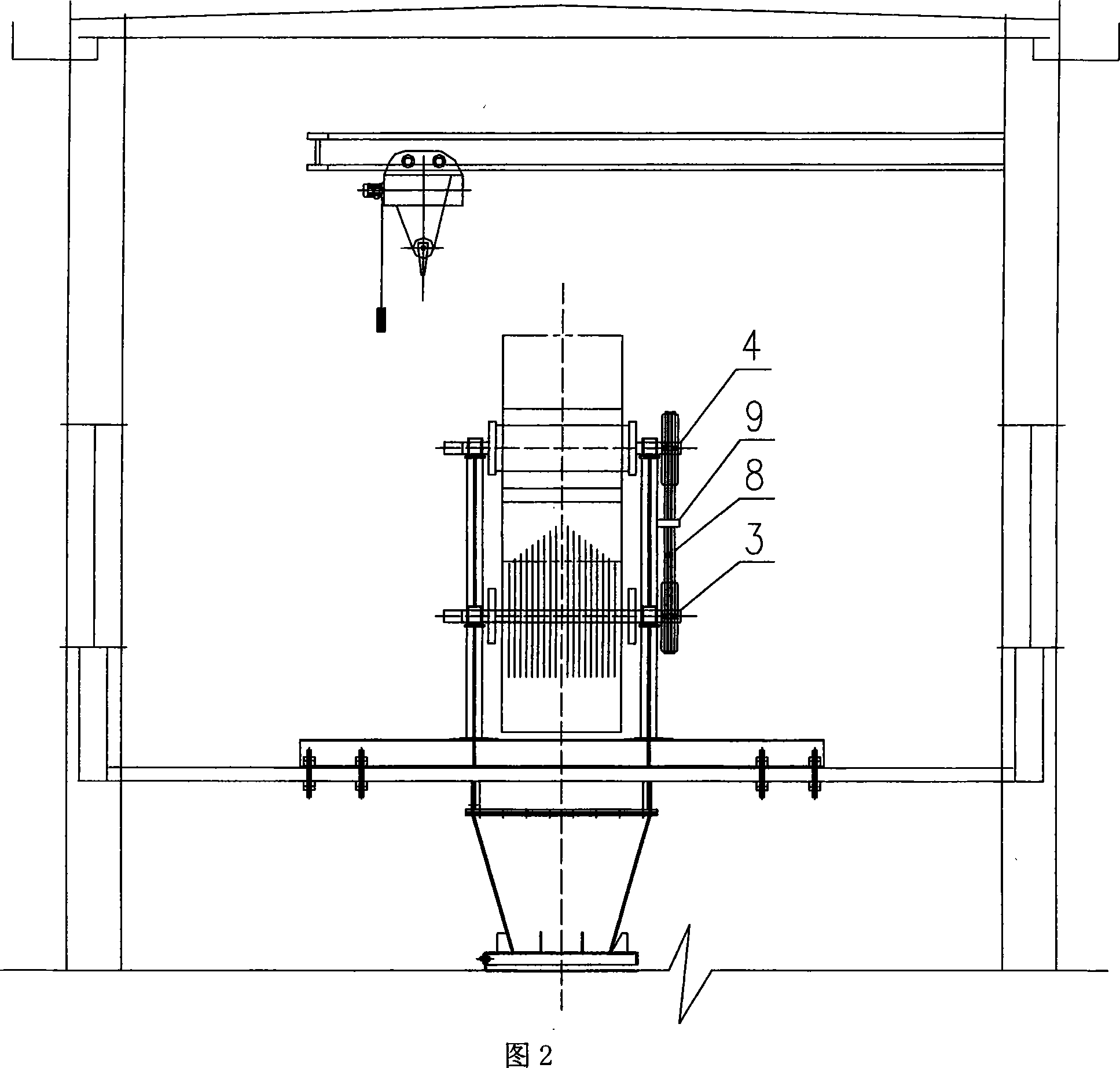

[0015] The structure and operation process of the device for quickly replacing belt conveyor belts of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] See Fig. 1, Fig. 2, the device that the present invention replaces belt conveyor tape quickly is by new tape reel support 1, old tape reel support 2, the new tape reel shaft 3 of belt transmission wheel, the old belt transmission wheel Tape reel shaft 4, guide frame 5, guide wheel 6, guide frame 5', guide wheel 6', anti-deviation frame 7, transmission belt 8, transmission belt tension adjustment pressure wheel 9, tape connecting plate 10, tape locking pressure plate 11 , adhesive tape connecting plate 10', adhesive tape locking platen 11', and connecting adhesive tape 12 are formed.

[0017] The new and old tape reel supports are set on a common base, and the drive pulleys are arranged on the old and new tape reel shafts, and the drive belts of the new and old tape r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com